Abstract

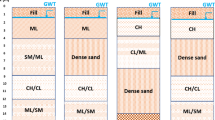

The pipe roofing method is widely used in tunnel construction because it can realize a flexible section shape and a large section area of the tunnel, especially under good ground conditions. However, the pipe roofing method has rarely been applied in soft ground, where the prediction and control of the ground settlement play important roles. This study proposes a sliced-soil–beam (SSB) model to predict the settlement of ground due to tunnelling using the pipe roofing method in soft ground. The model comprises a sliced-soil module based on the virtual work principle and a beam module based on structural mechanics. As part of this work, the Peck formula was modified for a square-section tunnel and adopted to construct a deformation mechanism of soft ground. The pipe roofing system was simplified to a three-dimensional Winkler beam to consider the interaction between the soil and pipe roofing. The model was verified in a case study conducted in Shanghai, China, in which it provided the efficient and accurate prediction of settlement. Finally, the parameters affecting the ground settlement were analyzed. It was clarified that the stiffness of the excavated soil and the steel support are the key factors in reducing ground settlement.

Similar content being viewed by others

Data availability statements The data sets generated during and/or analyzed in the current study are available from the corresponding author on reasonable request.

Abbreviations

- A :

-

constant in displacement equations

- [A v]:

-

general stiffness matrix of the beam

- B :

-

constant in displacement equations

- c :

-

effective cohesion

- c u :

-

undrained shear strength of the soft ground

- C :

-

thickness of the overlying soil layer

- d t :

-

diameter of pipe i

- d 1 :

-

outer diameter of a pipe

- d 2 :

-

inner diameter of a pipe

- D :

-

diameter of the circular-section tunnel

- D t :

-

diameter of the equivalent tunnel

- E :

-

pipe elastic modulus

- E s1−2 :

-

soil compression modulus

- E ref50 :

-

reference secant shear modulus

- E refoed :

-

reference oedometer modulus

- E refur :

-

reference unloading–reloading modulus

- G ref0 :

-

reference shear modulus at very low strains

- H :

-

height of the square-section tunnel

- i z :

-

settlement trough width

- k s :

-

foundation reaction coefficient

- k 1s :

-

latticed improvement stiffness

- k 2s :

-

layered improvement stiffness

- k t :

-

inner steel support stiffness

- [k]:

-

foundation stiffness matrix that is a combination of kt and ks

- K 0 :

-

coefficient of earth pressure at rest

- k t :

-

parameter in the Peck formula

- L :

-

width of the square-section tunnel

- m :

-

power for the stress-level dependency of stiffness

- p ref :

-

reference pressure

- P ps :

-

equivalent supporting pressure from the pipe roofing

- P sp :

-

earth pressure on the pipe roofing

- {q i}:

-

force acting on node i

- R f :

-

failure ratio

- v m :

-

maximum ground settlement

- V sloss :

-

soil volume loss

- V ploss :

-

tunnel section shrinkage

- V trialloss :

-

trial tunnel section shrinkage

- {w i}:

-

displacement of each beam

- z :

-

depth below the ground face

- Z 0 :

-

central depth of the tunnel

- Z m :

-

maximum depth of the mechanism

- α :

-

parameter controlling the shape of the mechanism

- β :

-

power exponent of the stress–strain power curve

- φ′:

-

effective internal friction angle

- γ 0.7 :

-

shear strain corresponding to 0.7G0ref

- γ s :

-

shear strain

- γ s,f :

-

shear strain at maximum shear strength

- v :

-

Poisson’s ratio of a pipe

- v ur :

-

Poisson’s ratio of unloading and reloading

- v s :

-

Poisson’s ratio of the soil

- ρ :

-

unit weight of the soil

- ρ s :

-

density of a pipe

- τ :

-

shear strength

- ψ :

-

dilation angle

References

Ağbay E, Topal T. Evaluation of twin tunnel-induced surface ground deformation by empirical and numerical analyses (NATM part of Eurasia tunnel, Turkey). Computers and Geotechnics, 2020, 119: 103367

Hounyevou Klotoé C, Bourgeois E. Three dimensional finite element analysis of the influence of the umbrella arch on the settlements induced by shallow tunneling. Computers and Geotechnics, 2019, 110: 114–121

Tan W L, Pathegama R G. Numerical analysis of pipe roof reinforcement in soft ground tunnelling. In: Proceedings of American Society of Civil Engineers (ASCE) Engineering Mechanics Conference. Reston: American Society of Civil Engineers, 2003, 1–10

Lu B, Dong J, Zhao W, Du X, Cheng C, Bai Q, Wang Z, Zhao M, Han J. Novel pipe-roof method for a super shallow buried and large-span metro underground station. Underground Space, 2022, 7(1): 134–150

Lu B, Zhao W, Wang W, Jia P, Du X, Cao W, Li W. Design and optimization of secant pipe roofing structure applied in subway stations. Tunnelling and Underground Space Technology, 2023, 135: 105026

Hasanpour R, Chakeri H, Ozcelik Y, Denek H. Evaluation of surface settlements in the Istanbul metro in terms of analytical, numerical and direct measurements. Bulletin of Engineering Geology and the Environment, 2012, 71(3): 499–510

Chung C C, Lin C P, Chin C H, Chou K H. Development and implementation of horizontal-plane settlement indication system for freeway health monitoring during underpass construction. Structural Control and Health Monitoring, 2017, 24(11): e1995

Xie X, Zhao M, Shahrour I. Experimental study of the behavior of rectangular excavations supported by a pipe roof. Applied Sciences, 2019, 9(10): 2082

Yang C, Chen Y, Guo Z, Zhu W, Wang R. Surface settlement control in the excavation of a shallow intersection between a double-arched tunnel and a connection tunnel. International Journal of Geomechanics, 2021, 21(4): 04021035

Zhou X Q, Pan J L, Liu Y, Yu C C. Analysis of ground movement during large-scale pipe roof installation and artificial ground freezing of Gongbei tunnel. Advances in Civil Engineering, 2021, 2021: 1–15

Cheng H Z, Chen J, Chen G L. Analysis of ground surface settlement induced by a large EPB shield tunnelling: A case study in Beijing, China. Environmental Earth Sciences, 2019, 78(20): 605

Fang Y S, Lin J S, Su C S. An estimation of ground settlement due to shield tunneling by the Peck–Fujita method. Canadian Geotechnical Journal, 1994, 31(3): 431–443

Fattah M Y, Shlash K T, Salim N M. Prediction of settlement trough induced by tunneling in cohesive ground. Acta Geotechnica, 2013, 8(2): 167–179

Ma L, Ding L Y, Luo H B. Non-linear description of ground settlement over twin tunnels in soil. Tunnelling and Underground Space Technology, 2014, 42: 144–151

Zhao W, Jia P J, Zhu L, Cheng C, Han J Y, Chen Y, Wang Z G. Analysis of the additional stress and ground settlement induced by the construction of double-O-tube shield tunnels in sandy soils. Applied Sciences, 2019, 9(7): 1399

Fang Y, Chen Z, Tao L, Cui J, Yan Q. Model tests on longitudinal surface settlement caused by shield tunnelling in sandy soil. Sustainable Cities and Society, 2019, 47: 101504

Mirhabibi A, Soroush A. Effects of surface buildings on twin tunnelling-induced ground settlements. Tunnelling and Underground Space Technology, 2012, 29: 40–51

Ocak I. A new approach for estimating the transverse surface settlement curve for twin tunnels in shallow and soft soils. Environmental Earth Sciences, 2014, 72(7): 2357–2367

Zhang Q, Wu K, Cui S, Yu Y, Zhang Z, Zhao J. Surface settlement induced by subway tunnel construction based on modified peck formula. Geotechnical and Geological Engineering, 2019, 37(4): 2823–2835

Wu C S, Zhu Z D. Analytical method for evaluating the ground surface settlement caused by tail void grouting pressure in shield tunnel construction. Advances in Civil Engineering, 2018, 2018: 1–10

Fang K D, Yang Z Y, Jiang Y S, Sun Z Y, Wang Z Y. Surface subsidence characteristics of fully overlapping tunnels constructed using tunnel boring machine in a clay stratum. Computers and Geotechnics, 2020, 125: 103679

Li X G, Chen X S. Using grouting of shield tunneling to reduce settlements of overlying tunnels: Case study in Shenzhen Metro construction. Journal of Construction Engineering and Management, 2012, 138(4): 574–584

Oh J Y, Ziegler M. Investigation on influence of tail void grouting on the surface settlements during shield tunneling using a stresspore pressure coupled analysis. KSCE Journal of Civil Engineering, 2014, 18(3): 803–811

An J B, Kang S J, Cho G C. Numerical evaluation of surface settlement induced by ground loss from the face and annular gap of EPB shield tunneling. Geomechanics and Engineering, 2022, 29(3): 291–300

Hou Y J, Zhou M Z, Zhang D L, Fang Q, Sun Z Y, Tian Y H. Analysis of four shield-driven tunnels with complex spatial relations in a clay stratum. Tunnelling and Underground Space Technology, 2022, 124: 104478

Peck R B. Deep excavations and tunnelling in soft ground. In: Proceedings of the 7th International Society for Soil Mechanics and Foundation Engineering. Mexico: EurekaMeg, 1969, 225–325

FLAC3D. Version 7.0. Minnesota: Itasca (Itasca Consulting Group, Inc.). 2019

Zhang Z G, Huang M S. Geotechnical influence on existing subway tunnels induced by multiline tunneling in Shanghai soft soil. Computers and Geotechnics, 2014, 56: 121–132

Sun Y Y, Zhou S H, Luo Z. Basal-heave analysis of pit-in-pit braced excavations in soft clays. Computers and Geotechnics, 2017, 81: 294–306

Chen K H, Peng F L. An improved method to calculate the vertical earth pressure for deep shield tunnel in Shanghai soil layers. Tunnelling and Underground Space Technology, 2018, 75: 43–66

Wang W D, Ng C W W, Hong Y, Hu Y, Li Q. Forensic study on the collapse of a high-rise building in Shanghai: 3D centrifuge and numerical modelling. Geotechnique, 2019, 69(10): 847–862

Lan L, Zhang Q, Zhu W, Ye G, Shi Y, Zhu H. Geotechnical characterization of deep Shanghai clays. Engineering Geology, 2022, 307: 106794

Ye G, Ye B. Investigation of the overconsolidation and structural behavior of Shanghai clays by element testing and constitutive modeling. Underground Space, 2016, 1(1): 62–77

Wu C, Ye G, Zhang L, Bishop D, Wang J. Depositional environment and geotechnical properties of Shanghai clay: A comparison with Ariake and Bangkok clays. Bulletin of Engineering Geology and the Environment, 2015, 74(3): 717–732

Zhou H, Hu Q, Yu X, Zheng G, Liu X, Xu H, Yang S, Liu J, Tian K. Quantitative bearing capacity assessment of strip footings adjacent to two-layered slopes considering spatial soil variability. Acta Geotechnica, 2023, 1–15

Mroueh H, Shahrour I. A simplified 3D model for tunnel construction using tunnel boring machines. Tunnelling and Underground Space Technology, 2008, 23(1): 38–45

Rankin W J. Ground movements resulting from urban tunnelling: Predictions and effects. Geological Society, 1988, 5(1): 79–92

Mair R J, Taylor R N, Bracegirdle A. Subsurface settlement profiles above tunnels in clays. Geotechnique, 1993, 43(2): 315–320

Mair R J. Centrifugal modelling of tunnel construction in soft clay. Dissertation for the Doctoral Degree. Cambridge: University of Cambridge, 1979

Osman A S, Bolton M D, Mair R J. Predicting 2D ground movements around tunnels in undrained clay. Geotechnique, 2006, 56(9): 597–604

Osman A S, Mair R J, Bolton M D. On the kinematics of 2D tunnel collapse in undrained clay. Geotechnique, 2006, 56(9): 585–595

Cheng P, Shen Y, Zhao X, Li X, Zhu H. Numerical analysis and parameter optimization of pipe curtain excavation method in soft soil subway station. Modern Tunnelling Technology, 2021, 58(S1): 240–250 (in Chinese)

Wang Z F, Shen S L, Modoni G, Zhou A. Excess pore water pressure caused by the installation of jet grouting columns in clay. Computers and Geotechnics, 2020, 125: 103667

Shen S L, Atangana Njock P G, Zhou A, Lyu H M. Dynamic prediction of jet grouted column diameter in soft soil using BiLSTM deep learning. Acta Geotechnica, 2021, 16(1): 303–315

Atangana Njock P G, Shen S L, Zhou A, Modoni G. Artificial neural network optimized by differential evolution for predicting diameters of jet grouted columns. Journal of Rock Mechanics and Geotechnical Engineering, 2021, 13(6): 1500–1512

Shen S L, Wang Z F, Cheng W C. Estimation of lateral displacement induced by jet grouting in clayey soils. Geotechnique, 2017, 67(7): 621–630

Shen S L, Wang Z F, Yang J, Ho C E. Generalized approach for prediction of jet grout column diameter. Journal of Geotechnical and Geoenvironmental Engineering, 2013, 139(12): 2060–2069

Wang Z F, Shen S L, Modoni G. Enhancing discharge of spoil to mitigate disturbance induced by horizontal jet grouting in clayey soil: Theoretical model and application. Computers and Geotechnics, 2019, 111: 222–228

Gunn M J. The prediction of surface settlement profiles due to tunnelling. In: Proceedings of the Wroth Memorial Symposium. Oxford: Thomas Telford Publishing, 1992, 304–316

Sketchley C J. Behaviour of Kaolin in Plane-strain. Dissertation for the Doctoral Degree. Cambridge: University of Cambridge, 1973

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52178342), the Tianjin Natural Science Foundation (No. 21JCZDJC00590), and the Shanghai Excellent Academic/Technical Leader Program (No. 20XD1432500).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Diao, Y., Xue, Y., Pan, W. et al. A 3D sliced-soil–beam model for settlement prediction of tunnelling using the pipe roofing method in soft ground. Front. Struct. Civ. Eng. 17, 1934–1948 (2023). https://doi.org/10.1007/s11709-023-0038-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-023-0038-2