Abstract

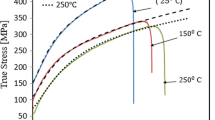

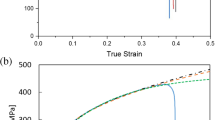

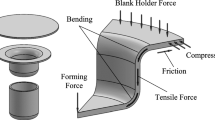

In the current work, to predict and improve the formability of deep drawing process for steel plate cold rolled commercial grade (SPCC) sheets, three parameters including the blanking force, the die and punch corner radius were considered. The experimental plan according to Taguchi’s orthogonal array was coupled with the finite element method (FEM) simulations. Firstly, the data from the test of stress-strain and forming limit curves were used as input into ABAQUS/Explicit finite element code to predict the failure occurrence of deep drawing process. The three parameters were then validated to establish their effects on the press formability. The optimum case found via simulation was finally confirmed through an experiment. In order to obtain the complex curve profile of cup shape after deep drawing, the anisotropic behavior of earring phenomenon was modeled and implemented into FEM. After such phenomenon was correctly predicted, an error metric compared with design curve was then measured.

Similar content being viewed by others

References

SHIM D S, YANG D Y, CHUNG S W, HAN M S. Optimization of forming steps in the incremental forming of twisted shapes using a line array roll set (LARS) [J]. Int J Precis Eng Manuf, 2010, 11(5): 715–723.

QUAN G Z, KU T W, KANG B S. Improvement of formability for multi-point bending process of AZ31B sheet material using elastic cushion [J]. Int J Precis Eng Manuf, 2011, 12(6): 1023–1030.

NGUYEN D T, KIM Y S, JUNG D W. Coupled thermomechanical finite element analysis to improve press formability for camera shape using AZ31B magnesium alloy sheet [J]. Metal Mater Inter, 2012, 18(4): 583–593.

HILL R. A theory of the yielding and plastic flow of anisotropic metals [J]. Proceedings of the Royal Society of London A, 1948, 193: 197–281.

HILL R. Constitutive modeling of orthotropic plasticity in sheet metals [J]. J Mech Phys Solids, 1990, 38(3): 405–417.

HILL R. A user-friendly theory of orthotropic plasticity in sheet metals [J]. Int J Mech Sci, 1993, 35(1): 19–25.

BARLAT F, CHUNG K, RICHMOND O. Strain rate potential for metals and its application to mini mum plastic work path calculations [J]. Int J Plast, 1993, 9: 51–63.

BARLAT F, MAEDA Y, CHUNG K, YANAGAWA M, BREM JC, HAYASHIDA Y, LEGE DJ, MATSUI K, MURTHA S J, HATTORI S, BECKER R C, MAKOSEY S. Yield function development for aluminum alloy sheet [J]. J Mech Phys Solids, 1997, 45(11): 1727–1763.

NGUYEN D T, KIM Y S. Combination of isotropic and kinematic hardening to predict fracture and improve press formability of a door hinge [J]. Proc Inst Mech Eng, Part B: J Eng Manuf, 2010, 224: 435–445.

NGUYEN D T, PARK J G, LEE H J, KIM Y S. Finite element method study of incremental sheet forming for complex shape and its improvement [J]. Proc Inst Mech Eng, Part B: J Eng Manuf, 2010, 224: 913–924.

NGUYEN D T, KIM Y S, JUNG D W. Finite element method study to predict spring-back in roll-bending of pre-coated material and select bending parameters [J]. Int J Precis Eng Manuf, 2012, 13(8): 1425–1432.

TAGUCHI G. On-line Quality Control during Production [M]. Tokyo: Japan Standard Association, 1981.

LIN Y C, CHEN M S, ZHONG J. Prediction of 42CrMo steel flow stress at high temperature and strain rate [J]. Mechanics Research Communications, 2008, 35(3): 142–150.

LIN Y C, CHEN X M. A combined Johnson-Cook and Zerilli-Armstrong model for hot compressed typical high-strength alloy steel [J]. Computational Materials Science, 2010, 49(3): 628–633.

LIN Y C, LI Q F, XIA Y C, LI L T. A phenomenological constitutive model for high temperature flow stress prediction of Al-Cu-Mg alloy [J]. Materials Science and Engineering A, 2012, 534: 654–662.

HECKER S S. Simple technique for determining forming limit curves [J]. Sheet Metal Industry, 1975, 52: 671–676.

HIBBIT D, KARLSSON B, SORENSEN P. ABAQUS User’s Manual, Ver. 6.10.1. [M]. Dallas: ABAQUS Inc, 2008.

CHUNG K, RICHMOND O. Ideal forming, Part II: Sheet forming with optimum deformation [J]. Int J Mech Sci, 1992, 34: 617–633.

CHUNG K, BARLAT F, BREM JC, LEGE D J, RICHMOND O. Blank shape design for a planar anisotropic sheet based on ideal forming design theory and fem analysis [J]. Int J Mech Sci, 1997, 39: 105–120.

WANG J, GOEL A, YANG F, GAU J T. Blank optimization for sheet metal forming using multi-step finite element simulations [J]. Int J of Adv Manuf Tech, 2009, 40(7/8): 709–720.

De-CARVALHO R, SILVA S, VALENTE RAF, ANDRADE-CAMPOS A. Blank optimization in a stamping process-Influence of the geometry definition [J]. Finit Elem Anal Des, 2012, 61: 75–84.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(107.02-2013.01) supported by the Vietnam’s National Foundation for Science and Technology Development

Rights and permissions

About this article

Cite this article

Nguyen, DT., Dinh, DK., Nguyen, HM.T. et al. Formability improvement and blank shape definition for deep drawing of cylindrical cup with complex curve profile from SPCC sheets using FEM. J. Cent. South Univ. 21, 27–34 (2014). https://doi.org/10.1007/s11771-014-1911-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-1911-x