Abstract

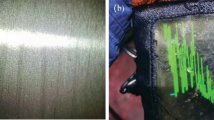

The guide-pieces, used in the process line of steel rolling, were the important components. The guidepieces, which were slide contacting with the rolled-piece, had a high temperature and high speed. The wear was very serious. The results from failure analysis showed that there were three failure forms in the guide-pieces: the first was the wear during heat friction, the second was the heat fatigue under the cycle of deep heating and deep cooling, and the third was the impact rupture. Among them, the wear was the main reason. To the wear of guidepieces, there were four mechanisms, namely abrasive wear, adhesive wear, fatigue wear and corrosion wear. The failure analysis to the guide-piece laid the foundation for its remanufacturing.

Similar content being viewed by others

References

Wang H D. Study on Wear-Resistance Materials and Wear Mechanisms of Quenching White Cast Iron Guide-Pieces [D]. Nanjing: Nanjing Engineering Institute of PLA University, 2000. (in Chinese)

Shao H S, Zhang Q. Abrasive Wear of Metals and the Wear-Resistance Materials [M]. Beijing: China Machine Press, 1988. (in Chinese)

Yang Y Y, Fang H S, Huang W G. A study on wear-resistance of the white layer [J]. Tribology International, 1996, 29(5): 425–428.

Zhu M H, Zhou Z R. Factors controlling white layer initiation in fretting and the effect on wear process [J]. Tribology, 2004, 24(1): 51–55. (in Chinese)

Gregory J R, Spearing S M. Nanoindentation of neat and in situ polymers in polymer-matrix composites [J]. Composites Science and Technology, 2005, 65(3–4): 595–607.

Sahoo P, Roy Chowdhury S K. A fractal analysis of adhesive wear at the contact between rough solids [J]. Wear, 2002, 253(9–10): 924–934.

Terheci M. Microscopic investigation on the origin of wear by surface fatigue in dry sliding [J]. Materials Characterization, 2000, 45(1): 1–15.

Magalhā Seabra J, Sá C. Experimental observations of contact fatigue crack mechanisms for austempered ductile iron (ADI) discs [J]. Wear, 2000, 246(1–2): 134–148.

Zhang S Y, Li S J, Luo X W, Zhou W F. Mechanism of the significant improvement in corrosion protection by lowering water sorption of the coating [J]. Corrosion Science, 2000, 42(12): 2037–2041.

Doche M L, Meynie V, Mazille H B, et al. Improvement of the corrosion resistance of low-pressure nitrided and post-oxidized steels by a polymer impregnation final treatment [J]. Surface and Coatings Technology, 2002, 154(2–3): 113–123.

Revesz A G, Fehlner F P. Role of noncrystalline films in the oxidation and corrosion of metals [J]. Oxidation of Metals, 1981, 15(3–4): 297–321.

Park C J, Kwon H S, Lohrengel M M. Micro-electrochemical polarization study on 25% Cr duplex stainless steel [J]. Materials Science and Engineering A, 2004, 372(1–2): 180–185.

Trueman A R, Schweinsberg D P, Hope G A. A study of the effect of cobalt additions on thecorrosion of tungsten carbide/carbon steel metal matrixcomposites [J]. Corrosion Science, 1999, 41(7): 1377–1389.

Abd El Aal E E. On the pitting corrosion currents of zinc by chloride anions [J]. Corrosion Science, 2004, 46(1): 37–49.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50235030) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Wang, Hd., Xu, Bs., Wei, Sc. et al. Failure analysis used for remanufacturing of steel rolling components. J Cent. South Univ. Technol. 12, 30–33 (2005). https://doi.org/10.1007/s11771-005-0006-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11771-005-0006-0