Abstract

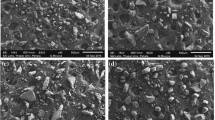

This study attempted to evaluate dry, semi dry and wet grinding methods on flour characteristics of Pusa 1121 basmati rice brokens. The flour obtained through grinding methods was characterized based on for physicochemical, morphological, pasting, flow properties, X-ray diffraction and Fourier transform infrared (FTIR) spectroscopy. Mean particle size of dry ground rice flour was higher in comparison to other grinding methods adopted. Amylose content (%) of flour analysed for different method dry, semi dry and wet was 21.76, 20.08 and 18.52, respectively. Dry ground rice flour contained higher peak viscosity (5353 cP) than the flour obtained from other grinding methods. Scanning electron micrographs revealed descriptive structural behaviour of representative grinding processes. Powder flow analysis is an effective tool to characterize the flow properties of powders to elucidate the effect of powder morphology, granule size and their distribution on flow behaviour and subsequent processing. The scanning electron microscopy, FTIR spectroscopy and X-ray diffraction pattern results indicated some minor changes in structure of rice flour. Different grinding methods resulted in variations in the physicochemical and other associated characteristics of rice flours suitable for specific uses.

Similar content being viewed by others

References

C.J. Bergman, K.R. Bhattacharya, K. Ohtsubo, Rice end-use quality analysis, in Rice: chemistry and technology, ed. by E.A. Champagne (American Association of Cereal Chemists Inc, St. Paul, 2004), pp. 415–472

K. Prasad, Y. Singh, A. Anil, Effects of grinding methods on the characteristics of Pusa 1121 rice flour. J Trop Agric Food Sci 40, 193–201 (2012)

K. Prasad, A. Anil, Y. Singh, A.S.K. Sinha, Concentration dependent rheological behaviour of promising basmati and non basmati rice flour. Int Food Res J 20, 2005–2008 (2013)

P.Y. Chiang, A.I. Yeh, Effect of soaking on wet-milling of rice. J Cereal Sci 35, 85–94 (2002)

A.I. Yeh, Preparation and applications of rice flour, in Rice: chemistry and technology, ed. by E.T. Champagne (The American Association of Cereal Chemists Inc, St. Paul, 2004), pp. 495–539

O. Naivikul, Rice: Science and Technology (Kasetsart University Press, Bangkok, 2004)

J. Chen, V.M.F. Lai, C. Lii, Effects of compositional and granular properties on the pasting viscosity of rice starch blends. Starch 55, 203–212 (2003)

C.P. Villareal, B.O. Juliano, S. Hizukuri, Varietal differences in amylopectin staling of cooked waxy milled rice. Cereal Chem. 70, 753–758 (1993)

Singh Y, Prasad K (2013) Comparative behavior of chemical and pasting characteristics of basmati rice brokens and corn flour. In: Proceedings of Sixth International Conference on Fermented Foods, Health Status and Social Well-being. December 6–7, 2013, Anand Agricultural University, Anand, pp 98–99

B.O. Juliano, Rice starch: production, properties and uses, in Starch: chemistry and technology, ed. by R.L. Whistler, J.N. Bemiller, E.F. Paschall (Academic Press Inc, New York, 1984)

B.O. Juliano, Structure, chemistry and function of the rice grain and its fraction. Cereal Foods World 37, 772–774 (1992)

M.H. Madsen, D. Christensen, Changes in viscosity properties of potato starches during growth. Starch 48, 245–249 (1996)

N. Singh, J. Singh, L. Kaur, N.S. Sodhi, B.S. Gill, Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem 81, 219–231 (2003)

Y. Singh, K. Prasad, Multivariate classification of promising paddy cultivars on the basis of physical properties. Pertanika J Trop Agric Sci 37, 327–342 (2014)

Y. Singh, K. Prasad, Physical characteristics of some of the paddy varieties as affected by shelling and milling operations. Oryza 50, 174–180 (2013)

Association of Official Analytical Chemists (AOAC), Official Methods of Analysis, 17th edn. (AOAC, Washington, 2002)

V.R. Williams, W.T. Wu, H.Y. Tsai, H.G. Bates, Varietal differences in amylose content of rice starch. J Agric Food Chem 6, 47–48 (1958)

V. Stojceska, P. Ainsworth, P. Andrew, I. Esra, I. Senol, Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J Food Eng 87, 554–563 (2008)

K. Prasad, Y. Singh, Rice based vegetable supplemented functional instant soup mix: development and optimization (Scholars Press, Saarbrücken, 2014), p. 84

A. Suksomboon, O. Naivikul, Effect of dry-and wet-milling processes on chemical, physicochemical properties and starch molecular structures of rice starches. Kasetsart J 40, 125–134 (2006)

J.J. Chen, Effect of milling methods on the physicochemical properties of waxy rice flour. Cereal Chem 76, 796–799 (1995)

B.O. Juliano, P.A. Hicks, Rice functional properties and rice food products. Food Rev Int 12, 71–103 (1996)

K.J.R. Vallons, L.A.M. Ryan, E.K. Arendt, Promoting structure formation by high pressure in gluten-free flours. LWT Food Sci Technol 44, 1672–1680 (2011)

S. Naruenartwongsakul, M.S. Chinnan, S. Bhumiratana, T. Yoovidhya, Effect of cellulose ethers on the microstructure of fried wheat flour-based batters. LWT Food Sci Technol 41, 109–118 (2008)

H.M. Lai, Effects of hydrothermal treatment on the physicochemical properties of pregelatinized rice flour. Food Chem 72, 455–463 (2001)

K. Ghiasi, K. Varriano-Marston, R.C. Hoseney, Gelatinization of wheat starch. II. Starch–surfactant interaction. Cereal Chem 59, 86–88 (1982)

S. Yoenyongbuddhagal, A. Noomhorm, Effect of raw material preparation on rice vermicelli quality. Starch 54, 534–539 (2002)

J. Vansteelandt, J.A. Delcour, Characterisation of starch from durum wheat (Triticum durum). Starch 51, 73–80 (1999)

P. Noosuka, S.E. Hill, I.A. Farhat, J.R. Mitchel, P. Pradipasena, Relationship between viscoelastic properties and starch structure in rice from Thailand. Starch 57, 587–598 (2005)

Acknowledgments

The first author acknowledges the receipt of fellowship from Sant Longowal Institute of Engineering and Technology (Deemed University), Longowal during his Doctoral studies and also thankful to Punjab Agricultural University, Ludhiana, India for providing paddy variety (Pusa 1121) for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, Y., Prasad, K. Effect of grinding methods for flour characterisation of Pusa 1121 basmati rice brokens. Food Measure 10, 80–87 (2016). https://doi.org/10.1007/s11694-015-9279-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-015-9279-7