Abstract

Online control of industrial processes by lean principle increases productivity and yields higher product quality. Polysaccharides are dissolved in liquids, such as water, in many industrial products, like paints, cosmetics and culinary products. In these products, it is important to control viscosity or create thixotropy and yield stress for product functionality. Electromagnetic field and electrical conductivity techniques were applied to a meter polysaccharide dissolution process online up to a 0.5 wt% concentration, and the resultant solution was also further tested by UV–Vis spectrophotometry. The electromagnetic field technique measures changes in the local electrical permittivity of the liquid and the interest in this research were to find out whether the changes correlate to the concentration changes during the dissolution of polymer polysaccharide. The results that were obtained showed good consistency, suggesting the feasibility of the electromagnetic field technique in online monitoring of a polysaccharide suspension concentration. Moreover, this technique gives the advantage of instant monitoring of a polysaccharide dissolution for improved process control.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Concentration metering of solutions is crucial in most industrial processes, but also particularly important in many areas such as environmental engineering, bioengineering and chemical engineering. In these applications, the interest may be in dosing the right amount of chemical in the manufacturing process, reporting the correct amount of a controlled substance to the end user, or the metering of harmful or toxic environmental substances for life-preserving purposes (Babick 2016; Lepot 2016; Cilliers 2011). For many applications, it is beneficial to perform the metering in situ and have the results online to get valuable information of different characteristics, such as the dissolution state, in process control for a faster response. Typically, dissolution is considered to be a process in which bulk solid material is disintegrated into liquid followed by concentration homogenization over the entire volume, and online monitoring of this would be beneficial for better process control.

Rheology modifiers are a group of additives which control the flow and workability properties of a fluid and are important in several industrial sectors such as the chemical industry, food industry, paper industry, oil recovery, drug delivery and agrochemical industry (Tadros 2013). A widely used type of such additives is polysaccharides, natural polymers which can be used as shear-thinning rheology modifiers in usually up to 1 wt% concentrations, after which they become gel-like. This concentration increases the viscosity significantly and is typically used in pharmaceutical and cosmetic products. Polysaccharides are renewable and nontoxic materials that are widely used in the food industry, pharmaceutics and cosmetics, and in a limited scope in other industries as well. Commercially used polysaccharides are often cellulose based organic compounds, such as methyl and hydroxymethyl cellulose, sodium alginate and different gums, such as guar gum and xanthan gum (Garcı́a-Ochoa 2000; Tadros 2013; Sworn 2009; Mishra 2009; Zohuriaan 2004). Most polysaccharides can be dissolved in cold or hot water-based systems, and in these systems, the concentration of polysaccharide dictates the rheology of the system (Sworn 2009; Guo 2017). In readily dissolved polysaccharides, the Gibbs free energy of dissolution reaction is negative, which means that dissolution occurs spontaneously (Koenig 2003).

At the beginning of the dissolution process, solid surfaces are wetted, then solute reacts with the material at the solid surface, molecules are removed from the surface, and the concentration in the solution is levelled by diffusion and convection. The Noyes–Whitney approach for modelling the dissolution rate has been used in several studies since 1897 (Hattori 2013; Dokoumetzidis 2006; Siepmann 2013):

where \(dm\) is the amount of dissolved substance during time \(dt\), \(K\) a constant, \(S\) surface area available for wetting, i.e. dissolution, \(c_{s}\) solution concentration at the surface boundary layer (solubility) and \(c_{t}\) concentration in the bulk solution. Often the increase of \(c_{t}\) is assumed to be negligible and the bulk volume where dissolution occurs is an infinite volume called the "sink". In a specified solute volume, the dissolution rate gradually decreases as \(c_{t}\) approaches \(c_{s}\) until all material is dissolved, provided that the solubility limit is not reached. It is, thus, generally agreed that the concentration gradient \(\left( {c_{s} - c_{t} } \right)\) is the main driving force for dissolution.

Nernst and Brunner later modified the theory by applying Fick’s first law of diffusion to Noyes–Whitney approach. In this theory, the driving force for dissolution is dependent on the diffusion coefficient (\(D\)) near stagnant unmixed boundary layer and the thickness of the dissolved boundary layer (\(\delta\)), as well as the concentration gradient \(\left( {c_{s} - c_{t} } \right)\) according to: (Siepmann et al. 2013)

This is the case for an unmixed solution; however, in practical cases the boundary layer thickness \(\delta\) is often decreased by forced convection over a solute particle (mixing), which speeds up the dissolution rate.

Viscosity, especially in the case of polymer solutions, is dependent on both the temperature and concentration. The former may exhibit strongly nonlinear behaviour, especially in more complex polymers, such as block copolymers (Safronov 2019), whereas the latter exhibits typically exponential dependency with an upper limit (Chirife 1997). The concentration dependency at low concentrations (<0.5 wt%) is, however, often close to linear.

The dependency of temperature and viscosity on diffusion coefficient \(D\) for dilute systems can be evaluated by Stokes–Einstein equation: (Tadros 2013)

where \(k\) is the Boltzmann constant, \(T\) absolute temperature, \(\eta\) the dynamic viscosity of the medium and \(R\) the effective radius of a spherical solute particle. By increasing the temperature, diffusion can be accelerated and, on the other hand, increasing medium viscosity decreases the diffusion coefficient. Also decreasing the effective radius of a solute particle increases the diffusion coefficient. Equation 3 applies for diffusion of particles in a liquid with a low Reynolds number (unmixed case). Some more sophisticated consideration methods for modelling of the dissolution process in respect of viscosity and temperature have also been reported (Costa 2001; Koenig et al. 2003).

Electromagnetic field (EMF) technique has been successfully employed for the detection of ceramic particle solids loading. This method was discovered to be capable of detecting the introduction of surface-active agents (dispersants) and colloid particles to ceramic slurry while it was mixed. In this method, the complex permittivity of the suspension is calculated from the energy loss in an induced EMF, and from that the type and amount of additives could be accurately determined. This technique is described in more detail in the work by Salpavaara (2015). The introduction of a small amount of a dispersant can be considered as a dissolution process, and thus, the EMF technique is highly suitable for following the dissolution process, as shown in the present work.

Dielectric measurements are widely used in polymer processing where polymers and composites are surveyed by metering dielectric properties (Xu 2018; de Andrade Raponi 2018). The dielectric response of concentration metering has been studied in Hou (2018). Different types of apparatus for studies of dissolution have been studied in Uddin (2011).

Electrical conductivity measurement has been applied in monitoring the electrolyte concentration in solutions such as hydrocolloid solutions with variable concentrations (Wu 2018; Ghaouar 2017; Marcotte 1998). The solubility of polysaccharides in aqueous solutions is good and studies of concentrations up to 6 wt% have been published (Razavi 2012).

The electric conductivity of ionic solutions is dependent on the number of dissolved anions or cations and temperature. Typically, an increase in ion concentration increases the electrical conductivity as the number of charge carriers increases, while the increase in electrical conductivity with temperature is due to the increased mobility of those charge carriers (Hayashi 2004).

Environmental and water purification processes have been studied extensively over the past years. Stoller (2018), Vilardi (2020a, b) UV–Vis spectroscopy is a widely used method to detect and quantify dissolved substances in water-based systems, and it is widely used in studies of controlled drug release into human metabolism, where the release of active agents is monitored to obtain optimal release rates (Costa et al. 2001). UV–Vis spectroscopy is based on Beer–Lambert’s law of absorption, where electromagnetic radiation within the ultraviolet or visible wavelengths passes through the sample with a known optical path length. The concentration of a dissolved substance can be calculated from the results of absorbance peaks at a characteristic wavelength of the dissolved substance, and the intensity of the absorbance peak is related to the solution concentration (Braeuer 2015; Jing 2005; Wypych 2013). UV–Vis spectroscopy has also been applied in online monitoring of water and wastewater treatment plants, with a sampling frequency of 1 min (Örmeci 2014). In this case, a side stream from the process was used for UV–Vis analysis, and the response time of the monitoring is dependent on the flow rate of this stream. Therefore, the information obtained from such monitoring is not real time and might be too slow for certain events in processes.

Other methods for metering concentrations of dissolved chemicals are various chromatographic techniques, such as liquid chromatography, high- or ultra-high performance liquid chromatography, gas chromatography and other spectroscopic techniques, such as nuclear magnetic resonance spectroscopy (NMR), and mass spectrometry, which can readily be combined with the latter chromatographic techniques (Örmeci et al. 2014). Although they can provide highly accurate results and are among the best methods to identify chemical substances, they require sample collection and separate runs, making them slow in comparison with online techniques. Another simple method to observe the dissolution of carbohydrate polymer is polarizing microscope (Lan 2011). This is a method for the visual observation of a dissolution state. Electrical conductivity and UV–Vis techniques were selected in our experiments as comparative methods because they are widely used methods with readily available equipment.

Experimental

The objective of this research work was to monitor online a polysaccharide dissolution process in water. It was done by comparing online electromagnetic field (EMF) and electrical conductivity measurements, with the experiment repeated thrice. The measurements were all further put to the test when the initial concentration was varied by dilution. UV–Vis data were collected as a quantification reference for the initial polysaccharide solution and also for each dissolution step.

The EMF measurements were conducted with ColloProbe (v1.0-0101) by ColloidTek Ltd, which meters the liquid’s complex permittivity in real time (Järveläinen 2015). The probe was immersed in the measured liquid, where it provided two variables: CIV (Collo Ion Viscosity) and CP (Collo Permittivity). The CIV was best suited to study the dissolution state, and a moving median of 10 was used to smoothen the data. The data transfer from the ColloProbe device to computer were digital.

For comparison, an electrical conductivity meter (Consort C 3010 analyser with SK20T sensor) was used next to ColloProbe in the online experiments. After the initial addition of polysaccharide, and each subsequent dilution, an UV–Vis spectrophotometer (Hitachi U-5100) was used for measuring the attained concentration of the polysaccharide. The measurements conducted and experiment procedures are shown in Fig. 1.

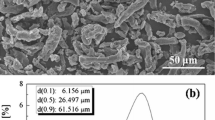

The investigated material was a free-flowing solid polysaccharide (PS) polymer powder, with molecular formula (C35H49O29)n and particle size d95 = 180 µm and d100 = 250 µm. The nature of this material is a polymer with an anionic charge on polymer side chains (Sworn 2009). It was dissolved by adding the powder slowly into deionized water to obtain a PS concentration 0.500 wt%.

The experimental set-up consisted of an impeller type mixer (IKA Eurostar 20 with a four-blade mixer) in the bottom of a vessel, and the measuring devices were located high enough to not get interference from the mixer. The mixing vessel was a VWR 2000-ml cylindrical plastic beaker with sample volume ~1830 ml. The mixer blade was placed 5 cm up from the bottom of the vessel. The EMF measuring probe was placed about 6 cm above the mixing blade facing away from the mixing blade shaft. The sampling set-up remained the same during all the experiments. The mixing vessel was covered by a cardboard plate during testing to reduce water vaporization. The PS/water mixture was mixed gently at 250 rpm to avoid foaming. The dosing of PS was performed manually within a few minutes by using a small spoon. After the addition of PS, some irregularly shaped lumps, “fisheyes”, with a diameter of a few centimetres were formed. These lumps of PS contained air which created some foam in the solution.

The measuring volume for ColloProbe extends up to 5 cm in every direction, but it decreases radially. It was made sure that there was nothing else, i.e. no stirrers, other probes or surface, except for the measured solution within this volume. The measuring interval in an online measurement was 5 s for CIV and 10 s for electrical conductivity, respectively. After a total mixing time of 66 h, the impeller was moved up and down a few times to smoothen the solution.

After the online dissolution experiment, the CIV and conductivity were measured again for a few minutes to obtain the result for PS concentration 0.500 wt%. This solution was further diluted with deionized water to 0.25, 0.125 and 0.0625 wt% concentrations. Deionized water was used as 0 wt% sample.

The diluted samples were then measured by ColloProbe, Consort C 3010 analyser and Hitachi U-5100 spectrophotometer to detect CIV, electrical conductivity and absorbance, respectively. The solution sample size for ColloProbe and conductivity measurements were 1800 g, and for UV–Vis measurement the solution volume was 2.5 ml. Conceivable foam and air inclusions in the samples were removed by allowing the mixed sample to settle for a few minutes. For ColloProbe and electrical conductivity, the sample concentration measurements were conducted by mixing the diluted sample for a few minutes followed by a short online measurement. The measurement collected data for a few minutes, during which the solution was not mixed. The median of the measurements was taken as a final value.

In spectrophotometry, the absorbance of PS as a function of wavelength was measured to detect the maximum peak of absorption. Once the maximum peak of absorption was detected, it was possible to calculate a correlation curve of the absorption as a function of concentration. When the concentration of the solution is the only variable, the absorption at peak wavelength approaches linearity when absorption/concentration diagram is plotted (Braeuer 2015). Deionized water was used to obtain a baseline in spectrophotometric measurements. The scanning speed was 400 nm/min, the sampling interval 2 nm and the slit width 5 nm. Rectangular integration was used in peak detection with a sensitivity of 1 and a threshold of 0.01. No software smoothing was used in the calculation of absorption spectra. Quartz cuvettes (type QS provided by Hellma) with an optical path of 10 mm were used and absorption was measured at wavelengths of 190–1100 nm.

Results and discussion

The online dissolution experiments were conducted during an extended period of 66 h. This was done to test the equipment and set-up for any long-term effects. However, the observed changes in measurands occurred right at the beginning, particularly during the first 30 min, so only that part was used in further analysis. The CIV and electrical conductivity curves for three dissolution online experiments for the first 30 min are shown in Figs. 2 and 3, respectively. The starting time 0:00 was the process step when the dosing of polysaccharide (PS) begun, and it was finished a few minutes later.

In general, the measured CIV and electrical conductivity result trends were quite similar. During the first 10 min, the CIV and electrical conductivity values increased in all three measurements with a steep slope followed by a levelling of the measured signal after 16 min. It is worth noting that the magnitude of the driving force is changing during dissolution due to the concentration gradient \(\left( {c_{s} - c_{t} } \right)\) (Eqs. 1 and 2). The addition of PS was performed over several minutes, and the available surface area was, thereby, increased. However, the increment of the available surface area could be somewhat unclear because of PS lumping. The dissolution rate during the first five minutes was high and quite constant, and once all PS powder was dissolved, the measured CIV and conductivity values levelled. Overall, it can be stated that the dissolution process followed the presented theories with reasonable accuracy.

It is also worth noting that the solubility limit for PS was not reached in the solution and the concentration gradient \(\left( {c_{s} - c_{t} } \right)\) remained relatively high. The forced convection caused by mixing also decreased the boundary layer thickness \(\delta\), (Eq. 2) which enhanced the dissolution of PS particles. According to online experiments, the average dissolution rate during the first 5 min was estimated as 0.015 and 0.016 g/s for CIV and electrical conductivity, respectively. The measured CIV variable correlated well with electrical conductivity in all experiments.

Some alterations were shown in both measured quantities CIV and electrical conductivity, respectively. Lumping of added PS because of manual dosing can be the reason for these alterations. These lumps may have become attached on the surface of the sensor which has altered the measured signal. However, after 30 min visual observation showed that all PS added was dissolved.

Lumping of PS increased the total dissolution time from the theoretical. Large irregularly shaped lumps with a diameter of about 10 mm effectively decreased the surface area for dissolution, hindering the diffusion of higher concentration from inside this irregular lump into the bulk solution. As the dissolution proceeded, the concentration of dissolved PS in the bulk increased, which slowed down the dissolution. The dissolution process could be faster if PS particles were introduced into the solvent more individually, i.e. avoid lumping of the PS which decreased the surface area for wetting and dissolving, hampering mixing of the solution.

The temperature profiles of the experiments were also measured with a thermocouple integrated to the electrical conductivity meter, as shown in Fig. 4.

The measured temperature data showed that the temperature remained quite constant during each experiment. The temperature in experiment 3 was about 1 °C higher than for the other measurements, but this is probably due to the fact that the experiment took place in regular laboratory conditions where slight ambient temperature variations may occur. Temperature variations due to processing itself can arise from reaction energy (exothermic or endothermic) and mechanical mixing energy (internal friction, i.e. viscosity), but they were not observed in these experiments, probably due to the relatively small amount of reacting material and small mixing energies involved. The higher temperature during experiment 3 also decreased the viscosity of the solution, which can explain the slightly lower CIV values at the end of the observation time, as shown in Fig. 2. Also slight temperature alteration can affect the measured signal since temperature remained relatively stable tests with temperature as a variable was not performed.

Earlier studies have shown the thermodynamic affinity of polysaccharides for water and negative Gibbs energy of mixing (Safronov et al. 2019). The reaction enthalpy of dissolution for polysaccharide applied was so small that it was not detected in our temperature measurements. Decreasing the temperature would have apparently slowed down the dissolution rate by decreasing the diffusion constant D as calculated in Eq. 3 for an unmixed case.

When the initial dissolution process to 0.5 wt% was completed, the obtained solution was diluted to PS solution concentrations of 0.25, 0.125 and 0.0625. Deionized water was used as the baseline for 0 wt% PS. The CIV, electrical conductivity and UV absorption of the diluted solutions were measured individually for each concentration after they were completely mixed. The varied PS concentrations showed a linear correlation to measured CIV, conductivity and absorption. For CIV, the correlations for experiments 1, 2 and 3 had R2-values of 0.9993, 0.9997 and 0.9995, respectively (Fig. 5), and the electrical conductivity/concentration correlation had R2-values of 0.9999, 0.998 and 0.9998 for experiments 1, 2 and 3, respectively (Fig. 6).

The measured values of a 0.5 wt% sample for CIV and electrical conductivity were a little higher than observed at the end of analysed online experiment time (at 30 min, Figs. 2 and 3). So, the CIV and electrical conductivity values increased slightly between 0.5 and 66 h of experiment time. The changes in the dissolved polysaccharide molecule chain (biological nature of PS) and dissolved CO2 during the abovementioned experiment time could explain this behaviour.

In spectrophotometric experiments, the absorption peak in PS solution samples was found at a wavelength of 256 nm. The absorption/concentration correlation was then calculated by using the measured absorption at this wavelength according to Beer–Lambert law (Wypych 2013), Fig. 7. Absorption increased linearly with concentration and the correlation was very good, R2 of 0.9978, 0.9992 and 0.9992 for samples diluted after experiment 1, 2 and 3, respectively.

The CIV measurements performed with the samples of descending concentration gave the best correlation R2 value 1. Electrical conductivity and spectrophotometry (UV–Vis) measurements yielded very similar results with both coefficients of determination R2 0.999.

Conclusions

Electromagnetic field (EMF) technique and electrical conductivity measurement were successfully used both to measure online dissolution reaction and quantify various concentrations of a slightly anionic polysaccharide (PS). The CIV variable of the EMF technique and the electrical conductivity had a similar correlation with the dissolution profile in online experiments. The results were consistent with theories of dissolving and both techniques can be used to monitor the PS dissolution process. Both EMF and conductivity measurements also gave accurate quantification of the dissolved PS.

The measurements can be used to monitor the proceeding of dissolution, and they may alert the operator for potential problems, such as too slow a dissolution rate which may be corrected by increasing the temperature in the solution. Quantification may be done by EMF, electrical conductivity and UV–Vis technique alike with similar accuracy; however, the applied UV–Vis method requires sampling and is not suitable for real-time monitoring of the solution. The electrical conductivity measurement and UV–Vis spectrophotometry are established methods for online process diagnostics; however, the EMF technique is less prone to contaminants, such as thin film formation on the sensor, than conductivity meters. It can provide information of the concentration instantly and can serve added value for a quicker response in process control. This experiment verifies that there is now a novel measuring method for detecting the dissolution state of a polysaccharide which can be used for more accurate process control online. However, constant development is being done to further improve this method to be used as an industrial process control method.

References

Babick F (2016) Suspensions of colloidal particles and aggregates. Springer, Cham. https://doi.org/10.1007/978-3-319-30663-6

Braeuer A (2015) ‘Interaction of matter and electromagnetic radiation. Supercrit Fluid Sci Technol. https://doi.org/10.1016/B978-0-444-63422-1.00002-X

Chirife J et al (1997) A simple model for predicting the viscosity of sugar and oligosaccharide solutions. J Food Eng 33(3–4):221–226. https://doi.org/10.1016/S0260-8774(97)00060-5

Cilliers JJ et al (2011) A review of froth flotation control. Int J Mineral Process 100(3–4):57–71. https://doi.org/10.1016/j.minpro.2011.05.002

Costa P et al (2001) Modeling and comparison of dissolution profiles. Eur J Pharmaceut Sci 13(2):123–133. https://doi.org/10.1016/S0928-0987(01)00095-1

de Andrade Raponi O et al (2018) Thermal, rheological, and dielectric analyses of the polymerization reaction of a liquid thermoplastic resin for infusion manufacturing of composite materials. Polym Test 71:32–37. https://doi.org/10.1016/J.POLYMERTESTING.2018.08.024

Dokoumetzidis A et al (2006) A century of dissolution research: from noyes and whitney to the biopharmaceutics classification system. Int J Pharmaceut 321(1–2):1–11. https://doi.org/10.1016/J.IJPHARM.2006.07.011

Garcı́a-Ochoa F, et al (2000) Xanthan gum: production, recovery, and properties. Biotechnol Adv 18(7):549–579. https://doi.org/10.1016/S0734-9750(00)00050-1

Ghaouar N et al (2017) Conductivity measurements of laccase for various concentrations, pH and ionic liquid solutions. Fluid Phase Equilib 433:184–192. https://doi.org/10.1016/J.FLUID.2016.10.032

Guo MQ et al (2017) Polysaccharides: structure and solubility. Solubil Polysacch. https://doi.org/10.5772/intechopen.71570

Hattori Y et al (2013) Dissolution process analysis using model-free Noyes-Whitney integral equation. Coll Surf B Biointerf 102:227–231. https://doi.org/10.1016/J.COLSURFB.2012.08.017

Hayashi M (2004) Temperature-electrical conductivity relation of water for environmental monitoring and geophysical data inversion. Environ Monit Assess 96(1–3):119–128. https://doi.org/10.1023/B:EMAS.0000031719.83065.68

Hou C-Y et al (2018) Low frequency complex dielectric (conductivity) response of dilute clay suspensions: modeling and experiments. J Coll Interf Sci 525:62–75. https://doi.org/10.1016/J.JCIS.2018.04.048

Järveläinen M, et al (2015) Kolloidisten suspensioiden online -analysointi: tutkimuksesta liiketoimintaa. Materia-lehti 5(2015): 54–57. http://www.vuorimiesyhdistys.fi/julkaisut/materia.

Jing X et al (2005) Effect of solution concentration on the UV–vis spectroscopy measured oxidation state of polyaniline base. Polym Test 24(2):153–156. https://doi.org/10.1016/J.POLYMERTESTING.2004.09.013

Koenig JL et al (2003) A review of polymer dissolution. Prog Polym Sci 28(8):1223–1270. https://doi.org/10.1016/S0079-6700(03)00045-5

Lan W et al (2011) Ultrasound-assisted dissolution of cellulose in ionic liquid. Carbohyd Polym 86(2):672–677. https://doi.org/10.1016/J.CARBPOL.2011.05.013

Lepot M et al (2016) ‘Calibration of UV/Vis spectrophotometers: a review and comparison of different methods to estimate TSS and total and dissolved COD concentrations in sewers, WWTPs and rivers. Water Res 101:519–534. https://doi.org/10.1016/J.WATRES.2016.05.070

Marcotte M et al (1998) Electrical conductivities of hydrocolloid solutions. J Food Process Eng. https://doi.org/10.1111/j.1745-4530.1998.tb00466.x

Mishra A et al (2009) Tamarind xyloglucan: a polysaccharide with versatile application potential. J Mater Chem R Soc Chem 19(45):8528. https://doi.org/10.1039/b911150f

Örmeci B et al (2014) Measurement of polyacrylamide polymers in water and wastewater using an in-line UV–vis spectrophotometer. J Environ Chem Eng 2(2):765–772. https://doi.org/10.1016/J.JECE.2014.02.015

Razavi SMA et al (2012) Effect of thermal treatments on functional properties of cress seed (Lepidium sativum) and xanthan gums: a comparative study. Food Hydrocoll 28(1):75–81. https://doi.org/10.1016/J.FOODHYD.2011.11.012

Safronov AP et al (2019) Flory–huggins parameters of guar gum, xanthan gum, agarose, and gellan gum in aqueous solutions. Polym Sci A 61(1):29–38. https://doi.org/10.1134/S0965545X19010139

Salpavaara T et al (2015) Passive resonance sensor based method for monitoring particle suspensions. Sens Actuat B Chem 219:324–330. https://doi.org/10.1016/J.SNB.2015.04.121

Siepmann J et al (2013) Mathematical modeling of drug dissolution. Int J Pharm 453(1):12–24. https://doi.org/10.1016/J.IJPHARM.2013.04.044

Stoller M et al (2018) Technical–economic evaluation of chromium recovery from tannery wastewater streams by means of membrane processes. Desalin Water Treat. https://doi.org/10.5004/dwt.2018.22533

Sworn G (2009) Xanthan gum. In: Handbook of hydrocolloids. Woodhead Publishing, pp. 186–203. doi: https://doi.org/10.1533/9781845695873.186.

Tadros, T. (2013) Encyclopedia of colloid and interface science. Springer, Berlin, Heidelberg, pp. 1020–1042. doi: https://doi.org/10.1007/978-3-642-20665-8_39

Uddin R et al (2011) Dissolution and dissolution apparatus: a review. Int J Curr Biomed Pharm Res 1(4):201–207. https://doi.org/10.1081/DDC-120021777

Vilardi G et al (2020a) Intensified water denitrification by means of a spinning disk reactor and stirred tank in series: kinetic modelling and computational fluid dynamics. J Water Process Eng. https://doi.org/10.1016/j.jwpe.2020.101147

Vilardi G et al (2020b) Nitrate green removal by fixed-bed columns packed with waste biomass: modelling and friction hparameter estimation. Chem Eng Res Des Inst Chem Eng 154:250–261. https://doi.org/10.1016/j.cherd.2019.12.020

Wu X et al (2018) Electric conductivity and electric convertibility of potassium acetate in water, ethanol, 2,2,2–trifluoroethanol, 2–propanol and their binary blends. Chin J Chem Eng 26(12):2581–2591. https://doi.org/10.1016/J.CJCHE.2018.06.004

Wypych G, et al (2013) Photophysics. In: Handbook of material weathering. Elsevier, pp. 1–25. doi: https://doi.org/10.1016/B978-1-895198-62-1.50004-4.

Xu X et al (2018) Measurements and analysis of the dielectric properties of aramid/epoxy composites based on free space method under stress conditions. Polym Test 72:55–62. https://doi.org/10.1016/J.POLYMERTESTING.2018.09.029

Zohuriaan M et al (2004) Thermal studies on natural and modified gums. Polym Test 23(5):575–579. https://doi.org/10.1016/J.POLYMERTESTING.2003.11.001

Acknowledgements

This work has been done under the Digital Colloids project (Business Finland Grant No 735/31/2017). The contributions of the participating companies are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Silvonen, J., Järvelä, N., Koppanen, M. et al. Online monitoring of polysaccharide solution concentration by electromagnetic field, electrical conductivity and spectrophotometry measurements. Chem. Pap. 75, 5885–5894 (2021). https://doi.org/10.1007/s11696-021-01733-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01733-5