Abstract

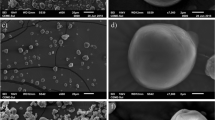

Spray-drying transforms functional yogurt into yogurt powder quickly and efficiently, maintaining product quality and enhancing storage stability. This process also adds value to the product. The study aimed to develop spray dried functional yoghurt powder encapsulating probiotics (Streptococcus thermophilus (S. thermophilus), Lactobacillus bulgaricus (L. bulgaricus), and Lactococcus lactis (L. lactis)) with longer shelf life. The production of functional yoghurt powder was optimized with Box–Behnken design using independent variables inlet air temperature (110–170 °C), feed temperature (10–20 °C), and pump speed (10–20%). The optimum functional yoghurt powder was obtained at 164.04 (164) °C inlet air temperature, 20 °C feed temperature, and 10.72 (11) % pump speed, respectively. The functional yoghurt powder with amorphous nature had storage viability (log CFU g−1) of 8.88 ± 0.03, 6.71 ± 0.12 and 8.16 ± 0.10 for S. thermophilus, L. bulgaricus, and L. lactis correspondingly on 49th day at 4 °C. The functional yoghurt powder demonstrated antibacterial activity, resulting in inhibition zones measuring approximately 18.33 ± 1.15 mm and 11.00 ± 0.00 mm against Klebsiella pneumoniae and Pseudomonas aeruginosa, respectively. Functional yoghurt powder had water activity 0.35–0.52, moisture content 7.27–16.22 (%), process yield 2.29–5.33 (%), hygroscopicity 10.09–16.87 (g/100 g) and degree of caking as 37.46–59.02 (%). The bulk densities, tapped densities, particle density and porosity of yoghurt powder ranged from 242 to 425 (kg m−3), 301.9–485.7 (kg m−3), 1050–2500 (kg m−3), and 58.67–87.85 (%) respectively. Furthermore, the solubility, dispersibility, and wettability of the powder ranged from 33 to 60%, 46.86–86.37%, and 2.13–4.28 min, respectively. The current study successfully achieved optimization at an inlet temperature of 164.04 °C (164 °C), a feed temperature of 20 °C, and a pump speed of 10.72% (11%), with desirability of 72.6%. This study makes a substantial advancement in the production of probiotic yoghurt powder infused with clove, achieving the recommended levels of viability, shelf life, powder characteristics, reconstitution capability, and antibacterial effects. Moreover, the spherical morphology of the functional yoghurt powder was revealed through scanning electron microscopy.

Similar content being viewed by others

Data Availability

Data will be provided in accordance with genuine requests to the corresponding author.

References

I. Atalar, M. Dervisoglu, Optimization of spray drying process parameters for kefir powder using response surface methodology. LWT Food Sci. Technol. 60, 751–757 (2015)

M. Selvamuthukumaran, Spray drying applications for food industries. Handbook Spray Drying (2019). https://doi.org/10.1201/9780429055133

M.T.C. Moreira, E. Martins, Í.T. Perrone, R. de Freitas, L.S. Queiroz, A.F. de Carvalho, challenges associated with spray drying of lactic acid bacteria: understanding cell viability loss. Compr. Rev. Food Sci Food Saf. 20, 3267–3283 (2021)

A.L. Favilla, E.R. dos Santos Junior, M.C. Rodrigues, Baião D. dos Santos, V.M. Paschoalin, M.A. Miguel et al., Microbial and physicochemical properties of spray dried kefir microcapsules during storage. LWT Food Sci. Technol. (2022). https://doi.org/10.1016/j.lwt.2021.112710

A. GÜneŞ Bayir, M.G. Bilgin, S.S. Kutlu, D. Demirci, F.N. Gölgeci, Microbiological, chemical and sensory analyzes of produced probiotic yoghurts added clove and propolis. Icontech. Int. J. 4, 1–14 (2020)

J.Y. Joung, J.Y. Lee, Y.S. Ha, Y.K. Shin, Y. Kim, S.H. Kim et al., Enhanced microbial, functional and sensory properties of herbal yogurt fermented with korean traditional plant extracts. Korean J. Food Sci. Anim. Resour. 36, 90–99 (2016)

M. Thaochalee, A. Amornsin, P. Itsaranuwat, Synbiotic ice cream containing germinated KDML105 rice flour and Lactobacillus acidophilus LA-5: physicochemical, probiotic viability and sensory evaluation. Int. J. Agricul. Technol 14, 933–948 (2018)

B. Koç, M. Sakin-YIlmazer, F. Kaymak-Ertekin, P. BalkIr, Physical properties of yoghurt powder produced by spray drying. J. Food Sci. Technol. 51, 1377–1383 (2014)

J. Huggett, E. Nowak, A.N.M. Kay Rutherfurd-Markwick, Advances in food processing and technology encapsulation of curcumin by milk and whey powders using spray drying. Adv Food Process Technol. 01, 1–9 (2018)

A. Ali, M.T. Javaid, D. Tazeddinova, A. Khan, T. Mehany, T.A. Djabarovich, Optimization of spray dried yogurt and its application to prepare functional cookies. Front. Nutr. 10, 1186469 (2023)

A. Szparaga, S. Tabor, S. Kocira, E. Czerwińska, M. Kuboń, B. Płóciennik et al., Survivability of probiotic bacteria in model systems of non-fermented and fermented coconut and hemp milks. Sustain. 11, 1–19 (2019)

D.A. Savaiano, R.W. Hutkins, Yogurt, cultured fermented milk, and health: a systematic review. Nutr. Rev. 79, 599–614 (2021)

T. Pérez, J.L. Balcázar, A. Peix, A. Valverde, E. Velázquez, I. de Blas et al., Lactococcus lactis subsp. tructae subsp. Nov. Isolated from the Intestinal mucus of brown trout (Salmo trutta) and rainbow trout (Oncorhynchus mykiss). Int. J. Syst. Evol. Microbiol. 61, 1894–1898 (2011)

J.R.M. de Lacerda, T.F. da Silva, R.E. Vollú, J.M. Marques, L. Seldin, Generally recognized as safe (GRAS) Lactococcus lactis strains associated with Lippia sidoides cham. are able to solubilize/mineralize phosphate. Springerplus. 5, 828–835 (2016)

Z. Hernández-López, E. Rangel-Vargas, J. Castro-Rosas, C.A. Gómez-Aldapa, A. Cadena-Ramírez, O.A. Acevedo-Sandoval et al., Optimization of a spray-drying process for the production of maximally viable microencapsulated Lactobacillus pentosus using a mixture of starch-pulque as wall material. LWT Food Sci. Technol. 95, 216–222 (2018)

F.B. Haffner, R. Diab, A. Pasc, Encapsulation of probiotics: insights into academic and industrial approaches. AIMS Mater Sci. 3, 114–136 (2016)

B. García-Gómez, M.L. Vázquez-Odériz, N. Muñoz-Ferreiro, M.A. Romero-Rodríguez, M. Vázquez, Effect of the milk heat treatment on properties of low-fat yogurt manufactured with microbial transglutaminase. Emirates J. Food Agric. 32, 739–749 (2020)

M. Ghasemlou, S.M.T. Gharibzahedi, Z. Emam-Djomeh, Relating consumer preferences to textural attributes of cooked beans: development of an industrial protocol and microstructural observations. LWT Food Sci. Technol. 50, 88–98 (2013)

S. Bansal, M. Mangal, S.K. Sharma, D.N. Yadav, R.K. Gupta, Optimization of fermentation conditions for probiotic soy yoghurt using response surface methodology. J. Food Process. Preserv. 39, 1809–1816 (2015)

E.A. Ismail, A.A. Aly, A.A. Atallah, Quality and microstructure of freeze-dried yoghurt fortified with additives as protective agents. Heliyon. 6, e05196 (2020)

B. Koc, M.S. Yilmazer, P. Balkir, F.K. Ertekin, Spray drying of yogurt: optimization of process conditions for improving viability and other quality attributes. Dry. Technol. 28, 495–507 (2010)

V. Sablania, S.J. Don Bosco, T. Ahmed, V. Venkateswara Sarma, Antimicrobial and antioxidant properties of spray dried Murraya Koenigii leaf powder. J. Food Meas. Charact. 13, 2288–2297 (2019)

I. Yoplac, L. Vargas, P. Robert, A. Hidalgo, Characterization and antimicrobial activity of microencapsulated citral with dextrin by spray drying. Heliyon. 7, e06737 (2021)

H.S. El-Sayed, H.H. Salama, A.E. Edris, Survival of Lactobacillus helveticus CNRZ32 in spray dried functional yogurt powder during processing and storage. J. Saudi Soc. Agric. Sci. 19, 461–467 (2020)

F.P. Downes, K. Ito, Culture methods for enumeration of microorganisms, in Compend methods microbiol exam foods. (APHA, Washington, 2001)

N.O. Nwamaioha, S.A.A. Ibrahim, Selective medium for the enumeration and differentiation of Lactobacillus delbrueckii ssp. bulgaricus. J. Dairy Sci. 101, 4953–4961 (2018)

Y. Liu, N. Charamis, S. Boeren, J. Blok, A.G. Lewis, E.J. Smid et al., Physiological roles of short-chain and long-chain menaquinones (Vitamin K2) in Lactococcus cremoris. Front. Microbiol. 13, 1–18 (2022)

D.R.C. Layusa, V.L. Barraquio, E.I. Dizon, F.B. Elegado, C.C. Sevilla, Optimization of spray drying parameters for yogurt-ice cream mix. Philipp Agric Sci. 96, 392–403 (2013)

M. Thakur, K. Pant, R.R. Naik, V. Nanda, Optimization of spray drying operating conditions for production of functional milk powder encapsulating bee pollen. Dry. Technol. 39, 777–790 (2021)

D. Seth, H.N. Mishra, S.C. Deka, Functional and reconstitution properties of spray-dried sweetened yogurt powder as influenced by processing conditions. Int. J. Food Prop. 20, 1603–1611 (2017)

İ Tontul, F. Ergin, E. Eroğlu, A. Küçükçetin, A. Topuz, Physical and microbiological properties of yoghurt powder produced by refractance window drying. Int. Dairy J. 85, 169–176 (2018)

G. Santos, T.P. Nunes, M.A.A.P. Silva, A. Rosenthal, A.A.C. Pagani, Development and acceptance of freeze-dried yogurt “powder yogurt.” Int. Food Res. J. 25, 1159–1165 (2018)

Y. Pratama, S.B.M. Abduh, A.M. Legowo, Y.B. Pramono, A.N. Albaarri, Optimum carrageenan concentration improved the physical properties of cabinet-dried yoghurt powder. IOP Conf. Ser. Earth Environ. Sci. (2018). https://doi.org/10.1088/1755-1315/102/1/012023

S.N.A. Azemi, N. Zainul, A.A. Ghani, J.T.Y. Huat, Proximate analysis of goat milk yogurt powder produced by freeze drying and vacuum-oven drying and in comparing with freeze-dried yogurt powder prepared with Tualang honey. J. Agro Biotechnol. 12, 101–111 (2021)

E. Martins, D.C. Cnossen, C.R.J. Silva, J.C. Cezarino, L.A. Nero, I.T. Perrone et al., Determination of ideal water activity and powder temperature after spray drying to reduce Lactococcus lactis cell viability loss. J. Dairy Sci. 102, 6013–6022 (2019)

C. Cao, X. Zhao, C. Zhang, Z. Ding, F. Sun, C. Zhao, Effect of inlet temperature on the physicochemical properties of spray-dried seed-watermelon seed protein powder. J. Food Sci. 85, 3442–3449 (2020)

I. Schmitz-Schug, P. Foerst, U. Kulozik, Impact of the spray drying conditions and residence time distribution on lysine loss in spray dried infant formula. Dairy Sci. Technol. 93, 443–462 (2013)

M.M. El-Said, H.F. Haggag, H.M. El-Din, A.S. Gad, A.M. Farahat, Antioxidant activities and physical properties of stirred yoghurt fortified with pomegranate peel extracts. Ann. Agric. Sci. 59, 207–212 (2014)

J.B.J. Tay, X. Chua, C. Ang, G.S. Subramanian, S.Y. Tan, E.M.J. Lin et al., Effects of spray-drying inlet temperature on the production of high-quality native rice starch. Processes. 9, 1–15 (2021)

L.S. Chang, Y.L. Tan, L.P. Pui, Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Brazilian J. Food Technol. 23, 1–7 (2020)

R. Monsalve-Atencio, K. Sánchez, J. Chica, J. Camaño, J. Saldarriaga, J. Quintero-Quiroz, Effect of the drying method and texture improvers on reconstitution behavior of yogurt powder: physical and microbiological properties. Vitae. 28, 1–14 (2021)

S.Y. Chong, C.W. Wong, Effect of spray dryer inlet temperature and maltodextrin concentration on colour profile and total phenolic content of sapodilla (Manilkara zapota) powder. Int. Food Res. J. 24, 2543–2548 (2017)

N. Choobkar, A. Daraei Garmakhany, A.R. Aghajani, M. Ataee, Response surface optimization of pudding formulation containing fish gelatin and clove (Syzygium aromaticum) and cinnamon (Cinnamomum verum) powder: effect on color, physicochemical, and sensory attributes of the final pudding product. Food Sci. Nutr. 10, 1257–1274 (2022)

R.Z. Kamil, R. Yanti, A. Murdiati, M. Juffrie, E.S. Rahayu, Spray and freeze - drying: strain - Dependent effect and its antibacterial property. Food Res. 4(6), 2181–2189 (2020)

A.N. Madhu, S.P. Awasthi, K.B.P.K. Reddy, S.G. Prapulla, Impact of freeze and spray drying on the retention of probiotic properties of Lactobacillus fermentum: an in vitro evaluation model. Int J Microbiol Res. 2(3), 243–251 (2011)

G.E. Gardiner, E. O’Sullivan, J. Kelly, M.A.E. Auty, G.F. Fitzgerald, J.K. Collins et al., Comparative survival rates of human-derived probiotic Lactobacillus paracasei and L. salivarius strains during heat treatment and spray drying. Appl. Environ. Microbiol. 66, 2605–2612 (2000)

N. Kearney, X.C. Meng, C. Stanton, J. Kelly, G.F. Fitzgerald, R.P. Ross, Development of a spray dried probiotic yoghurt containing Lactobacillus paracasei NFBC 338. Int. Dairy J. 19, 684–689 (2009)

A.R. Dijkstra, M.C. Setyawati, J.R. Bayjanov, W. Alkema, S.A.F.T. Van Hijum, P.A. Bron et al., Diversity in robustness of Lactococcus lactis strains during heat stress, oxidative stress, and spray drying stress. Appl. Environ. Microbiol. 80, 603–611 (2014)

L. Hu, J. Bi, X. Jin, Y. Qiu, R.G.M. van der Sman, Study on the rehydration quality improvement of shiitake mushroom by combined drying methods. Foods. (2021). https://doi.org/10.3390/foods10040769

Westergaard, V. Milk Powder Technology. Evaporation and Spray Drying. 2004, 337.

H. Wang, X. Tong, Y. Yuan, X. Peng, Q. Zhang, S. Zhang et al., Effect of spray-drying and freeze-drying on the properties of soybean hydrolysates. J. Chem. (2020). https://doi.org/10.1155/2020/9201457

B. Nurhad, R. Andoyo, R. Indiarto, Study the properties of honey powder produced from spray drying and vacuum drying method. Int. Food Res. J. 19, 907–912 (2012)

W. Tiago, S. Bhatia, Production of yogurt powder using foam-mat drying. AU J Technol. 15, 166–171 (2012)

T.S.A.N. Simões, A.F.V. Matias, V.C. Braz, D. Pasche, V. Meunier, J. Engmann et al., Effect of temperature shocks on the caking of moisture-sensitive amorphous powders. Powder Technol. 409, 117799 (2022)

C.J. Etti, Y.A. Yusof, N.L. Chin, S. Mohd Tahir, Effects of formulation on flowability of selected herbal powders using compendial methods and powder flow analyser. Int. Food Res. J. 23, S225–S230 (2016)

R.V. Tonon, C. Brabet, M.D. Hubinger, Influence of process conditions on the physicochemical properties of Açai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 88, 411–418 (2008)

B. Sunitha, J. Naga Bhavya, G. Arvind, S.K. Farzana, K. Anusha, Production of powdered yoghurt by spray drying. Int J Eng Res. 5, 668–678 (2016)

S. Santhalakshmy, S.J. Don Bosco, S. Francis, M. Sabeena, Effect of inlet temperature on physicochemical properties of spray-dried Jamun fruit juice powder. Powder Technol. 274, 37–43 (2015)

P. Lebrun, F. Krier, J. Mantanus, H. Grohganz, M. Yang, E. Rozet et al., Design space approach in the optimization of the spray-drying process. Eur. J. Pharm. Biopharm. 80, 226–234 (2012)

S. Suresh, G.K. Rajesh, Reconstitution properties of spray dried yoghurt powder. Int. Res. J. Eng. Technol. 7, 2694–2696 (2020)

S.S. Kim, S.R. Bhowmik, Survival of lactic acid bacteria during spray drying of plain yogurt. J. Food Sci. 55, 1008–1010 (1990)

S. Kiekens, D. Vandenheuvel, G. Broeckx, I. Claes, C. Allonsius, I. De Boeck et al., Impact of spray-drying on the pili of Lactobacillus rhamnosus GG. Microb. Biotechnol. 12, 849–855 (2019)

P. Kumar, H.N. Mishra, Yoghurt powder - A review of process technology, storage and utilization. Food Bioprod. Process. 82, 133–142 (2004)

Acknowledgements

This work was supported by UCSI Research Excellence & Innovative Grant, UCSI University, Malaysia (REIG—FAS- 2021/003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saleena, L.A.K., Yusof, Y.A., Song, A.AL. et al. Development of clove extract-fortified functional yoghurt powder using spray: drying. Food Measure 18, 2776–2796 (2024). https://doi.org/10.1007/s11694-024-02358-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02358-4