Abstract

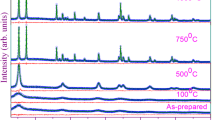

Structure-stability correlations in terms of microstructure related to tin oxidation were determined using an in situ high-temperature X-ray diffraction. Tin oxidation takes place over a broad temperature range between 300 and 900 °C, which resulted in SnO at 300 °C and SnO2 that is thermodynamically more stable phase above 500 °C. The initial conversion from tin to SnO ultimately resulted in a matrix expansion by 36%, which is mainly due to unit cell volume contraction, resulting in a temporary decrease in tin lattice strain. The tin unit cell volume is rapidly increased during the initial heating, decreased slightly during the formation of SnO, and changed marginally during the oxidation to SnO2.The tin lattice strain significantly increased from 0.84 × 10–4 to 4.76 × 10–4 and crystallite size decreased by 56% during the entire period of oxidation, indicating the ongoing lattice destabilization under thermal excitation. At high temperatures, SnO2 is the most stable oxide form of tin, which is stabilized under the low lattice strain of 9.30 × 10–5 and a large crystallite size of 39 nm that is mainly achieved via compact unit cell arrangement in space. The SnO has a strong orientation preference in the (112) direction, and as temperature increased, the orientation preference along this direction decreased. The stable SnO2 exhibits a strong crystallite orientation preference along the (111) direction, which intensified with temperature, resulting in a preferred crystallite growth along this direction.

Graphical abstract

Similar content being viewed by others

References

Abban S, Ikumapayi OM, Ogedengbe TS, Afolalu SA, Ananaba C, Ogundipe AT (2023) Development of aluminium-tin alloy for high strength application. Mater Today Proc

Al-Had NM, Kamari HM, Baqer AA, Shaari AH, Saion E (2018) Thermal calcination-based production of SnO2 nanopowder: an analysis of SnO2 nanoparticle characteristics and antibacterial activities. Nanomaterials 8:250. https://doi.org/10.3390/nano8040250

Aziz M, Abbas SS, Baharom WRW, Mahmud WZW (2012) Structure of SnO2 nanoparticles by sol–gel method. Mater Lett 74:62–64

Batzill M, Diebold U (2005) The surface and materials science of tin oxide. Prog Surf Sci 79(2):47–154

Boggs WE, Trozzo PS, Pellissier GE (1961) The oxidation of Tin: II. The morphology and mode of growth of oxide films on Pure Tin. J Electrochem Soc 108(1):13

Cahen S, David N, Fiorani JM, Maitre A, Vilasi M (2003) Thermodynamic modelling of the O–Sn system. Thermochim Acta 403(2):275–285

Chen JS, Lou XW (2013) SnO2-based nanomaterials: synthesis and application in lithium-ion batteries. Small 9(11):1877–1893

Cho S, Yu J, Kang SK, Shih D-Y (2005) Oxidation study of pure tin and its alloys via electrochemical reduction analysis. J Electron Mater 34(5):635–642

Choi SH, Kang YC (2014) Kilogram-scale production of SnO2 yolk-shell powders by a spray-drying process using dextrin as carbon source and drying additive. Chem Eur J 20(19):5835–5839

Cojocaru B, Avram D, Kessler V, Parvulescu V, Seisenbaeva G, Tiseanu C (2017) Nanoscale insights into doping behavior, particle size and surface effects in trivalent metal doped SnO2. Sci Rep 7(1):9598

Jia X, Lin Z, Yang TC, Puthen-Veettil B, Wu L, Conibeer G, Perez-Wurfl I (2018) Post-sputtering heat treatments of molybdenum on silicon wafer. Appl Sci 8:1692. https://doi.org/10.3390/app8091692

Jiang L, Sun G, Zhou Z, Sun S, Wang Q, Yan S, Li H, Tian J, Guo J, Zhou B, Xin Q (2005) Size-controllable synthesis of monodispersed SnO2 nanoparticles and application in electrocatalysts. J Phys Chem B 109(18):8774–8778

Kameshima Y, Tamura Y, Nakajima A, Okada K (2020) Electroplating of zinc and tin alloys with nickel and cobalt from ammonium oxalate electrolytes. Russ Chem Bull 69(7):1272–1278

Karunadasa KSP (2019) Dehydration of calcium chloride as examined by high-temperature X-ray powder diffraction. Int Multidiscip Res J 4:37–43

Karunadasa KSP, Manoratne CH (2022) Microstructural view of anatase to rutile phase transformation examined by in-situ high-temperature X-ray powder diffraction. J Solid State Chem 314:123377

Karunadasa KSP, Manoratne CH, Pitawala HMTGA, Rajapakse RMG (2019) Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in-situ high-temperature X-ray powder diffraction. J Phys Chem Sol 134:21–28

Karunadasa KSP, Rajapakse RMG, Pitawala HMTGA, Manoratne CH (2023) Microstructural insight into the thermal decomposition of MgCl2·6H2O examined by in-situ high-temperature X-ray powder diffraction. J Solid State Chem 322:123965

Kasper E, Werner J et al (2012) Growth of silicon based germanium tin alloys. Thin Solid Films 520(8):3195–3200

Kilby KT, Jiao S, Fray DJ (2010) Current efficiency studies for graphite and SnO2-based anodes for the electro-deoxidation of metal oxides. Electrochim Acta 55(23):7126–7133

Korotcenkov G, Cho BK (2012) Ozone measuring: What can limit application of SnO2-based conductometric gas sensors? Sens Actuators B Chem 161(1):28–44

Kumar GR, Sathishkumar M, Vignesh M, Manikandan M, Rajyalakshmi G, Ramanujam R, Arivazhagan N (2023) Metal additive manufacturing of commercial aerospace components–A comprehensive review. Proc Inst Mech Eng Part E J Process Mech Eng 237(2):441–454

Lee S, Ocon JD, Son YI, Lee J (2015) Alkaline CO2 electrolysis toward selective and continuous HCOO–production over SnO2 nanocatalysts. J Phys Chem C 119(9):4884–4890

Leitner J, Sedmidubský D (2019) Thermodynamic modeling of oxidation of tin nanoparticles. J Phase Equilib Diffus 40(1):10–20

Li F, Song J, Yang H, Gan S, Zhang Q, Han D, Ivaska A, Niu L (2009) One-step synthesis of graphene/SnO2 nanocomposites and its application in electrochemical supercapacitors. Nanotechnology 20(45):455602

Liu Y, Zheng C, Wang W, Zhan Y, Wang G (2001) Production of SnO2 nanorods by redox reaction. J Cryst Growth 233(1):8–12

Matussin S, Harunsani MH, Tan AL, Khan MM (2020) Plant-extract-mediated SnO2 nanoparticles: synthesis and applications. ACS Sustain Chem Eng 8(8):3040–3054

Miller SA, Gorai P, Aydemir U, Mason TO, Stevanović V, Toberer ES, Snyder GJ (2017) SnO as a potential oxide thermoelectric candidate. J Mater Chem C 5(34):8854–8861

Molloy KC (2009) Tin chemistry: fundamentals, frontiers, and applications. J Am Chem Soc 131(14):5361–5362

Mote VD, Purushotham Y, Dole BN (2012) Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J Theor Appl Phys 6(1):6

Ning J, Jiang T, Men K, Dai Q, Li D, Wei Y, Liu B, Chen G, Zou B, Zou G (2009) Syntheses, characterizations, and applications in lithium ion batteries of hierarchical SnO nanocrystals. J Phys Chem C 113(32):14140–14144

Ostrakhovitch EA (2022) Chapter 33 - Tin. In: Nordberg GF, Costa M (eds) Handbook on the toxicology of metals, 4th edn. Academic Press, pp 807–856

Poulier C, Smith DS, Absi J (2007) Thermal conductivity of pressed powder compacts: tin oxide and alumina. J Eur Ceram 27(2):475–478

Ren Y, Li S, Lv Z, Fan Y, He J, Song J (2023) Electrolysis synthesis of carbides and carbon dioxide capture in molten salts. Small 19(23):2207863

Saji KJ, Venkata Subbaiah YP, Tian K, Tiwari A (2016) P-type SnO thin films and SnO/ZnO heterostructures for all-oxide electronic and optoelectronic device applications. Thin Solid Films 605:193–201

Sharma V, Vyas R, Bazylewski P, Chang GS, Asokan K, Sachdev K (2016) Probing the highly transparent and conducting SnOx/Au/SnOx structure for futuristic TCO applications. RSC Adv 6(35):29135–29141

Song P, Wen D (2009) Experimental Investigation of the Oxidation of Tin Nanoparticles. J Phys Chem C 113(31):13470–13476

Wang H, Rogach AL (2014) Hierarchical SnO2 nanostructures: recent advances in design, synthesis, and applications. Chem Mater 26(1):123–133

Xiong L, Guo Y, Wen J, Liu H, Yang G, Qin P, Fang G (2018) Review on the application of SnO2 in perovskite solar cells. Adv Funct Mater 28(35):1802757

Yang F, Li JCM (2007) Deformation behavior of tin and some tin alloys. J Mater Sci Mater Electron 18(1):191–210

Yin H, Mao X, Tang D, Xiao W, Xing L, Zhu H, Wang D, SadowaY DR (2013) Capture and electrochemical conversion of CO2 to value-added carbon and oxygen by molten salt electrolysis. Energy Environ Sci 6(5):1538–1545

Zainulabdeen AA, Hashim FA, Assi SH (2019) Mechanical properties of tin-based babbitt alloy using the direct extrusion technique. IOP Conf Ser Mater Sci Eng 518(3):032031

Acknowledgements

This work was financially supported by Postgraduate Institute of Science, Peradeniya, Sri Lanka. The sample analysis was performed using X-ray diffractometer that is available at modern X-ray diffraction facility of Uva Wellassa University Sri Lanka.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has no competing interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Karunadasa, K.S.P. Structure-stability correlations in terms of microstructure during tin oxidation as examined by in situ high-temperature X-ray powder diffraction. Chem. Pap. 78, 3617–3628 (2024). https://doi.org/10.1007/s11696-024-03333-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-024-03333-5