Abstract

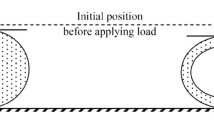

A new structure design method of elastic composite cylindrical roller bearing is proposed, in which PTFE is embedded into a hollow cylindrical rolling element, according to the principle of creative combinations and through innovation research on cylindrical roller bearing structure. In order to systematically investigate the inner wall bending stress of the rolling element in elastic composite cylindrical roller bearing, finite element analysis on different elastic composite cylindrical rolling elements was conducted. The results show that, the bending stress of the elastic composite cylindrical rolling increases along with the increase of hollowness with the same filling material. The bending stress of the elastic composite cylindrical rolling element decreases along with the increase of the elasticity modulus of the material under the same physical dimension. Under the same load, on hollow cylindrical rolling element, the maximum bending-tensile stress values of the elastic composite cylindrical rolling element after material filling at 0° and 180° are 8.2% and 9.5%, respectively, lower than those of the deep cavity hollow cylindrical rolling element. In addition, the maximum bending-compressive stress value at 90° is decreased by 6.1%.

Similar content being viewed by others

References

ERWIN V Z. Palmgren revisited—A basis for bearing life prediction [J]. Journal of the Society of Tribologists and Lubrication Engineers, 1998(2):18–23.

JOHNS P M, GOHAR R. Roller bearing under radial and eccentric loads [J]. Tribology International, 1981, 14(6):131–136.

ABU JADAYIL W M, JABER N M. Numerical prediction of optimum hollowness and material of hollow rollers under combined loading [J]. Materials and Design Journal, 2010, 31:1490–1496.

LUO Hong, LIU Jia-jun. Analysis of contact problems on hollow cylindrical roller [J]. Tribology, 1997, 17(3):253–259. (in Chinese)

BOWEN W L, BHATEJA C P. The hollow roller bearing [J]. Journal of Lubrication Technology (ASME), 1980, 102(4):222–234.

TEUSNER H. The logarithmic roller profile—the hertzian elastic contact problems [J]. Journal of Applied Mechanics (ASME), 1974, 41(2):484–490.

HATRNETT M J. The analysis of contact stresses in rolling element bearings [J]. Journal of Lubrication Technology (ASME), 1979, 101(1):105–109.

PIKOVOKII V A. Study of the working capacity of high-velocity radial bearing with hollow rollers [J]. Strength of Materials, 1982(10):1178–1185.

ABU J W M, FLUGRAD D R. Fatigue life investigation of solid and hollow rollers under pure normal loading [J]. Tribotest, 2007, 13(4):165–181.

PRASHAD H. Determination of stiffness of roller bearings—An alternative approach [J]. Journal of the Institution of Engineers (india): Mechanical Engineering Division, 2004, 81: 186–192. (india): Mechanical Engineering Division, 2004, 81: 186–192.

ZHANG Hong-wei, CHEN Jia-qing, ZHANG Xiang-dong. Numerical simulation on contact mechanics of hollow cylindrical roller bearings [J]. Bearing, 2011(8):1–6. (in Chinese)

DENG Song, HUA Lin, HAN Xing-hui, HUANG Song. Finite element analysis of contact fatigue and bending fatigue of a theoretical assembling straight bevel gear pair [J]. Journal of Central South University, 2013, 20(2):279–292.

LUO Hong, LIU Jia-jun. The hollow cylindrical roller bearing and its wear problems [J]. Tribology, 1993, 13(3):276–286. (in Chinese)

YAO Qi-shui. Improve the cylindrical roller bearing fatigue method and elastic composite cylindrical roller bearing. China Patent, 201110061171. 1[P]. 2011-07-27. (in Chinese)

YAO Qi-shui. A kind of elastic composite cylindrical roller bearing. China Patent, 201120066406. 1 [P]. 2011-11-23. (in Chinese)

YAO Qi-shui, YANG Wen, YU Jiang-hong, ZHANG Ran. Research on structure design of elastic composite cylindrical roller bearing [J]. China Mechanical Engineering, 2012, 23(24):2899–2902. (in Chinese)

YAO Qi-shui, YANG Wen, YU Jiang-hong, ZHANG Ran. Research of carrying capacity of elastic composite cylindrical roller bearing [J]. Journal of Mechanical Transmission, 2013, 37(5):6–9. (in Chinese)

FENG Wei, HUA Lin, HAN Xing-hui. Finite element analysis and simulation for cold precision forging of a helical gear [J]. Journal of Central South University, 2012, 19(12):3369–3377.

LU Yan-jun, ZHANG Yong-fang, YU Yang-bing, YU Lie. Nonlinear dynamics of flexible rotor system supported on fixed-tilting pad combination journal bearing [J]. Journal of Central South University of Technology, 2011, 18(3):610–617.

HARRIS T A. Roller bearing analysis: Original version 5, volume 1, basic concepts of bearing technology [M]. LUO Ji-wei Tr. Beijing: China Machine Press, 2006, 133–148.

HARRIS T A. Roller bearing analysis: Original version 5, volume 2, advanced concepts of bearing technology [M]. LUO Ji-wei Tr. Beijing: China Machine Press, 2009, 60–61.

WEI Yan-gang. Research on the performances of a novel roller bearing-deep cavity hollow cylindrical roller bearing [J]. Chinese Journal of Mechanical Engineering, 2005, 41(2):107–111. (in Chinese)

SHI Yi-ping, ZHOU Yu-rong. Example explanation of finite element analysis [M]. Beijing: China Machine Press, 2006, 125–164. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51175168) supported by the National Natural Science Foundation of China; Projects(2011GK3148, 2012GK3092) supported by Science and Technology Program of Hunan Province, China

Rights and permissions

About this article

Cite this article

Yao, Qs., Yang, W., Yu, Dj. et al. Bending stress of rolling element in elastic composite cylindrical roller bearing. J. Cent. South Univ. 20, 3437–3444 (2013). https://doi.org/10.1007/s11771-013-1868-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1868-1