Abstract

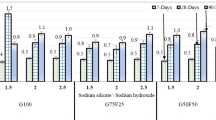

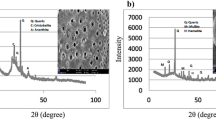

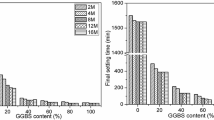

Experimental evaluations were conducted to determine the water sorptivity, setting time, and resistance to a highly acidic environment, of mortar with alkali-activated ground granulated blast furnace slag (GBS) binder and also of combinations of fly ash and GBS binders. Binders were activated using mixtures of NaOH and Na2SiO3 solutions. The molarity of NaOH in the mixtures ranged from 10 mol·L−1 to 16 mol·L−1, and the Na2SiO3/NaOH ratio was varied from 1.5 to 2.5. Mortar samples were produced using three binder combinations: 1) GBS as the only binder; 2) blended binder with a slag-to-fly ash ratio of 3:1; and 3) mixed binder with 1:1 ratio of slag to fly ash. Mortar samples were mixed and cured at (22 ± 2) °C till the day of the test. The impact of activator solution alkalinity, activator ratio Na2SiO3/NaOH, GBS content on the rate of water absorption were evaluated. After 7, 28, and 90 d of immersion in a 10% sulfuric acid solution, the resistance of a geopolymer matrix to degradation was assessed by measuring the change in sample weight. The influence of solution alkalinity and relative fly ash content on setting times was investigated. Alkali-activated mortar with a slag-to-fly ash ratio of 3:1 had the least sorptivity compared to the two other binder combinations, at each curing age, and for mortars made with each of the NaOH alkaline activator concentrations. Mortar sorptivity decreased with age and sodium hydroxide concentrations, suggesting the production of geopolymerization products. No reduction in weight of sample occurred after immersion in the strong acid H2SO4 solution for three months, regardless of binder combination. This was due to the synthesis of hydration and geopolymerization products in the presence of curing water, which outweighed the degradation of the geopolymer matrix caused by sulfuric acid.

Similar content being viewed by others

References

Mohamed O A, Rens K L, Stalnaker J J. Factors affecting resistance of concrete to freezing and thawing damage. Journal of Materials in Civil Engineering, 2000, 12(1): 26–32

Mohamed O, Kewalramani M, Ati M, Hawat W A. Application of ANN for prediction of chloride penetration resistance and concrete compressive strength. Materialia, 2021, 17: 101123

Mohamed O A. Effect of mix constituents and curing conditions on compressive strength of sustainable self-consolidating concrete. Sustainability (Basel), 2019, 11(7): 2094

Collins F, Sanjayan J. Microcracking and strength development of alkali activated GBS concrete. Cement and Concrete Composites, 2001, 23(4–5): 345–352

Allahverdi A F, Škvára F. Sulfuric acid attack on hardened paste of geopolymer cements-Part 1. Mechanism of corrosion at relatively high concentrations. Ceramics-Silikáty, 2005, 49(4): 225–229

Nedeljković M, Ghiassi B, van der Laan S, Li Z, Ye G. Effect of curing conditions on the pore solution and carbonation resistance of alkali-activated fly ash and slag pastes. Cement and Concrete Research, 2019, 116: 146–158

Mehta A, Siddique R, Ozbakkaloglu T, Uddin Ahmed Shaikh F, Belarbi R. Fly ash and ground granulated blast furnace GBS-based alkali-activated concrete: Mechanical, transport and microstructural properties. Construction & Building Materials, 2020, 257: 119548

Mohamed O A. Effect of immersing geopolymer slag-fly ash mortar in sulfuric acid on strength development and stability of mass. Construction & Building Materials, 2022, 341: 127786

Mohamed O A, Al Khattab R. Fresh properties and sulfuric acid resistance of sustainable mortar using alkali-activated GGBS/FA binder. Polymers, 2022, 14(3): 591

Mohamed O A, Al Khattab R, Al Hawat W. Effect of relative GGBS/fly contents and alkaline solution concentration on compressive strength development of geopolymer mortars subjected to sulfuric acid. Scientific Reports, 2022, 12(1): 5634

Parande A K, Ramsamy P L, Ethirajan S, Rao C R K, Palanisamy N. Deterioration of reinforced concrete in sewer environments. In: Proceedings of the Institution of Civil Engineers-Municipal Engineer. London: Thomas Telford, 2006: 11–20

Gutberlet T, Hilbig H, Beddoe R. Acid attack on hydrated cement—Effect of mineral acids on the degradation process. Cement and Concrete Research, 2015, 74: 35–43

Fattuhi N, Hughes B. The performance of cement paste and concrete subjected to sulphuric acid attack. Cement and Concrete Research, 1988, 18(4): 545–553

Ren J, Zhang L, San Nicolas R. Degradation of alkali-activated slag and fly ash mortars under different aggressive acid conditions. Journal of Materials in Civil Engineering, 2021, 33(7): 04021140

Zhang W, Yao X, Yang T, Zhang Z. The degradation mechanisms of alkali-activated FA/GBS blend cements exposed to sulphuric acid. Construction and Building Materials, 2018, 186: 1177–1187

Bakharev T. Resistance of geopolymer materials to acid attack. Cement and Concrete Research, 2005, 35(4): 658–670

Gu L, Bennett T, Visintin P. Sulphuric acid exposure of conventional concrete and alkali-activated concrete: Assessment of test methodologies. Construction & Building Materials, 2019, 197: 681–692

Lee N, Lee H. Influence of the slag content on the chloride and sulfuric acid resistances of alkali-activated fly ash/slag paste. Cement and Concrete Composites, 2016, 72: 168–179

Yip C K, Lukey G C, Provis J L, van Deventer J S. Effect of calcium silicate sources on geopolymerisation. Cement and Concrete Research, 2008, 38(4): 554–564

Ismail I, Bernal S A, Provis J L, San Nicolas R, Hamdan S, van Deventer J S. Modification of phase evolution in alkali-activated blast furnace GBS by the incorporation of fly ash. Cement and Concrete Composites, 2014, 45: 125–135

Degirmenci F N. Effect of sodium silicate to sodium hydroxide ratios on durability of geopolymer mortars containing natural and artificial pozzolans. Ceramics-Silikáty, 2017, 61(4): 340–350

Hall C. Water sorptivity of mortars and concretes: A review. Magazine of Concrete Research, 1989, 41(147): 51–61

ASTM C1585-20. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. West Conshohocken, PA: ASTM International, 2020

Bernal S A, Provis J L. Durability of alkali-activated materials: Progress and perspectives. Journal of the American Ceramic Society, 2014, 97(4): 997–1008

Duxson P, Provis J L, Lukey G C, Mallicoat S W, Kriven W M, van Deventer J S. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2005, 269(1–3): 47–58

Khattab R, Mohamed O A, Ahmed E A. Setting time and carbonation resistance of alkali-activated GGBS-fly ash mortar. In: Advances in Science and Engineering Technology International Conferences (ASET). Dubai: IEEE, 2022: 1–5

Mohamed O A, Al Khattab R, Ahmed E A. Sorptivity of mortar with alkali-activated slag and fly ash binders. Advances in Science and Engineering Technology International Conferences (ASET), Dubai: IEEE, 2022: 1–6

ASTM C267-20. Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. West Conshohocken, PA: ASTM International, 2020

Hooton R, Nokken M, Hooton R. Dependence of rate of absorption on degree of saturation of concrete. Cement, Concrete and Aggregates, 2002, 24(1): 20–24

Samantasinghar S, Singh S P. Fresh and hardened properties of fly ash-GBS blended geopolymer paste and mortar. International Journal of Concrete Structures and Materials, 2019, 13(1): 47

Rattanasak U, Chindaprasirt P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Minerals Engineering, 2009, 22(12): 1073–1078

Marjanović N, Komljenović M, Baščarević Z, Nikolić V, Petrović R. Physical-mechanical and microstructural properties of alkali-activated fly ash-blast furnace GBS blends. Ceramics International, 2015, 41(1): 1421–1435

Öz H Z, Doğan-Sağlamtimur N, Bilgil A, Tamer A, Günaydin K. Process development of fly ash-based geopolymer mortars in view of the mechanical characteristics. Materials (Basel), 2021, 14(11): 2935

Jang J, Lee N, Lee H. Fresh and hardened properties of alkali-activated fly ash/GBS pastes with superplasticizers. Construction & Building Materials, 2014, 50: 169–176

Gao X, Yu Q, Brouwers H. Characterization of alkali activated GBS-fly ash blends containing nano-silica. Construction & Building Materials, 2015, 98: 397–406

Dehghani A, Aslani F, Ghaebi Panah N. Effects of initial SiO2/Al2O3 molar ratio and GBS on fly ash-based ambient cured geopolymer properties. Construction & Building Materials, 2021, 293: 123527

Mohamed O. Durability and compressive strength of high cement replacement ratio self-consolidating concrete. Buildings, 2018, 8(11): 153

Lee N, Lee H. Setting and mechanical properties of alkali-activated fly ash/GBS concrete manufactured at room temperature. Construction & Building Materials, 2013, 47: 1201–1209

Acknowledgements

This project was funded by the Office of Research and Sponsored Programs at Abu Dhabi University (Nos. 19300460 and 19300643). The project is also funded by ASPIRE Award for Research Excellence (AARE), Abu Dhabi, UAE.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohamed, O.A., Al-Khattab, R. & Al-Hawat, W. Resistance to acid degradation, sorptivity, and setting time of geopolymer mortars. Front. Struct. Civ. Eng. 16, 781–791 (2022). https://doi.org/10.1007/s11709-022-0862-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0862-9