Abstract

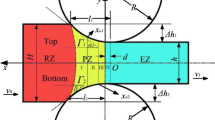

In order to predict the plate curvature during snake rolling, FE model was constructed based on plane strain assumption. The accuracy of the FE model was verified by the comparison between the plate curvature conducted by FE model and experiment respectively. By using FE model, the effect of offset distance, speed ratio, reduction, roll radius and initial plate thickness on the plate curvature during snake rolling was investigated. The experimental results show that, a proper offsetting distance can efficiently decrease plate curvature, however an excessive offsetting distance will increase plate curvature. A larger speed ratio, reduction will cause a large plate curvature, however a larger roll radius has effect to reduce plate curvature. Plate which undergoes a larger reduction and plate with a larger initial thickness always need a larger offset distance to keep the plate the minimum plate curvature, but for a larger roll radius a smaller offset distance is needed.

Similar content being viewed by others

References

Gao H, Chen G. Asymmetrical Cold Rolling Realized on Plain Mill for Steel Sheet by Larser-textured Rolls[J]. Iron and Steel, 1998, 33(3): 63–66

Ding Y, Jiang J H, Shan A D. Microstructures and Mechanical Properties of Commercial Purity Iron Processed by Asymmetric Rolling[J]. Materials Science and Engineering A, 2009, 509: 76–80

Jin H, Loyd D J. Evolution of Texture in AA6111 Aluminum Alloy After Asymmetric Rolling with Various Velocity Ratios between Top and Bottom Roll[J]. Materials Science and Engineering A, 2007, 465: 267–273

Lee J K, Lee D N. Texture Control and Grain Refinement of AA1050 Al Alloy Sheets by Asymmetric Rolling[J]. International Journal of Mechanical Sciences, 2008, 50: 869–887

Zeng Q L, Zhao J X, J Z Ma, et al. Realization of The Sledge Rolling and The Load Balance in The Plate Mill[J]. Steel Rolling, 2001, 18(4): 53–54 (In Chinese)

Pospiech J. A Note on The Influence of Some Factors Affecting Curvature in the Flat Rolling of Strip[J]. Journal of Mechanical Working Technology, 1987, 15: 69–80

Tanaka E, Tsonokawa K, Fukada T. Curling and Bowing of Rolled Strips[J]. Trans. Jpn. Inst. Met., 1963, 4: 124–133

Gao H, Ramalingam S C, Barber G C, et al. Analysis of Asymmetrical Cold Rolling with Varying Coefficients of Friction[J]. Journal of Materials Processing Technology, 2002, 124: 178–182

Lu J S, Harrer O K, Schewenzfeier W, et al. Analysis of The Bending of The Rolling Material in Asymmetrical Sheet Rolling[J]. International Journal of Mechanical Sciences, 2000, 42: 49–61

Phillip M, Schwenzfeier W, Fischer F D, et al. Front End Bending in Plate Rolling Influenced by Circumferential Speed Mismatch and Geometry[J]. Journal of Materials Processing Technology, 2007, 184: 224–232

Knight C W, Hardy S J, Lees A W, et al. Influence of Roll Speed Mismatch on Strip Curvature during the Roughing Stages of a Hot Rolling Mill [J]. Journal of Material Processing Technology, 2005, 168: 194–188

Knight C W, Hardy S J, Lees A W, et al. Investigations into the Influence of Asymmetric Factors and Rolling Parameters on Strip Curvature during Hot Rolling[J]. Journal of Materials Processing Technology, 2003, 134: 180–189

Nia F F, Salimi M, Movahhedy M R. Elasto-plastic Finite Element Simulation of Asymmetrical Plate Rolling using an ALE Approach[J]. Journal of Materials Processing Technology, 2006, 177: 525–529

Mousavi S A A A, Ebrahimi S M, Madoliat R. Three Dimensional Numerical Analyses of Asymmetric Rolling[J]. Journal of Materials Processing Technology, 2007, 187–188: 725–729

Chen D C, Chen C F. Use of Taguchi Method to Study a Robust Design for the Sectioned Beams Curvature during Rolling [J]. Journal of Materials Processing Technology, 2007, 190: 130–137

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Chinese “973” Project (No. 2010CB735811)

Rights and permissions

About this article

Cite this article

Fu, Y., Xie, S., Xiong, B. et al. Effect of rolling parameters on plate curvature during snake rolling. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 27, 247–251 (2012). https://doi.org/10.1007/s11595-012-0446-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-012-0446-y