Abstract

Two compound derived from fused Pyrazolo-Triazolo-Pyrimidine (C1 and C2), have inhibitory action against corrosion of Zinc in 1 M HNO3 examined experimentally by electrochemical tests and theoretically by density functional theory (DFT). The findings demonstrate that zinc corrodes in acidic conditions with greater corrosion resistance than C1 and C2. Concentration and corrosion inhibition directly relate to one another. The two Pyrazolopyrimidine-derived compounds had optimum inhibition efficiency of 92.06 and 79.36% for C1 and C2, respectively, at 700 ppm. In accordance to the polarization curves, the antagonists feature a mixed but primarily anodic inhibitor and a Langmuir process. DFT computations validated the compounds apparent antagonistic response. SEM also show the development of a barrier on the zinc surface. In conclusion, these two antagonists, C1 and C2, are successful in avoiding zinc dissolution in HNO3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zinc is a flexible metal with several applications across numerous sectors. A lot of alloys, coatings, and chemicals are made from zinc. Galvanizing steel to prevent corrosion is another common usage of it. In the building, automotive, and other industries, galvanized steel is employed. Due to their outstanding casting qualities, Zn alloys are used in die casting applications ( [1, 2]). Corrosion is a serious issue in a variety of industries, and it can lead to large economic losses. Widely used as an anode for sacrifice to avoid corrosion in other metals is zinc. However, zinc may corrode quickly in nitric acid solutions, losing its defensive qualities and producing hydrogen gas. Organic compounds have been proficiently suppressed of corrosion of Zn in HNO3. These substances work by creating a shield-like film on surface, which shields it from corrosive damage ( [3,4,5,6,7]). Corrosion of zinc is a well-known phenomenon that has received a great deal of research. Powerful oxidizer nitric acid easily reacts with zinc to produce zinc nitrate and hydrogen gas. Following is the response:

Nitric acid content, temperature, and the presence of other contaminants in the acid are a few of the variables that affect how quickly zinc corrodes in the solution. Corrosion typically occurs more quickly at higher temperatures and nitric acid contents ( [8,9,10]). One of the most important strategies for preventing corrosion in acidic settings is the use of organic inhibitors ( [11, 12]). Various industrial processes include the use of acidic solutions, and numerous minerals are shielded from the acid by organic inhibitors ( [13]). Heteroatom-containing compounds (N, P, and S) have demonstrated to be effective inhibitors. The outermost layer may capture these organic molecules, lowering the rate of corrosion in an acidic environment ( [14,15,16]).

Several organic compounds, including benzotriazole, a popular chemical inhibitor for the dissolution of metals in an acidic. To stop additional corrosion, it forms a shielding coating over the surface ( [17, 18]). As antioxidants, aliphatic, heterocyclic, and aromatic compounds have all received extensive study. In acid conditions, the amount of free electrons in π—orbital of N atom of aliphatic and cyclic amines regulates their restrictive features ( [19]). The corrosion inhibitor of zinc in (HNO3 + HCl) by ethanolamines and by ethylamines was investigated ( [20]). Oxalic acid impact on zinc corrosion in H3PO4 was studied ( [21]). Numerous metals have been demonstrated to respond favorably to hexamine as a powerful barrier to corrosion in acidic conditions ( [22, 23]). Additionally, it has been noted that imidazole are efficient inhibitors on Zn in the acid nitric. These substances create a shield-like film on surface, slowing the dissolution ( [24, 25]). It has been observed that -NH2 acids like glycine and alanine prevent the deterioration of zinc in HNO3. These substances creates a complex on the metal surface that slows corrosion ( [26]). Ahmed et al. ( [27]) also measured the inhibitory efficiency of other—NH2 acids. According to the experimental findings, lysine, which simulates -NH2 acid, can be employed as a reliable corrosion inhibitor. Polyethylene glycol has been shown to hinder metal corrosion in acidic situations ( [28]). Pyrazolopyrimidines derivatives are known to have potent pharmacological activities that enabled using them as anticancer agents and antiviral agents. They also manifest potential cytotoxicity activity against human laryngeal epidermoid carcinoma cells (Hep2). Furthermore, some pyrazolo pyrimidine derivatives manifested significant activity as anti-inflammatory agents. With respect to developing green, environmentally friendly and low–cost corrosion inhibitors, pyrimidine derivatives have recently gained attention due to their antioxidant, antiviral and antibacterial characteristics, in addition to their ease of synthesis. We have been aiming in this work to synthesize some new substituted heterocyclic systems on the basis of pyrazole moiety of expected biological interest and to test them as biodegradable agrochemicals ( [29, 30]). This work reveals an account of two compounds that were created by fusing Pyrazolo-Triazolo-Pyrimidine C1 and C2 as inhibiting corrosion for Zn in nitric acid utilising weight loss, potentiodynamic polarisation measurements, and theoretical DFT approaches. We determined and exploited quantum chemical data. By using FE-SEM/EDX, it was possible to assess the morphology and elements of the corrosion products generated by zinc.

Experimental details

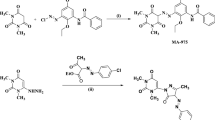

Synthesis of inhibitors

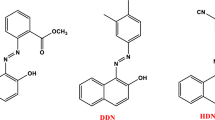

Quantum chemical parameters of 8-NH2-1-phenyl-7-(trichloromethyl)-1,8-dihydro-4H-pyrazolo [3,4-d] [1,2,4] triazolo[1,5-a]pyrimidin-4-one (C1) and 8-NH2-7-(2-hydroxyphenyl)-1-phenyl-1,6,7,8-tetrahydro-4H-pyrazolo [3,4-d][1,2,4]triazolo [1,5-a] pyrimidin-4-one (C2) are investigated in this work ( [29]). Figure 1 displays the compositions of the synthesized organic inhibitors employed in this research.

Electrode assembly

The WE had an surface area of 4 cm2 and was constructed from Zn placed in a glass tube with araldite epoxy. A big rod of Zn was sliced into rectangular pieces measuring 2 cm2 for weight method. The samples were polished with emery paper of progressively finer grade, washed in ethanol, rinsed in doubly distilled water, dried, weighed, and kept in desiccators.

The corrosive substance

By diluting AR reagent grade 68% concentrated acid with bi-distilled water, the medium, 1 M HNO3, was created. The studies were carried out in 1 M HNO3 solution with and without various doses of C1 and C2 (100–700 ppm).

Weight loss measurements

In the beginning, samples were weighed in a digital scale. At temperatures ranging from 25 to 55 °C, weighed samples were submerged in 100 mL of 1 M HNO3 without and with a range of the C1 and C2 (100–700 ppm). The specimens were removed from the test solution, dried in a moisture-free desiccator, and then weighed again using a Model FA 2104A sensitive analytical balance (cap.: 210 g, d.: 0.1 mg). In each case, the weight difference was used to calculate the weight reduction. Equation (1) was used to compute the corrosion rates:

where \({C}_{{\text{R}} },\) is the rate of corrosion (mmpy), \(\Delta W\) (g), is the difference in weight before and after immersion, \(A,\) is the area of Zn (cm2), \(t,\) is the time (h) and \(d,\) is density of Zn in g/cm ( [3]). The degree of surface coverage \((\theta )\) was calculated using Eq. (2):

where \({W}_{i}\) and Wo are the weight losses of Zn specimens in inhibited and uninhibited solutions, respectively. The inhibition efficiency \({\text{IE}}\%\) was calculated according to Eq. (3) ( [31]):

PDP method

With a scanning rate of 2 mVs−1, the electrode potential was changed from − 1.0 to + 1.0 V to record the potentiodynamic polarization (PDP) curves. For each inhibitor concentration, the aforementioned steps were carried out once more. Each experiment used a freshly made electrolyte and was conducted on a freshly abraded Zn electrode. The Electrochemical experiments were carried out by means of Electronic Potentioscan Wenking POS 73. All electrochemical parameters such as \({E}_{{\text{corr}}}\), \({I}_{{\text{corr}}}\), \({C}_{{\text{R}}}\), \({\beta }_{{\text{a}}}\) and \({\beta }_{{\text{c}}}\) were calculated. The inhibition efficiency was evaluated using Eq. (4):

where, \({I}_{{\text{corr}}}^{^\circ }\) and \({I}_{{\text{corr}}}\) are the corrosion current densities in absence and presence of inhibitor, respectively, and the value of \(\left.\left[1- \frac{{I}_{{\text{corr}}}}{{I}_{{\text{corr}}}^{^\circ }}\right.\right]\) is equivalent to the surface coverage.

Computational details

In this investigation, we employed density functional theory (DFT) techniques. Gaussian 09 was used for all calculations, and the B3LYP functional and 631G basis set were employed. By combining the three-parameter hybrid models of Beck’s (B) ( [32]) and the correlation function of Lee, Yang, and Parr’s (LYP) ( [33]), the B3LYP is a variant of the DFT method.

Adsorption should take place at the part of the molecule with the highest value of the local property softness (S) for the simplest transfer of electrons. I = -EHOMO and A = − ELUMO are the relationships between the ionization potential and electron affinity. The inhibitor molecule's absolute electronegativity(X) and hardness (ɳ) are calculated as ( [34]) (X = (I + A)/2) and (ɳ = (I−A)/2). The opposite of hardness is softness (S = 1/ɳ). ∆N, the number of electrons transferred from the inhibitor to the metallic surface, was computed using the obtained values of X and ɳ as follows: Since the work function of Zn is 4.31 eV, we can write ∆N = (ɸZn–Xinh.)/2 ɳinh. ∆N value ( [35]) below 3.6 indicates that the inhibitor molecule could release electrons.

Surface characterization

The surface morphology of zinc exposed for 30 days to HNO3 solutions devoid of C1 and C2 and containing 300 ppm of each was studied. SEM Model Quanta 250 FEG with an energy dispersive X-ray analyzer was used. The corrosion products are scrapped from the Zinc surface in the absence and presence of C1 and C2 inhibitor is examined by XRD instrument (Bruker D8-AD device- Germany) with Start Position at 4.0100 and End Position at 69.9900[°2θ], Step Size 0.0200 with scan Step time 0.6000[s],K-Alpha1equal 1.54060[Å] and Generator Settings 40 mA, 40 kV.

Results and discussion

Weight loss measurements

The weight loss experiment was conducted in 1 M HNO3 acid solution in the absence and presence of various concentrations C1 and C2 ranging from 100 to 700 ppm. The variation of inhibition efficiency and, CR with time at different temperature can be seen in Figs. 2 and 3. According to the figures, adding C1 and C2 to 1 M HNO3 solution reduces zinc weight loss and CR, and efficiency IE rises with increasing concentration of C1 and C2. The findings demonstrate that Zn corroded vigorously in the presence of an uncontrolled 1 M HNO3 solution, whereas an inhibitory presence greatly slowed the rate of break down. The findings also suggested that C1 and C2 could be good inhibitory for Zn in 1 M HNO3 solution. Furthermore, as seen in Fig. 2, inhibition efficiency decreases with increasing temperature, implying that part of the adsorbed inhibitors may be desorption at higher temperatures. It indicates that the inhibitor molecules were physically coated on the metal surface, and the adsorption mechanism can be referred to as physisorption ( [36]). According to Fig. 3, corrosion rate was seen to increase as temperature rose. Furthermore, a significant contact between the inhibitors and the metal surface is demonstrated by an increase in inhibition efficiency with concentration ( [37]). Table 1 condenses the inhibitory efficiency rate percentage (IE%) and obtained from the WL at different concentrations of C1 and C2. Due to protective film production and a decrease in the effective electron transfer rate at the contact, it has the lowest at 700 ppm. The addition of inhibitors under investigation, ranging in concentration from 100 to 700 ppm, inhibits the corrosion of zinc. For C1 and C2, the greatest inhibition efficiencies are 90.35 and 86.49%, respectively. The adsorption of the compounds on the Zn interface leading to a blockage of reaction sites, showing the creation of the barrier on the surface, that contributes for the inhibiting performance (IE %). The availability of adsorption sites in organic compounds that may have favorable adsorption accounts for the compounds’ considerable efficiency ( [38]).

PDP measurements

Figure 4 displays the Zn polarization curves in 1 M HNO3 across distinct C1 and C2 concentrations (100, 200, 300, 500 and 700 ppm). Table 2 contains the derived and listed polarization parameters. As inhibitory concentration rises, corrosion current density drops and efficiency expands, reaching value of 92.06% at 700 ppm for C1. The Tafel slope (βa and βc) alters when C1 and C2 are added, demonstrating that they behave as a mixed-type antagonist ( [39]). The inhibitors protective action is most likely related to the creation of an insoluble film ( [40]). Due to adsorption’s ability to block cathodic sites, which enables the formation of a protective, impenetrable covering, this suggests that the mechanism explaining the inhibitory action may be related to adsorption.

Adsorption isotherm and thermodynamic parameters

The routine involves fitting the surface coverage data into different adsorption models and the isotherm that best fits the data is used to describe the adsorption behavior. The best fit is usually the one that gives the highest regression coefficient (R2) value from the linear plots. The R2 values for each isotherm model of C1 and C2 at 298 K presented in Table 3 were used to determine the most suitable model. The data fit into Langmuir, Temkin, Freundlich, Frumkin, and Flory–Huggins isotherms but Langmuir gives the best fit. Langmuir isotherm with the highest R2 values, best describes the adsorption mechanism of inhibitors on carbon steel in hydrochloric acid medium. Therefore, Langmuir adsorption isotherm is appropriate for evaluating the adsorption equilibrium constant, Kads ( [41,42,43]).

According to the following Eq. (5), the adsorption attitude of C1 and C2 on the Zn surface respects the Langmuir adsorption isotherm.

where θ is the surface coverage, \({K}_{{\text{ads}}}\) is the adsorption constant, and C is concentration. Figure 5 shows the straight line with an R2 value near to one that represents the plot of C/θ as a function of C. It has been established that C1 and C2 have adsorbed on Zn and are currently occupying the active sites at the Zn/electrolyte junction. The explored inhibitor accumulates in one thin layer on the metallic substrate, interacting not at all with nearby molecules. Using Eq. (6), the standard free energy of adsorption, \({\Delta G}_{ads}^{o}\), is derived ( [44]).

where \({C}_{{\text{w}}}\) is the H2O concentration. In adherence to thermodynamic principles, the reaction takes place when the free energy is negative Table 4. Furthermore, the physical absorption process produces less heat than chemical absorption does.

Kinetic corrosion parameters

The apparent kinetic energies \({E}_{{\text{a}}}^{*}\), for corrode Zn in free and inhibited 1 M HNO3 at immersion time 96 mints were calculated from Arrhenius Eq. (7):

where \(A\) is the extrapolation factor, \(R\) is the gas constant and \(T\) is the absolute temperature. A plot of \({{\text{logC}}}_{{\text{R}}}\mathrm{versus }1000/{\text{T}}\) gives straight lines with slope \({E}_{{\text{a}}}^{*}/2.303R\) and the intercept is \(A\). Figure 6 shows the relation between log \({{\text{C}}}_{{\text{R}}}\) plotted against the 1/T for Zn corrosion in 1 M HNO3 in the absence and presence of 300 ppm of C1and C2. Table 5 contains the computed activation energy \({E}_{{\text{a}}}^{*}\).

It is noted that the values of \({E}_{{\text{a}}}^{*}\) were higher in 300 ppm of tested compounds than in their absence indicating C1 and C2 exhibited low \(\mathrm{IE \%}\) at higher temperatures. The difference between these values implied that C1 and C2 retarded effectively the corrosion of Zn in 1 M HNO3 ( [45]). Value of \({E}_{{\text{a}}}^{*}\) was found to be higher for C2 (37 kJ mol−1) than that of uninhibited blank (4.0 kJ mol−1). The increase in \({E}_{{\text{a}}}^{*}\) in C1 and C2 implied that addition of these compounds to the 1 M HNO3 a drop in insurance efficiency emerges as the temperature is elevated, according to the height of the energy barrier of the corrosive activity ( [46]). The Eyring transition state (Eq. 8) was used to compute \({\Delta H}^{*}\) and \({\Delta S}^{*}\) for the corrosion process.

where \(h\) is 6.23 × 10−34 J⋅s, \(N\) is 6.022 × 1023 mol−1, \({\Delta S}^{*}\) is the entropy change and \({\Delta H}^{*}\) is the enthalpy change of activation. Figure 7 show plot of \({\text{log}}{C}_{R}/T\) against \(1/T\), straight lines are obtained with a slope of \(\left(-{\Delta H}^{*} /2.303R\right)\) and intercept of \([{\text{log}}\left(R/Nh\right)+\left({\Delta S}^{*}/2.303R\right)]\) from which the values of \({\Delta H}^{*}\mathrm{and }{\Delta S}^{*}\) were calculated and given in Table 5. The activation enthalpy values are positive, which show that corrosion of Zn is endothermic. As the degree of orderliness decreases, the activation entropy values are on the negative side ( [47]). Inhibited solutions had higher positive \({\Delta H}^{*}\) and lower negative \({\Delta S}^{*}\) than the control solution, indicating that the inhibitor molecules increased the energy level of the corrosion activity. In other terms, it may be claimed that the deposited inhibitor increased the Zn surface ( [48]).

Analysis of frontier molecular orbitals

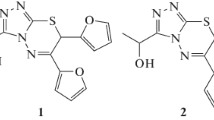

Recently, theoretical chemistry has been applied to the question of how corrosion inhibition takes place. An inhibitor's reactivity is determined in large part by its frontier molecular orbitals (MO), such as its HOMO and LUMO orbitals, as well as other qualities such as its hardness (ɳ), dipole moment (μ), and softness (S). To learn more about how the inhibitors' structures affect their effectiveness, quantum chemical computations were carried out. Figure 8 displays the optimal molecular structures of the compounds investigated, which were produced by employing the hybrid DFT functional (B3LYP/6-31G).

Table 6 lists the calculated quantum properties responsible for inhibition efficiency. These properties include the frontier molecular orbital energies (EHOMO and ELUMO), the energy gap (EHOMO—ELUMO) (∆E), the dipole moment (μ), the electronegativity (X), the electron affinity (A), the chemical hardness (ɳ), the chemical softness (S), the ionization potential (I), and the fraction of electrons transferred from the inhibitor to the zinc surface (∆N). Predicting the adsorption centers of the inhibitor compounds that interact with the surface metal atoms is a helpful use of frontier orbital theory. It was also crucial to account for the difference between the molecules' HOMO and LUMO energy levels.

Zinc corrosion in acid nitric is inhibited most effectively by inhibitors with high HOMO energy (EHOMO) due to their propensity to donate electrons to the metal's unoccupied d-orbitals; inhibitors with low LUMO energy (ELUMO) can accept electrons from the metal's surface with greater ease. The efficiency of inhibition increased with decreasing HOMO–LUMO (∆E) energy gap because stronger contacts developed between the responding species. Compounds C1 and C2 have a calculated ∆N value of 0.158, and 0.099; respectively, indicating that they can release electrons and verifying the establishment of a physical barrier on surface.

The significant interaction between the Zn and the inhibitors was further corroborated by low softness (S) and high hardness (η) ( [49]). C1 and C2 have a global electrophilicity (ω) of 1.585 and 1.846 and an absolute electronegativity (χ) of 3.646 and 3.900, respectively; these values represent the stability and reactivity of inhibitor molecules. The reactive functional groups in organic inhibitors serve as adsorption sites. Adsorption bonds are strongest when the donor atom has a high density of electrons. Figure 9 displays HOMO and LUMO density distributions for C1 and C2. This figure’s analysis reveals that HOMO density is equally spread over the triazole, pyrimidine, and substituted imidazole rings for both C1 and C2. However, the compounds’ LUMO density is concentrated on the triazole ring and its substituent at position 3.

Molecular electrostatic potential (MEP)

Relationships between activity detection and hydrogen bonding can be better understood with the use of the molecular electrostatic potential (MEP) ( [50]). As can be seen in Fig. 10, the B3LYP with the basis set 6-31G optimized results were used to create the MEP map of the compounds (C1 and C2). Colors are used to denote the various MEP surface zones. Indeed, the zone from red to green is favorable for electrophilic attacks. While the zone from green to blue is one that can be attacked by nucleophiles, the green zone represents zero potential.

Surface analysis techniques

SEM/EDX analysis

Figure 11 displays SEM images of Zn in 1 M HNO3 before and after being submerged in 300 ppm C1 and C2. According to Fig. 11a, Zn in 1 M HNO3 without an inhibitor appeared as a damaged surface with depth pits as compared to the inhibitor, which is depicted in Fig. 11b and c. The shielding layer of C1 and C2 molecules that have been adsorbed is responsible for the improved, smooth, fewer damaged surface. The other two inhibitors were able to fill all surface voids, creating a barrier between the metal and the medium that stopped further corrosion. Figure 11 shows the elemental compositions deduced from EDX spectra. It demonstrates that the Zn without C1 and C2 has peaks of Oxygen and other elements from the composition of the electrode. The EDX of Zn with C1 and C2, the peaks of C, O, and N in the Zn surface due to the presence of these elements in C1 and C2 indicating that the investigated molecule is adsorbed on Zn. Carbon units form the backbone of C1 or C2. The addition of C1 or C2 clearly raised the carbon % content of the inhibited metal surface, demonstrating adsorption onto surface and lowering corrosion.

XRD Analysis

Figure 12 Display the X-ray diffraction analysis for Zn surface in 1 M HNO3 (Blank), inhibited Zn in C1 and C2. The XRD pattern of Zn immersed blank nitric acid solution indicated the dominant peaks corresponding to three phases Zn, Zinc Oxide ZnO (zincite) and Zinc Nitrate Hydroxide Hydrate Zn5(NO3)2(OH)8(H2O)2 according to index references codes 00–001-1136, 01–078-7025 and 04–011-5271 respectively. The presence of the mention crystalline phase Zn5(NO3)2(OH)8(H2O)2 indicates that the presence of corrosion products on the sample surface. In fact, the nitrate group in the nitric acid solution reacts with zinc on the surface of the zinc sample and then to form Zinc Nitrate Hydroxide Hydrate Zn5(NO3)2(OH)8(H2O)2, which indicates the destructive effect of nitrate ions on the corrosion behavior of the zinc. As can be seen in the samples containing the inhibitor, the peaks of Zinc Nitrate Hydroxide Hydrate are not visible in the diffraction pattern of the samples, which indicates that the nitrate ion does not react with zinc in the samples containing the inhibitor ( [51])

Mechanism of inhibition process

The parameters that affect adsorption onto zinc surface include inhibitor's chemical composition, feature of corrosive media, and zinc's properties. One of best ways to prevent corrosion on metals is to use inhibitors. These inhibitors create a barrier against the metal's breakdown in the electrolyte by adhering molecules a protective hydrophobic layer ( [52]). By obstructing the active areas on the zinc that are prone to corrosion, inhibitors adsorb on the metal. The inhibiting effect of two synthesis fused Pyrazolopyrimidine like C1 and C2, on the corrosion of zinc has been investigated experimentally by electrochemical and density functional theory. Large numbers of N atoms with a lone pair of electrons are contained in either C1 or C2, assisting in successful adsorption onto the zinc surface. The functional groups of inhibitor molecules, the electron density, and the charge of the metal surface affect how inhibitors adsorb to the metal surface. Numerous studies have shown that the Zn surface is excessively positively charged. The positively charged sample surface promotes adsorption, resulting in a negative charge surface that allows cations adsorption from the solution. These derivative molecules can be protonated in solution because of the lone pair of the O atoms. Electrostatic contact and covalent bonds between inhibitors and the metal surface allowed protonated molecules to adsorb on the metal surface. DFT calculations show that the HOMO and LUMO of inhibitor molecules are located at the cyclopentadienyl ring and ester group, where the inhibitor molecules might adsorb in a flat orientation on the specimen surface by generating coordination bonds and/or feedback bonds ( [53]).

The thermodynamic indicated that the bonding between zinc and examining inhibitors obeyed physisorption. The inhibitor molecule with a single pair of electrons contains nitrogen and oxygen, which has facilitated its adsorption on the zinc surface. Water molecules that have accumulated on zinc surface and become adsorbent are replaced during this process. C1 or C2 belong to the biopolymer category; it is clear that the molecule is larger and thus capable of covering both cathodic and anodic areas due to the Umbrella effect. As a result, it functions as a mixed inhibitor. This hypothesis fits the weight loss observation and PDP method quite well. A schematic illustration of the mechanism of adsorption is provided in Fig. 13.

Compare the performance inhibitory action of C1 and C2 with other corrosion inhibitors

One of the most effective strategies to lower the financial risk associated with corrosion is to employ organic compounds. Numerous chemical compounds containing pyrimidine groups have been studied for their ability to suppress corrosion in a range of hostile solutions. In an attempt to lower the high costs related to corrosion difficulties in the industries, we have chosen two novel pyrimidine derivatives, namely 8-NH2-1-phenyl-7-(trichloromethyl)-1,8-dihydro-4H-pyrazolo[3,4-d] ( [1, 2, 4]) triazolo[1,5-a]pyrimidin-4-one (C1) and 8-NH2-7-(2-hydroxyphenyl)-1-phenyl-1,6,7,8-tetrahydro-4H-pyrazolo [3,4-d][1,2,4]triazolo [1,5-a] pyrimidin-4-one (C2) (Fig. 1). These are mostly organic compounds made of nitrogen that have highly reactive pi-electrons surrounding unsaturated C=C bonds and lone pair electrons surrounding the electronegative element. The antioxidant, antiviral, and antibacterial properties of pyrimidine derivatives, along with their ease of synthesis, have drawn interest recently in the context of producing green, inexpensive, and ecologically friendly nitrogen ( [30]). Table 7 presents a comparison between the inhibitory efficiency of compounds that have been previously reported and the chemicals that were examined in this investigation (C1 and C2). Inhibitory efficiency values were discovered by immersing in a range of different solutions, as shown in the table below. We can determine that our compounds are the most potent inhibitors by comparing these statistics. C1 and C2’s Zn corrosion inhibition efficacy was on par with, and in certain instances considerably higher than, that of a number of other inhibitors. Additionally, compared to the creation of this study, the prior organic inhibitors described in Table 7 feature bulky structures. These findings suggested that the latest work is a logical continuation of the research on organic inhibitors. Consequently, the synthetic compound's ability to effectively suppress corrosion may draw ongoing scientific interest.

Conclusion

From this research, the main conclusions drawn are listed below

Pyrazolopyrimidine-derived C1 and C2 act as deterioration avoidance for Zinc in 1 M HNO3. Concentration enhancement leads to increased efficiency. The two Pyrazolopyrimidine-derived compounds had maximum inhibitory efficiencies of 92.06 and 79.36% for C1 and C2, respectively, at 700 ppm. The inhibitors C1 and C2 function as mixed but mostly anodic inhibitors during corrosion by prohibiting both cathodic and anodic processes. The inhibitors adsorption of Zinc in 1 M HNO3 is best described by the Langmuir adsorption isotherm. This ΔG kJ/mol for C1 and C2 show that the inhibitors adsorption to the metal surface occurred spontaneously. Computational studies (using DFT/B3LYP method) aid in the identification of the most likely adsorption sites for the molecules. This information can be used to obtain a better understanding of corrosion, such as the most likely site for inhibitor adsorption.Additionally, SEM also show the development of layer on the zinc surface. In conclusion, these two inhibitors, C1 and C2, are successful in preventing zinc corrosion in 1 M HNO3.

References

Kania H, Saternus M (2023) Evaluation and current state of primary and secondary zinc production—a review. Appl Sci. https://doi.org/10.3390/app13032003

Pola A, Tocci M, Goodwin FE (2020) Review of microstructures and properties of zinc alloys. Metals 10(2):253

Gaber GA, Hosny S, Mohamed LZ (2021) Experimental and theoretical studies of 2-cyano-N-(4-morpholinobenzyldine) acetohydrazide as corrosion inhibitor for galvanized steel and 304 stainless steel in 1M H2SO4 solution Int. J Electrochem Sci 16:211214

Ibrahim T, AbouZour M (2011) Corrosion inhibition of mild steel using fig leaves extract in hydrochloric acid solution. Int J Electrochem Sci 6:6442–6455

Jyothi S, Rao YS, Ratnakumar PS (2019) Natural product as corrosion inhibitors in various corrosive media: a review. Rasayan J Chem 12:537–544

Mourya P, Banerjee S, Singh MM (2014) Corrosion inhibition of mild steel in acidic solution by Tagetes erecta (Marigold flower) extract as a green inhibitor. Corros Sci 85:352–363

Dharmaraj E, Pragathiswaran C, Govindhan P, Sahayaraj AP, Amalraj AJ, Dharmalingam V (2017) Corrosion inhibition of mild steel by plant extracts in acid media. Int J Nano Corr Sci and Engg 4(1):106–120

Khaled F, El-Shamy A, El-Mahdy G (2019) Corrosion behavior and inhibition efficiency for mild steel and zinc in 1 M HNO3 at different temperatures: Electrochemical and surface analysis studies. J Mol Liq 277:103–114

Castillo-Miranda JO, Rodríguez-Gómez FJ, Genescá-Llongueras J, Ruiz-Suárez LG, García-Reynoso JA (2021) Estimation and mapping of the contribution of nitric acid to atmospheric corrosion of zinc. Global J Environ Sci Manage 7(4):523–542

El-Sayed M, Abdallah M, El-Bindary A (2017) Corrosion inhibition performance for mild steel and zinc by some new synthesized Schiff bases derivatives in hydrochloric and nitric acids solutions: experimental and theoretical approaches. J Mol Liq 241:102–118

Chebabe D, Abbout S, Damej M, Oubair A, Lakbaibi Z, Dermaj A, Benassaoui H, Doubi M, Hajjaji N (2020) Electrochemical and theoretical study of corrosion inhibition on carbon steel in 1M HCl medium by 1,10-bis(4-amino-3-methyl-1,2,4-triazole-5-thioyl) decane. J Fail Anal Prev 20:1673–1683

Abdel-karim AM, Shahen S, Gaber GA (2021) 4-Aminobenzenesulfonic acid as effective corrosion inhibitor for carbon steel in hydrochloric acid Egypt. J Chem 64(2):825–834

Cruz J, Martínez R, Genesca J, García-Ochoa E (2004) Experimental and theoretical study of 1-(2-ethylamino)-2-methylimidazoline as an inhibitor of carbon steel corrosion in acid media. J Electroanal Chem 566:111–121

Migahed MA (2005) Electrochemical investigation of the corrosion behavior of mild steel in 2M HCl solution in presence of 1-dodecyl-4- methoxy pyridinium bromide. Mater Chem Phys 93:48–53

Ismail KM (2007) Evaluation of cysteine as environmentally friendly corrosion inhibitor for copper in neutral and acidic chloride solutions. Electrochim Acta 52:7811–7819

Atia S, Boudehane A, Zobeidi A, Douadi T, Lounas A, AlNoaimi M, Gherraf N (2017) Cyclic voltammetry studies of synthesized new azo schiff bases. Res J Pharm Biol Chem Sci 8:840–847

Kuznetsov YI (2018) Triazoles as a class of multifunctional corrosion inhibitors. A review. Part I. 1, 2, 3-Benzotriazole and its derivatives. Copper, zinc and their alloys. Int J Corrosion Scale Inhibition 7(3):271–307

Rodriguez J, Mouanga M, Roobroeck A, Cossement D, Mirisola A, Olivier MG (2018) Study of the inhibition ability of benzotriazole on the Zn-Mg coated steel corrosion in chloride electrolyte. Corros Sci 132:56–67

Vashi RT, Desai K (2013) Aniline as corrosion inhibitor for zinc in hydrochloric acid. Chem Sci Trans 2(2):670–676

Vashi RT, Bhajiwala HM (2010) Ethanolamines as corrosion inhibitors for zinc in (HNO3 + HCl) binary acid mixture. Der Pharma Chem 2(4):51–56

Vashi RT, Naik D (2019) Effect of Oxalic acid on corrosion inhibition of zinc in H3PO4. Int J Res Anal Rev 6(2):228x–235x

Vashi RT, Desai K (2012) Hexamine as corrosion inhibitor for zinc in hydrochloric acid. Der Pharma Chem 4(5):2117–2123

Vashi RT, Bhajiwala HM, Desai SA (2013) Hexamine as corrosion inhibitor for zinc in (HNO3 + H2SO4) binary acid mixture. Der Pharma Chemica 5(2):237–243

El-Asri A, Jmiai A, Lin Y, Taoufyq A, Rguiti MM, Bourzi H, El Issami S (2022) Understanding imidazole derivatives effect as a corrosion inhibitor for brass in nitric acid: a combined experimental and theoretical assessments. Corros Eng, Sci Technol 57(7):680–695

Bereket G, Öğretir C, Yurt AYSEL (2001) Quantum mechanical calculations on some 4-methyl-5-substituted imidazole derivatives as acidic corrosion inhibitor for zinc. J Mol Struct 571(1–3):139–145

Hamadi L, Mansouri S, Oulmi K, Kareche A (2018) The use of amino acids as corrosion inhibitors for metals: A review. Egypt J Pet 27(4):1157–1165

Ahmed ASI, Ghanem WA, Hussein WA, Gaber GA (2020) Evaluation of some inorganic anions and organic compounds as corrosion inhibitors of Cu-Zn alloys in H2SO4 and HNO3 solutions. Arch Metall Mater 65(2):639–651

Liang M, Zhou H, Huang Q, Hu S, Li W (2011) Synergistic effect of polyethylene glycol 600 and polysorbate 20 on corrosion inhibition of zinc anode in alkaline batteries. J Appl Electrochem 41:991–997

Hassan AY, Kadh MS, Saleh NM, Abou-Amra ES (2019) A Novel synthesis of fused pyrazolopyrimidine:pyrazolo-triazolo-pyrimidine for anticancer evaluation. IJARP 3(8):55–59

Ikenna BO, Mumtaz AQ, Ime BO (2023) A synthesized pyrimidine derivative with highly efficient long-term corrosion protection for API X60 steel in CO2-saturated NACE brine ID196 under hydrodynamic condition. J Mol Struct 1284:135399

Gaber GA, Ghobashy MM, Madani M, Alshangiti DM, Alkhursani SA, Al-Gahtany SA, Nady N (2021) Study of the corrosion-inhibiting activity of the green materials of the Posidonia oceanica leaves’ ethanolic extract based on PVP in corrosive media (1 M of HCl). Green Process Synthesis 10(1):555–568

Becke AD (1988) Density-functional exchange-energy approximation with correct asymptotic behavior. Phys Rev A 38(6):3098–3100

Lee C, Yang W, Parr RG (1988) Development of the Colle-Salvetti correlation-energy formula into a functional of the electron density. Phys Rev B 37(2):785–789

Martinez S (2003) Inhibitory mechanism of mimosa tannin using molecular modeling and substitutional adsorption isotherms. Mater Chem Phys 77(1):97–102

Obot IB, Macdonald DD, Gasem ZM (2015) Density functional theory (DFT) as a powerful tool for designing new organic corrosion inhibitors. Part 1: an overview. Corros Sci 99:1–30

Muhammad SL (2022) Corrosion inhibition of zinc in 0.5 M HNO3 using Azadirachta indica extract: experimental and computational study. Bayero J Pure Appl Sci 13(1):149–162

Abakedi O, Asuquo J (2016) Corrosion inhibition of aluminum in acidic medium by ethanol leaf extract of azadirachtaindica. J Basic Appl Res Biomed 2(4):556–560

Fekry AM, Ameer MA (2010) Corrosion inhibition of mild steel in acidic media using newly synthesized heterocyclic organic molecules. Int J Hydrogen Energy 35(14):7641–7651

Almahdy MS, Molouk AF, El-Hossiany A, Fouda AS (2023) Electrochemical studies of erica arborea extract as a green corrosion inhibitor for C-steel in sulfuric acid medium. Biointerface Res Appl Chem 3(5):472

Akinbulumo OA, Oludare JO, Ebenezer LO (2020) Thermodynamics and adsorption study of the corrosion inhibition of mild steel by Euphorbia heterophylla L. extract in 1.5 M HCl. Results Mater 5:100074

Nwabanne JT, Vincent NO (2012) Adsorption and thermodynamics study of the inhibition of corrosion of mild steel in H2SO4 medium using Vernonia amygdalina. J Miner Mater Charact Eng 11(09):885

Ituen E, Onyewuchi A, Abosede J (2017) Evaluation of performance of corrosion inhibitors using adsorption isotherm models: an overview.". Chem Sci Int J 18(1):1–34

Abdel-karim AM, Shahen S, Elsisi DM, Hyba AM, El-Shamy OA (2022) Experimental and theoretical studies of corrosion resistance enhancement of carbon steel in 1 M HCl by quinoxalinosulfonamide hybrid-bearing theophylline moiety. J Bio-and Tribo-Corrosion 8(3):70

Attia EM, Hassan NS, Hyba AM (2019) Potentiodynamic study on the effect of expired septazole and septrin drugs on the corrosion inhibition of tin electrode in 1M HCl solution. J Basic Appl Chem 9(2):11–18

Taha RH, Gaber GA, Mohamed LZ, Ghanem WA (2019) Corrosion inhibition of two schiff base complexes on the mild steel in 1M HCl solution. Egypt J Chem 62:367–381

Manamela KM, Murulana LC, Kabanda MM, Ebenso EE (2014) Adsorptive and DFT studies of some imidazolium based ionic liquids as corrosion inhibitors for zinc in acidic medium. Int J Electrochem Sci 9(6):3029–3040

Musa AY, Kadhum AAH, Mohamad AB, Takriff MS, Daud AR, Kamarudin SK (2010) On the inhibition of mild steel corrosion by 4-amino-5-phenyl-4H-1, 2, 4-trizole-3-thiol. Corros Sci 52(2):526–533

Abd El Wanees S, Seda SH (2019) Corrosion Inhibition of zinc in aqueous acidic media using a novel synthesized Schiff Base–an experimental and theoretical study. J Dispers Sci Technol. https://doi.org/10.1080/01932691.2018.1544080

Oyeneyin OE (2023) DFT and monte carlo simulations on the corrosion inhibitive potentials of some furan-based carbohydrazide derivatives. Lett Appl NanoBioSci 12(4):113

Samie F, Tidblad J, Kucera V, Leygraf C (2007) Atmospheric corrosion effects of HNO3 comparison of laboratory-exposed copper, zinc and carbon steel. Atmos Environ 41(23):4888–4896

Mikitha P, Padmalatha R (2021) Electrochemical, spectroscopic and theoretical studies for acid corrosion of zinc using glycogen. Chem Pap 75:1387–1399

Meysam MS, Hajar J, Saleh MA, Elnaz A, Reza TM, Mehdi DE (2023) 4-Ferrocenylbutyl-based corrosion inhibitors for mild steel in acidic solution. Mater Chem Phys 293:126895

Tan J, Guo L, Yang H (2020) Synergistic effect of potassium iodide and sodium dodecyl sulfonate on the corrosion inhibition of carbon steel in HCl medium: a combined experimental and theoretical investigation. RSC Adv 10:15163–15170

Mehta RK, Gupta SK, Yadav M (2022) Studies on pyrimidine derivative as green corrosion inhibitor in acidic environment: electrochemical and computational approach. J Environ Chem Eng 10:108499

Ibrahim MM, Mersal GAM, Fallatah AM (2020) Electrochemical, theoretical and surface physicochemical studies of the alkaline copper corrosion inhibition by newly synthesized molecular complexes of benzenediamine and tetraamine with π acceptor. J Mol Liq 320:114386

Khaled SMF, Murat S, Mothana GKA, Mehmet IY, Zülbiye K, Savas K, Fatma K (2023) Corrosion inhibition of mild steel in acidic media using new oxo-pyrimidine derivatives: Experimental and theoretical insights. J Mol Struct 1284:135361

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gaber, G.A., Hassan, A.Y., Kadh, M.S. et al. A computational and experimental investigation of novel synthesis fused pyrazolopyrimidine as zinc corrosion inhibitor in 1 M HNO3. Chem. Pap. 78, 3189–3203 (2024). https://doi.org/10.1007/s11696-024-03303-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-024-03303-x