Abstract

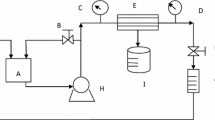

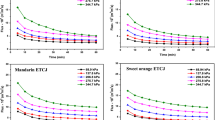

Cashew apple juice is one of the highly nutritious and perishable fruit juice. In this study, the shelf life extension of pre-treated cashew apple juice was undertaken using a non-thermal ultrafiltration technology. A total of 16 experiments were carried out at four different molecular weight cut-offs (5 kDa, 10 kDa, 30 kDa, and 50 kDa) and transmembrane pressures (35 kPa, 69 kPa, 103 kPa, and 138 kPa) to get the optimum process conditions. After considering the highest productivity and superior quality of the filtered juice, 30 kDa molecular weight cut-off and 138 kPa transmembrane pressure were found to be the optimum processing condition for the ultrafiltration of cashew apple juice. At the optimum condition, the ultrafiltered juice had 8.22°Brix TSS, 4.36 pH, 1.16 cP viscosity, 99.88%T clarity, 1.22 NTU turbidity, 0.064 abs color intensity, 196.00 mg/100 mL ascorbic acid content, 13.49 mg tannic acid/100 mL total tannin content and 110.77 mg GAE/100 mL total polyphenol content. Further, a resistance-in-series model was developed to quantify and study the limiting flux behaviour of the ultrafiltration membrane. The developed model has a huge significance (p < 0.05) during the commercialization of the system since it derived a mathematical relationship between the process parameters and the limiting flux of the membrane. Finally, a storage study was carried out and it was observed that the ultrafiltered juice was successfully stored for 12 weeks at 4 °C without any chemical and heat treatment (as compared to the normal shelf life of 1–2 days). This study helps to efficiently design and scaling-up of an ultrafiltration system for the clarification and cold sterilization of cashew apple juice.

Similar content being viewed by others

Data Availability

The datasets generated during the current study are available from the corresponding author upon request.

References

FAOSTAT 2022 Food and Agriculture Data -Food and Agriculture Organization of the United Nations. http://www.fao.org/faostat/en/#home

S. Abdullah, R.C. Pradhan, D. Pradhan, S. Mishra, Modeling and optimization of pectinase-assisted low-temperature extraction of cashew apple juice using artificial neural network coupled with genetic algorithm. Food Chem. 339, 127862 (2021). https://doi.org/10.1016/j.foodchem.2020.127862

I. Das, A. Arora, Post-harvest processing technology for cashew apple – a review. J. Food Eng. 194, 87–98 (2017). https://doi.org/10.1016/j.jfoodeng.2016.09.011

S. Abdullah, S. Karmakar, R.C. Pradhan, S. Mishra, Pressure-driven crossflow microfiltration coupled with centrifugation for tannin reduction and clarification of cashew apple juice: modeling of permeate flux decline and optimization of process parameters. J. Food Process Preserv. (2022). https://doi.org/10.1111/jfpp.16497

R. Kaprasob, O. Kerdchoechuen, N. Laohakunjit et al., Changes in physico-chemical, astringency, volatile compounds and antioxidant activity of fresh and concentrated cashew apple juice fermented with Lactobacillus plantarum. J. Food Sci. Technol. 55, 3979–3990 (2018). https://doi.org/10.1007/s13197-018-3323-7

S. Jafarzadeh, A. Mohammadi Nafchi, A. Salehabadi et al., Application of bio-nanocomposite films and edible coatings for extending the shelf life of fresh fruits and vegetables. Adv. Colloid. Interface Sci. 291, 102405 (2021). https://doi.org/10.1016/j.cis.2021.102405

L. Ma, M. Zhang, B. Bhandari, Z. Gao, Recent developments in novel shelf life extension technologies of fresh-cut fruits and vegetables. Trends Food Sci. Technol. 64, 23–38 (2017). https://doi.org/10.1016/j.tifs.2017.03.005

T.T.H. Le, L.T.K. Vu, N.L. Le, Effects of membrane pore size and transmembrane pressure on ultrafiltration of red-fleshed dragon fruit (Hylocereus polyrhizus) juice. J. Chem. Technol. Biotechnol. 96, 1561–1572 (2021). https://doi.org/10.1002/jctb.6672

T. Vu, J. LeBlanc, C.C. Chou, Clarification of sugarcane juice by ultrafiltration membrane: toward the direct production of refined cane sugar. J. Food Eng. (2020). https://doi.org/10.1016/j.jfoodeng.2019.07.029

T. Urošević, D. Povrenović, P. Vukosavljević et al., Recent developments in microfiltration and ultrafiltration of fruit juices. Food Bioprod. Process. 106, 147–161 (2017). https://doi.org/10.1016/j.fbp.2017.09.009

M. Cai, C. Xie, Y. Lv et al., Changes in physicochemical profiles and quality of apple juice treated by ultrafiltration and during its storage. Food Sci. Nutr. 8, 2913–2919 (2020). https://doi.org/10.1002/fsn3.1593

P. Rai, S. De, Clarification of pectin-containing juice using ultrafiltration. Curr. Sci. 96, 1361–1371 (2009)

A. Roy, S. De, Resistance-in-series model for flux decline and optimal conditions of Stevia extract during ultrafiltration using novel CAP-PAN blend membranes. Food Bioprod. Process. 94, 489–499 (2015). https://doi.org/10.1016/j.fbp.2014.07.006

P. Ghosh, S. Garg, I. Mohanty et al., Comparison and storage study of ultra-filtered clarified jamun (Syzygium cumini) juice. J. Food Sci. Technol. 56, 1877–1889 (2019). https://doi.org/10.1007/s13197-019-03648-2

C. Panigrahi, M. Mondal, S. Karmakar et al., Shelf life extension of sugarcane juice by cross flow hollow fibre ultrafiltration. J. Food Eng. 274, 109880 (2020). https://doi.org/10.1016/j.jfoodeng.2019.109880

H. Susanto, A. Roihatin, I.N. Widiasa, Production of colorless liquid sugar by ultrafiltration coupled with ion exchange. Food Bioprod. Process. 98, 11–20 (2016)

S. Karmakar, S. De, Cold sterilization and process modeling of tender coconut water by hollow fibers. J. Food Eng. 200, 70–80 (2017). https://doi.org/10.1016/j.jfoodeng.2016.12.021

N. Sadeghzadeh Benam, M. Goli, S.M. Seyedain Ardebili, N. Vaezshoushtari, The quality characteristics of dough and toast bread prepared with wheat flour containing different levels of Portulaca oleracea leaf powder. Food Sci. Technol. 42, e60820 (2021). https://doi.org/10.1590/fst.60820

S. Abdullah, R.C. Pradhan, S. Mishra, Effect of cellulase and tannase on yield, ascorbic acid and other physicochemical properties of cashew apple juice. Fruits 76, 51–60 (2021)

A. Patra, S. Abdullah, R.C. Pradhan, Microwave-assisted extraction of bioactive compounds from cashew apple (Anacardium occidenatale L.) bagasse: modeling and optimization of the process using response surface methodology. J. Food Meas. Charact. 15, 4781–4793 (2021)

G. Patel, A. Patra, S. Abdullah, M. Dwivedi, Indian jujube (Ziziphus mauritiana L.) fruit juice extraction using cellulase enzyme: modelling and optimization of approach by ANN-GA. Appl. Food Res. 2(1), 100080 (2022)

A. Patra, S. Abdullah, R.C. Pradhan, Application of artificial neural network-genetic algorithm and response surface methodology for optimization of ultrasound-assisted extraction of phenolic compounds from cashew apple bagasse. J. Food Process. Eng. 44, e13828 (2021)

S. Abdullah, R.C. Pradhan, M. Aflah, S. Mishra, Efficiency of tannase enzyme for degradation of tannin from cashew apple juice : modeling and optimization of process using artificial neural network and response surface methodology. J. Food Process. Eng. (2020). https://doi.org/10.1111/jfpe.13499

A. Patra, S. Abdullah, R.C. Pradhan, Optimization of ultrasound-assisted extraction of ascorbic acid, protein and total antioxidants from cashew apple bagasse using artificial neural network-genetic algorithm and response surface methodology. J. Food Process. Preserv. 46, 1–17 (2022). https://doi.org/10.1111/jfpp.16317

Z. Jafari, M. Goli, M. Toghyani, The effects of phosphorylation and microwave treatment on the functional characteristics of freeze-dried egg white powder. Foods 11(17), 2711 (2022)

H.A. Gulec, P.O. Bagci, U. Bagci, Clarification of apple juice using polymeric ultrafiltration membranes: a comparative evaluation of membrane fouling and juice quality. Food Bioprocess. Technol. 10, 875–885 (2017). https://doi.org/10.1007/s11947-017-1871-x

A. Laorko, Z. Li, S. Tongchitpakdee et al., Effect of membrane property and operating conditions on phytochemical properties and permeate flux during clarification of pineapple juice. J. Food Eng. 100, 514–521 (2010). https://doi.org/10.1016/j.jfoodeng.2010.04.039

V. Perreault, N. Gouin, A. Bérubé et al., Effect of pectinolytic enzyme pretreatment on the clarification of cranberry juice by ultrafiltration. Membranes (Basel) 11, 1–17 (2021). https://doi.org/10.3390/membranes11010055

A. Servent, F.A.P. Abreu, C. Dhuique-Mayer et al., Concentration and purification by crossflow microfiltration with diafiltration of carotenoids from a by-product of cashew apple juice processing. Innov. Food Sci. Emerg. Technol. 66, 102519 (2020). https://doi.org/10.1016/j.ifset.2020.102519

S. Mondal, C. Rai, S. De, Identification of fouling mechanism during ultrafiltration of stevia extract. Food Bioprocess. Technol. 6, 931–940 (2013). https://doi.org/10.1007/s11947-011-0754-9

L. Zhao, Y. Wang, X. Hu et al., Korla pear juice treated by ultrafiltration followed by high pressure processing or high temperature short time. LWT - Food Sci. Technol. 65, 283–289 (2016). https://doi.org/10.1016/j.lwt.2015.08.011

C. Conidi, A. Cassano, F. Caiazzo, E. Drioli, Separation and purification of phenolic compounds from pomegranate juice by ultrafiltration and nanofiltration membranes. J. Food Eng. 195, 1–13 (2017). https://doi.org/10.1016/j.jfoodeng.2016.09.017

Q. Lu, L. Li, S. Xue et al., Stability of flavonoid, carotenoid, soluble sugar and vitamin C in ‘Cara Cara’ Juice during storage. Foods 8, 1–15 (2019). https://doi.org/10.3390/FOODS8090417

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdullah, S., Karmakar, S., Mishra, S. et al. Ultrafiltration of cashew apple juice using hollow fibers for shelf life extension: process optimization, flux modelling and storage study. Food Measure 17, 2182–2192 (2023). https://doi.org/10.1007/s11694-022-01790-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01790-8