Abstract

The inability of wastewater treatment plants to effectively remove emerging pollutants has necessitated the need to develop newer advanced technologies. An integrated approach of combining advanced oxidation processes (AOPs) and membrane technologies promises superior performances. In this study, graphene oxide quantum dots-based membranes (GQDs-Ms) were fabricated via the phase inversion method. The GQDs-Ms revealed high oxygen content and a negative surface charge. The incorporating graphene oxide quantum dots (GQDs) into the polymer matrix led to enhanced hydrophilicity, pore size, porosity, improved flux as well as superior inhibition of Escherichia coli cells. A multi-AOPs approach was used in this work, wherein AOPs were applied as both pre-treatment (using GQDs) and post-treatment (combining GQDs with peracetic acid) in the disinfection of wastewater. The evaluation of GQDs-Ms performance was carried out and compared with a commercial membrane (Film Tec™NF270). The obtained % removals with GQDs-Ms were 83.45%, 64.12%, 40.76% and 70.36% for turbidity, total dissolved solids, total organic carbon and electrical conductivity, respectively, which compared nearly with commercial membrane’s performance. Interestingly, the integrated hybrid system can further remove and inactivate microbes in wastewater. The developed hybrid filtration-advanced technology system can substantially improve conventional wastewater treatment plants for water reuse.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The detection of emerging pollutants (EPs) such as pharmaceuticals in natural water sources, treated and untreated water continues to pose health risks globally (Arman et al. 2021). Owing to the design of existing wastewater treatment plants (WWTPs) and its inability to completely remove EPs, conventional techniques such as filtration, flocculation, coagulation, chlorine disinfection and sedimentation have been rendered ineffective in removing all detected EPs (Dharupaneedi et al. 2019). Among the several techniques that have been presented as alternatives, membrane technology and advanced oxidation processes (AOPs) have emerged as promising methods for eliminating EPs (Kusuma 2021). Membrane separation processes (MSPs) have recently been adopted as alternative technologies for adsorption, flocculation, extraction, sediment purification techniques and distillation (Winter et al. 2016). AOPs, on the other hand, have been identified as front-runners in the removal of recalcitrant organic pollutants as they produce highly reactive radicals that are known to oxidize harmful organic pollutants to less harmful compounds (Tshangana et al. 2021). Although MSPs and AOPs have shown effectiveness in remediating water contaminated with EPs, complete removal of the pollutants has not yet been achieved (Kumar et al. 2022). The possibility of integrating membrane technology and AOPs offers a flexible opportunity to simultaneously degrade and remove organic pollutants thereby improving the overall treatment efficiency. AOPs can be employed as either pre-treatment or post-treatment. When AOPs are applied as pre-treatment, membrane fouling is reduced remarkably due to reduction in organic load before the filtration step. Alternatively, AOPs can be applied after membrane filtration to improve the quality of the permeates for subsequent reuse or to meet discharge standards (Yang et al. 2020; Rosman et al. 2018). Integrating AOPs with membrane technology result in a positive synergy with several advantages which include but not limited to the following: simultaneous separation and photodegradation of recalcitrant organic pollutants as the membrane will retain all the un-oxidized organic pollutants, enhanced anti-fouling or self-cleaning properties that are imparted on the membrane and overall improved membrane fluxes (Rosman et al. 2018).

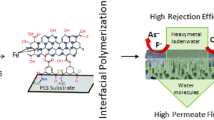

This study proposes an integrated hybrid filtration-advanced oxidation processes system based on polyethersulfone (PES)/graphene oxide quantum dots (GQDs) and peracetic acid (PAA). Wherein GQDs are not only used as photocatalysts but also as nanofillers to improve the PES membrane properties and performance. The premise of the study is based on AOPs being used in the pre-treatment step as well as post-treatment to mineralize any harmful contaminants that may have permeated through the membrane, as well as to remove organics or bacteria that require further treatment. In the post-treatment step, specifically the synergy between GQDs and peracetic acid (PAA) was exploited to simultaneously mineralize pollutants that were not retained by the membrane filtration process while also inactivating bacteria. The major strategy of incorporating PAA is based on a recent paper that reported on the activation of PAA using GQDs (Tshangana et al. 2022) as well as the favorable features of PAA: (i) PAA combines the benefits of being both an oxidant and a disinfectant and can easily be retrofitted in existing treatment plants; (ii) lower toxicity compared to chlorine; (iii) the high oxidation potential; (iv) microbial activity that is comparable to chlorine; (v) the formation of little to no toxic disinfection by-products (DBPs); and finally, (vi) economically viable and a feasible oxidant for water treatment (Henao et al. 2018; Du et al. 2018). The aim of this work was to develop an integrated hybrid filtration-advanced oxidation processes system for the treatment of wastewater. AOPs (utilizing GQDs) were applied as pre-treatment, and the membrane filtration performance of the fabricated PES/GQDs membrane was compared to a commercial membrane (CM). The study demonstrates an interesting approach in the integration of advanced technology process and membrane separation in the reclamation wastewater for further reuse.

Experimental

Chemicals and materials

Gafone 3100P polyether sulfone (PES) (MW = 58,000 and density of 1.37 g/cm3) was supplied by Solvay (Brussels, Belgium). Hollytex®-3329 non-woven polyester fabric was purchased from Kevin Filter Products Co. Farmingdale, New Jersey, USA. The fabric has the following characteristics: air permeability of 5.1 cfm, bulk porosity of 49.57%, thickness of 0.13 mm, water holding capacity of 24.15 wt% and weight of 96.5 g/m2. Nutrient agar (NA), nutrient broth, Luria broth were supplied by Thermo-Fischer, South Africa. The Escherichia coli (E. coli) strain (ATCC 25922) used was purchased from KWIK-STIK™ a product line of Microbiologics®. N-Methylpyrrolidone (NMP), Methyl orange and Rhodamine B dyes were purchased from Sigma-Aldrich, South Africa. Deionized (DI) water was acquired from Elix integral-10 water purification system. Commercial membrane (denoted as CM) was obtained from Hirose Paper Manufacturing in Japan.

The GQDs used in the study were synthesized and fully characterized as per a previous study (Tshangana et al. 2020). Characterization techniques such as X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS) were also performed. XRD patterns were collected using a Bruker D8 Discover equipped with a Lynx Eye detector, using Cu-Ka radiation (= 1.5405 A°, nickel filter). The data were collected in the range from 20 = 10° to 100°, scanning at 1° min-1, filter time-constant of 2.5 s per step and a slit width of 6.0 mm. Prior to analysis, the sample was placed on a silicon wafer slide. The X-ray diffraction data were processed using Eva (evaluation curve fitting) software. XPS analysis was carried out using AXIS Ultra equipped with Al (monochromatic) anode and a charge neutralizer. The following operating parameters were used: the emission was 10 mA, the anode (HT) was 15 kV and the operating pressure below 5 × 10–9 Torr. A hybrid lens was used and resolution to acquire scans was at 160 eV pass energy in slot mode. The center used for the scans was at 520 eV (width of 1205 eV) with steps at 1 eV and dwell time at 100 ms. The high-resolution scans were acquired using 80 eV pass energy in slot mode. The core level binding energies (BEs) were aligned with respect to the adventitious carbon C1s binding energy of 284.5 eV.

Fabrication of PES/GQDs mixed matrix membranes (MMM)

The PES/GQDs membranes were prepared via phase inversion method. Pristine membranes (the control: M0) were prepared without the incorporation of GQDs (Table 1). For the GQDs incorporated membrane, optimization studies were carried out and 5 wt% (w/w) concentration of GQDs were added as nanofillers in the PES matrix (M1). The membrane casting solutions were obtained by dissolving an accurately weighed mass of PES powder (20 wt%) and corresponding 5 wt% (w/w) of GQDs in NMP solvent. The mixture was vigorously stirred using a mechanical stirrer overnight at room temperature until dissolution. Before casting, the homogenous polymer solution was allowed to stand overnight to eliminate any formed bubbles before casting. Prior to casting, the surface of the non-woven fabric was wetted with NMP solvent. Subsequently, the polymer solution was spread thin on the non-woven fabric supported on a glass substrate using a casting knife (knife height set at 150 µm). After casting, the membranes were submerged in a coagulation bath (filled with deionized water) for 15 min at room temperature to initiate phase inversion resulting in the precipitation of the polymeric membrane off the glass. The resultant membranes were kept in deionized water (which was changed regularly to prevent the growth of bacteria) and dried before characterization. The composition of the membranes fabricated in this study is shown in Table 1.

Membrane characterization

Contact angle measurement

The hydrophilicity of the fabricated membranes (M0 (control) and M1) was assessed using contact angle (CA) measurements. The surface contact angle was measured using the static sessile drop observation using a contact angle goniometer (DSA30 Krüss GmbH, Hamburg, Germany). The membranes were mounted on planar glass substrates and held in place by a double-sided tape on the instrument stage. A minimum of 10 drops of deionized water (volume of 2 µL) were deposited on different sections of the surface of the membrane using a micro-syringe at the room temperature, and the recorded average values were reported as the final contact angle values.

Zeta potential

The zeta potential (ζ) of the fabricated membranes were measured using Anton Paar SurPASS Electrokinetic analyzer (Graz, Austria). The membrane coupons were individually mounted on sample holders that were then held in place with double-sided tape. To accurately measure the streaming potential, the membrane's surface was flushed with electrolyte solution. All measurements were performed at 300 mBar with potassium chloride solution (10 mM) as electrolyte at a pH range of 6–9. The zeta potentials (ζ) were determined from streaming potential measurements based on the Helmholtz–Smoluchowski equation (Eq. 1):

where ΔV is the measured streaming potential (V), η is the electrolyte viscosity (Pa.s), δ is the electrolyte conductivity (S/m), ΔP is the applied pressure (Pa), and ε is the permittivity of water.

Membrane porosity

Membrane porosity was determined using the gravimetric method (Fan et al. 2016) where the membranes were individually cut and left in DI water over night. This was followed by removing excess water droplets on the membrane surface by dabbing with a paper towel, and the weight of the wet membranes was measured using an analytical balance. The wet membranes were then dried and incubated at 45 °C. The dry membranes were re-weighed the next day after being allowed to cool to room temperature. A minimum of five samples were weighed to obtain an average value for the dry and wet membrane. The total porosity of each of the membranes (ε%) was determined using Eq. (2):

Where ε is the porosity of membrane, Ww is the weight (g) of the wet membrane, Wd is the weight (g) of dry the membrane, ρw is the density of pure water (g/cm3), A is the membrane area (cm2), and δ is the thickness of membrane (cm).

Water flux and water retention tests

Water flux

Permeation tests experiments were conducted using a dead-end filtration set-up (Sterlitech™ Washington, USA). The set-up (as shown in Fig. 1) has a cell diameter of 50 mm and with a capacity of 300 mL. In this work, 200 mL volume was used for all filtration experiments. Prior to filtration experiments, the membranes were cut into appropriate size and loaded into the dead-end cell. This was followed by membrane compaction at 6 bar using DI for 30 min or until stable fluxes were obtained. Pure water fluxes were then measured at varying applied pressure (1–6 bar) by collecting specific volume of permeate while recording time. The net water flow was obtained from correlating information of the membrane surface area, volume of effluent and the time taken using Eq. (3):

where V is the volume of permeate (L), A is the effective membrane area (m2), and t is the permeation time (h).

Water retention

Water retention capability tests of the synthesized membranes were carried out by soaking 0.1 g of the membrane in DI water for a period of 24 h. The weight of the wet membrane was recorded using an analytical balance. The membranes were then dried in the oven at 40 °C for 10 h, and the weight of the dry membrane was measured. The water retention capabilities of the membranes were estimated from the measured weights using Eq. (4):

Surface and cross-sectional analysis of the fabricated membranes

The surface and cross-sectional morphology of M0 (control) and M1 membranes was surveyed using field emission scanning electron microscopes (FESEM) (JSM-7800F) and JEOL (JEM-2100). The membrane samples for the cross-section imaging were immersed in liquid nitrogen for 30 s. The liquid nitrogen was used to splinter the membranes before mounting them on aluminum stubs. All the membrane samples were mounted on the aluminum stubs that were held in place using double-sided tape and subsequently sputtered with a 5 nm thick gold coating prior to imaging, to reduce sample charging.

Rejection studies

Rejection capability tests of the membranes were carried out using the fabricated membrane samples and 0.01 M of different salt solutions made up of Na2SO4, NaCl and MgSO4 salts. The operational pressure in these experiments was 6 bar. Membrane solute rejection R (%) was determined using Eq. (5):

where Cp and Cf are solute concentrations in the permeate and feed solution.

Dye removal tests

Dye solutions of methyl orange (MO) and Rhodamine B (RhB) (15 ppm) were utilized in the dye removal tests employing M0 (control) and M1 membranes. The operational pressure used for these experiments was 6 bar. For each membrane, the test time was 60 s. UV–vis measurements were used to determine the permeate dye concentrations.

Sampling site and sample collection

The wastewater effluent sample was obtained from a South African WWTP. Wastewater in this WWTP goes through different stages including a primary clarifier, an aeration tank, a secondary clarifier and finally, a disinfection unit where bacteria are removed. Keeping this in mind, for the purpose of this study, the sampling point was selected before the primary clarifier.

Antibacterial testing of PES/GQDs membranes against E. coli.

E. coli (ATCC 25922) was used to determine the antibacterial efficacy of the PES/GQDs membrane using a shake flask method as well as colony counting method as described by Najjar et al. (2019). The E. coli cells were cultured overnight at 37 °C in nutrient broth. To assess the antibacterial activity, the PES/GQDs membrane was immersed into flask containing 20 mL of sterile 0.9% saline which was sonicated for 20 min. The flask was inoculated with 500 μL of bacterial suspension of E. coli (1–5 × 107 CFU/mL). After inoculation, the flasks were incubated for 2.5 h at 37 °C on a rotary shaker to allow continuous stirring. One mL of the bacterial suspension was drawn at time 0 and after 2.5 h and spread on Nutrient Agar (NA) plates using the spread plating technique. Thereafter, the plates were incubated over 24 and 48 h, respectively, at 37 °C, and the number of colonies enumerated. After the shake flask method, the PES/GQDs membranes were rinsed once with saline and the bacteria on the membrane surface was visualized using FESEM.

The reduction in the number of viable E. coli cells was calculated using the following Eq. (6):

where T0 is time at 0 h, and Tt is time at t hour.

Zone inhibition studies were carried out by pouring 1 mL of the E. coli solution onto an LB agar plate, to ensure uniform distribution is achieved the agar plate was shaken. The membranes [M0 (control) and M1] with diameter 5 mm were placed in the center of the plate overnight and incubated overnight. Following, the diameter of the zone of inhibition (\(d_{{{\text{iz}}}}\)) and the diameter of the membranes were measured, and the normalized halo (\({\text{nw}}_{{{\text{halo}}}}\)) for each membrane is calculation in the Eq. (7) given below (Frígols et al. 2019):

Quantitative antimicrobial analysis of the PES/GQDs membranes

The quantitative analysis of the antibacterial properties of the membranes was evaluated using the colony-forming unit (CFU) count method (Dadari et al. 2022). Where the fabricated membranes were initially autoclaved to achieve sterilization. The fabricated membranes were subsequently soaked into the E. coli suspension (100 mL, 104 CFU/mL) and incubated at 37 °C and 120 rpm for 24 and 48 h. Following, the membranes were removed from the E. coli suspension and washed with buffer. From this, the solution was diluted with deionized water, and 1 mL of the diluted solution was spread on Luria Broth (LB) agar plates and incubated at 37 °C. After 24 and 48 h, the antibacterial rate was evaluated by counting the viable bacteria colonies as demonstrated in Eq. (8) (Ali et al. 2019):

where A and B are the colony counts of the E. coli cultures in contact with the M0 (control) and M1 membranes, respectively.

Antibacterial testing of real wastewater effluent

After being subjected to real wastewater effluent, the bacterial content of the fabricated PES/GQDs and the commercial membrane (used for comparative purposes) was evaluated by incubating the membranes M0 and M1 after use for 24 and 48 h at 37 °C in LB to obtain total bacterial count.

Integrated hybrid filtration-advanced oxidation process system

A pictorial representation of the integrated hybrid filtration-advanced oxidation processes system is shown in Fig. 2. AOP (using GQDs) was employed in the first step (pre-treatment) for the degradation of complex organic pollutants (such as natural organic matter) that have the potential to block the pores of the membrane and ultimately resulting in membrane fouling. This step is necessary to mitigate fouling of the membrane which could severely affect the overall performance of the membrane in terms of permeate flux and rejection of target pollutants. Prior to the AOPs step, the feedwater (collected from a South African wastewater treatment plant) was filtered using a sand-filter to remove the solid particles and the water quality parameters (WQPs) of the feedwater were assessed at the points labeled points 1, 2, 3 and 4. The PES/GQDs membrane was placed after the AOPs (pre-treatment step), to allow the filtration of simpler and less toxic AOP by-products through the membrane. Post membrane filtration, AOPs were used as a post-treatment to mineralize any harmful contaminants that permeated through the membrane, as well as to remove organics or bacteria that require further treatment.

Wastewater quality parameters

The quality of the wastewater samples was assessed at the following points: before pre-treatment (1), after pre-treatment (2), after the membrane filtration step (3) and after the AOPs step using GQDs/PAA (4). The following parameters were measured: pH, turbidity, total dissolved solids (TDS), total organic carbon (TOC) and the electrical conductivity (EC). A multiparameter meter (YSI Professional Plus) was used to measure the pH, TDS, and EC. An Orion TM AQUAfast AQ3010 Turbidity Meter was used to analyze the turbidity, while the TOC was quantified using a Teledyne Tekmar TOC Fusion instrument.

The removal rate of the water quality parameters was calculated using Eq. (9):

Where Cp is the treated water quality parameter, and Cf is the feed water quality parameter.

Results and discussion

Material characterization

The GQDs were characterized using TEM technique. The acquired micrograph (Fig. 3a) shows that synthesized GQDs were not aggregated and were mostly spherical in morphology. The average particle size was estimated to be 4.8 nm. EDX analysis was carried out to determine the elemental composition of the GQDs. From the EDX spectrum (Fig. 3b), it shows that the GQDs were composed of C and O which are the expected chemical elements of the successful synthesis GQDs as it has been previously reported in literature (Zhao et al. 2020). No other elemental peaks were observed confirming the high purity of the GQDs.

The successful incorporation of GQDs in the PES membrane was confirmed using FTIR (Fig. 4a–c). Incorporating GQDs in PES resulted in spectral vibrational changes. The sharp peak at 3100 cm−1 in PES disappeared and, in its place, a broader peak emerged on PES/GQDs which was assigned to the O–H stretching vibrations (Tshangana et al. 2020). Interestingly, after incorporating GQDs in the polymer, the original structure of the PES was not perturbed or distorted as evidenced by the signature peaks of the PES, i.e., benzene rings 1600 cm−1, other functional groups at 1296 cm−1, 1319 cm−1, sulfone at 1100–1140 cm−1 which were still present indicating that the structure of the PES was not affected neither was the structure of the GQDs after blending the two materials.

Utilizing XRD, the crystallinity of the GQDs was determined Fig. 5a. A noticeable peak seen at 2θ = 27 is as a result of the (002) Bragg's reflection and an interlaying spacing of 0.36 nm (Kumar et al. 2017). The discernible peak shows that, compared to the pristine graphene, the carbonization of citric acid produced GQDs that had a more compact interlayer spacing. The amorphous nature of the GQDs accounts for the small peaks in the XRD spectra at 35° and 48°. The Debye–Scherrer equation was used to calculate the average crystallite sizes of the GQDs, and the sizes were determined to be 3.1 nm. The broadness of the XRD peak at 270 further supports the small size of the GQDs. The structural composition of the GQDs was further investigated using XPS; the signals for C1s, O1s, and the Na auger peak were seen at 286.3, 531, and 495 eV, respectively, for the complete scan shown in Fig. 5b. It is worth noting that the NaOH utilized throughout the synthesis process is what caused the Na auger peak to appear at 495 eV. The GQDs' C1s peak was further deconvoluted into three carbon species that are centered at 285.1, 287.5, and 288.4, respectively. These three chemically different carbons are caused by the sp3 carbon (C–C, C–O), the sp2 carbon (C=C), and the oxidized carbon (C=O), respectively (Fig. 5c).

FESEM was used to assess the surface as well as the porosity of the membranes before and after the incorporation of GQDs. Figure 6 depicts surface micrographs of M0 (control) and M1 membranes. For M0 (control), the surface appeared relatively smooth; however, the addition of GQDs resulted in changes in surface morphology due to the presence of GQDs observed on the surface of M1. Cross-sectional images of the membranes show typical asymmetrical macrovoids in M0. The incorporation of GQDs in the casting solution resulted in an increase in the number of pores as well as wider interlocking channels. Similar observations were reported by Ren and Wang (2011) who attributed the changes to the hydrophilic nature of GQDs. The GQDs in the casting solution allowed the exchange between the organic solvent (i.e., NMP) and nonsolvent (i.e., water) is facilitated to yield wider channels with greater porosity and ultimately increased permeability of the membrane (Manawi et al. 2017a, b). Therefore, the introduction of GQDs increased the membrane porosity, according to morphological features from cross-sectional view FESEM pictures. To further confirm the porosity of the membranes, 3D AFM images were used to get information relating to the topography and membrane surface roughness. In the pristine membrane M0, the nodules are seen to be small with few depressions. The depressions on the membrane (M1) surface, however, became more apparent with the addition of GQDs, showing that the introduction of GQDs led to a rougher membrane surface as well as larger pores.

In the same vein, the average total porosity of M0 and M1 was calculated as 52 and 69%, respectively. The difference in total porosity of M0 and M1 indicates 17% increase in the porosity upon membrane modification with GQDs (Fig. 7). A similar trend was observed for the pore size, wherein the addition of GQDs resulted in the pore size increasing from 23 to 38 nm. The increase in membrane porosity is assumed to be due to increase in membrane pore size as postulated by Ren and Wang (2011).

Information relating to the hydrophilic nature of the membranes was determined by looking at two parameters: wettability of the membrane surface as well as the water retention capacity. A contact angle of 64.8° was recorded for the pristine PES membrane (Fig. 8). As per the Young model (Manawi et al. 2017a, b), the addition of GQDs increased the hydrophilicity of the membrane, and this was evidenced by a decrease in water contact angle to 38.5°. The increase in membrane hydrophilicity is based on the following premise: GQDs have a higher number of oxygen containing functional groups and during the phase inversion process as the solvent and nonsolvent exchange, GQDs will have more affinity toward water which will cause them to drift more toward the surface of the membrane (van de Witte et al. 1996).

Membrane performance

Water flux

Figure 9 shows pure water flux results of the pristine and PES/GQDs membrane as a function of applied pressure (1–6 bar). The measured flux for M0 was lower than those of the modified PES/GQDs membranes at all pressure values. The finding was ascribed to the hydrophobic nature of PES and the morphological structure of pristine PES membranes characterized by small pores and lower pore density observed in the FESEM and AFM (Fig. 6). The addition of GQDs in the membrane had an overall improvement in the flux, and this can be explained in relation to increase in membrane hydrophilicity, porosity, and subsequent changes in the morphological structure. Therefore, the overall effect of membrane modification with GQDs was the improvement of membrane pure water permeability from 4.5 to 6.2 Lm−2 h−1 bar−1. Furthermore, the increase in membrane flux values of M1 became wider from pressure values 3–6 bar.

Salt rejection

Salt rejection results of the PES/GQDs membrane are presented in Fig. 10. Overall, the membranes rejected between 40 and 50% of the model salts. The salt rejection percentage was in the order: NaCl ˃ NaSO4 ˃ MgSO4 which was ascribed to the hydration size of ions necessary for mass transfer via the pores of the membrane pores, ion diffusion as well as the electrostatic interaction with the membrane. Elsewhere, using polysulfone/graphene oxide (GO) membranes, the authors attributed the high salt rejection of the GO incorporated membrane to the dispersion of GO in the polymer matrix as well as the increased number of active sites on the membranes (Marjani et al. 2020). Contrary, in this study, the addition of GQDs in the membrane did not seem to improve salt rejection efficiency in this work. The low-salt rejection properties of the membranes offer advantages of resistance to flux loss due to concentration polarization. This makes the membranes energy efficient and suitable for treatment of wastewater.

Performance of M0 and M1 in the removal of dyes

UV–vis was used to measure the absorbance of each dye solution after being filtered through M0 and M1 to measure the membrane rejection efficiency. Standard solutions were prepared, and the concentrations were determined by plotting calibration diagrams. To investigate competitiveness of the synthesized membranes, dye rejection studies were also done using commercial membrane (CM) (Film Tec™NF270). The rejection of the dye solutions is presented in Fig. 11a. The CM recorded the highest dye removal (above 80% for both dyes), followed by M1 with a rejection rate of 62 and 65% of MO and RhB, respectively. This can be explained using the Donan phenomenon (or the electrostatic repulsion) (Peydayesh et al. 2020), where the cationic features of MO and RhB dyes and the anionic membrane surfaces result in attraction resulting in lower rejection.

This is further corroborated by zeta potential data presented in Table 2 which shows that the surfaces of M0 and M1 were negatively charged. The negative charges were attributed to the presence of the sulfonic group O=S=O on the PES (Hamzah et al. 2014). It is a known reality that negatively charged membranes offer better separation in mixtures because of the electrostatic repulsion between the membrane surface and the pollutants in aqueous medium. In contrast, M0 showed the lowest rejection rate of 47 and 51% for MO and RhB, respectively. Since M0 is less negatively charges than M1, lower repulsive interactions were expected resulting in poor dye rejection efficiency.

For the intended application, the long-term stability of the membranes was tested by measuring the flux at varying pH as described by Ma et al. (2023). Of interest in this study, the stability was only carried out for M1. From the results obtained, the M1 maintained high flux efficiency at different pH values recording the greatest flux at neutral pHs (Fig. 11b).

Antibacterial efficacy of PES/GQDs membranes

M0 (control) and M1 membranes were incubated in a suspension of E. coli for 24 and 48 h at 37 °C on NA, and the surface of the membranes was visualized using FESEM (Fig. 12). On the control membrane (M0), live healthy E. coli cells can be seen on the surface of the membrane (as well as on the insert). In contrast, after the incorporation of GQDs in the membrane (M1), there was a noticeable inhibitory effect resulting in the reduction in E. coli cells on the surface of the M1 after 24 h. The inhibitory effect of GQDs was significant after 48 h of incubation as there was no noticeable E. coli on the membrane just a smooth surface. It is known that all bacteria (both Gram-positive and negative) carry a net-negative charge (Ridgway et al. 1985). In Gram-negative bacteria specifically, the negative charge is ascribed to the phospholipids and polysaccharides that comprise the outer part of the bacterial cell membrane (Blenkinsopp and Costerton 1991). Contact angle and zeta potential results were used to elucidate the mechanism of inactivation. The M0 membrane (without GQDs) is hydrophobic in nature which result in the repulsion of water molecules on the surface of the membrane. This is likely due to the absence of hydrogen bonds on the boundary layer (Kang and Cao 2012). The vacant space will promote the settlement of bacteria or any other foulants on the surface of the membrane leading to membrane deterioration and poor performance. While with M1, a hydration layer will form in the vicinity of the membrane surface, and this would prevent the colonization of the E. coli cells on the membrane surface.

In this study, the antibacterial mechanism is postulated to be a synergistic combination that can occur either via oxidative stress or contact inhibition (trapping, wrapping, or cutting) (Fig. 13). The possible mechanism is based on membranes embedded with GQDs (M1) being able to cut through the E. coli cells resulting in the extraction of phospholipids. Alternatively, the E. coli cells could be wrapped or entrapped by the polymer or more likely through induced membrane stress which would increase the oxidative stress, in which vital cellular components would be oxidized and result in cell content leakage and cell death. Observations made in this work are consistent with what has been reported in previous studies (Zeng et al. 2016; Zhang et al. 2019).

Changes in the wastewater quality after treatment with hybrid filtration

Due to the superior performance of M1 over M0, treatment of wastewater using the hybrid AOPs-membrane system was only modeled with M1. The physicochemical properties of wastewater were assessed at different stages of the proposed hybrid AOPs-membrane treatment system (Fig. 2). The water quality parameters (WQPs) before and after treatment are summarized in Table 3. Compared to the PES/GQDs membrane (M1), the recorded percentage removals for the CM were as follows 86.6%, 64.4%, 51.21% and 76.83% for turbidity, TDS, TOC, and EC, respectively. While M1 recorded 83.45%, 64.12%, 40.76% and 70.36%. Each of the parameters is discussed separately in the subsequent sections.

Turbidity reduction

Water sample collected at point 2 shows remarkable reduction (83.4%) of the turbidity in the wastewater sample after pre-treatment with GQDs as an advanced oxidation process (AOP) (Fig. 14). The results suggested that AOPs (using GQDs as the photocatalyst) were able to remove a large portion of the dissolved and suspended solids and/or particulate matter in wastewater. Furthermore, passing the wastewater sample through the PES/GQDs membrane further reduced the turbidity which can be ascribed to the size exclusion effects of the membranes. After the second stage of wastewater treatment, turbidity reduction of 98% was achieved. It can be postulated that the by-products obtained after AOPs were larger than the pore sizes of M1 and were retained through size exclusion. When AOPs were further used as a polishing step, the overall turbidity reduction from the combined three stages was 99.6% showing effectiveness of the hybrid system in removing turbidity from wastewater.

Turbidity of the wastewater at different sampling points as represented in Fig. 2

Reduction in total organic carbon (TOC)

At the pre-treatment stage (sample point 2), the total organic carbon (TOC) was reduced by 40%. The membrane filtration step further reduced the TOC content with the overall TOC removal from the two steps reaching 44%. However, the membrane filtration step did not remove much of the TOC, and this was expected because typically a significant percentage of the organics tend not to be retained and thus, easily permeate through the membrane. Conversely, post-treatment the using GQDs degraded majority of the remaining TOC resulting in the overall TOC removal of 80.63%. TOC content was mainly reduced in the pre-treatment and post-treatment stages implying that oxidation played a significant role in the degradation of the organic pollutants that had passed through the membrane.

Total dissolved solids and Electrical conductivity

There was noticeable reduction in electrical conductivity (EC), and this is ascribed to the complexation that occurs between ions (from dissociated salts in wastewater) with either organic matter or suspended particulate in the wastewater sample (Urošević and Trivunac 2020) which will yield larger components. The latter will hinder passage through the PES/GQD membrane pores. TDS removal % was recorded to be 64.4% when using CM and 64.12% for M1.

Bacterial content after filtration

The total bacterial content of the wastewater permeate (sampling point 3) was observed visually by incubating the membranes M0 and M1 in LB after use (Fig. 15). In both bacterial tests (total coliform and total bacterial count), the pristine membrane (M0) had significant bacterial growth whereas no visible bacterial growth was observed on M1. The significant reduction in bacterial growth is attributed to the effect of AOPs and GQDs on the wastewater sample in the pre-treatment subsequently followed by PES/GQDs membrane filtration. Several studies have since documented the antimicrobial efficiency of GQDs embedded in polymer matrices (Tshangana et al. 2020; Zeng et al. 2016; Zhang et al. 2019).

Zone of inhibition tests was carried out to evaluate the antibacterial performance of the control membrane (M0), the membrane endowed with GQDs (M1) as well as the commercial membrane denoted as CM (Fig. 16a). As anticipated, the control membrane (M0) exhibited no antibacterial activity. However, compared to CM, the membrane fabricated in this work (M1) had higher the diameters of inhibition zone (diz) and nwhalo of 15.6 and 14.8, respectively. Where the CM recorded a diz of 11.3 and nwhalo of 7.2. To determine the antibacterial rate, quantitative analysis of the antibacterial capability of M0, M1 and CM membranes was carried out and the results are shown in Fig. 16b. The antibacterial rate for the pristine membrane recorded a zero antibacterial rate; however, the other two membranes reached 88% and 71% for M1 and CM, respectively. This was attributed to the modification of the GQDs which increased the antibacterial rate, another critical factor that played a key role in enhancing the antibacterial include the surface roughness, rougher membrane surfaces increase the probability of the E. coli attaching themselves on attachment sites.

Conclusion

PES/GQDs membranes were fabricated using phase inversion method. The fabricated membranes were characterized by high oxygen content and a negative surface charge. The incorporation of the GQDs in the PES matrix increased the oxygen content and further enhanced the hydrophilicity, pore size and porosity of the membrane. The flux of the membranes was improved remarkably. The PES/GQDs membrane had better dye rejection capabilities compared to the pristine membrane. However, the addition of GQDs did not seem to enhance salt rejection. Superior inhibition of E. coli cells was observed coupled with an overall reduction in the total bacterial count and total coliform count. The obtained percentage removals when using the PES/GQDs in the treatment of wastewater were 83.45%, 64.12%, 40.76% and 70.36% for turbidity, total dissolved solids (TDS), total organic carbon (TOC) and electrical conductivity (EC), respectively. Whereas the removal percentages using the commercial membrane were found to be 86.6%, 64.4%, 51.21% and 76.83% for the same operating parameters. The integrated hybrid approach developed in this study was able to pre-treat, separate/filtrate, and disinfect wastewater. This hybrid system presents a “three-in-one concept” which could be modular, flexible, and simple to implement while being effective for application in wastewater processing utilities. Furthermore, this advanced technology can remove recalcitrant pollutants in wastewater and thus, can contribute substantially to the improvement of conventional wastewater treatment plants. The results indicate that this hybrid filtration-advanced technology system can be an alternative to some of the current ineffective traditional wastewater treatment operations.

References

Ali FAA et al (2019) Evaluation of antibacterial and antifouling properties of silver-loaded GO polysulfone nanocomposite membrane against Escherichia coli, Staphylococcus aureus, and BSA protein. React Funct Polym 140:136–147. https://doi.org/10.1016/j.reactfunctpolym.2019.04.019

Arman NZ et al (2021) A review on emerging pollutants in the water environment: existences, health effects and treatment processes. Water 13(22):3258. https://doi.org/10.3390/w13223258

Blenkinsopp SA, Costerton JW (1991) Understanding bacterial biofilms. Trends Biotechnol 9:138–143. https://doi.org/10.1016/0167-7799(91)90045-J

Dadari S, Rahimi M, Zinadini S (2022) Novel antibacterial and antifouling PES nanofiltration membrane incorporated with green synthesized nickel-bentonite nanoparticles for heavy metal ions removal. Chem Eng J 431:134116. https://doi.org/10.1016/j.cej.2021.134116

Dharupaneedi SP et al (2019) Membrane-based separation of potential emerging pollutants. Sep Purif Technol 210:850–866. https://doi.org/10.1016/j.seppur.2018.09.003

Du P, Liu W et al (2018) Oxidation of amino acids by peracetic acid: reaction kinetics, pathways and theoretical calculations. Water ResX 1:100002. https://doi.org/10.1016/j.wroa.2018.09.002

Fan X, Su Y et al (2016) Manipulating the segregation behavior of polyethylene glycol by hydrogen bonding interaction to endow ultrafiltration membranes with enhanced antifouling performance. J Membr Sci 499:56–64. https://doi.org/10.1016/j.memsci.2015.10.026

Frígols B et al (2019) Graphene oxide in zinc alginate films: Antibacterial activity, cytotoxicity, zinc release, water sorption/diffusion, wettability and opacity.". PLoS ONE 14(3):e0212819. https://doi.org/10.1371/journal.pone.0212819

Hamzah S et al (2014) High performance of polysulfone ultrafiltration membrane: effect of polymer concentration. J Eng Appl Sci 9(12):2543–2550

Henao LD, Turolla A, Antonelli M (2018) Disinfection by-products formation and ecotoxicological effects of effluents treated with peracetic acid: a review. Chemosphere 213:25–40. https://doi.org/10.1016/j.chemosphere.2018.09.005

Kang GD, Cao YM (2012) Development of antifouling reverse osmosis membranes for water treatment: a review. Water Res 46:584–600. https://doi.org/10.1016/j.watres.2011.11.041

Kumar S et al (2017) Tunable (violet to green) emission by high-yield graphene quantum dots and exploiting its unique properties towards sun-light-driven photocatalysis and supercapacitor electrode materials. Mater Today Commun 11:76–86. https://doi.org/10.1016/j.mtcomm.2017.02.009

Kumar R et al (2022) A review on emerging water contaminants and the application of sustainable removal technologies. Case Stud Chem Environ Eng 6:100219. https://doi.org/10.1016/j.cscee.2022.100219

Kusuma TD et al (2021) Advanced oxidation processes: a promising route for abatement of emerging contaminants in water. Nanomater Nanocompos Environ Remed. https://doi.org/10.1007/978-981-16-3256-3_12

Ma X et al (2023) 2D lamellar membrane with MXene hetero-intercalated small sized graphene oxide for harsh environmental wastewater treatment. Sep Purif Technol 311:123248. https://doi.org/10.1016/j.seppur.2023.123248

Manawi Y, Kochkodan V, Mahmoudi E et al (2017a) Characterization and separation performance of a novel polyethersulfone membrane blended with acacia gum. Sci Rep 7:1–12. https://doi.org/10.1038/s41598-017-14735-9

Manawi Y, Kochkodan V, Mohammad AW, Atieh MA (2017b) Arabic gum as a novel pore-forming and hydrophilic agent in polysulfone membranes. J Membr Sci 529:95–104. https://doi.org/10.1016/j.memsci.2017.02.002

Marjani A, Nakhjiri AT, Adimi M et al (2020) Effect of graphene oxide on modifying polyethersulfone membrane performance and its application in wastewater treatment. Sci Rep 10:1–11. https://doi.org/10.1371/journal.pone.0236529

Najjar A, Sabri S et al (2019) Enhanced fouling resistance and antibacterial properties of novel graphene oxide-Arabic gum polyethersulfone membranes. Appl Sci 9:513. https://doi.org/10.3390/app9030513

Peydayesh M, Mohammadi T, Nikouzad SK (2020) A positively charged composite loose nanofiltration membrane for water purification from heavy metals. J Membr Sci 611:118205. https://doi.org/10.1016/j.memsci.2020.118205

Ren J, Wang R (2011) Preparation of polymeric membranes. In Membrane and desalination technologies 47–100. Humana Press, Totowa. https://doi.org/10.1007/978-1-59745-278-6_2

Ridgway HF, Rigby MG, Argo DG (1985) Bacterial adhesion and fouling of reverse osmosis membranes. J Am Water Work Assoc 77:97–106. https://doi.org/10.1002/j.1551-8833.1985.tb05574.x

Rosman N, Salleh WNW, Mohamed MA et al (2018) Hybrid membrane filtration-advanced oxidation processes for removal of pharmaceutical residue. J Colloid Interface Sci 532:236–260. https://doi.org/10.1016/j.jcis.2018.07.118

Tshangana CS, Muleja AA, Nxumalo EN et al (2020) Poly (ether) sulfone electrospun nanofibrous membranes embedded with graphene oxide quantum dots with antimicrobial activity. Environ Sci Pollut Res 27:26845–26855. https://doi.org/10.1007/s11356-020-09080-w

Tshangana CS, Muleja AA, Kuvarega AT et al (2021) The applications of graphene oxide quantum dots in the removal of emerging pollutants in water: an overview. J Water Process Eng 43:102249. https://doi.org/10.1016/j.jwpe.2021.102249

Tshangana CS, Muleja AA, Kuvarega AT et al (2022) The synergistic effect of peracetic acid activated by graphene oxide quantum dots in the inactivation of E. coli and organic dye removal with LED reactor light. J Environ Sci Health A 57:268–281. https://doi.org/10.1080/10934529.2022.2056385

Urošević T, Trivunac K (2020) Achievements in low-pressure membrane processes microfiltration (MF) and ultrafiltration (UF) for wastewater and water treatment. In Current Trends and Future Developments on (Bio-) Membranes 67–107. Elsevier. https://doi.org/10.1016/B978-0-12-817378-7.00003-3

van de Witte P et al (1996) Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci 117:1–31. https://doi.org/10.1016/0376-7388(96)00088-9

Winter J, Uhl W, Bérubé PR (2016) Integrated oxidation membrane filtration process-NOM rejection and membrane fouling. Water Res 104:418–424. https://doi.org/10.1016/j.watres.2016.08.024

Yang J, Monnot M, Ercolei L, Moulin P (2020) Membrane-based processes used in municipal wastewater treatment for water reuse: state-of-the-art and performance analysis. Membranes 10:131. https://doi.org/10.3390/membranes10060131

Zeng Z et al (2016) Graphene oxide quantum dots covalently functionalized PVDF membrane with significantly enhanced bactericidal and antibiofouling performances. Sci Rep 6(1):20142. https://doi.org/10.1038/srep20142

Zhang W, Yang Y, Ziemann E et al (2019) One-step sonochemical synthesis of a reduced graphene oxide–ZnO nanocomposite with antibacterial and antibiofouling properties. Environ Sci Nano 6:3080–3090. https://doi.org/10.1039/C9EN00753A

Zhao C et al (2020) Synthesis of graphene quantum dots and their applications in drug delivery. J Nanobiotechnol 18:1–32. https://doi.org/10.1186/s12951-020-00698-z

Acknowledgements

The authors would like to thank the University of South Africa and the Institute for Nanotechnology and Water Sustainability (iNanoWS) for funding.

Funding

Open access funding provided by University of South Africa.

Author information

Authors and Affiliations

Contributions

CT contributed to conceptualization; investigation; methodology; writing—original draft and editing; validation. AM contributed to conceptualization; methodology; writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tshangana, C., Muleja, A. Graphene oxide quantum dots membrane: a hybrid filtration-advanced technology system to enhance process of wastewater reclamation. Chem. Pap. 78, 1317–1333 (2024). https://doi.org/10.1007/s11696-023-03187-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-03187-3