Abstract

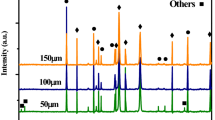

The corrosion resistance of NiCrAl+(ZrO2+Y2O3) thermal barrier coating, formed with the plasma spraying technique, on the 18 - 8 steel surface was investigated. The phase structure and morphology of the coating were analyzed by means of X-ray diffraction (XRD) and scanning electron microscopy (SEM). The electrochemical corrosion behavior of the coating in 1.0 mol/L H2SO4 solution was studied by using electrochemical measurement methods. The results show that the gradient plasma spraying coating is composed of the NiCrAlY coating and the (ZrO2+Y2O3) top coating, and the coating thickness is 360 µm. The microhardness of coating reaches 1 100 HV. The corrosion resistance of the plasma sprayed coating of the 18 - 8 steel surface is about 5 times as great as that of the original pattern. The corrosion resistance of the coating is enhanced notably.

Similar content being viewed by others

References

CHEN Bing-yi. Thermal barrier coatings of speed development[J]. Engineering of Aviation Manufacture, 1994(6): 25–26. (in Chinese)

Brindley W J, Miller R A. Thermal barrier coating life and isothermal oxidation of low-pressure plasma-sprayed bond coat alloys[J]. Surface and Coatings Technology, 1990, 43–44(1–2): 446–457.

ZHOU Hai, CHEN Fei. Study on oxidation resistance of plasma sprayed CoNiCrAlY+(ZrO2+Y2O3) coating on TiAl alloy[J]. Trans Mater Heat Treat, 2004, 25(2): 35–37. (in Chinese)

Evans A G, Hutchison J W. On the mechanics of delamination and spalling in compressed films[J]. Int J Solids Structures, 1993, 74(2): 1321–1326.

Luthra K L, Braint C L. Mechanism of adhesion of alumina on McrAlY alloys[J]. Oxid Met, 1986, 26: 397–403.

Lelait L, Alperine S, Mevrel R. Alumina scale growth at zirconia-McrAlY interface: a microstructural study [J]. J Mater Sci, 1992, 27: 5–12.

Friisa M, Perssona C. Influence of particle in-flight characteristics on the microstructure of atmospheric plasma sprayed yttria stabilized ZrO2[J]. Surface and Coatings Technology, 2001, 145(4): 115–127.

Krauss M. In-situ particle temperature, velocity and size measurements in the spray forming process[J]. Mater Sci Eng A, 2002, 326: 154–164.

Khor K A, Gu Y W, Dong Z L. Mechanical behavior of plasma sprayed functionally graded YSZ/NiCoCr-AlY composite coatings [J]. Surface and Coatings Technology, 2001, 139(2–3): 200–206.

Vanvalzah J R, Eaton H E. Cooling rate effects on the tetragonal to monoclinic phase transformation in aged plasma-sprayed yttria partially stablized zirconia [J]. Surface and Coatings Technology, 1991, 46(3): 289–300.

Khor K A, Dong Z L. Plasma sprayed functionally graded thermal barrier coatings [J]. Materials Letters, 1999, 38(6): 437–444.

Kawasaki A, Watanabe R. Thermal fracture behavior of metal/ceramic functionally graded materials [J]. Engineering Fracture Mechanics, 2002, 69: 1713–1728.

WANG Ning, LU Chun-yan. Effect of NiCrAlY coatings on oxidation resistance of Ni-base superalloy K17[J]. Corrosion Science and Protection Technology, 2002, 14(1): 7–11. (in Chinese)

Mendelson M L. Graded thermal barrier coatings: evaluation [J]. Ceramic Engineering and Science Processing, 1994, 15(14): 555–562.

HU Chuan-shun, WANG Fu-hui. Review of progress in thermal barrier coatings[J]. Corrosion Science and Protection Technology, 2000, 12(3): 160–163. (in Chinese)

ZHOU Wei-fang. Electrochemistry Measure [M]. Shanghai: Shanghai Scientific and Technical Press, 1985. 290–298. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (5040202140) supported by Scientific Research Common Program of Beijing Municipal Commission of Education

Rights and permissions

About this article

Cite this article

Chen, F., Lü, T., Ding, Hd. et al. Corrosion resistance of plasma sprayed NiCrAl+(ZrO2+Y2O3) thermal barrier coating on 18-8 steel surface. J Cent. South Univ. Technol. 12, 242–245 (2005). https://doi.org/10.1007/s11771-005-0050-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0050-9