Abstract

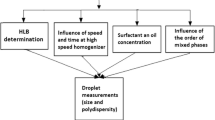

Combination of low energy and high energy methods were studied as alternative process to individual spontaneous emulsification and ultrasonication for production of stable nanoemulsions in order to reduce the synthetic surfactant requirement. A three-step procedure was used: The dispersed oil phase containing hydrophilic surfactant (Tween 80) was titrated into an aqueous phase for formation of nanoemulsion by spontaneous method. Then, it was homogenized by a high shear homogenizer and sonicated to form final stable nanoemulsions. Influence of orange oil to sunflower oil ratio, surfactant emulsion ratio (SER), ultrasonication (US) time and temperature and high shear homogenization (HSH) time on particle size and polydispersity index (PDI) of nanoemulsions were determined. Orange oil/sunflower oil ratio, SER, US time and temperature and HSH time all had an appreciable effect on nanoemulsion formation, particle size distribution and stability. Translucent nanoemulsions (70 nm) was obtained under following specific conditions: 10 wt% oil phase (7 wt% orange oil + 3 wt% sunflower oil), 2 wt% SER (Tween 80), 5 min HSH and 10 min US in an ice bath. The selected nanoemulsion was stable for 35-day storage at ambient temperature. These findings demonstrate that stable orange oil nanoemulsions can be produced from food-grade ingredients using combined processing operations (spontaneous homogenization, HSH and US homogenization) and low synthetic surfactant concentration. This study provides important information for design and application of essential oil nanoemulsion-based delivery systems in food, beverage and other applications.

Similar content being viewed by others

References

M. Viuda-Martos, Y. Ruiz-Navajas, J. Fernández-López, J. Pérez-Álvarez, Food Control 19, 1130–1138 (2008)

S. Rojas-Moreno, F. Cárdenas-Bailón, G. Osorio-Revilla, T. Gallardo-Velázquez, J. Proal-Nájera, Food Meas. 12, 650–660 (2018). https://doi.org/10.1007/s11694-017-9678-z

O.K. Topuz, E.B. Özvural, Q. Zhao, Q. Huang, M. Chikindas, M. Gölükçü, Food Chem. 203, 117–123 (2016)

Y. Chang, L. McLandsborough, D.J. McClements, Food Chem. 172, 293–304 (2015)

Y. Chang, D.J. McClements, J. Agric. Food Chem. 62, 2306–2312 (2014)

D.J. McClements, Soft Matter 7(6), 2297–2316 (2011)

Y. Zhang, S. He, Y. Li, H. Tang, Food Meas. 11, 864–871 (2017)

V. Ghosh, A. Mukherjee, N. Chandrasekaran, Colloids Surf. B Biointerfaces 114, 392–397 (2014)

F. Donsi, A. Cuomo, E. Marchese, G. Ferrari, Innov. Food Sci. Emerg. Technol. 22, 212–220 (2014)

Y. Li, Z. Zhang, Q. Yuan, H. Liang, F. Vriesekoop, J. Food Eng. 119, 419–424 (2013)

S. Calligaris, S. Plazzotta, F. Bot, S. Grasselli, A. Malchiodi, M. Anese, Food Res. Int. 83, 25–30 (2016)

J. Zhang, L. Bing, G. A. LWT-. Food Sci. Technol. 64, 1063–1070 (2015)

L. Salvia-Trujillo, A. Rojas-Graü, R. Soliva-Fortuny, O. Martín-Belloso, Food Bioprocess. Technol. 6, 2439–2446 (2013)

Y. Chang, L. McLandsborough, D.J. McClements, J. Agric. Food Chem. 60, 12056–12063 (2012)

A. Mirmajidi Hashtjin, S. Abbasi, Food Hydrocoll. 44, 40–48 (2015)

D.J. McClements, Soft Matter 8, 1719–1729 (2012)

J. Rao, D.J. McClements, Food Hydrocoll. 26, 268–276 (2012)

A.S. Kabalnov, A.V. Pertzov, E.D. Shchukin, J. Colloid Interface Sci. 118(2), 590–597 (1987)

S.M. Jafari, Y. He, B. Bhandari, Eur. Food Res. Technol. 225, 733–741 (2007)

W. Liu, D. Sun, C. Li, Q. Liu, J. Xu, J. Colloid Interface Sci. 303, 557–563 (2006)

O. Kaltsa, C. Michon, I. Mandala, Ultrason. Sonochem. 20, 881–891 (2013)

P.-H. Li, B.H. Chiang, Ultrason. Sonochem. 19, 192–197 (2012)

B. Abismail, J.P. Canselier, A.M. Wilhelm, H. Delmas, C. Gourdon, Ultrason. Sonochem. 7, 187–192 (2000)

S.Y. Tang, P. Shridharan, M. Sivakumar, Ultrason. Sonochem. 20, 485–497 (2013)

S.G. Gaikwad, A.B. Pandit, Ultrason. Sonochem. 15, 554–563 (2008)

L.S. Spinellia, C.R.E. Mansura, G. Gonzálezb, E.F. Lucasa, Colloid J. 72(1), 56–65 (2010)

P.-H. Li, W.C. Lu, Food Hydrocoll. 53, 218–224 (2015)

D.J. McClements, Food emulsions: Principles, Practices and Techniques, 3rd edn. (CRC Press, Boka Rayton, 2016), pp. 260–261

D.J. McClements, Crit. Rev. Food Sci. Nutr. 47, 611–649 (2007)

Acknowledgements

Gratitude is expressed to Givaudan International SA (Iran Branch) for kindly providing the orange essential oil.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Asadinezhad, S., Khodaiyan, F., Salami, M. et al. Effect of different parameters on orange oil nanoemulsion particle size: combination of low energy and high energy methods. Food Measure 13, 2501–2509 (2019). https://doi.org/10.1007/s11694-019-00170-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00170-z