Abstract

The use of mechanical joining technologies offers the possibility of joining mixed material structures, which are used in particular in lightweight construction. An integrated securing of the joinability in versatile process chains is currently hardly possible as the number of combinable tool variants as well as variable force- and path-based process parameters is infinite. A versatile process chain, i.e. a sequence of all the processes and process steps required for product manufacturing, enables targeted changes to the semi-finished product, the joint, the component or the joining process that exceed the originally planned extend while still ensuring joinability. In detail, it leads to a unique joint with its own mechanical property profile, which, against the background of the resulting infinite number of combinations, makes it impossible to secure the joinability on the conventional experimentally based approach without extensive safety factors. The Transregional Colaborative Research Center 285 (TCRC285), which also initiated this special issue, is intended to enable mechanical joining technology to be versatile in the sense of high application flexibility. This is to be achieved with a numerical representation of the complete process chain from the incoming semi finished product via the joining part production and the joining process to the property profile of the joint in the operating phase. Thus a predictability of the joinability can be achieved and improvements in the individual life cycles of a joint can be realized by grasping the cause-and-effect relationships. On the basis of this knowledge, new possibilities for intervention in the joining process are to be created for the adaptation of the joining processes. With the aid of the methods developed for this purpose, tools will later be available to the end user to substitute the large number of mechanical joining processes or joining task-specific configurations with a smaller number of adaptable processes. This expands the flexibility in material choices, enabling challenges in environmental issues and sustainability to be overcome.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Motivated by the oil crisis at the end of the 1970s, the automotive industry increasingly developed concepts for the growing use of aluminum materials [1]. Conventional thermal joining processes such as resistance spot welding (RSW) quickly reach their technical limits, especially when multimaterial joining is required, e.g. steel to aluminium or metals to plastics. Mechanical joining technologies were therfore developed under a high innovation pressure in an application-oriented manner and established in series production [2]. In order to avoid overdimensioning of the components, the joining component materials used (e.g. high-strength steels, light metals, fibre reinforced polymers—FRP) must be utilized as far as possible to their stress limits under the operating loads that occur and taking into account application-related safety factors. The joints have a property-defining function for the entire component structure by transferring the different forces (e.g. static, cyclic, impact) from one joining part to the other via the joints. However, the joining points are usually associated with a change in the original mechanical properties of the joined parts and form weak points of a component structure. Therefore, damage cases are often due to incorrectly designed or overstressed joints [3]. Highly developed lightweight materials, like high strength steels, are increasingly pushing current mechanical joining methods to their process limits [4]. Therefore, new variants of material-specific joining processes are continuously being developed, which, however, are no longer able to flexibly guarantee the joinability in case of a change of the material geometry combinations (MGC, e.g. joining part material and thickness) or under fluctuating joining conditions. Frequently, investments are then made in new joining systems instead of adapting existing ones to the new boundary conditions [5]. Joining technology is thus a cost driver for structures, especially for larger quantities due to lack of adaptability. In view of this, joining is a key technology both for the economical manufacture of products and for their properties.

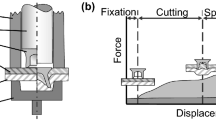

In this context, the single-stage and pre-hole-free processes have gained a particularly large share due to their high efficiency, although their capability for versatility, i.e. the targeted modification of processes or process steps while at the same time securing the joinability, is not given. The potential of these joining processes for the effective manufacture of lightweight structures in versatile process chains is thus not being exploited. A subdivision of the joining by forming processes according to DIN 8593 subdivides processes with and without auxiliary joining parts. Following the idea of a simple process, clinching involves joining two or more overlapping sheet metal, tube or profile parts without auxiliary joining parts by cold forming using a punch and a die, see Fig. 1. The joining partners are first partially penetrated and then upset, so that a generally force- and form-fit connection between components made of different, even higher-strength materials is created by widths or extrusion [6].

The subgroup “Joining by riveting” has gained particular importance in series production. In riveting, the joint is created by adding a bolt-shaped auxiliary joining part and plastic forming of the rivet and/or joining part and the resulting force- and form-fit connection. A preferred variant is self-piercing riveting with semi-hollow rivet, in which the auxiliary joining part is pressed through the punch-side joining part in an uninterrupted joining process and the die-side joining part is formed with the aid of the rivet and die geometry, see Fig. 2. In parallel, the rivet foot is spread in the later course of the process and anchors itself in the die-side joining part. The main advantage of clinching and semi-tubular riveting is the elimination of a pre-hole operation, which significantly reduces tolerance and positioning efforts and increases production efficiency. The disadvantage of these forming joining processes is their lack of versatility and predictability.

2 The Transregional Colaborative Research Center 285 (TCRC285)

The TCRC285 “Method development for mechanical joinability in versatile process chains” investigates scientific methods for versatility in the scope of the three areas of joinability (Fig. 3) using the example of mechanical joining: material (joining suitability), design (joining safety) and manufacturing (joining possibility). TCRC285 therefore investigates the interactions between the preceding manufacturing steps and the joint load-bearing capacity in order to establish a basis for achieving versatility of mechanical joining processes, including novel process approaches, and a transferable design methodology for mechanically joined joints. The findings of this TCRC thus serve to fully describe the joinability in versatile process chains.

The research initiative is divided into the three phases “fundamentals”, “processes and materials”, “process chains and versatility”. At the three locations Paderborn (TCRC and location spokesperson: Prof. Meschut), Dresden (location spokesperson: Prof. Brosius) and Erlangen (location spokesperson: Prof. Merklein), the scientists will investigate the fundamentals of predictable joinability in a holistic and method-oriented manner in the three areas: joining suitability (material), joining safety (construction and design) and joining possibility (manufacturing) in a total of 16 subprojects. In the research network, research is carried out across locations in the cross-sectional working groups “Modeling”, “Materials and Characterization”, “Technology”, “Demonstrator” and “Data Management”. The vision of the TCRC285 is to ensure mechanical joinability in versatile process chains. To answer the central question, existing intervention options for mechanical joining processes are being upgraded and additional ones created, and new process approaches are being investigated. These approaches are intended to provide the mechanical joining processes with the adaptability required for efficient use in versatile process chains. To this end, existing processes without pre-holes (clinching, self-pierce riveting) are being further developed to make them adaptable, and novel process approaches (e.g. joining with adaptive friction elements or joining without auxiliary parts with pin-structured joining parts) are being researched for hybrid metal-to-metal and metal-to-FRP joints in a manner suitable for the materials involved.

2.1 Joining suitability

In the TCRC, the materials aluminum, steel and FRP, which are used in particular in lightweight construction applications in automotive or mechanical engineering, are the focus of the investigations. In terms of joining suitability, the mechanical joining processes are customized within very narrow limits to the respective MGC and generally require an adjustment of the auxiliary joining part, tool and process parameters in the case of modified joining tasks. According to the state of the art, complex experimental sampling has to be carried out for new MGCs in order to validate the joints. The entire procedure for joint design takes place on the basis of experience as “trial and error” [7]. Here, the TCRC aims to create the basis for an end-to-end methodology for modeling and simulation in order to replace the heuristic methodology commonly used today and to make the development process more economical and resource-saving.

2.2 Joining possibility

The adaptability and predictability of the joining process is an important objective for the production engineering. In particular, the mechanical joining processes are fixed in a configuration (e.g. auxiliary parts, tools) to a certain MGC and usually cannot be reused unchanged if the production boundary conditions change (e.g. joining part material, thickness). This means that a very time-consuming safety relevant change is required by adapting or re-selecting the joining processes with renewed testing [7]. Within the scope of the TCRC, demand-oriented joining processes for versatile process chains, considering also per- and post treatment steps, will be developed. Adapted, non-destructive measurement methods in and after the joining process ensure the quality of the joint formation and thus the joining possibility. By means of numerical simulation of the mechanical joining processes, imperfect joints in the mechanical joining process chain are avoided.

2.3 Joining safety

The joining safety of a structure depends on the design and layout of the joints and the resulting stress state as well as on the material. Uncontrolled deformations frequently occur in mechanical joining processes. These lead to damage in the parts or elements to be joined, resulting in joints in the production process that do not comply with the quality guidelines or limiting the service life of the joints, e.g. under cyclic loads [8]. For the process simulation of mechanical joining techniques, the complete description of the stress state in three-dimensional space and a cross-scale modeling and simulation of joining process and joint is necessary to account for the complex damage behavior [9]. Micro-cracks or voids already formed during the manufacture of the joint can propagate under service loads, which is why a physically coupled model that takes into account material degradation due to corrosion in the classical mechanical damage formulation and fracture mechanics evaluation of corresponding joints is provided in the TCRC. The findings are used to develop a transferable design methodology for mechanically joined joints that are suitable for stresses with improved joint-specific material utilization.

References

Gould JE (2012) Joining aluminum sheet in the automotive industry—a 30 year history. Weld J 91:23–34

Meschut M, Hahn O, Janzen V, Olfermann T (2014) Innovative joining technologies for multi-material structures. Weld World 58:65–75. https://doi.org/10.1007/s40194-013-0098-3

Heermant C (2016) Schadensanalyse an Schraubverbindungen. In: Tagungsband DVM-Tag 2016-Bauteile Verstehen. Schraubenverbindungen

Meschut G, Janzen V, Olfermann T (2014) Innovative and highly productive joining technologies for multi-material lightweight car body structures. J Mater Eng Perform 23:1515–1523. https://doi.org/10.1007/s11665-014-0962-3

Bangel M, Müller S (2014) Trends in der Fügetechnik durch neue Karosseriekonzepte. In: 4. Fügetechnisches Gemeinschaftskolloquium Dresden

Mori K-I, Abe Y (2018) A review on mechanical joining of aluminium and high strength steel sheets by plastic deformation. Int J Lightweight Mater Manuf 1:1–11

Menne F (2018) Automatisierte Variantenreduzierung durch virtuelle Verbindungsauslegung beim Halbhohlstanznieten. Forschungsbericht des LWF. Disseration. Universität Paderborn (ISBN: 978-3-8440-5994-6)

Carboni M, Beretta S, Monno M (2006) Fatigue behaviour of tensile-shear loaded clinched joints. Eng Fract Mech 73:178–190. https://doi.org/10.1016/j.proeng.2011.04.586

Gude M, Hufenbach W, Kupfer R, Freund A, Vogel C (2015) Development of novel form-locked joints for textile reinforced thermoplastices and metallic components. J Mater Process Technol 216:140–145. https://doi.org/10.1016/j.jmatprotec.2014.09.007

Acknowledgements

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation)—TRR 285—Project-ID 418701707. The authors thank the German Research Foundation for their organisational and financial support

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Meschut, G., Merkein, M., Brosius, A. et al. Mechanical joining in versatile process chains. Prod. Eng. Res. Devel. 16, 187–191 (2022). https://doi.org/10.1007/s11740-022-01125-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-022-01125-y