Abstract

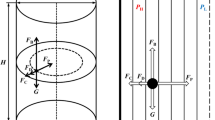

A special experiment setup was designed to observe the interaction between bubbles and particle in flotation cell and to analyze the bubble characteristics such as bubble size, distribution and bubble-loading efficiency. Bubbles in water-gas system and three-phase system were measured. The results indicate that with the current setup the bubbles as small as 10 µm can be easily distinguished. The average size of the bubbles generated under the given conditions in two-phase system is 410 µm at frother concentration of 0.004%, which is in good correspondence with the results of other works. The effect of frother on bubble size was probed. Increasing frother concentration from 0 to 0.004% causes a reduction of bubble size from 700 to 400 µm. The bubble loading efficiency was reported. The result indicates that the fine particle is more easily entrapped than the coarse particle. Some factors, which have effect on measurement accuracy were discussed. The aeration speed has a significant effect on the accuracy of results, if it surpasses 30 mL/s, and the image becomes unclear due to the entrapment of fine particle. Another factor, which can affect observing results, is the sampling position. At a wrong sampling position, the images become unclear.

Similar content being viewed by others

References

Clift R, Grace J R, Weber M E. Bubbles, Drops and Particles[M]. New York: Academic Press, 1978.

Lovett D A, Travers S M. Dissolved air flotation for abattoir wastewater [J]. Water Research, 1986, 20(4): 421–426.

Jameson G J. Hydrophobic and floc density in induced-air flotation for water treatment[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1999, 151(1–2): 269–281.

Kawase Y, Halard B, Moo-Young M, et al. Liquid phase mass transfer coefficients in bioreactors [J]. Biotechnology Bioengineering, 1992, 39: 1133–1140.

Ahmed N, Jameson G J. The effect of bubble size on the rate of flotation of fine particles [J]. International Journal of Mineral Processing, 1985, 14(3): 195–215.

Dai Z F, Daniel F, John R. Particle-bubble attachment in mineral flotation [J]. Journal of Colloid and Interface Science, 1999, 217(1): 70–76.

Dai Z F, Daniel F, John R. Particle-bubble collision models: a review [J]. Advances in Colloid and Interface Science, 2000, 85(2–3): 231–256.

Boyd J W R, Varley J. The uses of passive measurement of acoustic emissions from chemical engineering processes[J]. Chemical Engineering Science, 2001, 56(5): 1749–1767.

Rossi G L. A new intensity modulation based fiber optic probe for bubble shape detection, velocity and diameter measurements[J]. Review of Scientific Instruments, 1996, 67(7): 2541–2544.

Beck M, Lee K T, Stanley-Wood N G. A new method for evaluating the size of solid particles flowing in a turbulent fluid[J]. Powder Technology, 1973, 8: 85–92.

Lu W M, Lin L C. Gas dispersion and bubble size distribution in dual impeller stirred vessels [J]. Journal of the Chinese Institute of Chemical Engineering, 1995, 26(2): 119–125.

Leifer I, de Leeuw G, Kunz G, et al. Calibrating optical bubble size by the displaced-mass method[J]. Chemical Engineering Science, 2003, 58 (23–24): 5211–5216.

Hepworth N J, Hammond J R M, Novel J V. Application of computer vision to determine bubble size distributions in beer [J]. Journal of Food Engineering 2004, 61: 119–124.

Drenckhan W F, Hutzler E S, Weaire D E, et al. Bubble size control and measurement in the generation of ferro fluid foams[J]. Journal of Applied Physics, 2003, 93(12): 10078–10083.

Leifer I. Optical measurement of bubbles: system design and application [J]. Journal of Atmospheric and Oeanic Technology, 2003, 20: 1317–1332.

Wang W X, Xu Z H, Masliyah J H, et al. An induction time model for the attachment of an air bubble to a hydrophobic sphere in aqueous solutions[J]. International Journal of Mineral Processing, 2005, 75(1–2): 69–82.

Gu G X, Xu Z H, Nandakumar K, et al. Effects of physical environment on induction time of air-bitumen attachment [J]. International Journal of Mineral Processing, 2003, 69(1–4): 235–250.

Rodrigues R T, Rubio J. New basis for measuring the size distribution of bubbles[J]. Mineral Engineering, 2003, 16(8): 757–765.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50234010) supported by the National Natural Science Key Foundation of China; project (50304013) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Sun, W., Hu, Yh. & Liu, Rq. Bubble size measurement in three-phase system using photograph technology. J Cent. South Univ. Technol. 12, 677–681 (2005). https://doi.org/10.1007/s11771-005-0068-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0068-z