Abstract

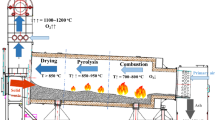

Based on the analysis of material motion in the axial direction, heat transfer and mass transport processes in a rotary kiln, and combining with pulverized coal combustion, material pyrogenation, cooling of furnace wall finally, and heat transfer and mass transport equations, the combined heat transfer mathematical model for alumina rotary kiln was built up. According to the in-site real operation parameters, the heat transfer mathematical model was solved numerically for an alumina rotary kiln to predict the temperature profiles of gas and material in the axial direction. The results show that as the excess air coefficient reduces from 1.38 to 1.20, the temperature of the sintering zone increases and the length decreases. However, as the excess air coefficient reduces from 1.20 to 1.10, the temperature of the sintering zone decreases and the length increases. When the mixed coal amount at the end of kiln is reduced from 68.6 kg/t to 62.0 kg/t and the burned coal amount at the head of kiln correspondingly increases from 155.3 kg/t to 161.9 kg/t, the sintering zone temperature increases and the length reduces. The suitable excess air coefficient and mixed coal amount at the end of kiln are recommended for the rotary kiln operation optimization.

Similar content being viewed by others

References

GOROG J P, ADAMS T N, BRIMACOMBE J K. Regenerative heat transfer in rotary kilns [J]. Metallurgical Transactions B, 1982, 13B(6): 153–163.

GOROG J P, ADAMS T N, BRIMACOMBE J K. Heat transfer from flames in a rotary kiln [J]. Metallurgical Transactions B, 1983, 14B(9): 411–424.

TSCHENG S H, WATKINSON A P. Convective heat transfer in a rotary kiln [J]. The Canadian Journal of Chemical Engineering, 1979, 57(8): 433–443.

LIU X Y, ZHANG J, SPECHT E, SHI Y C, HERZ F. Analytical solution for the axial solid transport in rotary kilns [J]. Chemical Engineering Science, 2009, 64(2): 428–431.

LIU Xiao-yan, SPECHT E. Temperature distribution within the moving bed of rotary kilns: Measurement and analysis [J]. Chemical Engineering and Processing, 2010, 49(2): 147–150.

BOATENG A A, BARR P V. A thermal model for the rotary kiln including heat transfer within the bed [J]. International Journal of Heat and Mass Transfer, 1996, 39(10): 2131–2147.

BOATENG A A, BARR P V. Modelling of particle mixing and segregation in the transverse plane of a rotary kiln [J]. Chemical Engineering Science, 1996, 51(17): 4167–4181.

BOATENG A A, BARR P V. Granular flow behaviour in the transverse plane of a partially filled rotating cylinder [J]. Journal of Fluid Mechanics, 1997, 330(5): 233–249.

HENEIN H, BRIMACOMBE J K, WATKINSON A P. Experimental study of transverse bed motion in rotary kilns [J]. Metallurgical Transactions B, 1983, 14B(6): 191–206.

FAN Xiao-hui, WANG Yi, CHEN Xu-ling. Mathematical models and expert system for grate-kiln process of iron ore oxide pellet production. Part II: Rotary kiln process control [J]. Journal of Central South University of Technology, 2012, 19(1): 200–205.

KONRAD S, JAN P, EDUARDO G. Model predictive control of a rotary cement kiln [J]. Control Engineering Practice, 2011, 19(16): 1–9.

LI S Q, CHI Y, LI R D, YAN J H, CEN K F. Axial transport and residence time of MSW in rotary kilns, theoretical and optimal analyses [J]. Powder Technology, 2002, 126(3): 228–240.

MARIAS F. A model of a rotary kiln incinerator including processes occurring within the solid and the gaseous phases [J]. Computers and Chemical Engineering, 2003, 27(6): 813–825.

LEGER C B, COOK C A, CUNDY V A, STERLIMG A M, DENG X, LIGHTY J S. Bed mixing and heat transfer in a batch loaded rotary kiln [J]. Environmental Progress, 1993, 12(2): 101–109.

LEGER C B, CUNDY V A, STERLING A M, MONTESTRUC A N, JACKWAY A L, OWENS W D. Field-scale rotary kiln incineration of batch loaded toluene/sorbent. I. Data analysis and bed motion considerations [J]. Journal of Hazardous Materials, 1993, 34(1): 1–29.

LEGER C B, CUNDY V A, STERLING A M. A three-dimensional detailed numerical model of a field-scale rotary kiln incinerator [J]. Environmental Science Technology, 1993, 27(4): 677–690.

JACKWAY A L, STERLING A M, CUNDY V A, COOK C A. Three-dimensional numerical modeling of a rotary kiln incinerator [J]. Environmental Science Technology, 1996, 30(5): 1699–1712.

MARIAS F, ROUSTAN H, PICHAT A. Modelling of a rotary kiln for the pyrolysis of aluminium waste [J]. Chemical Engineering Science, 2005, 60(16): 4609–4622.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(11C26214202599) supported by the SME Technology Innovation Fund of Ministry of Science and Technology, China

Rights and permissions

About this article

Cite this article

Yi, Zm., Xiao, H., Song, Jl. et al. Mathematic simulation of heat transfer and operating optimization in alumina rotary kiln. J. Cent. South Univ. 20, 2775–2780 (2013). https://doi.org/10.1007/s11771-013-1796-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1796-0