Abstract

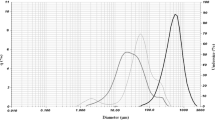

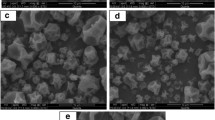

An alkaline-trigged release of microparticle was prepared. The microparticle was prepared by extruding the mixture of corn starch, zein and procyanidins, and the characteristics of microparticle were detected. The 90% of procyanidins was released at the beginning in pH9 buffer solution and decreased following the chasing time. Even under the extreme alkaline condition (pH 11), approximately 50% of procyanidins was detected after 2 days chasing. The microparticle prepared by extruding the mixture of corn starch and procyanidins (SP) and microparticle prepared by extruding the mixture of corn starch, zein and procyanidins (SZP) showed high antioxidant ability, and the SP displayed five times more ABTS·+ scavenging ratio than SZP. Both of them maintained the constant procyanidins release ratio of 60% and 15% in digestive juice, respectively. The change of morphology, disintegration of crystal and breakage of chemical bonds specified the relationship between procyanidins release and damage of microparticle structure.

Graphical abstract

Similar content being viewed by others

Abbreviations

- SP:

-

Microparticle prepared by extruding the mixture of corn starch and procyanidins

- SZP:

-

Microparticle prepared by extruding the mixture of corn starch, zein and procyanidins

References

B.L. White, L.R. Howard, R.L. Prior, Release of bound procyanidins from cranberry pomace by alkaline hydrolysis. J. Agric. Food Chem. 58, 7572–7579 (2010). https://doi.org/10.1021/jf100700p

M. Ahmad, B. Ashraf, A. Gani, A. Gani, Microencapsulation of saffron anthocyanins using β glucan and β cyclodextrin: microcapsule characterization, release behaviour & antioxidant potential during in-vitro digestion. Int. J. Biol. Macromol. 109, 435–442 (2018). https://doi.org/10.1016/j.ijbiomac.2017.11.122

S. Haghju, S. Beigzadeh, H. Almasi, H. Hamishehkar, Chitosan films incorporated with nettle (Urtica dioica L.) extract-loaded nanoliposomes: I. Physicochemical characterisation and antimicrobial properties. J. Microencapsul. 33, 438–448 (2016). https://doi.org/10.1080/02652048.2016.1208294

E. Chezanoglou, A.M. Goula, Co-crystallization in sucrose: a promising method for encapsulation of food bioactive components. Trends Food Sci. Technol. 114, 262–274 (2021). https://doi.org/10.1016/j.tifs.2021.05.036

H. Li, Y. Li, T. Zhang, T. Liu, J. Yu, Technology, co-encapsulation of Lactobacillus paracasei with lactitol in caseinate gelation cross-linked by Zea mays transglutaminase. LWT Food Sci. 147, 111535 (2021). https://doi.org/10.1016/j.lwt.2021.111535

S. Dutta, A. Kundu, A. Dutta, S. Saha, K. Banerjee, A comprehensive chemical profiling of phytochemicals from Trachyspermum ammi and encapsulation for sustained release. LWT Food Sci. 147, 111577 (2021). https://doi.org/10.1016/j.lwt.2021.111577

Kathrin, F. J. F 2021. Marketing and Technology, Symrise invests in Twin Screw Extrusion Technology for Encapsulated Flavors.

J. Harrington, M. Schaefer, Chapter 8—extrusion-based microencapsulation for the food industry, in Microencapsulation in the food industry. ed. by A.G. Gaonkar, N. Vasisht, A.R. Khare, R. Sobel (Academic Press, San Diego, 2014), pp. 81–84

R. Berendsen, C. Güell, M. Ferrando, Spray dried double emulsions containing procyanidin-rich extracts produced by premix membrane emulsification: effect of interfacial composition. Food Chem. 178, 251–258 (2015). https://doi.org/10.1016/j.foodchem.2015.01.093

M.J. Teng, Y.S. Wei, T.G. Hu, Y. Zhang, H. Wu, Citric acid cross-linked zein microcapsule as an efficient intestine-specific oral delivery system for lipophilic bioactive compound. J. Food Eng. 281, 109993 (2020). https://doi.org/10.1016/j.jfoodeng.2020.109993

X. Huang, Y. Wang, H. Zhang, M. Zhao, Y. Fang, Construction and characterization of medium-chain triglyceride(MCT)/zein microcapsules with core–shell structure. Food Sci. 40, 21–27 (2019). https://doi.org/10.7506/spkx1002-6630-20170831-368

E. Habeych, B. Dekkers, A.J. van der Goot, R. Boom, Starch–zein blends formed by shear flow. Chem. Eng. Sci. 63, 5229–5238 (2008). https://doi.org/10.1016/j.ces.2008.07.008

H. Andersson, C. Öhgren, D. Johansson, M. Kniola, M. Stading, Extensional flow, viscoelasticity and baking performance of gluten-free zein-starch doughs supplemented with hydrocolloids. Food Hydrocoll. 25, 1587–1595 (2011). https://doi.org/10.1016/j.foodhyd.2010.11.028

A. Homayouni, A. Amini, A.K. Keshtiban, A.M. Mortazavian, K. Esazadeh, S. Pourmoradian, Resistant starch in food industry: a changing outlook for consumer and producer. Starch 66, 102–114 (2014). https://doi.org/10.1002/star.201300110

C. Franco, S. Preto, C.F. Ciacco, Studies on the susceptibility of granular cassava and com starches to enzymatic attack part I: study of the conditions of hydrolysis. Starch 39, 432–435 (2010). https://doi.org/10.1002/star.19870391207

F. Villas-Boas, Y. Yamauti, M.M.S. Moretti, C.M.L. Franco, Influence of molecular structure on the susceptibility of starch to α-amylase. Carbohyd. Res. 479, 23–30 (2019). https://doi.org/10.1016/j.carres.2019.05.001

R. Bai, Y. Cui, L. Luo, D. Yuan, Z. Wei, W. Yu, B. Sun, A semisynthetic approach for the simultaneous reaction of grape seed polymeric procyanidins with catechin and epicatechin to obtain oligomeric procyanidins in large scale. Food Chem. 278, 609–616 (2019). https://doi.org/10.1016/j.foodchem.2018.11.091

S. Zheng, K. Huang, C. Zhao, W. Xu, Y. Sheng, Y. Luo, X. He, Procyanidin attenuates weight gain and modifies the gut microbiota in high fat diet induced obese mice. J. Funct. Foods 49, 362–368 (2018). https://doi.org/10.1016/j.jff.2018.09.007

Y. Ji, X. Lin, J. Yu, Preparation and characterization of oxidized starch-chitosan complexes for adsorption of procyanidins. LWT Food Sci. Technol. 117, 108610 (2020). https://doi.org/10.1016/j.lwt.2019.108610

J. Song, J. Zong, C. Ma, S. Chen, D. Zhang, Microparticle prepared by chitosan coating on the extruded mixture of corn starch, resveratrol, and α-amylase controlled the resveratrol release. Int. J. Biol. Macromol. 185, 773–781 (2021). https://doi.org/10.1016/j.ijbiomac.2021.06.154

F. Finocchiaro, B. Ferrari, A. Gianinetti, A study of biodiversity of flavonoid content in the rice caryopsis evidencing simultaneous accumulation of anthocyanins and proanthocyanidins in a black-grained genotype. J. Cereal Sci. 51, 28–34 (2010). https://doi.org/10.1016/j.jcs.2009.09.003

Q. Li, X. Wang, J. Chen, C. Liu, T. Li, D.J. McClements, T. Dai, J. Liu, Antioxidant activity of proanthocyanidins-rich fractions from Choerospondias axillaris peels using a combination of chemical-based methods and cellular-based assay. Food Chem. 208, 309–317 (2016). https://doi.org/10.1016/j.foodchem.2016.04.012

M. Sun, C. Sun, H. Xie, S. Yan, H. Yin, A simple method to calculate the degree of polymerization of alginate oligosaccharides and low molecular weight alginates. Carbohyd. Res. 486, 107856 (2019). https://doi.org/10.1016/j.carres.2019.107856

D. Roberts, V. Reyes, F. Bonilla, B. Dzandu, C. Liu, A. Chouljenko, S. Sathivel, Viability of Lactobacillus plantarum NCIMB 8826 in fermented apple juice under simulated gastric and intestinal conditions. LWT Food Sci. Technol. 97, 144–150 (2018). https://doi.org/10.1016/j.lwt.2018.06.036

L. Chen, F. Ren, X. Yu, Z. Zhang, D. Xu, Q. Tong, Pasting investigation, SEM observation and the possible interaction study on rice starch–pullulan combination. Int. J. Biol. Macromol. 73, 45–48 (2015). https://doi.org/10.1016/j.ijbiomac.2014.11.010

R.G. Utrilla-Coello, L.A. Bello-Pérez, E.J. Vernon-Carter, E. Rodriguez, J. Alvarez-Ramirez, Microstructure of retrograded starch: quantification from lacunarity analysis of SEM micrographs. J. Food Eng. 116, 775–781 (2013). https://doi.org/10.1016/j.jfoodeng.2013.01.026

F.J. Warren, M.J. Gidley, B.M. Flanagan, Infrared spectroscopy as a tool to characterise starch ordered structure—a joint FTIR–ATR, NMR, XRD and DSC study. Carbohydr Polym 139, 35–42 (2016). https://doi.org/10.1016/j.carbpol.2015.11.066

Y. Sun, C. Shi, J. Yang, S. Zhong, Z. Li, L. Xu, S. Zhao, Y. Gao, X. Cui, Fabrication of folic acid decorated reductive-responsive starch-based microcapsules for targeted drug delivery via sonochemical method. Carbohyd. Polym. 200, 508–515 (2018). https://doi.org/10.1016/j.carbpol.2018.08.036

X. Bai, C. Li, L. Yu, Y. Jiang, M. Wang, S. Lang, D. Liu, Development and characterization of soybean oil microcapsules employing kafirin and sodium caseinate as wall materials. LWT Food Sci. Technol. 111, 235–241 (2019). https://doi.org/10.1016/j.lwt.2019.05.032

X.-R. Kong, Z.-Y. Zhu, X.-J. Zhang, Y.-M. Zhu, Effects of Cordyceps polysaccharides on pasting properties and in vitro starch digestibility of wheat starch. Food Hydrocoll. 102, 105604 (2020). https://doi.org/10.1016/j.foodhyd.2019.105604

M. Zeng, Y. Huang, L. Lu, L. Fan, D. Lourdin, Effects of filler-matrix morphology on mechanical properties of corn starch–zein thermo-moulded films. Carbohyd. Polym. 84, 323–328 (2011). https://doi.org/10.1016/j.carbpol.2010.11.038

A.K. Oladele, K.G. Duodu, N.M. Emmambux, Pasting, flow, thermal and molecular properties of maize starch modified with crude phenolic extracts from grape pomace and sorghum bran under alkaline conditions. Food Chem. 297, 124879 (2019). https://doi.org/10.1016/j.foodchem.2019.05.153

Y. Jing, J. Huang, X. Yu, Maintenance of the antioxidant capacity of fresh-cut pineapple by procyanidin-grafted chitosan. Postharvest Biol. Technol. 154, 79–86 (2019). https://doi.org/10.1016/j.postharvbio.2019.04.022

R. Hao, Q. Li, J. Zhao, H. Li, W. Wang, J. Gao, Effects of grape seed procyanidins on growth performance, immune function and antioxidant capacity in weaned piglets. Livest. Sci. 178, 237–242 (2015). https://doi.org/10.1016/j.livsci.2015.06.004

R. Paliwal, S. Palakurthi, Zein in controlled drug delivery and tissue engineering. J. Control. Release 189, 108–122 (2014)

M.-J. Teng, Y.-S. Wei, T.-G. Hu, Y. Zhang, K. Feng, M.-H. Zong, H. Wu, Citric acid cross-linked zein microcapsule as an efficient intestine-specific oral delivery system for lipophilic bioactive compound. J. Food Eng. 281, 109993 (2020). https://doi.org/10.1016/j.jfoodeng.2020.109993

F. Zhang, Q. Wu, Z.-C. Chen, M. Zhang, X.-F. Lin, Hepatic-targeting microcapsules construction by self-assembly of bioactive galactose-branched polyelectrolyte for controlled drug release system. J. Colloid Interface Sci. 317, 477–484 (2008). https://doi.org/10.1016/j.jcis.2007.09.065

D. Banerjee, R. Chowdhury, P. Bhattacharya, In-vitro evaluation of targeted release of probiotic Lactobacillus casei (2651 1951 RPK) from synbiotic microcapsules in the gastrointestinal (GI) system: experiments and modeling. LWT Food Sci. Technol. 83, 243–253 (2017). https://doi.org/10.1016/j.lwt.2017.05.011

F. Bi, X. Zhang, R. Bai, Y. Liu, J. Liu, J. Liu, Preparation and characterization of antioxidant and antimicrobial packaging films based on chitosan and proanthocyanidins. Int. J. Biol. Macromol. 134, 11–19 (2019). https://doi.org/10.1016/j.ijbiomac.2019.05.042

B. Wei, H. Qi, Z. Wang, Y. Bi, J. Zou, B. Xu, X. Ren, H. Ma, The ex-situ and in-situ ultrasonic assisted oxidation of corn starch: a comparative study. Ultrason. Sonochem. 61, 104854 (2020). https://doi.org/10.1016/j.ultsonch.2019.104854

D. Domene-López, J.J. Delgado-Marín, I. Martin-Gullon, J.C. García-Quesada, M.G. Montalbán, Comparative study on properties of starch films obtained from potato, corn and wheat using 1-ethyl-3-methylimidazolium acetate as plasticizer. Int. J. Biol. Macromol. 135, 845–854 (2019). https://doi.org/10.1016/j.ijbiomac.2019.06.004

A.-Q. Zhao, L. Yu, M. Yang, C.-J. Wang, M.-M. Wang, X. Bai, Effects of the combination of freeze-thawing and enzymatic hydrolysis on the microstructure and physicochemical properties of porous corn starch. Food Hydrocoll. 83, 465–472 (2018). https://doi.org/10.1016/j.foodhyd.2018.04.041

L. Jiang, F. Jia, Y. Han, X. Meng, Y. Xiao, S. Bai, Development and characterization of zein edible films incorporated with catechin/β-cyclodextrin inclusion complex nanoparticles. Carbohyd. Polym. 261, 117877 (2021). https://doi.org/10.1016/j.carbpol.2021.117877

M. Ma, Y. Yuan, S. Yang, Y. Wang, Z. Lv, Fabrication and characterization of zein/tea saponin composite nanoparticles as delivery vehicles of lutein. LWT Food Sci. Technol. 125, 109270 (2020). https://doi.org/10.1016/j.lwt.2020.109270

K.M. Tavares, A.D. Campos, M.C. Mitsuyuki, B.R. Luchesi, J.M. Marconcini, Corn and cassava starch with carboxymethyl cellulose films and its mechanical and hydrophobic properties. Carbohydr. Polym. 223, 115055 (2019). https://doi.org/10.1016/j.carbpol.2019.115055

M.A. Javaid, K.M. Zia, A. Iqbal, S. Ahmad, N. Akram, X. Liu, H. Nawaz, M.K. Khosa, M. Awais, Utilization of waxy corn starch as an efficient chain extender for the preparation of polyurethane elastomers. Int. J. Biol. Macromol. 148, 415–423 (2020). https://doi.org/10.1016/j.ijbiomac.2020.01.011

Acknowledgements

This work was supported by the Shandong Provincial Natural Science Foundation, China (Grant No. ZR2017MC073)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, J., Jiang, L., Qi, M. et al. An alkaline-trigged and procyanidins-stabilized microparticle prepared by extruding the mixture of corn starch, zein and procyanidins. Food Measure 16, 3618–3629 (2022). https://doi.org/10.1007/s11694-022-01432-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01432-z