Abstract

There exists strong experimental evidence that bainitic ferrite is formed as a supersaturated solid solution of carbon within a tetragonally-distorted body-centered iron structure (BCT), where carbon preferentially occupies the octahedral site. Despite this, the BCT structure has not yet been accounted for in the computational analysis of the thermodynamics of the bainite transformation. In the present work, we propose to calculate the onset of the bainite transformation based on the T0′ concept, including the effect of Zener-ordering. This mechanism stabilizes the BCT structure, makes it energetically more favorable than BCC and leads to a significantly higher solubility of C compared Fe-BCC. The computational predictions are made based on a recent reassessment of low-T Gibbs energies and finally compared to experiments. The important role of C is emphasized, with the Fe-C system used as a showcase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bainitic steels are of great technological importance, and they are regaining specific industrial interest due to their microstructure combining high strength and good toughness. Bainite forms from austenite during cooling, and it initially consists of two phases, ferrite, and austenite. The microstructure of bainitic ferrite consists of bainitic ferrite platelets separated by austenite films. Due to its particularity of metastability and fast transformation, there is still no clear and comprehensive understanding of the bainite transformation. There exists some debate[1] on the formation mechanism.[2, 3] Also, contradicting modeling approaches for the prediction of the bainite start temperature (Bs) have been proposed. Bhadeshia and Edmonds[2] postulate that the bainite transformation is diffusionless and displacive. Thus, the bainite start temperature, Bs, is calculated from the T0 line, which is the temperature where the Gibbs energy of austenite is equal to that of ferrite at identical compositions of the two phases, with an additional strain energy of 400 J mol−1.[4] This point is called T0’ temperature.

The calculations of Bs can be performed on the basis of Calphad-type thermodynamic databases.[5] Additionally, numerous empirical models[6] have been developed for specific alloy compositions and steel groups. However, these approaches commonly fail when applied to other alloy compositions and, for this reason, these cannot be used for general predictions on the Bs temperatures and kinetic simulation of bainite processing. Although of general nature, within the model of Bhadeshia, the calculation relies on the accuracy of the thermodynamic database and any prediction of Bs temperatures will only be as accurate as the underlying databases are. Therefore, recently, a reassessment of the Fe-C-Ni-Mn-Si thermodynamic modeling has been performed and included in the mc_fe_bainite database.[7] This database is used throughout, here.

In the present work, we propose a methodology to calculate Bs based on the T0’ approximation of Bhadeshia,[2] with a particular focus on the impact of C on the Bs temperature. It is postulated that C becomes trapped in a set of preferred interstitial sites of the body-centered Fe lattice during the transformation, also known as Zener ordering.[2, 8] This transformation finally leads to a certain amount of tetragonal distortion of the lattice into the body-centered tetragonal (BCT) crystal structure,[9, 10] which stabilizes the BCT lattice relative to the parent austenite and, thus, increases the T0’ temperature with respect to the case without consideration of the BCT distortion.

2 Thermodynamic Modeling

The bainite and martensite transformations occur during undercooling of austenite. While these two states are metastable, Kaufman and Cohen[11] introduced a link to the Gibbs energy of the parent phase γ (austenite) and the product phase α (ferrite). This link to thermodynamic equilibrium is reasoned on the basis that the formation of bainite is diffusionless, i.e. the parent and product phase have identical chemical composition, and its growth is thus determined by the difference in Gibbs energy of the two phases. According to this concept, the bainite transformation can only occur below the T0 line, with:

Due to the displacive nature of the bainite reaction and differences in the molar volume of parent and product phases, the transformation is accompanied by a characteristic amount of strain energy \({(E}_{\mathrm{str}}\)), which serves as an energy barrier for the nucleation of bainite and leads to a decrease of the transformation temperature. The corresponding thermodynamic value, T0’, can thus be correlated to the bainite start temperature. This additional strain energy has initially been estimated to be 270 J mol−1.[2] Later, Bhadeshia revised the strain energy contribution to 400 J mol−1,[4] which is used further in the present work. Generally, the relation holds:

The accurate evaluation of this relationship clearly relies on the availability of proper multi-component Gibbs energies, typically compiled in the form of Calphad-type thermodynamic databases.[5] There exist several thermodynamic databases, among them, some are commercialized, and others are open and freely available. They can be used for multiple purposes, such as simple thermodynamic equilibrium or kinetic precipitation modeling.[12] Our present calculations are based on the special open-database mc_fe_bainite,[7] which has recently been assessed in order to have a better consistency of the Gibbs energy curves with experimental evidence. Special emphasis has been put on the low-T range, where the bainite and martensite transformations typically occur. In this special database, the authors[7] have incorporated substantial improvements of the T0 curves compared to the original database and demonstrated very good agreement with available experimental data[13,14,15] and other consistent thermodynamic datasets.[16]

The calculation of the bainite start temperature has been subject to controversy[1] due to the debate on the growth mechanism, which is either diffusionless,[2] assuming that the growth of bainitic ferrite is rapid and does not involve redistribution of C between ferrite and austenite. Or diffusion-controlled,[17] stating that carbon escapes the ferritic platelet during the transformation assuming local equilibrium of C at the interface. In both approaches, a calculation of the bainite start temperature remains based on thermodynamic modeling. A schematic view of this procedure based on the theory of Bhadeshia[8] is shown in Fig. 1.

According to Bhadeshia and co-workers,[2, 8] T0’ (Fig. 1) corresponds to the Bs temperature, i.e. the temperature below which the bainite transformation is observed. This is schematically shown in the Time Temperature Transformation (TTT) diagram, Fig. 2.

Previous calculations of Bs[18,19,20] using various thermodynamic databases show discrepancies between experiments and modeling results, particularly at lower temperatures. In Fig. 3, we show the comparison of the mc_fe database to the newly developed database mc_fe_bainite,[7] emphasizing the relevance of accurate thermodynamic data on the results of Bs calculations. In addition, a significant C-dependence of T0 and T0’ is evident, with the differences becoming increasingly prominent with increasing C content. The different lines in the figure are calculated on basis of the two different thermodynamic databases.[7, 21]

3 Modeling

3.1 Strain Energy

Bhadeshia et al.[4] proposed to calculate T0’ by adding a strain energy contribution of 400 J mol−1 to the T0 temperature. This value is adopted here. The recently optimized database mc_fe_bainite[7] is used for all further calculations. It is emphasized that only carbide-free bainite is considered in the following to avoid ambiguity arising from secondary phase precipitation, which might precede or overlap the bainite transformation.

3.2 BCT Zener-Ordering Transformation

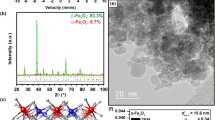

Numerous studies have demonstrated that, during the martensitic transformation in steel, the crystal structure becomes distorted due to transformation strains, which leads to the formation of a body-centered tetragonal structure (BCT). Only recently, such experimental evidence[9, 10] has also been provided for bainitic ferrite. The crystallography of this transformation is schematically shown in Fig. 4. During cooling, the strain applied to the FCC lattice distorts the lattice by the so-called Bain strain. In Fig. 4, the BCT structure is illustrated within two FCC cells with interstitial C (shown in red). Since the virtual body-centered cell is distorted in the vertical direction, the interstitial positions occupied by the red C atoms are also stretched, thus offering energetically preferred positions. The preferential occupation of these sites is also known as Zener ordering.[2, 8]

In our modeling, it is assumed that the displacive formation of ferritic bainite platelets from the parent austenite is so rapid that the C atoms are trapped in the preferred interstitial sites[23] and, thus, support the formation of a tetragonal phase. From an energetic point of view, it is favorable for the C atoms to reside in only a third of the possible interstitial sites, i.e. those sites, which are expanded in the tetragonal structure. The FCC to BCT transformation is energetically more favorable than the transformation into a BCC lattice, where the C atoms remain in random interstitial positions. Since the total free energy of BCT is lower than the BCC structure with randomly dissolved C, the solubility of C in BCT Fe is increased, in agreement with experimental evidence.[24] Although this effect is well accepted for the martensite transformation,[25, 26] it has not yet been taken into account for the thermodynamic calculation of Bs.

To account for the BCT transformation and the effect of Zener ordering, C trapping on particular interstitial Fe-BCC lattice sites is introduced on basis of the trapping model developed by Fischer et al.[27] This approach is implemented in the MatCalc software package,[28] which is used throughout the present work. The main input of the trapping model, in addition to the multicomponent database[7, 21] accounting for the thermodynamics of the system and the number of trapping sites, is the trapping enthalpy, ΔE, between the trap site and trapped element[29] and the coordination number (CN), which correspond to the number of trapping sites for C with respect to one Fe atom in the BCC lattice. The depth of the trap, ΔE, determines the decrease of total energy in the system when compared to the condition without trapping. The ratio of free and trapped atoms, which is the ratio of C atoms on random interstitial positions and C atoms on the one third energetically preferred ones, is given by the modified Oriani equation as:[27, 29]

where \({y}_{\mathrm{L}}\) is the site fraction of C in the lattice and \({y}_{\mathrm{T}}\) the site fraction of trapped C. R is the universal gas constant and T is the temperature.

Considering that there exist three octahedral sublattices, which are associated with a local tetragonal distortion,[25] the occupation of the interstitial site by C can occur in one of these three positions. In our modeling approach, the free energy of the phases (i.e. BCC and FCC) is taken from the thermodynamic Calphad database, whereas the energy of the BCT phase is derived from BCC, taking into account the site occupancy of interstitial sites and the energy difference caused by C-trapping, as proposed by Fischer et al.[27]

4 Data Collection

There exist several papers,[6, 20] where Bs temperatures have been collected from original experimental sources in order to build empirical models for the prediction of the bainite start temperature. One of the aspects of these data collections is that they do not always correctly reflect the original data. In the present work, all data are recollected from the original sources (see “Appendix”) and only those results are accounted for that appear to be reliable. In case of extrapolation with overlapping pearlite formation or unclear data at all, these data are omitted.

4.1 The Role of Fe-C and the Alloying Elements

While studies agree that C in steel is the key for the bainite transformation, the empirical equations[6, 30, 31] refer also to the influence of the alloying elements. These equations provide a different influence of the Fe-C system (see Table 2 of Kang et al.[31]), which cannot be legitimate. Leach et al.[20] reviewed it and showed the serious drawback (Fig. 1 of the original work[20]) of going from multicomponent systems to the original effect given by Fe-C. Accordingly, due to the key role of C in the bainite transformation, the models should first take into account the Fe-C system and then add the effect of the alloying elements afterward.

5 Results and Discussion

5.1 Fe-C

To calculate the bainite start temperature, we use the metastable (without consideration of carbide) Fe-C system as a showcase, since it is a key system for the bainite transformation. The influence of the trapping energy as well as the site occupancy of C next to the Fe atoms is evaluated. The site occupancy of C trapped on the interstitial octahedral sites of the BCC-lattice has often been described in the literature[25, 32, 33] and is given to 1/3, consistent with the fact that one of the three octahedral sublattice sites represents an energetically preferred position during the Bain path transformation.[34] More specifically, Svoboda et al.[29] describe it with respect to the development of the applied trapping model (see Table 1 of the original paper). The energy of the C trap in an octahedral site has been calculated by density functional theory (DFT) and molecular dynamics (MD) in the literature.[24, 35,36,37] The different calculations are reviewed and collected in Table 1.

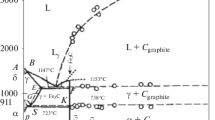

While Jang et al.[24] calculated the dissolution energy of C in octahedral sites in BCC by DFT, Hristova et al.[35] tested several empirical potentials for their calculation in a molecular dynamics simulation. The study of Hristova et al.[35] has revealed a range of dissolution enthalpies from 2.89 to 24.1 kJ mol−1 depending on the applied potential, which they tested in order to see which one is the most appropriate for non-equilibrium in the Fe-C systems. The value of Nematollahi et al.[37] is discarded for the present work, as their investigation is based on the study of pearlite and thus takes into account cementite in addition to ferrite. According to our assessment based on the calculations in multicomponent systems, the optimized value for the calculation of Bs is roughly 20 kJ mol−1, which is in good agreement with the calculated value of Jang et al.[24] Considering the equilibrium phase diagram, and using the thermodynamic parameters from the mc_fe_bainite database[7] (Fig. 5, black lines), C trapping in the octahedral sites of the Fe lattice is considered with a site occupancy of 1/3 and a trapping energy of 20 kJ mol−1 (blue solid line). The calculation performed by Jang et al.[24] is shown as a dashed grey line for comparison.

The direct consequence of the consideration of BCT is an increase in the maximum solubility of C in ferrite (further denoted as Zener-ordered BCT structure). The phase boundaries of the equilibrium phase diagram are plotted in a parameter study considering the thermodynamic parameters as given by Jacob et al.[7] with the conventional equilibrium α/α + γ phase boundaries and α’/α’ + γ in Fig. 6, using different site occupancies (with the fixed trapping energy of 20 kJ mol−1) and different trapping energies with a fixed occupancy of 1/3.

By increasing the amount of C in the different interstitial positions of Fe, the solubility limit of C increases by a factor ~ 30 from the equilibrium calculation to the fully occupied interstitial sites of the Fe lattice. Considering now that one third of the interstitial sites is constantly occupied, the trapping energy of C is increased gradually from 5 kJ mol−1 to 25 kJ mol−1 (Fig. 6b). The solubility limit increases significantly and reaches almost 1 wt.% of C with ΔE = 25 kJ mol−1. For both calculations, the maximum C solubility is obtained at a lower temperature compared to the equilibrium phase diagram, which is attributed to the observation that Zener ordering becomes increasingly prominent with decreasing temperature.

Based on these calculations, the T0 temperatures (now called T0Tr and T0’Tr) are plotted in Fig. 7. The consideration of C trapping in interstitial Fe sites increases the temperature of the T0’Tr temperature. The temperature difference between T0’ and T0’Tr increases with increasing C content.

5.2 Extension to Multicomponent Alloys

Van Bohemen[6], who collected Bs temperatures from various sources, grouped all of these alloys into categories. His collection of data has been recollected from the original sources by the present authors. Following his grouping of alloys, the Bs values taken from original experimental works are plotted for categories/sets 1 and 2. Taking group 1, as given by van Bohemen[6], the T0’ and T0’Tr are calculated for each individual chemical composition. By increasing the C-content in the alloy, the deviation between the calculated T0’ and Bs increases, whereas, by considering the trapping of C in the interstitial sites of Fe (using CN = 1/3 and ΔE = + 20 kJ mol−1), the calculated T0’Tr follow the experimental trend for both groups.

The data collected by van Bohemen[6] do not follow any particular chemistry trend, i.e. variation of specific alloying elements, thus emphasizing the relevance of C compared to other alloying elements. Whereas an increase in the C content leads to an increased deviation from the experiments compared to the calculated T0’, the application of the C-trapping model leads to a good reproduction of the experiments.

In addition to set 1 and set 2 from van Bohemen[6], the C dependency is studied for the sample Fe-C-0.45Mn-3.33Ni-1.52Cr. These experiments were used to show the importance of the database (see Fig. 3) and to improve the thermodynamic database in our previous work[7] (Fig. 8). It is now used as show case for the demonstration of our modeling approach (Fig. 9). The calculation of T0’ (black line) and T0’Tr (grey dashed line) are compared to the experimental Bs. By using the accepted value of Estr = 400 J mol−1, we observe a parallel shift (at a higher temperature) relative to the given experimental values, while, by using Estr = 700 J mol−1, a good correlation between experimental results and the calculated T0’Tr is observed. This observation is seen as an indication that the accepted value of Estr = 400 J mol−1 is not a universal energy value that can be applied to every alloy system. In practical analyses, further consideration of Estr should be carried out based on the constitution of the considered alloy, i.e. composition, thermal history, and thus its related microstructure (e.g. solid solution strengthening, plastic deformation, etc...).

5.3 Influence of Alloying Elements on the Tetragonality

The effect of Zener ordering on the bainite transformation has only recently been experimentally confirmed. A systematic experimental study of the effect of single specific alloying elements on the BCT transformation has unfortunately not yet been performed. Nevertheless, there exist some studies that investigate the effect of alloying elements on the tetragonality,[38,39,40] i.e. Ni[39, 40] using DFT. Chentouf et al.[39] suggested that Ni increases the energy required for the tetragonal lattice distortion, the same researchers,[40] in a later study, suggested that Ni has negligible influence on the thermodynamics of the tetragonality.

Si is used to suppress the formation of carbides in the material and has been found to slow down the reaction kinetics of bainite.[19] While Lin et al.,[19] as well as Wu et al.,[18] in their study with a variable amount of Si, are claiming that their results are in better agreement with the WBs (Widmanstätten and bainite ferrite start) approach than with the T0’, Ranjan et al.[41] confirmed the presence of BCT in their samples, in agreement with our approach. In contrast to the effect of Si, which inhibits the formation of carbides, Cr promotes them. Nevertheless, according to Al-Zoubi et al.[38], the tetragonality is not affected by Cr, which is confirmed by the present calculations.

6 Conclusion

In the present work, the calculations accounting for the BCT transformation T0’Tr show a clear improvement in the predicted Bs compared to T0’ calculation. The present manuscript introduces a simple way to obtain bainite start temperature based on an open-source thermodynamic database and implemented models of trapping of interstitial C in the Fe lattice within the MatCalc software package in compliance with experimental findings. Based on crystallographic considerations, 1/3 of the octahedral Fe interstitial sites can be occupied by C atoms. The trapping enthalpy is obtained with ΔE = 20 kJ mol−1, in agreement with DFT data. The influence of other alloying elements on the tetragonality is reviewed and found to be minor in view of the typical alloying contents in bainitic materials. Though, showing the major influence of C in the bainite transformation.

References

L.C.D. Fielding, The Bainite Controversy, Mater. Sci. Technol. (United Kingdom), 2013, 29, p 383.

H.K.D.H. Bhadeshia, and D.V. Edmonds, The Mechanism of Bainite Formation in Steels, Acta Metall., 1980, 28, p 1265.

M. Hillert, L. Höglund, and J. Ågren, Role of Carbon and Alloying Elements in the Formation of Bainitic Ferrite, Metall. Mater. Trans. A, 2004, 35A, p 3693.

H.K.D.H. Bhadeshia, A Rationalisation of Shear Transformations in Steels, Acta Metall., 1981, 29, p 1117.

H.L. Lukas, S.G. Fries, and B. Sundman, Computational Thermodynamics The Calphad Method. Cambridge University Press, Cambridge, 2007.

S.M.C. Van Bohemen, Bainite and Martensite Start Temperature Calculated with Exponential Carbon Dependence, Mater. Sci. Technol., 2012, 28, p 487.

A. Jacob, E. Povoden-Karadeniz, P. Retzl, and E. Kozeschnik, Reassessment of Low-Temperature Gibbs Energies of BCC and FCC in Steel for T0-Temperature Evaluation, Calphad, 2023, 81, p 102531.

H.K.D.H. Bhadeshia, Bainite in Steels Theory and Practice Third Edition. CRC Press, Cambridge, 2019.

C.N. Hulme-Smith, I. Lonardelli, A.C. Dippel, and H.K.D.H. Bhadeshia, Further Evidence of Tetragonality in Bainitic Ferrite, Scr. Mater., 2013, 69, p 409.

C.N. Hulme-Smith, M.J. Peet, I. Lonardelli, A.C. Dippel, and H.K.D.H. Bhadeshia, Further Evidence of Tetragonality in Bainitic Ferrite, Mater. Sci. Technol. (United Kingdom), 2015, 31, p 254.

L. Kaufman, and M. Cohen, Thermodynamics and Kinetics of Martensitic Transformations, Prog. Met. Phys., 1958, 7, p 165.

P. Retzl, S. Zamberger, and E. Kozeschnik, Progress of Physics-based Mean-field Modeling and Simulation of Steel, Mater. Res. Express, 2021, 8, p 76502.

K. Ishida, and T. Nishizawa, Ferrite/Austenite stabilizing parameter of alloying elements in steel at 200~500°C, Trans Jap Inst Met, 1974, 15, p 217.

E. Scheil, and E. Saftig, Messung der Umwandlungswärme bei der Martensitbildung an Eisen-Nickel-Legierungen mit Hilfe eines Trockeneiskalorimeters, Arch. für das Eisenhüttenwesen, 1960, 31, p 623.

K.K. Srivastava, and J.S. Kirkaldy, The Alpha-Gamma Phase Boundaries and the T 0 line for Fe-Mn Alloys, Metall. Trans. A, 1982, 13, p 2113.

G. Ghosh, and G.B. Olson, Computational Thermodynamics and the Kinetics of Martensitic Transformation, J. Phase Equilibria, 2001, 22, p 199.

M. Hillert, Critical Limit for Massive Transformation, Metall. Mater. Trans. A, 2002, 33, p 2299.

H.D. Wu, G. Miyamoto, Z.G. Yang, C. Zhang, H. Chen, and T. Furuhara, Incomplete Bainite Transformation in Fe-Si-C Alloys, Acta Mater., 2017, 133, p 1.

S. Lin, A. Borgenstam, A. Stark, and P. Hedström, Effect of Si on Bainitic Transformation Kinetics in Steels Explained by Carbon Partitioning, Carbide Formation, Dislocation Densities, and Thermodynamic Conditions, Mater Charact, 2022, 185, p 111774.

L. Leach, P. Kolmskog, L. Höglund, M. Hillert, and A. Borgenstam, Use of Fe-C Information as Reference for Alloying Effects on BS, Metall. Mater. Trans. A, 2019, 50, p 4531.

E. Povoden-Karadeniz, https://www.matcalc.at/index.php/databases/open (2020).

G.F. Vander Voort, Ed., Atlas of Time Temperature Diagrams for Iron and Steels, ASM International, Metals Park, OH, 1991.

O. Shchyglo, T. Hammerschmidt, M. Čak, R. Drautz, and I. Steinbach, Atomistically Informed Extended Gibbs Energy Description for Phase-Field Simulation of Tempering of Martensitic Steel, Materials (Basel), 2016, 9, p 669.

J.H. Jang, H.K.D.H. Bhadeshia, and D.W. Suh, Tempering of Low-Temperature Bainite, Scr. Mater., 2013, 68, p 195.

X. Zhang, H. Wang, T. Hickel, J. Rogal, Y. Li, and J. Neugebauer, Mechanism of Collective Interstitial Ordering in Fe-C Alloys, Nat. Mater., 2020, 19, p 849.

T. Liu, L. Liang, D. Raabe, and L. Dai, The Martensitic Transition Pathway in Steel, J. Mater. Sci. Technol., 2023, 134, p 244.

F.D. Fischer, J. Svoboda, and E. Kozeschnik, Determination of Depths of Traps for Interstitials from Thermodynamic Data: A New View on Carbon Trapping and Diffusion, Model. Simul. Mater. Sci. Eng., 2013, 21, p 065012.

E. Kozeschnik, Mean-Field Microstructure Kinetics Modeling, Encycl. Mater. Met. Alloys, 2022, 4, p 521.

J. Svoboda, Y.V. Shan, E. Kozeschnik, and F.D. Fischer, Determination of Depths of Multiple Traps for Interstitials and Their Influence on Diffusion Kinetics, Model. Simul. Mater. Sci. Eng., 2014, 22, p 065015.

Z. Zhao, C. Liu, Y. Liu, and D.O. Northwood, A New Empirical Formula for the Bainite Upper Temperature Limit of Steel, J. Mater. Sci., 2001, 36, p 5045.

S. Kang, S. Yoon, and S.-J. Lee, Prediction of Bainite Start Temperature in Alloy Steels with Different Grain Sizes, ISIJ Int., 2014, 54, p 997.

P. Maugis, and L. Huang, Modeling the Snoek peak in bct-Martensite, J. Alloys Compd., 2022, 907, p 164502.

H.K.D.H. Bhadeshia, Carbon in Cubic and Tetragonal Ferrite, Philos. Mag., 2013, 93, p 3714.

E.C. Bain, The Nature of Martensite, Trans. AIME, 1924, 70, p 25.

E. Hristova, R. Janisch, R. Drautz, and A. Hartmaier, Parameterized Electronic Description of Carbon Cohesion in Iron Grain Boundaries, Comput. Mater. Sci., 2011, 50, p 1088.

X. Zhang, T. Hickel, J. Rogal, and J. Neugebauer, Interplay Between Interstitial Displacement and Displacive Lattice Transformations, Phys. Rev. B, 2016, 94, p 1.

G.A. Nematollahi, J. Von Pezold, J. Neugebauer, and D. Raabe, Thermodynamics of Carbon Solubility in Ferrite and Vacancy Formation in Cementite in Strained Pearlite, Acta Mater., 2013, 61, p 1773.

N. Al-Zoubi, N.V. Skorodumova, A. Medvedeva, J. Andersson, G. Nilson, B. Johansson, and L. Vitos, Tetragonality of Carbon-doped Ferromagnetic Iron Alloys: A First-principles Study, Phys. Rev. B Condens. Matter Mater. Phys., 2012, 85, p 1.

S. Chentouf, S. Cazottes, F. Danoix, M. Goune, H. Zapolsky, and P. Maugis, Effect of Interstitial Carbon Distribution and Nickel Substitution on the Tetragonality of Martensite: A First-Principles Study, Intermetallics, 2017, 89, p 92.

P. Eyméoud, L. Huang, and P. Maugis, Atomistic Investigation on the Impact of Substitutional Al and Si Atoms on the Carbon Kinetics in Ferrite, Scr. Mater., 2021, 205, p 10.

R. Ranjan, and S.B. Singh, Carbide-Free Bainite Transformations Above and Below Martensite Start Temperature Investigated by In-Situ High-Energy X-Ray Diffraction, Acta Mater., 2021, 202, p 302.

W. Steven and A. Haynes, J. Iron Steel Institue 349 (1956).

U. S. Steel Company,journal of the iron Pittsburg, PA, Supplement to the USS Atlas of Isothermal Transformation Diagrams (1953).

O. (USA) ASM International, Metals Park, Atlas of Time Temperature Diagrams for Iron and Steels (1991).

U. ASM international, Metals Park, OH, Atlas of Isothermal and Cooling Transformation Diagrams (1968).

Y. Ohmori, H. Ohtsubo, Y.C. Jung, S. Okaguchi, and H. Ohtani, Morphology of bainite and widmanstätten ferrite, Metall. Mater. Trans. A, 1994, 25, p 1981.

In Verlag Stahleisen MBH, Dusseldorf, Ger. (1954).

Acknowledgments

The authors gratefully acknowledge the financial support under the scope of the COMET program within the K2 Center “Integrated Computational Material, Process and Product Engineering (IC-MPPE)” (Project No 886385). This program is supported by the Austrian Federal Ministries for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK) and for Labor and Economy (BMAW), represented by the Austrian Research Promotion Agency (FFG), and the federal states of Styria, Upper Austria, and Tyrol.

Funding

Open access funding provided by TU Wien (TUW).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Data collected from Van Bohemen and Leach et al. (compostions wt.%)

Group 1 Van Bohemen

C | Si | Mn | Ni | Cr | Mo | Bs (°C) | Original references | |

|---|---|---|---|---|---|---|---|---|

1 | 0.2 | 0.1 | 0.53 | 1.75 | 0.5 | 0.25 | 620 | Ref [42] |

2 | 0.24 | 0.17 | 0.42 | 1.84 | 0.18 | 0.2 | 640 | Ref [42] |

3 | 0.44 | 0.28 | 0.77 | 0.18 | 0.98 | 580 | Ref [43] | |

4 | 0.48 | 0.25 | 0.86 | 0.18 | 0.98 | 0.04 | 560 | Ref [44] |

5 | 0.55 | 1.03 | 0.6 | 0.19 | 0.36 | 548 | Ref [45] | |

6 | 0.59 | 0.34 | 0.66 | 0.17 | 0.65 | 0.02 | 579 | Ref [44] |

7 | 0.74 | 0.25 | 0.34 | 0.2 | 1.43 | 0.23 | 510 | Ref [43] |

8 | 0.75 | 1.75 | 1 | 520 | Ref [43] | |||

9 | 0.8 | 1.88 | 521 | Ref [43] | ||||

10 | 1 | 0 | 0.35 | 0 | 1.2 | 0.3 | 500 | Ref [43] |

11 | 1.03 | 0.31 | 0.53 | 0 | 1.01 | 520 | Ref [46] | |

12 | 1.15 | 0.03 | 0.76 | 0 | 0 | 0.53 | 530 | Ref [43] |

Group 2—Van Bohemen

C | Si | Mn | Ni | Cr | Mo | Bs (°C) | Original references | |

|---|---|---|---|---|---|---|---|---|

13 | 0.19 | 0.14 | 1.37 | 0.56 | 0.2 | 0.31 | 600 | Ref [42] |

14 | 0.23 | 0.23 | 1.86 | 0 | 590 | Ref [46] | ||

15 | 0.38 | 0.25 | 1.49 | 0.24 | 0.14 | 0.41 | 548 | Ref [44] |

16 | 0.38 | 0.2 | 0.69 | 1.58 | 0.95 | 0.26 | 530 | Ref [43] |

17 | 0.38 | 0.33 | 0.55 | 0.16 | 1.25 | 0.31 | 550 | Ref [42] |

18 | 0.39 | 0.23 | 0.62 | 1.44 | 1.11 | 0.18 | 531 | Ref [44] |

19 | 0.4 | 0.21 | 1.34 | 1.03 | 0.53 | 0.22 | 541 | Ref [44] |

20 | 0.5 | 0.32 | 0.8 | 0.11 | 1.04 | 0.24 | 538 | Ref [47] |

21 | 0.79 | 0.22 | 0.23 | 5.25 | 0.04 | 0.01 | 488 | Ref [43] |

22 | 0.97 | 0.32 | 0.72 | 1.54 | 0.8 | 0.26 | 464 | Ref [43] |

23 | 1.2 | 0 | 1.88 | 0 | 0 | 0 | 440 | Ref [43] |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jacob, A., Schuscha, B., Retzl, P. et al. Thermodynamic Prediction of the Impact of Carbon on Bainite Formation, Including the BCT Transformation. J. Phase Equilib. Diffus. 44, 729–737 (2023). https://doi.org/10.1007/s11669-023-01067-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-023-01067-7