Abstract

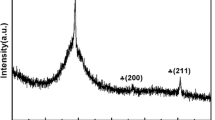

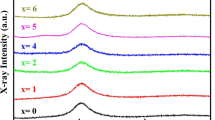

Cu46Zr46Al4.8Ti3.2 bulk metallic glass (BMG) was successfully synthesized by copper-mold casting and the mechanical properties at room temperature were measured by compression tests. The structure and thermal characteristics were analyzed by XRD and DSC, and the fracture surface morphology was examined by SEM. The glassy alloy with 4 mm in diameter shows an high fracture strength of 1 960 MPa, with an improvement of about 20% compared to the ultimate compression fracture strength of the Cu46Zr46Al8 BMG, which suggests that the Ti addition improves the compression fracture strength. The different degrees of the adiabatic heating induce four types of fracture features: a vein-like structure, an elongated and striated vein pattern, melting and smooth regions. The elongated and striated vein patterns as well as the melting region show that enormous strain energy is released, which causes significant adiabatic heating. Furthermore, many micro-cracks observed in the smooth region are caused by the strong shear force. In addition, the strong shear force leads to many shear bands as well as the melting in the lateral surface.

Similar content being viewed by others

References

JAN S. Bulk metallic glasses [J]. Physics Today, 2013, 66(2): 32–37.

CHEN M W. A brief overview of bulk metallic glasses [J]. NPG Asia Materials, 2011, 3: 82–90.

WANG W H. Bulk metallic glasses with functional physical properties [J]. Advanced Materials, 2009, 21(45): 4524–4544.

AXINTE E. Metallic glasses from “alchemy” to pure science: Present and future of design, processing and applications of glassy metals [J]. Materials Design, 2012, 35: 518–556.

SURYANARAYANA C, INOUE A. Bulk metallic glasses [M]. BocaRaton: CRC Press, 2011: 1–523.

INOUE A, TAKEUCHI A. Recent development and application products of bulk glassy alloys [J]. Acta Materialia, 2011, 59(6): 2243–2267.

WU Y, WANG H, WU H H, ZHANG Z Y, HUI X D, CHEN G L, MA D, WANG X L, LU Z P. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties [J]. Acta Materialia, 2011, 59(8): 2928–2936.

CHEN Z H, ZHANG L K, LIU J Z, CHEN D. Cryogenic treatment induced hardening for Cu-Zr-Ag-Al bulk metallic glasses [J]. Science China-Technological Science, 2013, 56(3): 657–641.

ZHANG T, KUROSAKA K, INOUE A. Thermal and mechanical properties of Cu-based Cu-Zr-Ti-Y bulk glassy alloys [J]. Materials Transactions, JIM, 2001, 42(10): 2042–2045.

CALIN M, ECKERT J, SCHULTZ L. Improved mechanical behavior of Cu-Ti-based bulk metallic glass by in situ formation of nanoscale precipitates [J]. Scripta Materialia, 2003, 48(6): 653–658.

GREER A L. Metallic glasses ... on the threshold [J]. Materials Today, 2009, 12(1/2): 14–22.

TREXLER M M, THADHANI N N. Mechanical properties of bulk metallic glasses [J]. Progress in Materials Science, 2010, 55(8): 759–839.

WU F F, ZHANG Z F, MAO S X. Size-dependent shear fracture and global tensile plasticity of metallic glasses [J]. Acta Materialia, 2009, 57(1): 257–266.

XU J, RAMAMURTY U, MA E. The fracture toughness of bulk metallic glasses [J] JOM, 2010, 62(4): 10–18.

BRUCK H A, ROSAKIS A J, JOHNSON W L. The dynamic compressive behavior of beryllium bearing bulk metallic glasses [J]. J Mater Res, 1996, 11(2): 503–511.

WANG W H. The elastic properties, elastic models and elastic perspectives of metallic glasses [J]. Progress in Materials Science, 2012, 57(3): 487–656.

CHENG Y Q, MA E. Atomic-level structure and structure-property relationship in metallic glasses [J]. Progress in Materials Science, 2011, 56(4): 379–473.

YU P, BAI H Y, TANG M B, WANG X L, WANG W H. CuZr-based bulk metallic glasses with good glass-forming ability prepared by Al addition [J]. Acta Physica Sinica, 2005, 54(7): 3284–3289. (in Chinese)

PAULY S, GORANTLA S, WANG G, KUHN U, ECKERT J. Transformation-mediated ductility in CuZr-based bulk metallic glasses [J]. Nature Materials, 2010, (6): 473–477.

XI X K, ZHAO D Q, PAN M X. Fracture of brittle metallic glasses: Brittleness or plasticity [J]. Physical Review Letters, 2005, 94(12):125510.

ZHANG Z F, ECKERT J, SCHULTZ L. Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass [J]. Acta Materialia, 2003, 51(4): 1167–1179.

ZHENG W, HUANG Y J, WANG G Y, LIAW P K, SHEN J. Influence of strain rate on compressive deformation behavior of a Zr-Cu-Ni-Al bulk metallic glass at room temperature [J]. Metallurgical And Materials Transactions A-Physical Metallurgy and Materials Science, 2011, 42(6): 1491–1498.

TABACHNIKOVA E D, BENGUS V Z, MISKUF J. Low temperature ductile shear failure of Zr41.2Ti13.8Ni10 Cu12.5Be22.5 and Cu50Zr35TiHf5Ni2 bulk amorphous alloys [J]. Materials Science Forum, 2000, 343/346: 197–202.

XUE Y F, CAI H N, WANG L, WANG F C, ZHANG H F. Effect of loading rate on failure in Zr-based bulk metallic glass [J]. Materials Science and Engineering A, 2008, 473(1/2): 105–110.

YANG Ying-jun, XING Da-wei, WANG Gang, SUN Jian-fei, WEI Si-dong, SHEN Jun. Compressive fracture behavior of Cu-based bulk amorphous alloys [J]. Rare Metal Materials and Engineering, 2007, 36(6): 1029–1032. (in Chinese)

WANG G Y, LIAW P K, MORRISON M L. Progress in studying the fatigue behavior of Zr-based bulk-metallic glasses and their composites [J]. Intermetallics, 2009, 17(8): 579–590.

SCHMITZ S, LÖSER W, KLAUSS H, BUECHNER B. Effect of elements with positive enthalpy of mixing on mechanical properties of bulk metallic glasses [J]. Journal of Alloys and Compounds, 2011, 509: 131–135.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(NCET-10-0360) supported by the Program for New Century Excellent Talents in University, China; Project supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Chen, D., Dong, Jf. & Ma, Gz. Synthesis and compressive fracture behavior of a CuZr-based bulk amorphous alloy with Ti addition. J. Cent. South Univ. 20, 1137–1141 (2013). https://doi.org/10.1007/s11771-013-1595-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1595-7