Abstract

The main goal of this work was to investigate the stability of standard palm olein (SPOo) and special quality palm olein (SQPOo) under continuous frying conditions. The rate of free fatty acid (FFA) formation was slightly higher for SPOo than SQPOo during 56 h of frying. An equilibrium state was reached at around 40 h for SPOo and 32 h for SQPOo, whereby FFA varied within a narrow range of 0.30–0.32 and 0.22–0.25%, respectively. Smoke point of SPOo and SQPOo progressively dropped from 212 to 184 °C and from 227 to 191 °C. Tocols of SPOo and SQPOo declined from 550 to 273 mg kg−1 and from 720 to 447 mg kg−1 after 56 h of frying, respectively. Oxidative stability of both oils decreased after the successive frying. Induction time of SPOo dropped from 22.3 to 14.9 h while SQPOo decreased from 25.5 to 18.3 h. Polar and polymer compounds increased as frying progressed. The SPOo had higher levels of polar compounds, averaging 11.8%, compared to the 10.2% in SQPOo. However, SPOo had lower levels of polymer compounds compared to SQPOo, averaging 2.1 and 2.5%, respectively. Hence, this work confirms that frying performance using SPOo was comparable to SQPOo for use in industrial production of snack foods (potato chips).

Similar content being viewed by others

Introduction

Over the last four decades, there has been a great increase of frying oil and fat consumption, as a wide range of fried and pre-fried foods have been developed [1]. Most of the oils and fats are consumed for industrial frying of snack foods such as potato chips, which are one of the popular consumer snack foods throughout the world [2]. In general, the manufacturers producing potato chips in mass quantities under continuous process conditions require large volumes of oil as a frying medium. The frying oil is used as a heat transfer medium; however, some of the oil is absorbed by the fried foods, and hence become a source of flavor and nutrition.

In the snack foods industry, palm olein is one of the oils, which is often regarded as a heavy duty frying oil, where re-using frying oil is normal [3]. Palm olein, with its inherent frying properties, is used due to its techno-economic advantages over other oils and fats [4]. Past studies have demonstrated the frying performances of palm olein during continuous frying of snack foods [5–8].

There are mainly two types of palm olein available in the market i.e. SPOo and SQPOo. The SPOo is graded with a maximum FFA of 0.1% and peroxide value (PV) of 2–4 mequiv O2 kg−1, which comprises the bulk of refined palm olein imported from Malaysia. Upon arrival, the oil is required to be polished or re-refined to minimize the FFA and PV to less than 0.05% and 1 mequiv O2 kg−1, respectively before being utilized for industrial frying purposes.

The SQPOo is a superior quality palm olein produced under stringent quality assurance from harvesting until refining with FFA and PV of less than 0.05% and 1 mequiv O2 kg−1, respectively. In contrast to SPOo, SQPOo has excellent resistance to deterioration during shipment. Thus, SQPOo does not require light refining and can be used directly by the snack food manufacturers. However, SQPOo is traded at a premium price of about $50 per tonnes (FOB Bulk) higher than that of SPOo.

The price of SPOo relies much on the global demand of oils and fats. In 2006, the average price of SPOo rose to US$450 per tonne (FOB Bulk) compared to about US$400 per tonne (FOB Bulk) in 2005. The increase in the price of palm oil products is due to positive market sentiments from the anticipated demand from the biodiesel industry as well as the higher traded price of soybean oil [9]. In addition, the rise of world crude oil prices also contributes to the positive palm oil market outlook.

This scenario, however, may affect the operational cost of some snack food industries due to the price increase of SPOo. Therefore, this study was initiated to evaluate the frying stability of SPOo compared with that of SQPOo under continuous frying conditions. Our hypothesis was that both oils should have almost similar or comparable performance during continuous frying of snack foods (potato chips). We speculate that the SPOo may be utilized directly for industrial frying without having to be re-refined and hence the operational cost can be minimized.

Materials and Methods

Frying Protocol and Oil Sampling

Standard palm olein and SQPOo were refined by PGEO Edible Oils Sdn. Bhd. (Malaysia) and Golden Jomalina Food Industries Sdn. Bhd. (Malaysia), respectively. Four frying sessions of the two oils were evaluated in duplicate using a 200-L capacity pilot plant continuous fryer (Heat and Control, Inc., Brisbane, Australia). The oil was first pumped from the fresh oil tank to the fryer. The oil was then heated at 180 °C in the fryer through heat exchangers. Atlantic-type potatoes were washed, peeled and sliced in a straight-cut manner automatically, conditioned (washed) and air-dried before being fried for about 2 min. The production rate was then gradually increased until a rate of 50 kg h−1 was reached. This rate was then maintained for the whole frying duration. The oil was continuously compensated at 0.4 L h−1 and filtered as frying progressed. The fried products (potato chips) were seasoned and packed using metallized film.

Frying oil was sampled in 500-mL dark amber bottles, flushed in nitrogen and stored at −20 °C for subsequent analyses. About 500 mL of the oil sample was also collected at predetermined intervals throughout frying and stored in an identical manner. All analyses performed for the oil samples were evaluated in triplicates. Each day, the oil in the fryer was cooled to 60 °C, filtered and pumped into the used oil tank overnight for the next-day operation. Each frying session was carried out for a total of 56 h.

Peroxide Value (PV)

The peroxide value was determined following AOCS Official Method Cd 8b-90 [10]. The oil sample, in a mixture of acetic acid (Systerm, Shah Alam, Malaysia) and iso-octane (Merck, Darmstadt, Germany), was treated with a solution of potassium iodide (Systerm, Shah Alam, Malaysia). The liberated iodine was then titrated with a standard volumetric sodium thiosulfate solution (Merck, Darmstadt, Germany) until the yellowish iodine color had faded. A few drops of starch solution (Univar, Seven Hills, Australia) were then added and the titration continued until the blue color has disappeared.

p-Anisidine Value (AnV)

The p-Anisidine value was analysed to determine the amount of aldehydes as described in IUPAC 2.504 [11]. The oil sample was initially mixed with iso-octane (Merck, Darmstadt, Germany) before being reacted with an anisidine reagent (Sigma, St Louis, USA). Measurement of anisidine value was performed at the wavelength of 350 nm in a 10 mm cell using a Lambda 35 Spectrometer (Perkin Elmer, MA, USA).

Free Fatty Acids (FFA)

The free fatty acid content was measured by a titration method defined in AOCS Official Method Ca 5a-40 [10]. The oil sample was dissolved in iso-propanol (Systerm, Shah Alam, Malaysia) with phenolphthalein (J.T. Baker, Phillipsburg, USA) as indicator. The mixture was then titrated with sodium hydroxide (Koch-Light, Suffolk, UK) until a permanent faint pink color appeared and persisted for at least 1 min. The free fatty acid content was calculated as a percentage of palmitic acid.

Iodine Value (IV)

The iodine value was determined with reference to ISO 3961:1996 Animal and vegetable fats and oils—determination of IV [12]. The oil sample, in a mixture of cyclohexane (Merck, Darmstadt, Germany) and glacial acetic acid (Systerm, Shah Alam, Malaysia) was reacted with Wijs reagent (Merck, Darmstadt, Germany) followed by addition of potassium iodide (Systerm, Shah Alam, Malaysia) and distilled water after a specified time. The liberated iodine was further titrated with sodium thiosulfate (Univar, Seven Hills, Australia) until the yellowish iodine color almost faded. A small amount of starch solution (Merck, Darmstadt, Germany) was then added to the solution as an indicator and the titration continued until the blue color had disappeared.

Fatty Acid Composition

The fatty acid composition was determined using a Hewlett-Packard 6890 Series gas chromatography (GC). The analysis was done according to ISO 5508:1990 Animal and vegetable fats and oils—analysis by GC of the methyl esters of fatty acids [13]. The oil sample was first dissolved in n-hexane (Merck, Darmstadt, Germany) before methylation using sodium methoxide (Merck, Darmstadt, Germany). The solution was then diluted with distilled water and allowed to settle for 5 min. The upper layer of fatty acid methyl ester (FAME) was collected and decanted for GC analysis.

The GC was equipped with a flame ionization detector (FID), electronic integrator and data processor. The flow rate of the helium (carrier gas) was positioned at 0.8 mL min−1 with a split ratio of 1:100. A fused silica capillary column (DB-23, 60 m × 0.25 mm, i.d. 0.25 μm film (J&W Scientific, Folsom, USA) was used in the GC. The FID and injector temperature were set at 240 °C. The column was initially conditioned by setting at ambient temperature for an hour before programmed to 220 °C at a rate of 3 °C min−1. This temperature was maintained for about 16 h until a stable base-line was obtained. The temperature was then set to 180 °C and remained isothermal. Fatty acid methyl ester was quantified by comparing the retention time and the peak areas with a RM-6 methyl ester standard (Supelco, Bellefonte, USA).

Smoke Point

The smoke point was determined using the Cleveland open cup method as described in AOCS Official Method Cc 9a-48 [10]. The oil sample was poured into the Cleveland open cup up to the filling line. The light beam was positioned across the centre of the cup. The thermometer was suspended at the centre of the cup in a vertical position. The cup was heated rapidly up to 40–50 °C, followed by regulated heating at the rate of about 5 °C min−1. The smoke point was designated when the oil sample gave off a thin and continuous stream of bluish smoke.

Tocopherols and Tocotrienols (Tocols)

Tocopherols and tocotrienols were analyzed using HPLC as described in AOCS Official Method Ce 8-89 [10]. The oil sample was dissolved with n-hexane (Merck, Darmstadt, Germany) before being injected into the HPLC. The HPLC was fitted with a 250 × 4.6 mm column, packed with 5 μm of silica (Phenomenex, Torrance, USA). A fluorescence detector (Perkin Elmer, Massachusetts, USA) was used at 290 and 330 nm for excitation and emission wavelengths, respectively. Iso-propanol (Merck, Darmstadt, Germany) was used as the mobile phase at a flow rate of 1 mL min−1. A total of 5 min was necessary to assay tocols content of the sample. Tocols were identified by comparing the retention times of Standard Tocopherols and Tocotrienols (Isomer Kits of ChromaDex, Santa Ana, USA).

Oxidative Stability

The oxidative stability or induction period is an expression of the stability of oils and fats toward oxidation [14]. In other words, the induction period is the length of time before the resistance of oils and fats toward oxidation is overcome. Oxidative stability was measured using a 679 Rancimat (Metrohm, Herisau, Switzerland) at 110 °C following the AOCS Official Method Cd 12b-92 [10]. The oil sample was placed directly on the bottom of the reaction tube. The tubing from the air manifold was connected to the conductivity measurement tube. The aeration tube was then adjusted to within 5 mm from the bottom of the reaction and conductivity tube before measuring the air flow at 2.5 ± 0.2 mL s−1. A plot of water conductivity versus time was profiled from a multi channel strip chart recorder and the OSI reflection point was attained by a micro-processor-computed slope algorithm. The reflection point is the induction time in which the oil is considered oxidized.

Polar Compounds

Polar compounds were determined gravimetrically using silica column chromatography following the IUPAC 2.507 [11]. The oil sample was dissolved with a mixture of petroleum benzene (PB):diethyl ether (DE) of 87:13 (v/v). Both chemicals (PB and DE) were obtained from Univar, Seven Hills, Australia. The solution was then transferred into a 4.5-m glass column, packed with Silica Gel 60 No. 7734 (Merck, Darmstadt, Germany) and a PB:DE mixture. Non polar fraction was separated by passing 150 mL of PB:DE mixture through the column within 60–70 min. The column outlet was rinsed with a PB:DE mixture for completion of non polar fraction separation.

The non polar substance was then collected in the flask. Solvent (PB:DE mixture) was removed from a non polar fraction using a rotary evaporator. Shortly before termination of distillation, nitrogen was introduced to the system from a rubber bulb. The residue was cooled at room temperature as the flask was flushed with nitrogen. The amount of polar compounds were calculated by deducting the weight of the sample dissolved in a PB:DE mixture with the mass of non polar residue.

Polymer Compounds

Polymer compounds were analyzed based on the method described by Peled et al. [15]. The oil sample was initially reacted with 1% sulfuric acid (Systerm, Shah Alam, Malaysia) in methanol (Systerm, Shah Alam, Malaysia). The solution was then refluxed using an Erlenmeyer conical flask with a ground-joint fitted with a reflux condenser. The process consumed about 2½ h with stirring throughout. The methanolic layer was separated from the semi-solid or viscous residue after 2½ h of cooling. The insoluble residue was rinsed several times using methanol before being transferred to a conical flask by dissolving it with chloroform (LAB-SCAN, Dublin, Ireland). Chloroform was then removed using a rotary evaporator and the residue was dried in an oven at a temperature of 130 °C for about 30 min. The dried residue was finally weighed after being cooled at room temperature.

Statistical Analysis

Analysis of variance (ANOVA) at 95% confidence level (α = 0.05) was evaluated using SPSS 15.0 for Windows Version. Arrangement of data for the statistical analysis was done using Microsoft Office Excel 2003.

Results and Discussion

Initial Oil Quality

The fresh SPOo and SQPOo were of good quality with FFA of 0.05–0.03%, respectively (Table 1). According to the Palm Oil Refiners Association of Malaysia, the standard trading specifications for palm olein is maximum 0.1% FFA [16]. The PV and AnV in these oils were also no higher than 1 mequiv O2 kg−1 and 1 unit, respectively (Table 1), which further attest to the high quality of oils used in this study. The PV is often used to determine the primary oxidative deterioration of oils and fats. In contrast, the AnV measures secondary decomposition products such as aldehydes and ketones. The IV of both oils were approximately 56, which reflected the overall similarity in fatty acid composition of the starting oils (Table 2). IV is commonly used by the industry as guidance in describing the saturation of oils and fats [17].

Tocols are vital constituent in oils, acting as natural antioxidants by slowing down the rate of oxidative degradation [18]. As shown in Table 1, SPOo had a lower amount of tocols (550 mg kg−1) than in SQPOo (720 mg kg−1). The sufficient amount of tocols is may be responsible for the initial oxidative stability of SPOo (22.3 h) and SQPOo (25.5 h). The importance of tocols as antioxidants suggests that oils containing high levels of such substances would be expected to demonstrate greater stability [18].

Fatty acid compositions of SPOo and SQPOo are shown in Table 2. SPOo contained 46.2% of saturated fatty acids and 41.7% of monounsaturated fatty acids. SQPOo saturated and monounsaturated fatty acids contents of 45.7% and 46.2%, respectively, were not significantly different from the fatty acids content of SPOo (Table 2). In addition, the amount of polyunsaturated fatty acids present in SPOo and SQPOo was observed to be similar (11.5%). The stability of the oils is influenced by their fatty acid compositions, where the higher level of unsaturated fatty acids contributes to the susceptibility to oxidation [19].

Physico-Chemical Properties of Oil During Frying

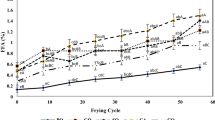

Free Fatty Acids

In this study, the FFA content was used as the principal measurement to determine the acidity development in oils during frying. The free fatty acid content increased moderately in SPOo and SQPOo as frying progressed. A steady state was reached after 40 h for SPOo and 32 h for SQPOo, whereby FFA stabilized within a narrow range of 0.30–0.32 and 0.22–0.25%, respectively (Fig. 1). According to Razali [4], increased FFA content in oils is absorbed by the fried foods (potato chips) and the lost frying oil being replaced with fresh oil containing lower FFA results in a constant FFA content in the frying oil. This constant FFA content is considered the equilibrium point. Normally, an oil containing 0.5% FFA is discarded [20].

Razali [4] conducted a frying study using a 2000-L capacity potato chips production plant and observed that FFA increased moderately from 0.04 to 0.21% as frying progressed. However, after 40 h of frying, FFA stabilized between 0.20–0.24% until 1900 hours. Kristott [21] observed a 0.21% FFA content in frying oil after 20 h of operation. However, FFA further increased to 0.25%, where it remained constant through 40 h. In their [21] study, an industrial production of potato chips (140 kg h−1) using palm olein suggested that the stabilization of FFA at 0.25% was likely with prolonged frying.

Smoke Point

The smoke point is defined as the temperature at which an oil or fat produces a continuous wisp of smoke during heating [22]. The amount of smoke emanating from the frying oil is directly proportional to the concentration of low-molecular-weight decompositions such as FFA and volatile compounds in the oil [14]. Smoke point of SPOo and SQPOo dropped from 212 to 184 °C and from 227 to 191 °C, respectively after 56 h of frying (Fig. 1). However, the smoke point of SPOo (184 °C) and SQPOo (191 °C) were still above the frying temperature of 180 °C and much higher compared to the smoke point of 170 °C defined as the limit by some countries [20].

Tocols

Tocols are susceptible to high temperature deterioration. The reduction of tocols in SPOo and SQPOo was evident as frying progressed (Fig. 2). SPOo displayed a two-step drop of tocols from 550 mg kg−1 to an average of 423 mg kg−1 after 24 h and 241 mg kg−1 after 32 h, where it remained constant until the end of the frying test (56 h).

In the case of SQPOo, the tocols declined by two-fold from 720 mg kg−1 to about 446 mg kg−1 after 8 h, and then varied within a narrow range of 441–451 mg kg−1 (Fig. 2). Thus, the total tocols in SPOo was almost 40% lower (273 mg kg−1) compared to SQPOo of 447 ppm after 56 h of frying. Hence the amount of tocols remaining in SPOo and SQPOo were about 47% (65% tocopherols and 40% tocotrienols) and 62% (77% tocopherols and 56% tocotrienols), respectively of their original content.

Razali [4] also observed similar tocols trend in his study. The tocols in palm olein dropped from an initial content of 800 mg kg−1 to an average of 530 mg kg−1 after 1900 hours using a potato chips production plant, which correspond to about 66% of tocols retention in the palm olein under continuous frying conditions over extensive frying periods.

Oxidative Stability

As expected, SPOo showed a drop in oxidative stability from 22.3 h to around 18 h after 24 h of frying (Fig. 3). The oil stability decreased from 14.4 h before stabilization to 14–15 h after 56 h of frying (Fig. 2). The reduction of 29% in oxidative stability from its initial state of 25.5 h was detected for SQPOo after 8 h. Subsequently, the oxidative stability remained constant within a range of 17.9–18.9 h throughout the frying period.

Razali [4] also noted a similar trend in oxidative stability of palm olein during industrial frying of potato chips. The oxidative stability of palm olein was 42 h when tested at 100 °C. The oxidative stability of palm olein dropped to 21 h and subsequently hovering within 19.8–22.5 h after 79 h of frying. Oxidative stability of 21 h was achieved after 1900 hours of frying, which represents 50% of its original oxidative stability.

Polar Compounds

The amount of polar compounds is used as a chemical measurement of high-temperature degradation of frying oils [23]. The initial polar compounds in SPOo and SQPOo were 6.8 and 7.7% respectively, which is higher compared to other vegetable oils. The higher polar compounds in these two oils due to the higher level (6%) of diacylglycerols compared to other vegetable oils [24]. A comparison of polar compounds formation showed that there was a small difference between SPOo and SQPOo throughout the successive frying (Fig. 4). Standard palm olein had a higher level of polar compounds, averaging at 11.8%, compared to that of SQPOo at 10.2%. These levels were still well below the discard point of 25% polar compounds adopted by some countries [24]. German standard specify a maximum of 27% polar compounds for frying oils [25]. Razali [4] and Kristott [21] also found that polar compounds of palm olein used in industrial fryer averaged 10 and 9%, respectively.

Polymer Compounds

Polymer compounds are formed as a result of oxidative and thermal reaction [17]. However, during frying operation, the main reaction is polymerization rather than oxidation, as the oxygen supply is limited by steam blanketing of the fried foods [26]. Polymerization is mainly responsible for the increased viscosity of frying oil and contributes to the tendency of an oil to foam [27]. In contrast to polar compounds formation, no significant different in polymer compounds were observed between SPOo and SQPOo after 56 h of frying (Fig. 4). The formation of polymer compounds of these oils was 4–5-fold lower than the maximum limit of 10% polymer compounds adopted by some countries [24]. Razali [4] also found that the polymer compounds of palm olein averaged 2% after 1900 hours of frying.

In general, SPOo and SQPOo exhibited equivalent stabilities under continuous frying conditions. Therefore, in consideration of the results above, it can be seen that SPOo can be used as an alternative frying medium to SQPOo by snack food manufacturers, as the SPOo can be consumed directly for industrial frying of snack foods without the need to re-refine the oil upon arrival.

References

Masson L, Robert P, Dobarganes MC, Urra C, Romero N, Ortiz J, Goichoechea E, Pérez P, Salamé M, Torres R (2002) Stability of potato chips fried in vegetable oils with different degree of unsaturation—effect of ascorbyl palmitate during storage. Grasas y Aceites 53:190–198

Razali I, Fauziah A, Nor Aini S (1999) Quality of potato chips fried in palm olein and high oleic sunflower oil during batch frying, Proceedings of the PORIM International Palm Oil Congress, Kuala Lumpur, pp 99–103

Nallusamy S (2006) The role of palm oil in the snack food industry, Presented at International Palm Oil Trade Fair and Seminar, Kuala Lumpur

Razali I (2005) Palm oil and palm olein frying applications. Asia Pac J Clin Nutr 14(4):414–419

Du Plessis LM, Meredith AJ (1999) Palm olein quality parameter changes during industrial production of potato chips. J Am Oil Chem Soc 76:731–738

Sebedio JL, Dobarganes C, Marquez G, Wester I, Christie WW, Dobson G, Zwobada F, Chardigny JM, Mairot TH, Lahtinen R (1996) Industrial production of crisps and pre fried French fries using sunflower oils. Grasas y Aceites 47:5–13

Bracco U, Dieffenbacher A, Kolarovic L (1981) Frying performance of palm oil liquid fractions. J Am Oil Chem Soc 58:6–12

Robertson JA, Morrison WH, Yon BGL, Shaw RL (1978) Flavor and chemical evaluation of potato crisps fried in sunflower, cottonseed and palm oils. J Food Sci 43:420–423

Malaysian Palm Oil Board, Overview of the Malaysian oil palm industry 2006, http://www.econ.mpob.gov.my/economy/EID_Review06.htm (Accessed Mar. 2007)

Firestone D (ed) (1998) Official methods and recommended practices of the AOCS, 5th edn. American Oil Chemists’ Society, Champaign

Dieffenbacher A, Pocillinton WD (ed) (1992) Standard methods for the analysis of oils, fats and derivatives, 7th edn. International Union of Pure and Applied Chemistry, Oxford

ISO 3961:1996 (1996) Animal and vegetable fats and oils:determination of iodine value, International Organization for Standardization, Switzerland

ISO 5508:1990 (1990) Animal and vegetable fats and oils:analysis of gas-liquid chromatography methyl ester of fatty acids, International Organization for Standardization, Switzerland

Matthäus B (2006) Utilization of high-oleic rapeseed oil for deep-fat frying of French fries compared to other commonly used edible oils. Eur J Lipid Technol 108:200–211

Peled M, Gutfinger T, Letan A (1975) Effect of water and BHT on stability of cottonseed oil during frying. J Sci Food Agric 26:1655–1666

Palm Oil Refiners Association of Malaysia, PORAM Standard Specifications for Processed Palm Oil, http://www.poram.org.my/database/contract/specifications.htm Accessed Feb. 2007

Tompkin C, Perkins EG (2000) Frying performance of low-linolenic acid soybean oil. J Am Oil Chem Soc 77:223–229

Normand L, Eskin NAM, Przybylski R (2006) Comparison of the frying stability of regular and high-oleic acid sunflower oils. J Am Oil Chem Soc 83:331–334

Institute of Shortening and Edible Oils (2006) Reaction of fats and oils in food fats and oils, 9th edn. Washington, pp 23–24

Razali I (2001) The performance of palm olein during industrial production of fried food, presented at 92nd. AOCS annual meeting and expo, Minneapolis

Kristott J (2002) Performance of High-Oleic Oils during Frying Comparison with Palm Olein, Technical Communication 11, Britannia Food Ingredients

Canola Council of Canada, Canola oil:physical, chemical properties, http://www.canola-council.org/Chemical1-6_.html (Accessed Feb. 2007)

Warner K, Gupta M (2003) Frying quality and stability of low- and ultra-low-linolenic acid soybean oils. J Am Oil Chem Soc 80:275–280

Berger KG (2005) The use of palm oil in frying. Malaysian Palm Oil Council, Selangor, pp 44–51

Billek G, Guhr G, Waibel J (1978) Quality assessment of used frying fats: a comparison of four methods. J Am Oil Chem Soc 55:728–732

Gertz C, Kochhar SP (2001) A new method to determine oxidative stability of vegetable fats and oils at simulated frying temperature. Oléagineux Corps gras Lipides 8:82–88

Teah YK (1988) Improvements in the frying quality of vegetable oils by blending with palm olein. Palm Oil Develop 8:1–4

Acknowledgments

The authors are grateful to the Director-General of Malaysian Palm Oil Board for permission to publish this paper. Our special acknowledgments are also extended to the Director of Product Development and Advisory Services Division, Head of Unit of Analytical and Quality Development, and the Group Leader and staff of Innovative Products for their support and technical assistance.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ahmad Tarmizi, A.H., Ismail, R. Comparison of the Frying Stability of Standard Palm Olein and Special Quality Palm Olein. J Am Oil Chem Soc 85, 245–251 (2008). https://doi.org/10.1007/s11746-007-1184-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1184-8