Abstract

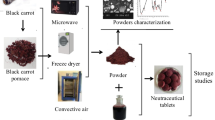

Barberry fruit is a good source of natural antioxidants and various functional compounds. The barberry pulps throw away during producing barberry juice. The aim of the study was to develop the barberry pulp powder as an additive with nutritional value (antioxidant activity, total phenols, and flavonoids content) and quality properties (color properties, sensory properties, flowability). The heating drying was conducted at different conditions (50, 60, and 70 °C for 10, 13, and 16 h). In the second step, the best powder was used to develop compressed tablets of barberry powder with different concentrations (30–50%). The amount of antioxidant activity and flavonoid compounds of powders were in the range of 63.32–80.23% and 164.42–232.91 ppm, respectively. Drying increased the values of DPPH scavenging activity, total phenol and flavonoid content (p < 0.05). The Carr index (0.15–0.19), and Hausner ratio (1.22–1.25) determined the good flowability. According to the results, the optimal temperature and time for drying was 60 °C for 13 h. This sample was applied for tablet preparation. The tablets had a diameter of 5 mm and thickness of 3 mm and included 14.40–17.35%, 48.77–65.13%, and 70.09–98.33 mg GAE/100 g of fiber, antioxidant activity and, total phenol content, respectively.

Similar content being viewed by others

References

H. Hassanpour, S. Alizadeh, Evaluation of phenolic compound, antioxidant activities and antioxidant enzymes of barberry genotypes in Iran. Sci. Hortic. 200, 125–130 (2016)

M. Sarraf, A. Beig-babaei, S. Naji-Tabasi, Investigating functional properties of barberry species: an overview. J. Sci. Food Agric. 99, 5255 (2019)

I. Kosalec, B. Gregurek, D. Kremer, M. Zovko, K. Sanković, K. Karlović, Croatian barberry (Berberis croatica Horvat): a new source of berberine—analysis and antimicrobial activity. World J. Microbiol. Biotechnol. 25(1), 145–50 (2009)

J. Aliakbarlu, S. Ghiasi, B. Bazargani-Gilani (eds.), Effect of Extraction Conditions on Antioxidant Activity of Barberry (Berberis Vulgaris L.) Fruit Extracts (Faculty of Veterinary Medicine, Urmia University, Urmia, 2018)

M. Hemmati, E. Zohoori, O. Mehrpour, M. Karamian, S. Asghari, A. Zarban, R. Nasouti, Anti-atherogenic potential of jujube, saffron and barberry: anti-diabetic and antioxidant actions. EXCLI J. 14, 908 (2015)

S.B. Ardestani, M.A. Sahari, M. Barzegar, S. Abbasi, Some physicochemical properties of Iranian native barberry fruits (abi and poloei): Berberis integerrima and Berberis vulgaris. J. Food Pharm. Sci. (2013). https://doi.org/10.14499/jfps

M. Imanshahidi, H. Hosseinzadeh, Pharmacological and therapeutic effects of Berberis vulgaris and its active constituent, berberine. Phytother. Res. 22(8), 999–1012 (2008)

S.A. Mortazavi, A. Sharifi, A. Maskooki, M. Niakousari, A.H. Elhamirad, Optimisation of bioactive compounds extraction from barberry fruit (Berberis vulgaris) using response surface methodology. Res. Innov. Food Sci. Technol. 3(1), 24–11 (2014)

N. Mokhber-Dezfuli, S. Saeidnia, A.R.M. Gohari, M. Kurepaz-Mahmoodabadi, Phytochemistry and pharmacology of berberis species. Pharmacogn. Rev. 8, 8 (2014)

N. Gholizadeh-Moghadam, B. Hosseini, A. Alirezalu, Classification of barberry genotypes by multivariate analysis of biochemical constituents and HPLC profiles. Phytochem. Anal. 30, 385–394 (2019)

M. Sarraf, A. Beig-babaei, S. Naji-Tabasi, Application of QuEChERS method for extraction of functional compounds. SN Appl. Sci. 2, 1–6 (2020)

M. Sarraf, A. Beig-babaei, S. Naji-Tabasi, Optimizing extraction of berberine and antioxidant compounds from barberry by maceration and pulsed electric field-assisted methods. J. Berry Res. (2020)

A.K. Gupta, M.A. Rather, A.K. Jha, A. Shashank, S. Singhal, M. Sharma, U. Pathak, D. Sharma, A. Mastinu, Artocarpus lakoocha roxb. and artocarpus heterophyllus lam. flowers: new sources of bioactive compounds. Plants 9(10), 1329 (2020)

A. Kumar, M. Premoli, F. Aria, S.A. Bonini, G. Maccarinelli, A. Gianoncelli, M. Memo, A. Mastinu, Cannabimimetic plants: are they new cannabinoidergic modulators? Planta 249, 1681–1694 (2019)

A. Mahdavi, P. Moradi, A. Mastinu, Variation in terpene profiles of thymus vulgaris in water deficit stress response. Molecules 25, 1091 (2020)

S.V. Rad, S.A.R. Valadabadi, M. Pouryousef, S. Saifzadeh, H.R. Zakrin, A. Mastinu, Quantitative and qualitative evaluation of sorghum bicolor L. under intercropping with legumes and different weed control methods. Horticulturae 6, 78 (2020)

Y.L. Siow, L. Sarna, O. Karmin, Redox regulation in health and disease: therapeutic potential of berberine. Food Res. Int. 44(8), 2409–2417 (2011)

A. Zarei, S. Changizi-Ashtiyani, S. Taheri, M. Ramezani, A quick overview on some aspects of endocrinological and therapeutic effects of Berberis vulgaris L. Avicenna J. Phytomed. 5(6), 485 (2015)

A.E. Abd El-Wahab, D.A. Ghareeb, E.E. Sarhan, M.M. Abu-Serie, M.A. El Demellawy, In vitro biological assessment of Berberis vulgaris and its active constituent, berberine: antioxidants, anti-acetylcholinesterase, anti-diabetic and anticancer effects. BMC Complement. Altern. Med. 13(1), 218 (2013)

A. Buriani, S. Fortinguerra, V. Sorrenti, G. Caudullo, M. Carrara, Essential oil phytocomplex activity, a review with a focus on multivariate analysis for a network pharmacology-informed phytogenomic approach. Molecules 25(8), 1833 (2020)

C.A. Breda, E.J. Sanjinez-Argandoña, A.C. de Correia, Shelf life of powdered Campomanesia adamantium pulp in controlled environments. Food Chem. 135(4), 2960–2964 (2012)

Z. Réblová, Effect of temperature on the antioxidant activity of phenolic acids. Czech J. Food Sci. 30(2), 171–175 (2012)

T. Tiho, J. Yao, C. Brou, A.A. Adima, Drying temperature effect on total phenols and flavonoids content, and antioxidant activity of Borassus aethiopum Mart ripe fruits’ pulp. J. Food Res. 6(2), 50 (2017)

J. Bochnak, M. Świeca, Potentially bioaccessible phenolics, antioxidant capacities and the colour of carrot, pumpkin and apple powders: effect of drying temperature and sample structure. Int. J. Food Sci. Technol. 55(1), 136–45 (2020)

W. Liaotrakoon, V. Liaotrakoon, Influence of drying process on total phenolics, antioxidative activity and selected physical properties of edible bolete (Phlebopus colossus (R. Heim) Singer) and changes during storage. Food Science and Technology 2018

A. Taufiq, Y. Yusof, N. Chin, S. Othman, A. Serikbayeva, M. Aziz, In-vitro dissolution of compressed tamarind and pineapple powder tablets. Agric. Agric. Sci. Proc. 2, 53–59 (2014)

M. Ong, Y. Yusof, M. Aziz, N. Chin, N.M. Amin, Characterisation of fast dispersible fruit tablets made from green and ripe mango fruit powders. J. Food Eng. 125, 17–23 (2014)

S. Pushkar, N.K. Sachan, S. Ghosh, Pharmacotechnical assessment of processed watermelon flesh as novel tablet disintegrant. In Chemistry of Phytopotentials: Health, Energy and Environmental Perspectives, Springer: 2012; pp 159 – 63

L.P. Zea, Y.A. Yusof, M.G. Aziz, C.N. Ling, N.A.M. Amin, Compressibility and dissolution characteristics of mixed fruit tablets made from guava and pitaya fruit powders. Powder Technol. 247, 112–119 (2013)

F. Sharİfİ, L. Poorakbar, The survey of antioxidant properties of phenolic compounds in fresh and dry hybrid Barberry fruits (Berberis x integerrimavulgaris). Cumhuriyet Üniversitesi Fen-Edebiyat Fakültesi Fen Bilimleri Dergisi 36(3), 1609–17 (2015)

A.M. Goula, K.G. Adamopoulos, Spray drying of tomato pulp: effect of feed concentration. Dry. Technol. 22(10), 2309–2330 (2004)

A.M. Goula, K.G. Adamopoulos, Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Drying Technol. 26(6), 726–737 (2008)

B.R. Bhandari, N. Datta, B.R. D’Arcy, G.B. Rintoul, Co-crystallization of honey with sucrose. LWT-Food Sci. Technol. 31(2), 138–142 (1998)

N. Jinapong, M. Suphantharika, P. Jamnong, Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. J. Food Eng. 84(2), 194–205 (2008)

A. Correia, A. Loro, S. Zanatta, M. Spoto, T. Vieira, Effect of temperature, time, and material thickness on the dehydration process of tomato. Int. J. Food Sci. 2015

A.P. Larrosa, T.R. Cadaval, L.A. Pinto, Influence of drying methods on the characteristics of a vegetable paste formulated by linear programming maximizing antioxidant activity. LWT-Food Sci. Technol. 60(1), 178–85 (2015)

G.L. Dotto, V.C. Souza, L.A. Pinto, Drying of chitosan in a spouted bed: the influences of temperature and equipment geometry in powder quality. LWT-Food Sci. Technol. 44(8), 1786–1792 (2011)

P.P. Lewicki, Design of hot air drying for better foods. Trends Food Sci. Technol. 17(4), 153–163 (2006)

S. Simal, A. Femenıa, P. Llull, C. Rossello, Dehydration of aloe vera: simulation of drying curves and evaluation of functional properties. J. Food Eng. 43(2), 109–114 (2000)

S. Pokharkar, S. Prasad, H. Das, A model for osmotic concentration of banana slices. J. Food Sci. Technol. (Mysore) 34(3), 230–232 (1997)

S. Naji-Tabasi, M. Mohebbi, Evaluation of cress seed gum and xanthan gum effect on macrostructure properties of gluten-free bread by image processing. J. Food Meas. Charac. 9(1), 110–9 (2015)

A. Kammoun Bejar, N. Kechaou, N. Boudhrioua Mihoubi, Effect of microwave treatment on physical and functional properties of orange (Citrus sinensis) peel and leaves. J. Food Process. Technol. 2(2), 109 (2011)

D. Albanese, L. Cinquanta, G. Cuccurullo, M. Di Matteo, Effects of microwave and hot-air drying methods on colour, β-carotene and radical scavenging activity of apricots. Int. J. Food Sci. Technol. 48, 1327–1333 (2013)

G. İzli̇, Total phenolics, antioxidant capacity, colour and drying characteristics of date fruit dried with different methods. Food Sci. Technol. 37(1), 139–147 (2017)

P. Suvarnakuta, C. Chaweerungrat, S. Devahastin, Effects of drying methods on assay and antioxidant activity of xanthones in mangosteen rind. Food Chem. 125(1), 240–247 (2011)

E.S. Tan, A. Abdullah, M.Y. Maskat, editors. Effect of drying methods on total antioxidant capacity of bitter gourd (Momordica charantia) fruit. AIP Conference Proceedings; 2013: American Institute of Physics

S. Dwivedy, K. Rayaguru, G. Sahoo, Effect of drying methods on quality characteristics of medicinal Indian borage (Coleus aromaticus) leaves. J. Food Process Technol. 3(11), 1–6 (2012)

F. AlJuhaimi, N. Uslu, M.M. Özcan, E. ELBabiker, K. Ghafoor, Effect of drying on antioxidant activity, total phenol and mineral contents of pear fruits. J. Food Saf. Food Qual. 67, 164–167 (2016)

C.-H. Chang, H.-Y. Lin, C.-Y. Chang, Y.-C. Liu, Comparisons on the antioxidant properties of fresh, freeze-dried and hot-air-dried tomatoes. J. Food Eng. 77(3), 478–485 (2006)

F. Que, L. Mao, X. Fang, T. Wu, Comparison of hot air-drying and freeze-drying on the physicochemical properties and antioxidant activities of pumpkin (Cucurbita moschata Duch.) flours. Int. J. Food Sci. Technol. 43, 1195–1201 (2008)

B. Sultana, F. Anwar, M. Ashraf, N. Saari, Effect of drying techniques on the total phenolic contents and antioxidant activity of selected fruits. J. Med. Plants Res. 6(1), 161–167 (2012)

A. Vega-Gálvez, K. Ah-Hen, M. Chacana, J. Vergara, J. Martínez-Monzó, P. García-Segovia, R. Lemus-Mondaca, K. Di Scala, Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 132(1), 51–59 (2012)

E.F. Zanoelo, L. Cardozo Filho, E.L. Cardozo Júnior, Superheated steam-drying of mate leaves and effect of drying conditions on the phenol content. J. Food Process Eng. 29(3), 253–68 (2006)

V. Dewanto, X. Wu, R.H. Liu, Processed sweet corn has higher antioxidant activity. J. Agric. Food Chem. 50(17), 4959–4964 (2002)

M.L. Chen, D.J. Yang, S.C. Liu, Effects of drying temperature on the flavonoid, phenolic acid and antioxidative capacities of the methanol extract of citrus fruit (Citrus sinensis (L.) Osbeck) peels. Int. J. Food Sci. Technol. 46(6), 1179–85 (2011)

S.-M. Jeong, S.-Y. Kim, D.-R. Kim, S.-C. Jo, K. Nam, D. Ahn, S.-C. Lee, Effect of heat treatment on the antioxidant activity of extracts from citrus peels. J Agric Food Chem 2004, 52 (11), 3389–93

S.R. Georgetti, R. Casagrande, C.R.F. Souza, W.P. Oliveira, M.J.V. Fonseca, Spray drying of the soybean extract: effects on chemical properties and antioxidant activity. LWT-Food Sci. Technol. 41(8), 1521–1527 (2008)

V. Mrkìc, E. Cocci, M.D. Rosa, G. Sacchetti, Effect of drying conditions on bioactive compounds and antioxidant activity of broccoli (Brassica oleracea L.). J. Sci. Food Agric. 86(10), 1559–1566 (2006)

N. Deepa, C. Kaur, B. George, B. Singh, H. Kapoor, Antioxidant constituents in some sweet pepper (Capsicum annuum L.) genotypes during maturity. LWT-Food Sci. Technol. 40(1), 121–129 (2007)

S.-C. Ho, C.-C. Lin, Investigation of heat treating conditions for enhancing the anti-inflammatory activity of citrus fruit (Citrus reticulata) peels. J. Agric. Food Chem. 56(17), 7976–7982 (2008)

G. Xu, X. Ye, J. Chen, D. Liu, Effect of heat treatment on the phenolic compounds and antioxidant capacity of citrus peel extract. J. Agric. Food Chem. 55(2), 330–5 (2007)

S. Peighambardoust, K. Sarabandi, Effect of spray drying conditions on physicochemical, functional properties and production yield of malt extract powder. J. Food Res. 27(2), 75–90 (2017)

B. Adhikari, T. Howes, B. Bhandari, V. Troung, Effect of addition of maltodextrin on drying kinetics and stickiness of sugar and acid-rich foods during convective drying: experiments and modelling. J. Food Eng. 62(1), 53–68 (2004)

A. Guo, J. Beddow, A. Vetter, A simple relationship between particle shape effects and density, flow rate and Hausner ratio. Powder Technol. 43(3), 279–284 (1985)

N. Malekizadeh, S.H. Peighambardoust, A. Oladghaffari, K. Sarabandi, Effects of different concentrations of maltodextrin and drying temperatures of spray drying process on physicochemical properties of encapsulated Sumac extract. Iran. Food Sci. Technol. Res. J 14(2), 321–334 (2017)

M. Zhang, J. Tang, A. Mujumdar, S. Wang, Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 17(10), 524–534 (2006)

M. Zhang, H. Jiang, R.-X. Lim, Recent developments in microwave-assisted drying of vegetables, fruits, and aquatic products—Drying kinetics and quality considerations. Dry. Technol. 28, 1307–1316 (2010)

D. Ashebir, K. Jezik, H. Weingartemann, R. Gretzmacher, Change in color and other fruit quality characteristics of tomato cultivars after hot-air drying at low final-moisture content. Int. J. Food Sci. Nutr. 60(sup7), 308–315 (2009)

H.-W. Xiao, J.-W. Bai, L. Xie, D.-W. Sun, Z.-J. Gao, Thin-layer air impingement drying enhances drying rate of American ginseng (Panax quinquefolium L.) slices with quality attributes considered. Food Bioprod. Process 94, 581–591 (2015)

N. Ngwuluka, B. Idiakhoa, E. Nep, I. Ogaji, I. Okafor, Formulation and evaluation of paracetamol tablets manufactured using the dried fruit of Phoenix dactylifera Linn as an excipient. Res. Pharm. Biotechnol. 2(3), 025–032 (2010)

M. Saifullah, Y. Yusof, N. Chin, M. Aziz, Physicochemical and flow properties of fruit powder and their effect on the dissolution of fast dissolving fruit powder tablets. Powder Technol. 301, 396–404 (2016)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors have declared that they do not have any conflict of interest for publishing this research.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naji-Tabasi, S., Emadzadeh, B., Shahidi-Noghabi, M. et al. Physico‐chemical properties of powder and compressed tablets based on barberry fruit pulp. Food Measure 15, 2469–2480 (2021). https://doi.org/10.1007/s11694-021-00834-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00834-9