Abstract

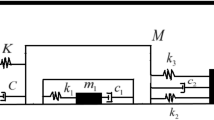

In order to discover the causes of the abnormal noise of shock absorbers, it is necessary to identify the operating characteristics of the shock absorbers. A micro-process model for operation of the hydraulic shock absorber was presented. A novel concept, which describes the process of hydraulic shock absorber by dividing it into smaller steps, was proposed. The dynamic model and the differential equations were established. The results of numerical simulation agree well with data obtained from the vibrostand test, indicating that the collision between the piston and the oil, the alternation of static friction and sliding friction acted between the piston and the cylinder, and the adherence between valve plate and piston result in impact on the piston head near the top dead center and the bottom dead center. Ultimately, the impact excites the high-frequency vibration of the piston structure, which can generate the abnormal noise in the hydraulic shock absorber after its transfer. And the maximum vibration acceleration on the piston head and the abnormal noise increase with the increase of the gap between the oil and piston rod head, the maximum static friction force and the adhering function, respectively.

Similar content being viewed by others

References

YU Da-wei, LUO Jin-liang. An analysis on the cause of abnormal sound of automobile shock absorber [J]. Journal of Weapon, 2000, 21(1): 19–26. (in Chinese)

RUNLING P, JIN J, RALPH O B. Design of an optimal shock-damping isolator with application to casters [J]. Journal of Sound and Vibration, 2006, 289(2): 278–293.

CHAOS C P, SHAW S W. The dynamic response of multiple pairs of subharmonic torsional vibration absorbers [J]. Journal of Sound and Vibration, 2000, 231(2): 411–431.

ZHANG Li-jun, YU Zhuo-ping. Experimental research on the abnormal noise of hydraulic suspension shock absorber [J]. Journal of Vibration and Shock, 2002, 21(1): 13–18. (in Chinese)

SHEKHAR C, HATWAL H, MALLIK A K. Performance of non-linear isolators and absorbers to shock excitations [J]. Journal of Sound and Vibration, 1999, 227(2): 293–307.

YANG Ping, TAN Yong-hong, YANG Jian-min, SUN Nin. Measurement, simulation on dynamic characteristics of a wire gauze-fluid damping shock absorber [J]. Mechanical Systems and Signal Processing, 2006, 20(3): 745–756.

TANG Hua-ping, PENG Ya-qing. Optimal design method for force in vibration control of multi-body system with quick startup and brake [J]. Journal of Central South University of Technology, 2005, 12(4): 459–463.

LU Zhen-hua, LI Shi-min. Simulation techniques for nonlinear dynamic characteristics of telescopic hydraulic dampers [J]. Journal of Tsinghua University: Science and Technology, 2002, 42(11):30–37. (in Chinese)

ZHANG Jun-qing, JIN Da-feng, ZHAO Liu-qi, LI Zhi-guo. A study of non-linear mathematical model of double cylinder vibration damper [J]. Engineering Mechanism, 2002, 33(11): 16–18. (in Chinese)

SCHIEHLEN W, HU B. Spectral simulation and shock absorber identification [J]. International Journal of Non-linear Mechanics, 2003, 38(2): 161–171.

LI Zheng. Reason analysis and simulation investigation of front shock absorber abnormal sound for Chang’an SC6350 [D]. Chongqing: Chongqing University, 2004. (in Chinese)

BLUNDELL M V. The influence of rubber bush compliance on vehicle suspension movement [J]. Materials and Design, 1998, 19 (11): 29–37.

BESINGER F H, CEBON D, COLE D J. Damper models for heavy vehicle-ride dynamics [J]. Vehicle System Dynamics, 1995, 24(1):35–64.

MOLLICA R, YOUCEF T K. A non-linear dynamic model of a monotube shock absorber [C]// Proceedings of the American Control Conference. Albuquerque, New Mexcico: IEEE Press, 1997: 704–708.

WANG Shao-chun, DENG Zong-quan, HU Ming, GAO Hai-bo. Dynamic model building and simulation for mechanical main body of lunar lander [J]. Journal of Central South University of Technology, 2005, 12(3): 329–334.

HIROFUMI M, MASATO K, HIDEAKI K. Mechanism analysis of shock ratting noise [J]. TOYOTA Technical Review, 1997, 47(1):96–103. (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(200244) supported by the Visiting Scholar Foundation of the State Key Laboratory of Mechanical Transmission, Chongqing University

Rights and permissions

About this article

Cite this article

Shu, Hy., Zhang, Ww. & Feng, Y. Micro-process model of hydraulic shock absorber with abnormal structural noise. J. Cent. South Univ. Technol. 15, 853–859 (2008). https://doi.org/10.1007/s11771-008-0157-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-008-0157-x