Abstract

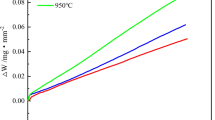

The effects of acid-soluble Al content on the physical and chemical performances of high Al steels were investigated. The results show that the distribution of acid-soluble Al in steel substrate is uniform. With increasing Al content, the strength and toughness of steels decrease a little but the hardness increases. The average yield strength and tensile strength are 425 MPa and 570 MPa, respectively, and the Rockwell hardness is 89. 7. For non-Al steels the average oxidation rate is up to 0.421 mg/(cm2 · h) at 1373 K. For high Al steels, when the mass fraction of Al is less than 5%, there is a thinner gray oxidized layer on surface and the oxidation rate is high; when the mass fraction of Al is more than 8.0%, the thin, close and yellow glossing film still exists, and the average oxidation rate is only 0.016 mg/(cm2 · h).

Similar content being viewed by others

References

ZHANG Ji-shi. The characteristics of heat treatment for carbon steel containing aluminum [J]. Oversea Metal Heat Treatment, 1995, 16(6): 27–31. (in Chinese)

YAN Gen-fa, CHEN Liang, YIN Chao-hai. The coldheading steel wire for tap bolts [J]. Iron and Steel, 1997, 32(10): 12–15. (in Chinese)

ZHOU Yun, WANG Shi-jun, WANG Hai-chuan, et al. Process of feeding Al wire in slab concasting mould[J]. Special Steel, 2003, 24(1): 39–41. (in Chinese)

WU Jian-zhong, YANG Hong-gang. Process of feeding Al in wire in mould of slab concaster[J]. Special Steel, 2001, 22(6): 45–46. (in Chinese)

ZHOU Lan-ju. The process experiment of feeding Al wire Into CC mould[J]. Shandong Metallurgy, 1997, 19(5): 36–39. (in Chinese)

WEN De-zhi, LI Shang-ji. Continuous casting technique and trial production of aluminum containing steel for chains[J]. Iron and Steel, 1997, 32(2): 19–23. (in Chinese)

DING Yi, HUANG Xing-lu, GU Bo-qin, Microstructure and anti-oxidation properties of hot-dip aluminized Q235 steel[J]. Chemical Engineering & Machine, 2001, 28(4): 197–200. (in Chinese)

NI Zhi-jian, REN Zhong-yuan, HUANG Di-guang. The performance and effect factor of hot-dipping aluminized steels[J]. J Northwestern Inst Arch Eng, 1997, 14(3): 42–46. (in Chinese)

YANG Shi-wei, WANG Hai-long, LONG Ping, et al. High temperature oxidation resistance of hot dipping aluminized steel[J]. Corrosion Science and Protection Technique, 1994, 6(4): 330–332. (in Chinese)

HAO Jian-tang, LU Jie. Hot Dip aluminizing of heat-resistant steel and its properties[J]. Iron and Steel, 1996, 31(12): 45–48. (in Chinese)

Kobayashi S, Yakou T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment[J]. Materials Science and Engineering A, 2002, 338(1–2): 44–53.

Wang C J, Lee J W, Twu T H. Corrosion behaviors of low carbon steel, SUS310 and Fe-Mn-Al alloy with hot-dipped aluminum coatings in NaCl-induced hot corrosion[J]. Surface and Coatings Technology, 2003, 163–164: 37–43.

Wolff I M, Iorio L E, Rumpf T, et al. Oxidation and corrosion behaviour of Fe-Cr and Fe-Cr-Al alloys with minor alloying additions[J]. Materials Science and Engineering A, 1998, 241(1–2): 264–276.

García-Alonso M C, López M F, Escudero M L, et al. Corrosion behaviour of an Fe3Al-type intermetallic in a chloride containing solution[J]. Intermetallics, 1999, 7(2): 185–191.

CAO Xue-zeng, CHENG Ai-ying. Structure and performance of hot-Al impregnation[J]. Physical Testing & Chemical Analysis (Part A: Physical Testing), 2002, 38(6): 240–242. (in Chinese)

WEI Xing-zhao, MENG Ji-long, LI Wen-fang, et al. Corrosion resistance of aluminized steel to high temperature H2S gas[J]. J South China Univ of Tech, 1997, 25(9): 137–141. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (200202) supported by the Science and Technology Foundation for Excellent Youth of Anhui Province; project (2003kj077) supported by the Education Office of Anhui Province

Rights and permissions

About this article

Cite this article

Wang, Hc., Dong, Yc., Zhang, Wm. et al. Physical and chemical performances of high Al steels. J Cent. South Univ. Technol. 12, 385–388 (2005). https://doi.org/10.1007/s11771-005-0166-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0166-y