Abstract

The analysis of drops and rheological measurements of the emulsion produced were presented in the article. The influence of stirring time and rotation frequency on the drops size of the emulsion produced in the propeller of diameter D = 0.1 m and liquid height H = 0.5D equipped with four standard flat dividers was defined. The Smith turbine stirrer was used to stir the emulsion produced. The drop size was defined for three different propeller rotation frequencies, 500 rpm, 1000 rpm and 1500 rpm. The stirring time, after which the samples were collected, was accordingly 15 min and 45 min. To produce the emulsion, sunflower oil was used in the oil phase and distilled water in the water phase. There were 6 measurement series all together, and they were presented as the diameter size distribution. The mean arithmetic diameter da, median dm and the mean Sauter diameter d32 were determined. The rheological measurements of the produced emulsions were presented in graphics as a function τ = f(γ) and were described as Herschel–Bulkley and Bingham models presented in Table 3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multiple emulsion is a system of at least two non-stirring with each other liquids, where every another phase is dispersed in the previous phase. Nowadays, when we can observe the increase in food, cosmetics and pharmaceutical industries, the simplest procedure of emulsion production is very important, the one which may be introduced in these industries. One of the methods of emulsion production is two-step method, during which a singular emulsion in the first step is produced in the apparatus, and then, it is introduced to the continuous phase (the second step). This method was already used in the 1970s by Matsumoto et al. (1976). Two-step emulsion production method suggested by Matsumoto et al. (1976) was used by Vasiljevic et al. (2006) in his research on characteristics and drug release properties of multiple W/O/W. Two-step multiple emulsion production method, where the first singular emulsion was added to the third continuous phase, was used by Garti (1997), Ursica et al. (2005) and Surh et al. (2007). Research on emulsions produced in two-step method is also conducted by Schuch et al. (2013), Perez-Moral et al. (2014), Bou et al. (2014), Aditya et al. (2015), Sung et al. (2015), Mahammadi et al. (2016), Mehrania et al. (2017), Mutaliyeva et al. (2017) and Yamanaka et al. (2017). Ursica et al. (2005) and Yamanaka et al. (2017) presented the analysis of multiple emulsions drop size produced in two-step method in order to assess the produced emulsions quality and stability. Both Perez-Moral et al. (2014) and Yamanaka et al. (2017) used, among the others, lecithin in the second step of their (W/O/W) emulsion production research. Comparative study of the stability of multiple emulsions containing a gelled or aqueous internal phase was presented by Perez-Moral et al. (2014). The research describing the liquid source influence, which was used as a lipid phase of the primary emulsion for riboflavin encapsulation, and physicochemical properties of multiple emulsion were conducted on emulsion produced by Bou et al. (2014) by using the two-step method. In their work, Mahammadi et al. (2016) descried the result of nano-encapsulation of olive leaf extract and its application in soybean oil obtained for emulsions produces in two stages.

The topic of Mehrania et al. (2017) research includes rheological and releasing double nano-emulsion properties containing crocin. Double emulsions were prepared using two-stage emulsification of W1/O microemulsion in outer aqueous phase containing biopolymers (W2). Three different biopolymers were used in the research: angum gum, arabic gum and protein whey concentrate in two different intensities.

Mutaliyeva et al. (2017) presented the study of biocompatible and non-toxic systems of insulin supplies using double emulsions. When creating macrocapsules, they were heading to preserve its stability and biological activity. The process of emulsion production, stability and characteristics of the produced emulsion were investigated by measurements of size distribution (DLS) and interfacial charge (zeta-potential). Matos et al. (2014) worked on preparation of multiple emulsion of type W1/O/W2 containing trans-resveratrol. They used mechanical agitation and membrane emulsification as techniques to produce emulsion.

The effect of operating parameters in the continuous CTF contactor on multiple emulsion appearance, structure and rheological behaviour was analysed by Dluska and Markowska-Radomska (2010). They used single-stage method to produce multiple emulsion.

Li et al. (2012) worked on emulsion production using magnetic agitator. In order to produce emulsion, they used water, ionic liquid and surfactant. The different type of emulsion was obtained for different water fractions ranging from 0.1 to 0.9. Multiple emulsion was produced for water fractions ranging from 0.68 to 0.75. They showed the possibility of producing W/IL/W emulsion using ionic fluid.

The novel approach of making a multiple emulsion by single-step emulsification was presented by Zhang and Li (2013). The multiple emulsions were prepared by adding the aqueous phase containing water and the xanthan gum to the oil phase containing polydimethylsiloxane polymer and emulsifier. The emulsion was produced while homogenizing through high shear mixer equal to 10,000 rpm for 3 min. After this time, the emulsion which they produced was cooled to the desired temperature while stirring. The samples formulated with different emulsifier concentrations were characterized. The stability of the produced emulsion over time stored at different temperatures was evaluated by microscopic analysis. The studies presented by Zhang and Li (2013) showed the impact of the emulsifier concentration on the emulsion structure as well as on the rheological behaviour.

Major-Godlewska (2019) studied the structure, including the droplet size of the inner oil phase during the formation of the multiple emulsion, and put aside emulsion for 3 and 30 days and then mixed by shaking or mechanical mixing. In her paper, she also presented the rheological properties of the emulsion produced and the emulsion obtained in 30 days from its production.

The rheological properties of the multiple emulsion W/Si/W formation by single-step emulsification was presented and analysed in the paper by Li and Zhang (2015).

The aim of the study presented in this paper was to define structure changes, including inner oil phase drops size and rheological properties during multiple emulsion production using soya lecithin for different rotation frequencies of Smith turbine impeller.

Experimental

Materials

Refined sunflower oil produced for Jeronimo Martins Polska S.A. was used as oil phase who was dyed by Sudan III (producer: Eurochem BGD Sp. z o. o.). Distilled water was used as water phase. Lecithin from soya beans (producer: Vemica) was used as emulsifier.

Procedure of the emulsion production

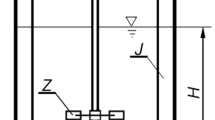

To dissolve 16 g of soy lecithin, distilled water was added and stirred with magnetic agitator until mixture homogeneity was obtained. Sunflower oil was coloured by Sudan III. First the water phase with lecithin was poured into the vessel of diameter D = 0.1 m, and then, during stirring with Smith turbine (ds = 0.33D, Z = 6), oil phase was added (sunflower oil with Sudan III). The part of individual phase contained 70 vol.% of oil phase and 30 vol% of water phase. The height of the liquid in the vessel was H = 0.5D. Emulsion was prepared in room temperature by using agitated vessel with four planar baffles (B = 0.1D). Geometrical parameters of the vessel are presented in Fig. 1 and were described in detail in paper by Major-Godlewska (2019). The rotation frequency was different for each of the emulsion produced. For the first emulsion produced, the rotation frequency was 500 rpm. During the production of the second emulsion, a rotation frequency of 1000 rpm was assumed. The last emulsion produced was created at a rotation frequency of 1500 rpm. Samples were taken for description after the stirring time of 15 and 45 min.

Microstructure studies

The evaluation of the structure and droplet size of the produced emulsion was performed using the diagnostic inverted microscope OPTA-TECH MW 100, with software and digital camera OPTA-TECH 5MP.

Rheological measurements

The rheological measurements of multiple emulsion samples were carried out on a rheoviscometer of type RT 10 by firm Haake equipped with the system of two co-axial cylinders (DG 41). The range shear rate, in temperature 23 °C, for each sample was γ < 1; 50 > 1/s.

Results and discussion

Oil in water in oil (O/W/O) emulsion

As the result of the tests of six measurements series, over 4000 drops of the internal oil phase were obtained, which were analysed. Samples of the produced emulsion were taken from the vessel to determine the structure and type of emulsion. Studies determining the type of emulsion produced were carried out using a microscope after 15 min and after 45 min of stirring. Images obtained for emulsion stirred with Smith turbine with a rotation frequency of 500 rpm, 1000 rpm and 1500 rpm are shown in Fig. 2. As it can be seen in Fig. 2, the use of the given emulsion preparation procedure results in the formation of an unstable emulsion described as oil in water in oil (O/W/O) emulsion type. Putting the emulsion aside caused gradual, slow phase stratification. Irregular shapes of the water phase were observed in the analysed images. The images obtained enabled to determine the type of emulsion and diameter of the inner oil phase.

The population of inner oil phase drops in the number from 600 to 800 were taken for each series for the analysis. The mean arithmetic diameter da defined as da= Σxidi/Σxi, median dm and the mean Sauter diameter d32 defined as d32= Σxid3i/Σxid2i were calculated with the obtained values. Distribution of inner oil phase drops in the produced emulsion is presented in histogram in Fig. 3. For 15-min stirring time, where the stirrer rotation frequency was 500 rpm (Fig. 3a), 0.78–5.34 μm diameter range drops were 85% of the analysed population, where the highest number, about 45% of the analysed population, was drops of diameter from d = 1.82 μm to d = 3.52 μm. The population of droplets with the diameter in the range 1.1–5.37 μm accounts about 66% of the emulsion produced, stirred for 45 min (Fig. 3b) with the rotation frequency of 500 rpm. Comparing the number of 1.82–3.52 μm range drops, where 15-min stirring resulted in the most populous number, when the time was prolonged to 45 min, the number of drops decreased to 25% of the whole population and it was 20% less than that in the 15-min stirring time.

The increase in the rotational frequency of the Smith turbine to 1000 rpm for the same stirring time of 15 min and 45 min had an impact on the droplet size. Analysing the population of about 650–700 drops presented in the form of the relation of the number of drops = f(d) in Fig. 4a, b, the higher number of drops in the diameter range from 1.1 to 3.32 μm was observed, which was about 62% of the analysed population in 15-min stirring time than in the 45-min stirring time, where the same diameter drops were 54% of the analysed population. Analysing the drop diameter in the range of 4.3–6.45 μm, it was found that the percentage of droplets with these diameters was similar and for the stirring time of 15 min, it was about 22%, while for 45 min, about 20%.

Analysing the volume of drops which were obtained for the emulsion produced in the Smith turbine, when rotation frequency was 1500 rpm, it was found that 47% of analysed population were drops in the range of 1.1–3.02 μm for the stirring time of 15 min and 36% of analysed population of droplets the inner oil phase for stirring time 45 min. Analysing the drop diameter in the range of 4.3–6.45 μm in both cases, i.e. for stirring time of 15 and 45 min, a similar number was obtained representing about 20% of the analysed drop population.

Table 1 presents the arithmetic diameter da which was calculated for the drop population presented in Fig. 3, 4 and 5 in the form of droplets distribution of the inner oil phase of the produced emulsion O/W/O (for different Smith turbine rotation frequencies: 500, 1000, 1500 rpm and two stirring times: 15 and 45 min). Then, for the same population of internal oil phase droplets, the median dm and Sauter diameter d32 are given in Table 2.

Analysing the values of the mean Sauter diameter d32, it can be seen that in the case of a stirrer frequency of 500 rpm and 1000 rpm when extending the stirring time from 15 min up to 45 min, the values of the mean Sauter diameter d32 increases. It is different when the emulsion produced was stirred with the rotation frequency of 1500 rpm. In this case, a decrease in the value of the mean Sauter diameter was observed from d32 = 40.6 μm for 15-min stirring to d32 = 27.35 μm for 45-min stirring. Analysing the effect of the rotation frequency of the Smith turbine on the mean Sauter diameter d32, it was observed that at the stirring time of 15 min, the value d32 increases for higher rotation frequencies. However, for a stirring time of 45 min, the value of the mean Sauter diameter d32 tends to decrease as the rotation frequency increases. Analysing the values of the mean alternative diameter da and the median dm, it can be stated that for the droplet population adopted for the analysis, larger diameter da and dm droplets were obtained for the emulsion in which samples were taken for testing after 45 min.

The values of the diameter obtained for the emulsion produced with rotation frequency of 500 rpm were compared with the data presented in the paper of Major-Godlewska (2019). It was found that when the amount of soya lecithin added changed, the diameter values changed. For the stirring time of 15 min, larger diameters da, dm and d32 were obtained for the emulsion in which 8 g of soy lecithin was used for production. If the stirring time is extended to 45 min, this situation is reversed and larger diameter values da, dm and d32 were obtained for the emulsion in which 16 g of soy lecithin was used for production.

The resulting populations of internal oil phase droplets were presented as a data set for d ≤ 20 μm assuming a constant range of drop diameter for comparative purposes. It was observed that drops with the diameter of d ≤ 20 μm accounted for 93–98% of the analysed population for 5 series. In the case of the drops population obtained for a stirring time of 45 min, where the emulsion produced was stirred with a rotation frequency of 500 rpm, the droplets of the internal oil phase in the range d ≤ 20 μm accounted for 86% of the analysed population. This indicates that 14% of the analysed population were drops with the diameter larger than 20 μm. This value is greater than the value obtained when stirring lasted 15 min at a rotation frequency of 500 rpm. At that time, drops with the diameter of d > 20 μm were only about 2% of the analysed population. A comparison of the obtained drops for d ≤ 20 μm is presented in Fig. 6. The highest number of drops equal to 330 (Fig. 6a) was obtained in the range of 2.01–4 μm for the system in which the emulsion produced was stirred for 15 min with a rotation frequency of 500 rpm. Comparing the number of drops in the range of 0–2 μm, it was observed that the few drops, i.e. 205 for a stirring time of 15 min and 172 for a stirring time of 45 min, were obtained for emulsion stirred with a rotation frequency of 1500 rpm (Fig. 6c). In the case of the droplets diameter in the range 4.01–6 μm or 6.01–8 μm, a different distribution was observed. The highest number of drops was obtained for the emulsion produced with a rotation frequency of 1500 rpm (Fig. 6c). For both stirring times of 15 min and 45 min, the drop population in the range of d < 4.01–6 > μm were 131 or 143 drops, respectively, and in the range of d < 6.01–8 > μm were 55 or 71, respectively. The number of droplets of the internal oil phase for the diameter range of 4.01–6 μm was close to 100 drops or less than 100 drops at the rotation frequency of 500 rpm (Fig. 6a) or 1000 rpm (Fig. 6b). Comparing the number of drops with diameter in the range from 10 to 18 μm at the same rotation frequencies, the higher number of drops was observed (Fig. 6) when the emulsion produced was stirred for 45 min compared to the number of drops obtained for the stirring time of 15 min.

Rheological properties

The rheological properties of the emulsion produced were also analysed. The knowledge of the rheological properties is important in the produced processes and in emulsion final production phases. The values of shear rate γ and shear stress τ are presented as a relation τ = f(γ) in Fig. 7. In the analysed stirring time, i.e. 15 min and 45 min, it was observed that the values of shear stress τ and shear rate γ can be described using Herschel–Bulkley model (Fig. 7a). The values of constant and exponent of Herschel–Bulkley model obtained on the basis of experimental data are presented in Table 3. The mean mistake in each of the analysed cases was not greater than 3%.

Increasing the stirring time from 15 min to 45 min has no significant influence on the rheological properties of the emulsion produced when Smith turbine with rotation frequency equal to 500 rpm is used during the production process (Fig. 7a). When Smith turbine rotation frequency was 1500 rpm, it was observed at shear rate γ, 1/s ≤ 7 values shear stress τ for both stirring times (15 min and 45 min) were similar. Only for γ, 1/s > 7, the difference was visible, and assuming constant shear rate γ, higher shear stress values τ were obtained for emulsion produced in 15 min compared to data obtained for a stirred emulsion for 45 min. For the more precise description of the rheological properties, when the mean relative error was not more than ± 3%, experimental data were described by Herschel–Bulkley and Bingham model (Table 3). The rheological properties obtained for the emulsion stirred with the rotation frequency of 1500 rpm for 15 min were described by Herschel–Bulkley model, whereas the data obtained for emulsion stirred for 45 min were described by Bingham model. The values of both equations are presented in Fig. 7c, in the form of dependencies τ = f(γ).

Comparing the results presented by Major-Godlewska (2019), for the emulsion produced in the Smith turbine, with the stirred rotation frequency of 500 rpm when 8 g of soy lecithin was used with the results presented in this paper (500 rpm frequency and 16 g of soy lecithin), it was found that the amount of lecithin used to produce the emulsion affects its rheological properties. In Fig. 8, the data were presented in the form of equation τ = f(γ). The values obtained when 16 g of lecithin was used during the emulsion production where the stirrer rotation frequency was 500 rpm were marked as points. The values obtained with the equation presented by Major-Godlewska (2019) were marked as line. The larger amount of lecithin in the emulsion increases the value of shear stress τ assuming the same constant shear rate γ. At the shear rate γ = 5 1/s, the value of shear stress τ for the emulsion with 16 g of lecithin is about 27% greater than value τ obtained for the emulsion with 8 g of lecithin. At higher shear rates γ, the difference in the values of τ increases, for example when γ is about 40 1/s, the difference in the value of τ is about 40%.

Relation τ = f(γ) for the produced emulsion stirred for 15 and 45 min with the rotation frequency of 500 rpm; 16 g of soy lecithin—points: ( )15 min, (

)15 min, ( ) 45 min; 8 g soy lecithin—line (presented by Major-Godlewska (2019))

) 45 min; 8 g soy lecithin—line (presented by Major-Godlewska (2019))

Conclusions

On the basis of the data obtained in 6 series of measurements (over 4000 inner oil phase drops) during emulsion production in the tank (D = 0.1 m and H = 0.5D) with Smith turbine, sunflower oil (70 vol%) and distilled water (30 vol%) with 16 g of soya lecithin produced multiple unstable emulsion of type oil in water in oil (O/W/O) in 15 and 45 min of stirring, with three different stirrer rotation frequencies (500 rpm, 1000 rpm and 1500 rpm).

Both the stirring time and the frequency of rotation of the stirrer influence the size and distribution of inner oil phase drops. It was found that using three different rotation frequencies (500 rpm, 1000 rpm and 1500 rpm) of the Smith turbine stirrer, higher values of mean arithmetic diameter drop da and median dm were obtained when the produced emulsion was stirred for 45 min. In the case of mean Sauter diameter d32, the influence of rotation frequency was visible. For the stirring time of 15 min, the values of the mean Sauter diameter were greater for each of the higher frequencies of rotation of the stirrer. The greatest value of d32 = 40.6 μm in the studied range was obtained when the produced emulsion was stirred with rotation frequency equal to 1500 rpm. For stirring time equal to 45 min, the greatest value of d32 = 70.98 μm was obtained for frequency rotation equal to 500 rpm, and it was found that with increasing frequency of stirrer rotation, the value of the mean Sauter diameter d32 decreases.

When the emulsion produced was stirred with the rotation frequency of 500 or 1000 rpm in the analysed shear rate range, there were no major differences in shear stress values τ at given shear rates γ. When the stirrer rotation frequency during the emulsion production was 1500 rpm, the influence of stirring time was visible. This is noticeable in the obtained shear stress values for given shear rates presented in the form of a flow curve τ = f(γ), for the range γ, 1/s > 7.

Rheological properties of the emulsion produced are described by Herschel–Bulkley or Bingham model presented in Table 3.

The amount of soya lecithin used to produce the emulsion affects the rheological properties. Higher shear stress values at given shear rate values were obtained for the emulsion for which a larger amount of soy lecithin was used.

Abbreviations

- D :

-

Diameter of the vessel (m)

- d :

-

Diameter of the drop (μm)

- d a :

-

Arithmetic mean diameter of the drop (μm)

- d m :

-

Median diameter of the drop (μm)

- d 32 :

-

Sauter mean diameter (μm)

- H :

-

Liquid height in the vessel (m)

- τ :

-

Shear stress (Pa)

- γ :

-

Shear rate (s−1)

References

Aditya NP, Aditya S, Yang H, Kim HW, Park SO, Ko S (2015) Co-delivery of hydrophobic curcumin and hydrophilic catechin by a water-in-oil-in-water double emulsion. Food Chem 173:7–13. https://doi.org/10.1016/j.foodchem.2014.09.131

Bou R, Cofrades S, Jimenez-Colmenero F (2014) Physicochemical properties and riboflavin encapsulation in double emulsions with different lipid sources, LWT Food Sci. Technol 59:621–628. https://doi.org/10.1016/j.lwt.2014.06.044

Dłuska E, Markowska-Radomska A (2010) Regimes of multiple emulsion of W1/O/W2 and O1/W/O2 type in the continuous Couette–Taylor flow contactor. Chem Eng Technol 1:113–120. https://doi.org/10.1002/ceat.200900278

Garti N (1997) Double emulsions-scope, limitations and new achievements. Colloids Surfaces A: Physicochem Eng Aspects 123–124:233–246. https://doi.org/10.1016/S0927-7757(96)03809-5

Li F, Zhang W (2015) Stability and rheology of W/Si/W multiple emulsions with polydimethylsiloxane. Colloids and Surfaces A: physicochem Eng Aspects 470:290–296. https://doi.org/10.1016/j.colsurfa.2015.02.001

Li J, Zhang J, Han B, Zhao Y, Yang G (2012) Formation of multiple water-in-ionic liquid-in-water emulsions. J Colloid Interface Sci 368:395–399. https://doi.org/10.1016/j.jcis.2011.10.083

Mahammadi A, Jafari SM, Esfanjani AF, Akhavan S (2016) Application of nano-encapsulated olive left extract in controlling the oxidative stability of soybean oil. Food Chem 190:513–519. https://doi.org/10.1016/j.foodchem.2015.05.115

Major-Godlewska M (2019) Evaluation of drops dimensions in time and rheological properties of the multiple emulsion. Chem Pap 73:2073–2080. https://doi.org/10.1007/s11696-019-00754-5

Matos M, Gutierrez G, Coca J, Pazos C (2014) Preparation of water-in-oil-in-water (W1/O/W2) double emulsions containing trans-resveratrol. Colloids Surfaces A: Physicochem Eng Aspects 442:69–79. https://doi.org/10.1016/j.colsurfa.2013.05.065

Matsumoto S, Kita Y, Yonezawa D (1976) An attempt at preparing water-in-oil-in-water multiple-phase emulsion. J Colloid Interface Sci 57:353–361. https://doi.org/10.1016/0021-9797(76)90210-1

Mehrania MA, Jafari SM, Makhmal-Zadeh BS, Maghsoudlou Y (2017) Rheological and release properties of double nano-emulsions containing crocin prepared with Angum gum, Arabic gum and whey protein. Food Hydrocoll 66:259–267. https://doi.org/10.1016/j.foodhyd.2016.11.033

Mutaliyeva B, Grigoriev D, Madybekova G, Sharipova A, Aidarova S, Saparbekova A, Miller R (2017) Microencapsulation of insulin and its release using w/o/w double emulsion method. Colloids Surfaces A: Physicochem Eng Aspects 521:147–152. https://doi.org/10.1016/j.colsurfa.2016.10.041

Perez-Moral N, Watt S, Wilde P (2014) Comparative study of the stability of multiple emulsions containing a gelled or aqueous internal phase. Food Hydrocoll 42:215–222. https://doi.org/10.1016/j.foodhyd.2014.05.023

Schuch A, Deiters P, Henne J, Kohler K, Schuchmann HP (2013) Production of W/O/W (water-in-oil-in-water) multiple emulsions: droplet breakup and release of water. J Colloid Interface Sci 402:157–164. https://doi.org/10.1016/j.jcis.2013.03.066

Sung MR, Xiao H, Decker EA, Mc Clements DJ (2015) Fabrication, characterization and properties of filled hydrogel particles formed by the emulsion-template method. J Food Eng 155:16–21. https://doi.org/10.1016/j.jfoodeng.2015.01.007

Surh J, Vladisavljevic GT, Mun S, McClements DJ (2007) Preparation and characterization of water/oil and water/oil/water emulsions containing biopolymer-gelled water droplets. J Agric Food Chem 55:175–184. https://doi.org/10.1021/jf061637q

Ursica L, Tita D, Palici I, Tita B, Vlaia V (2005) Particle size analysis of some water/oil/water multiple emulsions. J Pharm Anal 37:931–936. https://doi.org/10.1016/j.jpba.2004.10.055

Vasiljevic D, Parojcic J, Primorac M, Vuleta G (2006) An investigation into the characteristics and drug release properties of multiple W/O/W emulsion systems containing low concentration of lipophilic polymeric emulsifier. Int J Pharm 309:171–177. https://doi.org/10.1016/j.ijpharm.2005.11.034

Yamanaka Y, Kobayashi I, Neves MA, Ichikawa S, Uemura K, Nakajima M (2017) Formulation of W/O/W emulsions loaded with short-chain fatty acid and their stability improvement by layer-by-layer deposition using. LWT Food Sci Technol 76:344–350. https://doi.org/10.1016/j.lwt.2016.07.063

Zhang W, Li F (2013) Preparation and characterization of multiple emulsions (W/Si/W) by single-step emulsification. Colloids Surfaces A: Physicochem Eng Aspects 423:98–103. https://doi.org/10.1016/j.colsurfa.2013.02.004

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Major-Godlewska, M. The influence of stirring time and frequency of impeller rotation on evaluation of drops dimensions and rheological properties of the multiple emulsion. Chem. Pap. 74, 3135–3143 (2020). https://doi.org/10.1007/s11696-020-01146-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01146-w

) intensity, (

) intensity, ( ) summary volume %

) summary volume %

)15 and (

)15 and ( ) 45 min

) 45 min