Abstract

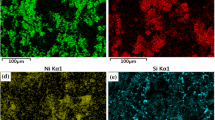

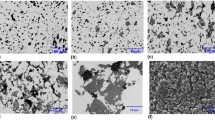

The surface modified nanocopper particles were prepared with chemical reduction method. The wear test was carried out on a T-11 ball-on-plate friction and wear tester made in Poland. The material of the upper sample was GCr15 and the counterpart was AISI-1045 steel. The morphologies of the worn surfaces of the samples were observed by optical microscope and scanning electron microscope, while the element distributions on the worn surfaces were determined by means of electron microprobe analysis. As the results, a film mainly made of Cu is formed on the worn surface. The film on the surface of the still upper sample is thicker than that formed on the revolving counterpart. At the edge of the groove of the worn surface made by the milling before test there is Cu element observed obviously, but there is not any Cu element in the bottom of the groove. A possible action mechanism of the film is suggested. The friction movement can induce reactivity of the metal and continuously produce activation surface. It benefits the film formed by nano-Cu in lubricant on the worn surface. Hardness and modulus of nano-Cu films were successfully measured and analyzed by the nanoindentation instrument. The results show that the hardness and modulus of the films are lower than those of the initial surface.

Similar content being viewed by others

References

XU Bin-shi. Surface Engineering and Maintenance [M]. Beijing: Machine Press, 1996. (in Chinese)

XUE Q J, DANG H X. General introduction on tribology research and its trend [J]. Tribology, 1993, 12 (1):78–79. (in Chinese)

LIU Qian, XU Bin-shi. Research progress of lubricant nano materials and lubricant additive [J]. Aeronautical manufacturing technology, 2004(2): 71–73. (in Chinese)

WANG Ru-lin. Lubricant Tribological Chemistry [M]. Beijing: Petrochemical Publishing House, 1994. (in Chinese)

SHI Pei-jing, XU Bin-shi, QIAO Yu-lin, et al. Tribological behaviour of oil-soluble organo-molybdenum compound as lubricating additives [J]. Trans Nonferrous Met Soc China, 2004, 14(2): 386–390.

XU Bin-shi, MA Shi-ning, XU Yi, et al. Preparation and application of in-situ friction-repairing nano-copper particles lubricating additives [A]. Proceedings of International Conference on Intelligent Maintenance Systems (IMS) [C]. Changsha: National University of Defense Technology Press, 2003. 283–288.

LIU Wei-min, XUE Qun-ji, ZHOU Jing-fang, et al. Antiwear properties of nanoparticles and application study of nanoparticles as additives in the wear-repairing agent [J]. China Surface Engineering, 2001, 14 (3): 21–23. (in Chinese)

XU Bin-shi, WANG Hai-dou, LIANG Xiu-bing, et al. The good maintenance technologies based on nano surface engineering [A]. Proceedings of International Conference on Intelligent Maintenance Systems (IMS) [C]. Shangsha: National University of Defense Technology Press, 2003. 457–466.

SHI Pei-jing, XU Yi, LIU Qian et al. Preparation of nanoparticles self-repairing additive and its application in engines [J]. China Surface Engineering, 2004, 17 (2): 37–40. (in Chinese)

YU He-long, XU Yi, LIU Qian, et al. Tribological behavior of Nano-Cu particles as 50CC lubricating oil additive [J]. China Surface Engineering, 2005, 18(2): 23–26 (in Chinese)

LIU Qian, XU Yi, SHI Pei-jing, et al. Investigation of tribological properties of Cu nanoparticle as lubricating oil additive [J]. Material Protection, 2004, 9 (37s): 176–177.

Beake B D, Leggett G J. Nanoindentation and nanoscratch testing of uniaxially biaxially drawn poly (ethylene terephthalatc) film [J]. Polymer, 2002 (43): 319–327.

Beake B D, Chen S, Hull J B, et al. Nanoindentation behavior of clay/poly(ethylene oxide) nanocomposites [J]. Journal of Nanoscience and Nanotechnology, 2002, 2(1): 73–79.

Oliver W C, Pharr G M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. J Mater Res, 1992, 7 (6): 1564–1583.

Van Vliet K J, Gouldstone A. Mechanical properties of thin films quantified via instrumented indentation [J]. Surface Engineering, 2001, 17 (2): 140–145.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50235030) supported by the National Natural Science Foundation of China; Project (G1999065009) supported by the National Key Basic Research Special Foundation

Rights and permissions

About this article

Cite this article

Liu, Q., Xu, Y., Shi, Pj. et al. Analysis of self-repair films on friction surface lubricated with nano-Cu additive. J Cent. South Univ. Technol. 12, 186–189 (2005). https://doi.org/10.1007/s11771-005-0037-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0037-6