Abstract

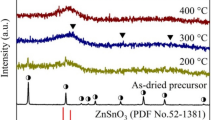

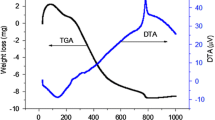

Sn-doped In2O3 (ITO) nano-powders were prepared by hydrothermal-calcining process. Using SnCl4 · 5H2O and In as starting materials, the crystallites were characterized by XRD, TEM and BET. The effects of the conditions on the product were investigated. The results show that the phase of hydrothermal precursor obtained by hydrothermal process is related to the temperature of hydrothermal reaction, i. e., the phases are amorphous In(OH)3 in 160–180 °C; In(OH)3 crystal in 200 °C and (In1−x Sn x ) OOH crystal in 200–300 °C. ITO nano-powders with hexagonal structure and average size of 65 nm are obtained by calcining the precursor derived from the hydrothermal process at 350–650 °C. The BET of ITO crystal can reach 84. 023 4 m2 · g−1.

Similar content being viewed by others

References

LI Feng-guang, LIU Dong-ping, Deng Pei. Preparation and capability research of spherical nano- In2O3-(SnO2) powder[J]. Rare Metals and Cemented carbides, 1999(3): 15–17.

Vossen J L. Transparent conducting films[J]. Physical Thin Films, 1997(9): 1–71.

DUAN Xue-chen, YANG Xiang-ping. Application and development of new material-ITO films[J]. Rare Metals and Cemented Carbides, 1999(3): 58–60.

ZHANG Yan-feng, ZHANG Jiu-xing. Preparation of nano-ITO powder by co-precipitation method and structure token [J]. Functional Material, 2003, 34(5): 573–574.

WEN You. Production, application and expliture of ITO films [J]. Rare Metals and Cemented Carbides, 1997(3): 56–60.

HUA Yang, HAN Sang-do, LI Wang, et al. Preparation and characterization of indium-doped tin dioxide nanocrystalline powders [J]. Materials Chemistry and Physics, 1998, 56(2): 153–156.

LIU Shi-you. The productive situation and application of indium-doped tin dioxide films[J]. Materials Science and Engineering, 1997, 17(2): 98–100.

SONG Wei-ming, ZHOU Hui-liang, HU Qi-lin, et al. Preparation of indium-doped tin dioxide nanocrystal powders by sol-gel process [J]. Journal of Ningxia University: Natural Science Edition, 2000, 21(4): 339–341.

YU Da-bin, YU Wei-chao, WANG De-bao, et al. Structural, optical, and electrical properties of indium tin oxide films with corundum structure fabricated by a sol-gel route based on solvothermal reactions[J]. Thin Solid Films, 2002, 419 (1–2): 166–172.

Kim B C, Lee J H, Kim J J, et al. Rapid rate sintering of nanocrystalline indium tin oxide ceramics: particle size effect [J]. Materials letters, 2002, 52(1–2): 114–119.

YU Da-bin, WANG De-bao, LU Jun, et al. Preparation of corundum structure Sn-doped In2O3 nanoparticles via controlled co-precipitating and postannealing route [J]. Inorganic Chemistry Communications, 2005, 8(5): 475–477.

Udawatte C P, Yanagisawa K. Fabrication of low-porosity indium tin oxide ceramics in air from hydrothermally prepared powder [J]. Communications of the American Ceramic Society, 2001, 84(1): 251–253.

XU Hua-rui, ZHU Gui-sheng, ZHOU Huai-ying, et al. Preparation of monodispersed tin-doped indium oxide nano-powders under moderate conditions [J]. Materials Letters, 2005, 59(1): 19–21.

TANG San-chuan, YAO Ji-sheng, CHEN Jian, et al. Preparation of indium tin oxide (ITO) with a single-phase structure [J]. Journal of Materials Processing Technology, 2003, 137(1–3): 82–85.

CHEN Shi-zhu, YIN Zhi-min, HANG Bo-yun, et al. Study on atomizing-combustion technique for nanosized ITO powder [J]. Nonferrous Metals, 2000, 59(2): 88–90.

Yanagisawa K, Udawatte C P. Preparation and characterization of cine indium tin oxide (ITO) powders by a hydrothermal treatment and post annealing method [J]. Journal of Material Research, 2000, 15(6): 1404–1408.

LIU Xue-ying, GU Ying-ying. Preparation of ITO nanopowders by coprecipitation method [J]. Guangzhou Chemical Industry and Technology, 2005, 33(1):31–34.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (2001BA901A09) supported by the National Western Development and Technique Foundation during the 10th Five-Year Plain Period

Rights and permissions

About this article

Cite this article

Gu, Yy., Qin, Lp. & Liu, Xy. Preparation of ITO nano-powders by hydrothermal-calcining process. J Cent. South Univ. Technol. 13, 389–392 (2006). https://doi.org/10.1007/s11771-006-0054-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-006-0054-0