Abstract

It is critical to characterize the degradation products of therapeutic drugs to determine their safety as these degradation products may possess fatal effects on the human physiological system. Favipiravir (FVP), a novel anti-Covid-19 drug, that is recently used all over the world with a great impact on humanity was our target to explore more about its toxicity, the margins of its safety, and its degradants in different degradation conditions. The goal of this study is to identify, characterize, and confirm the structures of FVP oxidative and alkaline breakdown products, as well as to assess their safety utilizing in-vitro SRB cytotoxicity assay on normal human skin fibroblasts (NHSF) cell lines. After oxidative and alkaline degradation of FVP, one degradation product was produced in each condition which was isolated from FVP using flash chromatography, characterized by 1HNMR and LC–MS/MS techniques. A reversed-phase Thermo Fischer Hypersil C18 column (4.6 × 150 mm, 5 m) was used to achieve HPLC chromatographic separation. Acetonitrile-5 mM potassium dihydrogen phosphate (pH 2.5) (50:50, v/v) was employed as the mobile phase, with a flow rate of 1 mL/min. At 332 nm, the column effluent was measured. Over the concentration range of 0.5–100 µg/mL, the calibration curve was linear. The intra-day and inter-day relative standard deviations were less than 2%, and good percentage recoveries were obtained that fulfilled the acceptance criteria of the International Conference on Harmonization (ICH) recommendations. The Plackett–Burman design was used to assess the robustness. Each degradant was isolated single using Flash chromatography and methylene chloride: methanol gradient mobile phase. The chemical structures of the degradation products have been confirmed and compared to the intact FVP using 1H-NMR, and Mass spectroscopy. A postulated mechanism of the degradation process has been depicted and the degradants fragmentation pattern has been portrayed. In addition, the in vitro SRB cytotoxicity assay to evaluate the safety profile of FVP and the degradation end products showed their high safety margin in both conditions with IC50 ˃100 µg/ml with no signs of toxicity upon examination of the treated NHSF cells under the optical microscope

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Favipiravir (FVP) is a novel antiviral drug used as a medication for a pandemic influenza infection in Japan (Furuta et al. 2017). The activation process of a prodrug of FVP was performed by intracellular phosphorylation to the actively favipiravir ribofuranosyl-5B-triphosphate. FVP targeted the prevention of viral replication through selective suppression of RNA-dependent RNA polymerase (RdRp) of influenza viruses (Bai et al. 2016; Tanaka et al. 2017). After numerous clinical trials to evaluate the suitability for potential repurposing of FVR in Covid 19, it was recommended to use FVP as a medication for the treatment of SARS-CoV2 because the selectivity index against SARS-CoV2 was 6.46 (Agrawal et al. 2020; Elfiky, 2021; Ivashchenko et al. 2021).

Degradation of the active ingredients and verification of their acceptable safety limits according to ICH guidelines, are of great importance (CPMP, 2007; ICH Q1A(R2), 2003). Thus, the stability of drug substances and pharmaceutical dosage forms are evaluated and tested under drastic conditions by studying the effect of different factors like heat, pH of the medium, and light to understand the behavior of drug molecules (Blessy et al. 2014). Identification of the degradation products followed by isolation and characterization steps are helpful to predict the degradation mechanism of the drug molecule subjected to various conditions such as hydrolysis, oxidation, and photolysis (Udutha et al. 2021). Furthermore, the toxicity of isolated degradation products can be evaluated by performing in vivo and in vitro toxicity studies (M. A. Mohd Shafiee, 2021; Wang et al. 2002).

After a literature survey, It was found that few analytical methods were reported for estimation of FVP in different matrices using different techniques; spectrophotometric (BULDUK, 2021), spectrofluorimetric (Mikhail et al. 2021) chromatographic (Abdallah et al. 2022; BULDUK, 2021; I. A. Abdallah, 2022; Kaddah et al. 2021; Mikhail et al. 2021; M. I. Morsy et al. 2021; Mosaad I. Morsy et al. 2021), and voltametric methods (Mehmandoust et al. 2021). Although few stability-indicating HPLC methods were previously reported, no comprehensive stability-indicating method with isolation and characterization of the degradation products has been published yet for the quantification of FVP. Moreover, the studied drug was subjected in the reported methods to forced degradation study using different conditions resulting in different degradation pathway.(Gökce, 2021; Lingabathula, 2021; Marzouk et al. 2022; Mosaad I. Morsy et al. 2021).

In the presented work, an attempt has been made to study the oxidative and alkaline degradation products of FVP as per ICH guidelines (ICH Q1A(R2), 2003), isolation, and characterization using flash chromatography and HPLC–MS respectively. Further, based on the MS and 1H-NMR of the obtained degradation products, chemical structures have been elucidated and the degradation mechanism has been predicted. This represents the first study to isolate and characterize the structures of FVP forced degradation products and their safety potential.

Materials and methods

Chemicals and reagents

FVP with a purity of 99.7% was graciously provided by Liptis Pharmaceutical Industries (Cairo, Egypt). Sigma Aldrich provided HPLC-grade methanol, acetonitrile, hydrochloric acid (HCl), sodium hydroxide (NaOH), deuterated chloroform (CDCl3), and deuterated DMSO (DMSO-d6) (St. Louis, MO, USA). J.T. Baker Chemical Co. provided potassium dihydrogen phosphate, phosphoric acid, sodium hydroxide, and hydrogen peroxide (30% w/v) (Phillipsburg, NJ, USA). A MilliQ plus water system filtered distilled water (Millipore; Billerica, MA, USA).

Instrumentation

The DionexUltiMateTM 3000 HPLC (Thermo Scientific, Dionex, Sunnyvale, CA, USA) was used for chromatographic separations. A WPS-3000TSL autosampler, an LPG-3400SD quaternary pump, a VWD-3000 variable wavelength detector, and a TCC-3000SD column thermostat comprise the instrument. Chromeleon 7 software was used to process and collect data.

Isolation of oxidative and alkaline degradation products of FVP was carried out on Flash chromatography apparatus (puriFlash XS 520 Plus) (Interchim, France).

Analyst 1.6.3 software was used to collect the mass spectrometric data. For MS scans to identify FVP and its degradation products (FDP1 & FDP2), the following operating source conditions were optimized: 20 psi curtain gas, 5500 V ion spray voltage, 500 °C temperature, 30 V declustering potential, 20 psi ion source gas 1 (GS 1), 20 psi ion source gas 2 (GS 2) The primary nebulizer gas was air, while the secondary gas was nitrogen.

The 1H-NMR analysis was carried out on a 400 MHz NMR spectrometer (Bruker, Fällanden, Switzerland) with DMSO-d6 as a solvent. The chemical shifts are expressed as % of TMS (= 0.00 ppm) as the internal standard.

BMG LABTECH- FLUOstar Omega (Ortenberg, Germany) microplate reader was used to measure the absorbance at 540 nm in the cytotoxicity experiment.

HPLC chromatographic conditions

A Thermo Fischer Hypersil C18 column was used to achieve chromatographic separations (150 × 4.6 mm, 5 mm). At a flow rate of 1 mL/min, the mobile phase was made up of (A) acetonitrile and (B) 5 mM potassium dihydrogen phosphate (pH = 2.5) (A: 50, B: 50, v/v). FVP and its degradation products were determined using a 323 nm detection wavelength and a 10 µL injection volume. All the chromatograms were taken at 30 °C.

Forced degradation study

The forced deterioration testing was conducted in methanol at a concentration of 1 mg/mL. The drug was alkaline hydrolyzed by placing it in a boiling water bath kept at 100 °C for 2 h after being treated with 1 M sodium hydroxide. The drug was oxidatively degraded by immersing it in a boiling water bath at 100 °C for 2 h after being treated with 10% hydrogen peroxide.

Preparation of samples for chromatographic analysis

To produce the required assay values of 100 µg/mL, the samples from the alkaline and oxidative hydrolysis stress tests were neutralized and diluted with methanol. Before HPLC analysis, the final sample solutions were filtered through a 0.45 µm membrane. To avoid degradation, all sample solutions were kept in a refrigerator at 4 °C.

Method validation

As indicated in the ICH recommendations Q2 (R1) (ICH Q1A(R2), 2003), the suggested chromatographic technique was validated in terms of selectivity, the limit of detection (LOD), the limit of quantification (LOQ), linearity, accuracy, precision, and robustness (R1).

Isolation of degradation products

A flash chromatography apparatus (puriFlash XS 520 Plus) was used for the isolation of the degradation products (FDP) of FVP using a normal phase silica gel column (12 g 30 mm) and methylene chloride/methanol gradient. The FDP mixture is composed of one degradation product (FDP1) and the drug FVP from the oxidative degradation and another mixture from the alkaline degradation consists of one degradation product (FDP 2) and FVP. Both mixtures were introduced to flash chromatography separately with a mobile phase composed of methylene chloride/methanol gradient. The flow rate was set at 15 mL/min and fractions 3 mL each collected where the two degradation products (FDP 1) and (FDP 2) were isolated in pure form at polarity (9.5: 0.5) methylene chloride/methanol of the mobile phase. The two degradants were obtained in a pure form as solids after being collected separately, concentrated and the mobile phase removed (Ahmed et al. 2020).

Cell culture

Normal Human Skin Fibroblasts (NHSF) cell line was obtained from Nawah Scientific Inc., (Mokatam, Cairo, Egypt). Cells were maintained in DMEM media supplemented with 100 mg/mL of streptomycin, 100 units per mL of penicillin, and 10% of heat-inactivated fetal bovine serum in humidified, 5% (v/v) CO2 atmosphere at 37 °C.

Cytotoxicity assay

Cell viability was assessed by SRB assay. Aliquots of 100 ml cell suspension (5 × 103 cells) were in 96-well plates and incubated in complete media for 24 h. Cells were treated with another aliquot of 100 mL media containing (FVP, FDP 1, FDP 2, and doxorubicin as positive control) at various concentrations ranging from (0.01, 0.1, 1, 10, 100 mm). After 72 h of drug exposure, cells were fixed by replacing media with 150 mL of 10% TCA and incubated at 4 1C for 1 h. The TCA solution was removed, and the cells were washed 5 times with distilled water. Aliquots of 70 mL SRB solution (0.4% w/v) were added and incubated in a dark place at room temperature for 10 min. Plates were washed 3 times with 1% acetic acid and allowed to air-dry overnight. Then, 150 mL of TRIS (10 mM) was added to dissolve the protein-bound SRB stain; the absorbance was measured at 540 nm using a microplate reader. The percentage of cell viability was calculated by using the following formula (Basiouni et al. 2020):

Results and discussion

HPLC method development and optimization

The chromatographic technique was created by choosing a mobile phase and a stationary phase that were both adequate for separating FVP from its degradation products. To determine chromatographic conditions ideally suited to the structural properties of FVP, preliminary tests were undertaken using a C18 column (150 × 4.6 mm, 5 mm) and attempting several mobile phases with varied polarity. Water as the aqueous phase was not suited since the peak shape and symmetry were unsatisfactory, thus a mobile phase with a high proportion of an organic modifier was used. The form and symmetry of the peaks were then improved by screening potassium dihydrogen phosphate buffers at various concentrations (10–50 mM) and pH values (3–5).

Peak tailing was seen when using low concentrated phosphate buffers, however, the pH 2.5 buffer worked well since the pH was significantly lower than the pKa of FVP (pKa = 5.1). Following UV scanning of the drug solution, FVP was discovered at 332 nm, which was reported as the wavelength of maximum absorbance (max) (Fig. 1). Acceptable peak shapes and resolution between FVP and its degradation products were observed using isocratic elution as described under chromatographic conditions, and the chromatograms shown in Fig. 2 were acquired using the optimized conditions for FVP separation from its alkaline and oxidative degradation products. In the presence of FVP degradation products, Table 1 illustrates the results of system suitability parameters for FVP.

Forced degradation study

According to ICH regulations, FVP 's degradation behavior was investigated, and the drug was discovered to be unstable under oxidative and alkaline circumstances.

All degradation samples were neutralized, as in alkaline hydrolysis, or left to bubble off the remaining hydrogen peroxide. Before HPLC injections, all samples were diluted with the mobile phase. All these steps demonstrate that the degradation products isolated on the HPLC chromatograms were degradants rather than residual reagent peaks. Furthermore, the existence of degradation products in the sample was confirmed by using Flash Chromatography followed by TLC to isolate them as single compounds.

When FVP was subjected to oxidative degradation, one degradation product (FDP 1) was detected using HPLC – UV. Under alkaline hydrolysis, one degradation product (FDP2) was also produced.

Method validation

Linearity

From the standard FVP solution, solutions at six different concentrations were generated, and a calibration curve was built by graphing the peak regions as a function of concentration. As indicated in Table 2, the regression equation was Y = 0.4434 X + 0.153, and the correlation coefficient was 0.9994, suggesting that the suggested approach is linear.

Precision

By assessing solutions of three distinct concentrations on the same day and three consecutive days, the repeatability (intra-day) and intermediate precision (inter-day) were determined. Relative standard deviations were under 2%. (Table 2). As a result, the procedure was deemed accurate enough.

Accuracy

Spiking FVP into synthetic solutions with degradation products at three different concentrations (2, 20, and 80 µg/mL) in triplicate were used to test the method's accuracy. Then, for each of these three FVP concentrations, compute the % recoveries (Table 2). Recoveries of a reasonable percentage were achieved (between 98 and 101 percent). As a result, the established approach for detecting stability is precise.

Specificity

Three laboratory-prepared mixes of the oxidative and alkaline degradation products (FDP1 & FDP2) with known amounts of the intact medication inside the linear area were analyzed to determine selectivity. The degradation products and intact FVP did not interact with each other.

Detection limit (LOD) & quantitation limit (LOQ)

Table 2 shows that the LOD and LOQ, respectively, are 0.037 and 0.122 g/mL.

Robustness

The robustness of the approach was evaluated using Plackett-design. Burman's Small variations from the procedure conditions were investigated, and the resulting reactions were noted. Table 3 shows the results of eleven randomized runs with three center points. At p values less than 0.5, all parameters were determined to be non-significant, and the coefficient plot (Fig. 3) verified the non-significance of these factors in terms of theoretical plates and FVP selectivity.

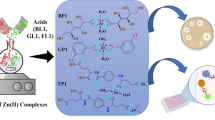

Characterization of degradation products

At the inception, intact FVP has been confirmed by 1H-NMR and Mass spectroscopy. In the 1H-NMR spectrum, four protons have been detected at δH 13.37 (singlet for 1H), 8.72 (singlet for 1H), and 8.50 (doublet for 2Hs) ppm of cyclic NH, aromatic H, and NH2 respectively. Besides, ESI–MS has revealed the protonated molecule at 158 m/z in the positive mode and 156 m/z in the negative mode which was attributed to [M + 1]+ and [M-1]+ of FVP respectively (Fig. 4).

In the alkaline conditions, FVP was converted to the depicted structure in (Fig. 4) firstly, the acidic proton was abstracted by alkali to afford the charged phenoxide structure (I) followed by the alkaline hydrolysis of the amide to the corresponding acid (II) as reported (Lopez et al. 2003). The afforded acid was then decarboxylated under the effect of the alkali and heating (Diefallah, 1979; Mohammed Farrag El-Behairy and Sundby, 2013) to afford compound III. Then, compound III attached its resonance structure to afford the alkaline degradant IV. Compound IV (alkaline degradant) showed 227 m/z in ESI–MS analysis that corresponding to molecular ion peak [M + 1]+. The 1H-NMR spectrum revealed the presence of four singlet signals (each for 1H) that were noticeable in the aromatic region at δH 8.30, 7.55, 7.42, and 7.29 ppm.

For the oxidative degradation, as depicted in (Fig. 5), all protons, at positions 4, and 5 of FVP have been oxidized to OH. While NH2 of carboxamide at position 2 converted to NO2. In addition, N-oxide has been formed from nitrogen at position 1. The postulated structure has been confirmed by 1H-NMR and Mass spectroscopy (Figs. 6, 7, 8, 9 and 10). In the 1H-NMR of the oxidative degradant, all characteristic signals of FVP have disappeared while two broad singlet signals were detected at δH 8.25, 7.37 ppm that are corresponding to both OHs at position 4 and 5. In ESI–MS, a molecular ion peak at 235 m/z was observed that represents [M]+.

Cytotoxicity assay

Sulforhodamine B (SRB) cytotoxicity testing is one of the most often used in vitro procedures for predicting a substance's potential toxicity in cell culture. In cell-based investigations, SRB is a sensitive and repeatable test for cytotoxicity. In slightly acidic circumstances, SRB binds stoichiometrically to protein components of cells fixed to tissue culture plates. The dye is then removed from stained cells and quantified using a colorimetric assay in basic conditions. The colorimetric analysis yields a total protein mass estimate that is proportional to the number of cells present. FVP and its breakdown products (FDP 1 and FDP 2) were tested in vitro against NHSF cell lines to determine their potential toxicity and/or safety (Ahmed et al. 2020; Mohammed F. El-Behairy et al. 2021). The effect of these chemicals on the viability and proliferation of the NHSF cell line was assessed using the SRB assay, as well as photos taken with an optical microscope to detect any morphological changes on the examined cells. After 72 h of incubation, the percentage of cell viability was assessed at five different doses (0.01. 0.1, 1, 10, and 100 µg/ml) in comparison to doxorubicin, a typical cytotoxic agent. For the oxidative and alkaline degradation products (FDP1 & FDP2), cell viability reached 100% at concentrations of 0.01 mM. Favipiravir, FDP 1, and FDP 2 at two concentration levels (0.1 and 100 µg/ml) were compared to doxorubicin at the same concentration levels, as shown in (Fig. 11). It clearly reveals that at 0.1 and 100 mM of FVP, FDP 1, and FDP 2 (IC50 = ˃ 100 µg/ml), no morphological alterations occur (Fig. 12). This demonstrates that FVP and its breakdown products are non-toxic at concentrations more than 100 µg/ml.

Conclusion

Favipiravir, its oxidative and alkaline degradation products (FDP1 & FDP2) were separated using HPLC – UV on a reversed-phase Eclipse XDB C18 column (4.6 150 mm, 5 mm) using isocratic mode with a flow rate of 1 mL/min and detected at 332 nm. The method was validated according to the ICH guidelines and was linear over the concentration range of 0.5 to 100 µg/mL. In vitro evaluation of FVP and the produced degradants showed no cytotoxicity effect on normal skin fibroblasts cell lines with IC50 ˃100 µg/ml with no signs of toxicity upon examination of the treated NHSF cells under the optical microscope.

Abbreviations

- DOE:

-

Design of experiment

- FVP:

-

Favipiravir

- FDP1:

-

Oxidative degradation product

- FDP2:

-

Alkaline oxidative product

- HPLC:

-

High-performance liquid chromatography

- ICH:

-

International conference on harmonization

- LOD:

-

Detection limit

- LOQ:

-

Quantitation limit

- NHSF:

-

Normal skin fibroblasts cell lines

- TLC:

-

Thin layer chromatography.

References

Abdallah IA, S. F. H., A. Bedair, A. H. Elshafeey and F. R. Mansour, (2022) Menthol-assisted homogenous liquid-liquid microextraction for HPLC/UV determination of favipiravir as an antiviral for COVID-19 in human plasma. Bioanalysis 14:205–216

Abdallah IA, Hammad SF, Bedair A, Mansour FR (2022) Menthol-assisted homogenous liquid-liquid microextraction for HPLC/UV determination of favipiravir as an antiviral for COVID-19 in human plasma. J Chromatogr B 1189:123087. https://doi.org/10.1016/j.jchromb.2021.123087

Agrawal U, Raju R, Udwadia ZF (2020) Favipiravir: A new and emerging antiviral option in COVID-19. Med J Armed Forces India 76(4):370–376. https://doi.org/10.1016/j.mjafi.2020.08.004

Ahmed RM, Fayed MAA, El-Behairy MF, Abdallah IA (2020) Identification, isolation, structural characterization, in silico toxicity prediction and in vitro cytotoxicity assay of simeprevir acidic and oxidative degradation products. RSC Adv 10(70):42816–42826. https://doi.org/10.1039/D0RA09253C

Bai CQ, Jin-Song Mu, Kargbo D, Song YB, Niu WK, Nie WM, Kanu A, Liu WW, Wang YP, Dafae F, Yan T, Yi H, Deng YQ, Hui-Jun L, Yang F, Zhang XG, Sun Y, Cao YX, Hao-Xiang S, Sun Y, Liu WS, Wang CY, Qian J, Liu L, Wang H, Tong YG, Liu ZY, Chen YS, Wang HQ, Kargbo B, Gao GF, Jiang JF (2016) Clinical and virological characteristics of Ebola Virus disease patients treated with favipiravir (T-705)—Sierra Leone, 2014. Clin Infect Dis 63(10):1288–1294. https://doi.org/10.1093/cid/ciw571

Basiouni S, Fayed MAA, Tarabees R, El-Sayed M, Elkhatam A, Töllner KR, Hessel M, Geisberger T, Huber C, Eisenreich W, Shehata AA (2020) Characterization of sunflower oil extracts from the lichen usnea barbata. Metabolites 10(9):353. https://doi.org/10.3390/metabo10090353

Blessy M, Patel RD, Prajapati PN, Agrawal YK (2014) Development of forced degradation and stability indicating studies of drugs-A review. J Pharm Anal 4(3):159–165. https://doi.org/10.1016/j.jpha.2013.09.003

BULDUK, I. (2021) HPLC-UV method for quantification of favipiravir in pharmaceutical formulations. Acta Chromatogr 33:209–215

CPMP. (2007). Eur Med. Agency Insp: 1–8

Diefallah E-HM (1979) Notizen: Kinetics of the alkaline decarboxylation of trichloroacetate ion in water - ethanol solutions. z Für Naturfor B 34(5):744–745. https://doi.org/10.1515/znb-1979-0519

El-Behairy MF, Sundby E (2013) Synthesis of the antiepileptic (R)-Stiripentol by a combination of lipase catalyzed resolution and alkene metathesis. Tetrahedron Asym 24(5–6):285–289. https://doi.org/10.1016/j.tetasy.2013.02.006

El-Behairy MF, Ahmed RM, Fayed MAA, Mowafy S, Abdallah IA (2021) Insights into flibanserin oxidative stress degradation pathway: in silico – in vitro toxicity assessment of its degradates. New J Chem 45(5):2620–2630. https://doi.org/10.1039/D0NJ05548D

Elfiky AA (2021) SARS-CoV-2 RNA dependent RNA polymerase (RdRp) targeting: an in silico perspective. J Biomol Struct Dyn 39(9):3204–3212. https://doi.org/10.1080/07391102.2020.1761882

Furuta Y, Komeno T, Nakamura T (2017) Favipiravir (T-705), a broad spectrum inhibitor of viral RNA polymerase. Proc Jpn Acad Ser B Phys Biol Sci 93(7):449–463. https://doi.org/10.2183/pjab.93.027

Gökce S, Höl A, Bulduk I (2021) Development and validation of UPLC-MS / MS method for obtaining favipiravir tablet dosage form and evaluation of its behavior under forced conditions. J Pharm Res Int 33(56A):130–140. https://doi.org/10.9734/jpri/2021/v33i56A33895

ICH Q1A(R2). (2003). Ich Harmon. Tripart. Guidel., 4, 24.

Ivashchenko AA, Dmitriev KA, Vostokova NV, Azarova VN, Blinow AA, Egorova AN, Gordeev IG, Ilin AP, Karapetian RN, Kravchenko DV, Lomakin NV, Merkulova EA, Papazova NA, Pavlikova EP, Savchuk NP, Simakina EN, Sitdekov TA, Smolyarchuk EA, Tikhomolova EG, Yakubova EV, Ivachtchenko AV (2021) AVIFAVIR for treatment of patients with moderate coronavirus disease 2019 (COVID-19): Interim results of a phase II/III multicenter randomized clinical trial. Clin Infect Dis 73(3):531–534

Kaddah MMY, Talaat W, El Demellawy MA (2021) Determination and structural characterization of ravidasvir metabolites by LC coupled to triple quadrupole linear ion trap MS: Application to pharmacokinetics and phase I metabolism in rats. Biomed Chromatogr 35(9):e5146. https://doi.org/10.1002/bmc.5146

Lingabathula S, Jain N (2021) STABILITY Indicative And Cost Effective Analytical Method Development And Validation Of Favipiravir And Peramivir In Bulk And Pharmaceutical Dosage Form By UsiNG RP-Hplc. Int J Appl Pharm 13(4):265–271

Lopez X, Mujika JI, Blackburn GM, Karplus M (2003) Alkaline hydrolysis of amide bonds: effect of bond twist and nitrogen pyramidalization. J Phys Chem A 107(13):2304–2315. https://doi.org/10.1021/jp022014s

Marzouk HM, Rezk MR, Gouda AS, Abdel-Megied AM (2022) A novel stability-indicating HPLC-DAD method for determination of favipiravir, a potential antiviral drug for COVID-19 treatment; application to degradation kinetic studies and in-vitro dissolution profiling. Microchem J 172:106917. https://doi.org/10.1016/j.microc.2021.106917

Mehmandoust M, Khoshnavaz Y, Tuzen M, Erk N (2021) Voltammetric sensor based on bimetallic nanocomposite for determination of favipiravir as an antiviral drug. Mikrochim Acta 188(12):434. https://doi.org/10.1007/s00604-021-05107-2

Mikhail IE, Elmansi H, Belal F, Ehab Ibrahim A (2021) Green micellar solvent-free HPLC and spectrofluorimetric determination of favipiravir as one of COVID-19 antiviral regimens. Microchem J 165:106189. https://doi.org/10.1016/j.microc.2021.106189

Mohd Shafiee MA, M. A. M. A. a. S. S. S. A. (2021) Review on the In vitro cytotoxicity assessment in accordance to the international organization for standardization (ISO) Malaysian. J Med Heal Sci 17:261–269

Morsy MI, Nouman EG, Abdallah YM, Zainelabdeen MA, Darwish MM, Hassan AY, Gouda AS, Rezk MR, Abdel-Megied AM, Marzouk HM (2021) A novel LC-MS/MS method for determination of the potential antiviral candidate favipiravir for the emergency treatment of SARS-CoV-2 virus in human plasma: Application to a bioequivalence study in Egyptian human volunteers. J Pharm Biomed Anal 199:114057. https://doi.org/10.1016/j.jpba.2021.114057

Tanaka T, Kamiyama T, Daikoku T, Takahashi K, Nomura N, Kurokawa M, Shiraki K (2017) T-705 (Favipiravir) suppresses tumor necrosis factor α production in response to influenza virus infection: A beneficial feature of T-705 as an anti-influenza drug. Acta Virol 61(1):48–55. https://doi.org/10.4149/av_2017_01_48

Udutha S, Borkar RM, Shankar G, Sony T, Aishwarya Jala E, Vamshi Krisna T, Kiran Kumar S, Misra S, Prabhakar RS (2021) Stress degradation study of bortezomib: effect of co-solvent, isolation and characterization of degradation products by UHPLC-Q-TOF-MS/MS and NMR and evaluation of the toxicity of the degradation products. New J Chem 45(18):8178–8191. https://doi.org/10.1039/D0NJ05781A

Wang K, Shindoh H, Inoue T, Horii I (2002) Advantages of in vitro cytotoxicity testing by using primary rat hepatocytes in comparison with established cell lines. J Toxicol Sci 27(3):229–237. https://doi.org/10.2131/jts.27.229

Acknowledgements

The authors would like to thank Liptis Pharmaceutical Industries (Cairo, Egypt) for providing the Favipiravir to conduct this study, and the Faculty of Pharmacy, University of Sadat City, Sadat City 32897, Egypt, for supporting the run of this work in their labs.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). No fund.

Author information

Authors and Affiliations

Contributions

All authors shared Conceptualization; Data curation; Formal analysis; Funding acquisition; Investigation; Methodology; Project administration; Resources; software; Supervision; Validation; Visualization; Roles/Writing – original draft; Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdallah, I.A., El-Behairy, M.F., Ahmed, R.M. et al. The anti-COVID-19 drug Favipiravir: Degradation, Method development, Validation, NMR/LC–MS characterization, and In-vitro safety evaluation. Chem. Pap. 76, 6415–6426 (2022). https://doi.org/10.1007/s11696-022-02327-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-022-02327-5