Abstract

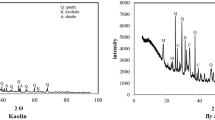

This study examines the use of fly ash, a thermal power plant waste, and the effect of diatomite, a fossil algae type, on waste-based geopolymers in the production of sustainable geopolymer binders. The effects of 1%, 2%, 3%, 4% and, 5% diatomite substitution on waste-based mortars were investigated. Mortars containing 10% and 12% Na+ by weight based on the binder material were cured at 75 °C for 48 h. The flexural and compressive strength, abrasion resistance, determination of ultrasonic pulse velocity, and resistance to high temperatures of geopolymer mortar samples were investigated. In addition, FESEM images, EDX and XRD analyses of geopolymer mortar samples were made, and their microstructures were examined. 2% diatomite substitution increased flexural and compressive strength. In parallel with this situation, it was concluded that the abrasion resistance and ultrasonic pulse velocity of the geopolymer mortar with 2% diatomite substituted increased. In addition, it has been shown in FESEM images that the microstructure has a denser morphology. All geopolymer mortars lost strength after the high temperatures of 300 °C, 600 °C and 900 °C. As a result, it was concluded that diatomite containing highly reactive silica can be used in geopolymer systems.

Similar content being viewed by others

References

Zhang P, Zheng Y, Wang K, Zhang J (2018) A review on properties of fresh and hardened geopolymer mortar. Compos Part B Eng 152:79–95. https://doi.org/10.1016/J.COMPOSITESB.2018.06.031

Malhotra VM (2002) Introduction: sustainable development and concrete technology. Concr Int 24(7):22

Ma Y, Ye G (2015) The shrinkage of alkali activated fly ash. Cem Concr Res 68:75–82. https://doi.org/10.1016/J.CEMCONRES.2014.10.024

Morsy MS, Alsayed SH, Al-Salloum Y et al (2014) Effect of sodium silicate to sodium hydroxide ratios on strength and microstructure of Fly ash geopolymer binder. Arab J Sci Eng 39(6):4333–4339. https://doi.org/10.1007/S13369-014-1093-8

Duan P, Yan C, Zhou W (2017) Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cem Concr Compos 78:108–119. https://doi.org/10.1016/j.cemconcomp.2017.01.009

John SK, Nadir Y, Girija K (2021) Effect of source materials, additives on the mechanical properties and durability of fly ash and fly ash-slag geopolymer mortar: a review. Constr Build Mater 280:122443. https://doi.org/10.1016/J.CONBUILDMAT.2021.122443

Saha S, Rajasekaran C (2017) Enhancement of the properties of fly ash based geopolymer paste by incorporating ground granulated blast furnace slag. Constr Build Mater 146:615–620. https://doi.org/10.1016/j.conbuildmat.2017.04.139

Pasupathy K, Berndt M, Sanjayan J et al (2017) Durability of low-calcium fly ash based geopolymer concrete culvert in a saline environment. Cem Concr Res 100:297–310. https://doi.org/10.1016/J.CEMCONRES.2017.07.010

Kumar EM, Perumal P, Ramamurthy K (2022) Alkali-activated aerated blends: interaction effect of slag with low and high calcium fly ash. J Mater Cycles Waste Manag 24:1378–1395. https://doi.org/10.1007/s10163-022-01434-5

Saxena R, Gupta T (2022) Assessment of mechanical, durability and microstructural properties of geopolymer concrete containing ceramic tile waste. J Mater Cycles Waste Manag 24:725–742. https://doi.org/10.1007/s10163-022-01353-5

Irshidat MR, Al-Nuaimi N, Rabie M (2022) Sustainable alkali-activated binders with municipal solid waste incineration ashes as sand or fly ash replacement. J Mater Cycles Waste Manag 24:992–1008. https://doi.org/10.1007/s10163-022-01374-0

Altanlar A (2021) (TÜİK) Türkiye İstatistik Kurumu. 37198:3–4

Somna K, Jaturapitakkul C, Kajitvichyanukul P, Chindaprasirt P (2011) NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 90:2118–2124. https://doi.org/10.1016/j.fuel.2011.01.018

Pacheco-Torgal F, Castro-Gomes J, Jalali S (2008) Alkali-activated binders: a review. Part 2. About materials and binders manufacture. Constr Build Mater 22:1315–1322. https://doi.org/10.1016/J.CONBUILDMAT.2007.03.019

Palomo A, Grutzeck MW, Blanco MT (1999) Alkali-activated fly ashes: a cement for the future. Cem Concr Res 29:1323–1329. https://doi.org/10.1016/S0008-8846(98)00243-9

Fernández-Jiménez A, Palomo JG, Puertas F (1999) Alkali-activated slag mortars: mechanical strength behaviour. Cem Concr Res 29:1313–1321. https://doi.org/10.1016/S0008-8846(99)00154-4

Xu H, Van Deventer JSJ (2002) Geopolymerisation of multiple minerals. Miner Eng 15:1131–1139. https://doi.org/10.1016/S0892-6875(02)00255-8

Brough AR, Holloway M, Sykes J, Atkinson A (2000) Sodium silicate-based alkali-activated slag mortars: Part II. The retarding effect of additions of sodium chloride or malic acid. Cem Concr Res 30:1375–1379. https://doi.org/10.1016/S0008-8846(00)00356-2

Durak U (2022) The improvement of strength and microstructural properties of fly ash-based geopolymer by adding elemental aluminum powder. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-022-01520-8

Durak U, İlkentapar S, Karahan O et al (2021) A new parameter influencing the reaction kinetics and properties of fly ash based geopolymers: a pre-rest period before heat curing. J Build Eng. https://doi.org/10.1016/J.JOBE.2020.102023

Bakharev T (2005) Geopolymeric materials prepared using class F fly ash and elevated temperature curing. Cem Concr Res 35:1224–1232. https://doi.org/10.1016/J.CEMCONRES.2004.06.031

Rattanasak U, Chindaprasirt P (2009) Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner Eng 22:1073–1078. https://doi.org/10.1016/j.mineng.2009.03.022

Atiş CD, Görür EB, Karahan O et al (2015) Very high strength (120 MPa) class F fly ash geopolymer mortar activated at different NaOH amount, heat curing temperature and heat curing duration. Constr Build Mater 96:673–678. https://doi.org/10.1016/j.conbuildmat.2015.08.089

Provis JL, Palomo A, Shi C (2015) Advances in understanding alkali-activated materials. Cem Concr Res 78:110–125. https://doi.org/10.1016/J.CEMCONRES.2015.04.013

Nath SK, Mukherjee S, Maitra S, Kumar S (2017) Kinetics study of geopolymerization of fly ash using isothermal conduction calorimetry. J Therm Anal Calorim 127:1953–1961. https://doi.org/10.1007/s10973-016-5823-x

Nath SK, Maitra S, Mukherjee S, Kumar S (2016) Microstructural and morphological evolution of fly ash based geopolymers. Constr Build Mater 111:758–765. https://doi.org/10.1016/J.CONBUILDMAT.2016.02.106

Manikandan P, Vasugi V (2021) A critical review of waste glass powder as an aluminosilicate source material for sustainable geopolymer concrete production. SILICON. https://doi.org/10.1007/s12633-020-00929-w

Pascual AB, Tognonvi TM, Tagnit-Hamou A (2021) Optimization study of waste glass powder-based alkali activated materials incorporating metakaolin: activation and curing conditions. J Clean Prod 308:127435. https://doi.org/10.1016/J.JCLEPRO.2021.127435

Durak U, Karahan O, Uzal B, et al (2018) The ınvestigation of mechanical effects of nano sio 2 particles for different sodium ıon concentrations on fly ash based geopolymer mortar. pp 4–9

Okoye FN, Prakash S, Singh NB (2017) Durability of fly ash based geopolymer concrete in the presence of silica fume. J Clean Prod 149:1062–1067. https://doi.org/10.1016/J.JCLEPRO.2017.02.176

Barış KE, Tanaçan L (2021) Improving the geopolymeric reactivity of Earth of Datça as a natural pozzolan in developing green binder. J Build Eng 41:102760. https://doi.org/10.1016/J.JOBE.2021.102760

Thammarong S, Lertcumfu N, Jaita P et al (2019) The effects of replacement metakaolin with diatomite in geopolymer materials. Key Eng Mater 798:267–272. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/KEM.798.267

Akhtar F, Rehman Y, Bergström L (2010) A study of the sintering of diatomaceous earth to produce porous ceramic monoliths with bimodal porosity and high strength. Powder Technol 201:253–257. https://doi.org/10.1016/J.POWTEC.2010.04.004

İlkentapar S, Örklemez E, Üniversitesi E et al (2020) Uçucu Kül Esaslı Geopolimer Harçlara Diatomit İkamesinin Isı İletkenliğe Etkisi the effect of diatomite addition on fly ash based geopolymer mortars on thermal conductivity values. Erciyes Univ J Institue Sci Technol 36:2020

TS EN 196–1 (2016) Methods of testing cement—part:1 determination of strength. TSE

TS EN 1015–3 (2000) Methods of test for mortar for masonry: Part 3. Determination of consistence of fresh mortar (by flow table). TSE, Ankara

Standard T (2005) Turkish Standard Ts 2824 En 1338

TSE- EN (2017) Turkish Standard 12504–4. Türk Stand 15189:

de la Rilem PDR (1995) 129-MHT: test methods for mechanical properties of concrete at high emperatures. Mater Struct 28:410–414

Messina F, Colangelo F et al (2018) Alkali activated waste fly ash as sustainable composite: Influence of curing and pozzolanic admixtures on the early-age physico-mechanical properties and residual strength after exposure at elevated temperature. Compos Part B Eng 132:161–169. https://doi.org/10.1016/j.compositesb.2017.08.012

Durak U, Karahan O, Uzal B et al (2021) Influence of nano SiO2 and nano CaCO3 particles on strength, workability, and microstructural properties of fly ash-based geopolymer. Struct Concr 22:E352–E367. https://doi.org/10.1002/SUCO.201900479

Bilim C, Karahan O, Atiş CD, Ilkentapar S (2013) Influence of admixtures on the properties of alkali-activated slag mortars subjected to different curing conditions. Mater Des 44:540–547. https://doi.org/10.1016/J.MATDES.2012.08.049

İlkentapar S, Atiş CD, Karahan O, Görür Avşaroğlu EB (2017) Influence of duration of heat curing and extra rest period after heat curing on the strength and transport characteristic of alkali activated class F fly ash geopolymer mortar. Constr Build Mater 151:363–369. https://doi.org/10.1016/J.CONBUILDMAT.2017.06.041

Whitehurst EA (1951) Soniscope tests concrete structures. J Proc 47:433–444. https://doi.org/10.14359/12004

Nuaklong P, Jongvivatsakul P, Pothisiri T et al (2020) Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J Clean Prod 252:119797. https://doi.org/10.1016/j.jclepro.2019.119797

Lahoti M, Wong KK, Yang EH, Tan KH (2018) Effects of Si/Al molar ratio on strength endurance and volume stability of metakaolin geopolymers subject to elevated temperature. Ceram Int 44:5726–5734. https://doi.org/10.1016/J.CERAMINT.2017.12.226

Junaid MT, Khennane A, Kayali O et al (2014) Aspects of the deformational behaviour of alkali activated fly ash concrete at elevated temperatures. Cem Concr Res 60:24–29. https://doi.org/10.1016/J.CEMCONRES.2014.01.026

Kong DLY, Sanjayan JG, Sagoe-Crentsil K (2007) Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem Concr Res 37:1583–1589. https://doi.org/10.1016/J.CEMCONRES.2007.08.021

Khedmati M, Alanazi H, Kim Y et al (2018) Effects of Na 2 O/SiO 2 molar ratio on properties of aggregate-paste interphase in fly ash-based geopolymer mixtures through multiscale measurements. Constr Build Mater 191:564–574. https://doi.org/10.1016/j.conbuildmat.2018.10.024

Xiao R, Ma Y, Jiang X et al (2020) Strength, microstructure, ef fl orescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J Clean Prod 252:119610. https://doi.org/10.1016/j.jclepro.2019.119610

Komljenović M, Baščarević Z, Bradić V (2010) Mechanical and microstructural properties of alkali-activated fly ash geopolymers. J Hazard Mater 181:35–42. https://doi.org/10.1016/J.JHAZMAT.2010.04.064

Lee B, Kim G, Kim R et al (2017) Strength development properties of geopolymer paste and mortar with respect to amorphous Si/Al ratio of fly ash. Constr Build Mater 151:512–519. https://doi.org/10.1016/J.CONBUILDMAT.2017.06.078

Ryu GS, Lee YB, Koh KT, Chung YS (2013) The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr Build Mater 47:409–418. https://doi.org/10.1016/J.CONBUILDMAT.2013.05.069

Shao NN, Liu Z, Xu YY et al (2015) Fabrication of hollow microspheres filled fly ash geopolymer composites with excellent strength and low density. Mater Lett 161:451–454. https://doi.org/10.1016/J.MATLET.2015.09.016

Acknowledgements

This work with project code FLY-2019-948 is supported by Erciyes University Scientific Research Project Coordination Unit.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Özsoy, A., Örklemez, E. & İlkentapar, S. Effect of addition diatomite powder on mechanical strength, elevated temperature resistance and microstructural properties of industrial waste fly ash-based geopolymer. J Mater Cycles Waste Manag 25, 2338–2349 (2023). https://doi.org/10.1007/s10163-023-01692-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01692-x