Abstract

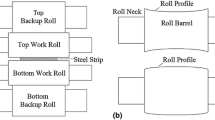

Backup rolls of hot rolling mills have long service life, can withstand harsh working conditions during rolling. However, they undergo severe roll wear that affects the contact force between rolls, resulting in roll fatigue and even spalling accidents. In this study, a fatigue-damage prediction model of a backup roll considering roll wear is proposed. The elastic deformation model of a fast roll system is established using influence function method to calculate the contact stress between rolls. Considering the uneven wear of rolls, a dynamic fatigue-damage prediction model of a backup roll based on the fatigue-damage accumulation theory is established. The model can be used to calculate the wear and fatigue damage caused to a roll after rolling a piece of strip steel. The analysis results show that the proposed model optimized the actual grinding quantity of the backup roll. That is, after optimization, the proportion of secondary grinding is reduced by 35.54%, and the backup-roll consumption is reduced by 8.02%. Therefore, the application of the proposed model can effectively reduce roll consumption, improve grinding efficiency, and provide theoretical support and industrial application reference for the prediction and control of fatigue damage to backup rolls in the field of hot rolling.

Similar content being viewed by others

References

X. Chen, N. Wang, X. Ma et al., Hot deformation behaviour and Hansel-Spittel constitutive model of Cr5 alloy for heavy backup roll. Int. J. Comput. Mater. Sci. Surf. Eng. 7, 205–217 (2018)

Q. Xiao-Feng, R. Jiajun, L. Feng et al., Degradation of Cr5 backup roll material under rolling contact fatigue. Mater. Express. 6(4), 357–362 (2016)

L. Hongbo, Z. Jie, C. Jianguo et al., Characteristics of backup roll wear contour in a CVC continuous hot rolling mill. J. Eng. Sci. 30(5), 558–561 (2008)

X.Y. Song, X.J. Zhang, L.C. Fu et al., Evaluation of microstructure and mechanical properties of 50Cr5NiMoV steel for forged backup roll. Mater. Sci. Eng. A. 677(20), 465 (2016)

Q. Dong, Z. Wang, Y. He, et al. The effect of shifting modes on work roll wear in strip steel hot rolling process. Ironmaking & Steelmaking, 1–8 (2022)

Q. Dong, J. Cao, D. Wen, Spalling prevention and wear improvement of rolls in steel strip hot-rolling process. J. Fail. Anal. Prev. 15(5), 626–632 (2015)

M.F. Frolish, D.I. Fletcher, J.H. Beynon, A quantitative model for predicting the morphology of surface initiated rolling contact fatigue cracks in back-up roll steels. Fatigue Fract. Eng. Mater. Struct. 25(11), 1073 (2002)

M.F. Frolish, J.H. Beynon, Design criteria for rolling contact fatigue resistance in back-up rolls. Ironmak. Steelmak. 31(4), 300 (2004)

P. Dou, S.F. Suo, B.Z. Bai et al., Vertical short crack initiation in medium carbon bainitic steel under mild tractive rolling contact. J. Iron. Steel Res. Int. 15(3), 37 (2008)

Q. Dong, J. Cao, H. Li et al., Analysis of spalling in roughing mill backup rolls of wide and thin strip hot rolling process. Steel Res. Int. 86(2), 129–136 (2015)

Wu. Li Yanlong, Q.X. Qiong, Contact fatigue damage and subsurface microstruture of Cr5 backup roll. J. Northeast. Univ. Nat. Sci. Edit. 41(6), 818 (2020)

S. Dale, Q. Xiaofeng, X. Riyang, Effect of friction coefficients on the backup Rolls’Subsurface contact Fatique damage. J. Northeast. Univ. Nat. Sci. Edit. 35(5), 731 (2014)

D. Benasciutti, On thermal stress and fatigue life evaluation in work rolls of hot rolling mill. J. Strain Anal. Eng. Des. 47(5), 297–312 (2012)

M.R. Aridi, N.A. Noda, Y. Sano et al., Fatigue failure analysis for bimetallic work roll in hot strip mills. Steel Res. Int. 93(2), 2100313 (2022)

J. Zhao, X. Wang, Q. Yang et al., High precision shape model and presetting strategy for strip hot rolling. J. Mater. Process. Technol. 265, 99–111 (2019)

X. Wang, F. Li, B. Li et al., Design and application of an optimum backup roll contour configured with CVC work roll in hot strip mill. ISIJ Int. 52(9), 1637–1643 (2012)

G.Y. Song, Q. Yang, X.C. Wang, Research on wear evolution laws of the work rolls during hot temper rolling process. J. Fail. Anal. Prev. 18(4), 912 (2018)

R. Servin-Castañeda, A.M. Garcia-Lara, R.D. Mercado-Solís et al., Development of mathematical model for control wear in backup roll for hot strip mill. J. Iron. Steel Res. Int. 21(1), 46–51 (2014)

C. Bataille, E. Luc, M. Bigerelle et al., Rolls wear characterization in hot rolling process. Tribol. Int. 100, 328–337 (2016)

Shao J, He A, Yang Q, Guo H. Work roll wear prediction model taking in account lubrication in hot rolling. China Mech. Eng. 20(03):0. (2009)

Y. Yan, C. Jiang, W. Li, Simulation on coupling effects between surface wear and fatigue in spur gear. Eng. Fail. Anal. 134, 106055 (2022)

M. Burstow, Experience of premium grade rail steels to resist rolling contact fatigue (RCF) on GB network. Ironmak. Steelmak. 40(2), 103–107 (2013)

L.J. Dong, A.N.R. He, Y. Song et al., Online calculation model of roll vertical stiffnessin a hot rolling-mill. J. Univ. Sci. Technol. Beijing. 31(11), 1452 (2009)

E.A. Ariza, A.P. Tschiptschin, C.R.F. Azevedo, Failure analysis of a martensitic stainless steel (CA-15M) roll manufactured by centrifugal casting. Part II: Thermal stress analysis by FEA. Eng. Failure Anal. 48, 78–93 (2015)

X.F. Qin, L. Feng, X.G. Zhao, An approach for subsurface rolling contact fatigue damage assessment of backup roll material. J. Fail. Anal. Prev. 17(5), 942 (2017)

W. Zhang, G. Wang, Y. Zhang et al., Formation Mechanism and Improvement of Magnetic Particle Inspection Defects in Cr5 Backup Roller Forged Ingot[J]. Metals. 12(2), 295 (2022)

A. Di Schino, P. Di Nunzio, Metallurgical aspects related to contact fatigue phenomena in steels for back-up rolls. Acta Metall. Slovaca. 23(1), 62–71 (2017)

K. Hu, R. Xue, Q. Shi, W. Han, F. Zhu, J. Chen, FEM simulation of thermo-mechanical stress and thermal fatigue life assessment of high-speed steel work rolls during hot strip rolling process. J. Therm. Stress. 45(7), 538–558 (2022)

P. Palit, S.N. Patel, J. Mathur et al., Analysis of a progressive failure of a work roll in hot strip mill. J. Fail. Anal. Prev. 19(5), 1297–1303 (2019)

M. Tahir, R. Mattsson. Modeling and analysis of the work-roll grinding depth and the roll wear of the work-roll in Steckel hot rolling mill[C]//The 9th International Rolling Conference and the 6th European Rolling Conference. AIM-Associazione Italina di Metallurgia, (2013)

T. Yu, J. Bi, L. Liu Research on intelligent CVC roll grinding and interpolation strategy[C]//2006 International Technology and Innovation Conference (ITIC 2006). IET, 1909-1912 (2006)

Acknowledgments

This research is supported by the National Natural Science Foundation of China (52004029).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, T., Sun, W., Chen, S. et al. Fatigue-Damage Prediction Model of Backup Roll of Hot Strip Mills and its Applications. J Fail. Anal. and Preven. 23, 880–893 (2023). https://doi.org/10.1007/s11668-023-01630-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01630-x