Abstract

A simplified model for the growth of particles in a multicomponent system has been developed. The model takes into account of the effects of cross diffusion and finite interface mobility. It can be applied in a straightforward way to treat precipitation under the conditions of paraequilibrium (PARA) or non-partitioning local equilibrium (NPLE).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Classical sharp-interface models such as those in DICTRA[1] and its analytic approximation[2] for the growth or shrinkage of a particle are based on the assumption that thermodynamic equilibrium prevails locally at the migrating sharp interface. The migration rate may then be calculated by finding the operating tieline at the interface and a numerical solution of the full multicomponent diffusion equations. The calculation of the operating tieline involves a solution of a system of highly non-linear equations. The solution requires extensive computer efforts and often has problems with convergence, especially when miscibility gap phases are involved. Therefore, a simplified model is of great interest and often necessary. The main purpose of the simplified model is to replace the tedious seek for the operating interfacial tieline with a single approximate equation from which the migration rate may be directly calculated. One of such simplified models was developed by Ågren et al. during the Ringberg workshop 1997.[3] The model has been compared with more detailed calculations using DICTRA and it is shown that it is quite accurate for such cases where the transformation is controlled by slow substitutional diffusion, e.g. formation of \(\gamma '\) in Ni-base alloys and MC cubic carbides in alloyed steels. Nevertheless, the approach fails to capture the rapid growth or dissolution of cementite that has been observed experimentally and may occur without any long-range transport of substitutional elements. The purpose of the present report is to present a modification that includes such a rapid reaction and at the same time is capable of considering cross diffusions and interface frictions.

2 Review of Present Simplified Model

For the convenience of the reader we shall first review the present simplified model. The critical size is a main concept in this model. For a given composition of the matrix there is a critical particle size for each phase representing an unstable equilibrium between that phase and the matrix. Smaller particles will shrink and larger ones will grow. We shall first discuss how to calculate the critical size. It should be emphasized that in the simplified model the concentration field of a species in the matrix are replaced by a single value, the average matrix content of that species.

2.1 The Critical Size

We consider a case when the matrix \(\alpha\) has a homogeneous content of species j, represented by the mole fraction \(x_j^{\alpha }\) and there is a driving force to precipitate \(\beta\) phase. The driving force is defined as positive when there is a tendency for the \(\beta\) phase to form and in a system with n components it is given by

or equivalently

The index m means that the quantity is given per mole of atoms. The chemical potentials \(\mu _i\) of the elements \(i=1,...n\) are evaluated for the actual matrix composition \(x_j^{\alpha }\) which at every instant will be approximated as homogeneous but may vary in time. The precipitate composition \(x_j^{\beta }\) is obtained from a multidimensional tangent plane to the \(\beta\) Gibbs energy “curve” parallel to the tangent plane of the \(\alpha\) “curve” for the matrix composition under consideration. Another way of expressing this is to say that \(\Delta G_m\) (positive or negative) is the addition to the molar Gibbs energy of the \(\beta\) phase that would cause the two phases to be in equilibrium. Actually this is how the driving force is calculated in Thermo-Calc.[4] However, \(G_m^{\beta }\) depends on the size of the \(\beta\) particle. Assuming spherical incompressible particles with isotropic interfacial energy \(\sigma\) the capillarity effect reduces the driving force for formation of a particle with radius r

where \(V_m\) is the molar volume approximated as the same in both phases and \(\Delta G_m\) is given by Eq 1. Thus there is a critical size \(r_c\) where the reduced driving force vanishes. As mentioned this particle size represents an unstable equilibrium; if the particle is smaller it will dissolve and if it is bigger it will grow. From Eq 3 and \(\Delta G_m(r)=0\) one finds that the critical size is given by

If the Gibbs energy of the precipitate phase is always higher than that of the matrix the driving force \(\Delta G_m\) will always be negative and Eq 4 will result in a negative critical radius, i.e. the particle could never grow but will always dissolve.

2.2 Driving force and Driving Pressure for Growth or Shrinkage of a Particle with Radius r

According to the mean-field approximation for an assembly of \(\beta\) particles in a homogeneous \(\alpha\) matrix, we may introduce the critical size from Eq 4 and rephrase Eq 3 into

The “driving pressure” for a particles of radius r is expressed from the driving force as

2.3 Irreversible Processes

The total driving pressure \(P^{\text {tot}}(r)\) for growth or shrinkage of a particle with radius r is dissipated by various irreversible processes. The rate of dissipation expressed per unit area of the partcle/matrix interface is obtained as \(P^{\text {tot}}(r)v\), where v is the migration rate of the interface. That rate of dissipation thus has the unit \(J\,m^{-2}\,s^{-1}\). In the present study we consider diffusion in the matrix and the interfacial migration itself as processes that dissipate the driving force. The diffusion in the precipitate is ignored. In more complex cases more processes may be involved and dissipate driving force for a particle with size r. The processes are coupled in series, i.e. they are all needed and the rate of growth will then be controlled by the slowest mechanism. We thus write in general

where the summation is performed over all processes k. In the next section we shall discuss the dissipation caused by the different processes.

2.3.1 Long Range Diffusion in Matrix

We assume that long-range diffusion in the matrix is governed by the linear law.[5]

where \(J_i^{\alpha }\) is the diffusive flux of element i and \(L_{ij}^{\alpha }\) the so-called phenomenological coefficients containing a combination of the diffusional mobilities in the matrix \(\alpha\). \(\nabla \Phi _j^{\alpha }\) is the gradient in the appropriate diffusion potential of j. Both the L parameters and the \(\Phi\)s depend on the choice of frame of reference.[5] In the lattice-fixed frame of reference \(L_{ij}^{\alpha }\) is non-zero only when \(i=j\) and given by \(x_i^{\alpha }M_i^{\alpha }\) if the vacancy mechanism is assumed. \(M_i^{\alpha }\) is the diffusional mobility of i. The corresponding driving forces are simply \(\nabla \Phi _i=\nabla \mu _i\), i.e. the gradients in chemical potentials. In the number-fixed frame of reference the first \(n-1\) driving forces are \(\nabla \Phi _i=\nabla (\mu _i-\mu _n)\) and the \(L_{ij}\) are more complex combinations of the mobilities. The driving force corresponding to the reference component is zero. It should be emphasized that Eq 8 is more general than the one suggested in Ref. [3] which was only given in the lattice-fixed frame of reference.

It is convenient to use the matrix-vector notation and write Eq 8 as

where \(\mathbf{J}\) and \(\nabla {\varvec{\Phi }}\) are columnar vectors and \(\mathbf{L}\) is a symmetric \(n*n\) matrix. For convenience we have thus dropped the index \(\alpha\). Assuming simple spherical symmetry with variation only in the radial direction \(\xi\) we have \(\nabla {\varvec{\Phi }}=\partial {\varvec{\Phi }}/\partial \xi\).

The rate of dissipation caused by diffusion of all elements in the matrix counted per unit volume is \(-\mathbf{J}^T\nabla {\varvec{\Phi }}\) where \(\mathbf{J}^T\) is the transpose of \(\mathbf{J}\), i.e. \(\mathbf{J}\) written as a row vector. Counted per area of interface of the growing or shrinking particle the dissipation is

where the integration is taken over \(\ell\), an effective diffusion distance here approximated with the particle radius r. Eq 10 may seem as a grave approximation but it should be kept in mind that this whole procedure should be regarded as an approximation where computational simplicity is emphasized rather than mathematical rigour.

The difference in composition between the matrix and the particle is related to the diffusive flux in the matrix by means of a flux balance for each component and written in matrix vector notation it is

where \(\Delta \mathbf{x}=\big [\mathbf{x}^{\alpha }-\mathbf{x}^{\beta }\big ]\) and it should be kept in mind that \(\mathbf{J}=\mathbf{J}^{\alpha }\). From Eq 9 we express the required gradient \(\nabla {\varvec{\Phi }}\) to give the flux \(\mathbf{J}\) in the matrix as

where \(\mathbf{L}^{-1}\) is the inverse of \(\mathbf{L}\). Combination with Eq 11 yields

Inserting Eqs 11 and 13 in Eq 10 yields

Eq 14 thus approximates the part of the driving force dissipated by diffusion in the matrix.

2.3.2 Interface Friction

A part of the driving force is also dissipated by interface friction and its expression is simple:

where \({M^{\text {int}}}\) is the interface mobility.

2.4 Dissipation Balance and Interface Migration Rate

Summation over all processes thus yields the total driving pressure as

We now set the total driving pressure equal to the total dissipation and use Eq 6 to rephrase Eq 16 to

This result can also be expressed in terms of the critical radius by means of Eq 5

Here it should be emphasized again that the critical radius is calculated from the actual matrix composition by means of Eqs 1 and 4. Equation 18 is the equation derived by Ågren et al.[3] if the lattice-fixed frame is used and it is identical to that derived by Morral and Purdy already in 1994[6] if the number-fixed frame is applied, although both derivations did not include the finite interface mobility.

3 Extension to Include Rapid Diffusers

The major effect of fast diffusers is that under some conditions the formation or dissolution of the particles may be governed by the fast diffusion of the rapid diffusers. In that case the reaction will not result in any redistribution of the slow diffusing substitutional elements, i.e. the two phases will have the same content of the substitutional elements. This may happen in two extremes referred to as paraequilibrium (PARA) or non-partioning local equilibrium (NPLE). We shall discuss both of them. In both cases it is convenient to express the content using the so-called u-fractions defined from the ordinary mole fractions \(x_k\) as

where \(j\in s\) denotes that the summation is taken only over all substitutional (slow-diffusing) components. The two extremes only differe in the way the driving force is calculated.

3.1 Driving Force and Critical Size Under PARA Conditions

In PARA there is no redistribution of the slow diffusing element, not even on the atomic scale, i.e. \(u_j^{\alpha }=u_j^{\beta }=u_j^0\), where \(u_j^0\) is the initial content of the substitutional elements of the matrix. For the fast diffusers \(u_j^{\alpha }\ne u_j^{\beta }\) and the driving force per mole of substitutional elements then is given by Eq 1 rewritten as

where the subscript ms stands for one mole of substitutional elements. The expression for the driving force has been divided into 2 terms, one for the slow diffusing substitutional elements and one for the fast diffusing interstitials.

The composition of \(\beta\) is obtained from a multidimensional tangent plane to the \(\beta\) Gibbs-energy “curve” parallel to the tangent plane of \(\alpha\) for the matrix composition under consideration. However, in the case of PARA equilibrium the two phases are constrained to have same value of the u fractions of the substitutional elements and only the content of the fast diffusers differ. For the case of one fast diffuser, e.g. C, the Gibbs energy diagram becomes two dimensional, see Fig. 1 where the chemical potential of A is the average chemical potential of the slow diffusers in \(\alpha\) and is given by,

Again the summation is taken over the substitutional elements only.

In practice the calculation can be done in different ways. The driving force \(\Delta G_{ms}\) may be evaluated as the addition to the Gibbs energy curve of the \(\beta\) phase that would make the two phases being in PARA equilibrium, i.e. having the same u fraction of the substitutional elements. The similarity with the case of only slow diffusers discussed in Sect. 2 can be easily seen.

3.2 Driving Force and Critical Size Under NPLE Conditions

If there is some redistribution of slow diffusers on the scale of a few atoms then it is possible to establish full local equilibrium but without long range-range redistribution of the slow diffusers. This is referred to as non-partitioning local equilibrium (NPLE). In this case the Gibbs energy curves are multidimensional but it is easy to calculate the NPLE because the operating tieline is given by the condition that the growing \(\beta\) phase should have the same content, expressed in u fractions, of the slow diffusers as the shrinking \(\alpha\) phase. The driving force is still given by Eq 20 and its first summation with the contribution from the slow diffusers will be the same but the chemical potentials for the fast diffusers may be changed in the direction that makes the driving force lower than that for PARA, i.e.

3.3 Dissipation and Growth Rate Under PARA or NPLE Conditions

Under PARA or NPLE case the slow diffusers dissipate no driving force because they are approximated as being immobile and we thus have instead of Eq 17

where \(\Delta \mathbf{u}=\big [\mathbf{u}^{\alpha }-\mathbf{u}^{\beta }\big ]\) is the difference in u fraction for the fast diffusing components and \(V_{ms}\) is the volume per mole of substitutional elements. The matrix \(\mathbf{L}_{\text {int}}\) is the corresponding matrix for the fast diffusers. For the case of only one fast diffuser C it contains a single parameter \(L_{CC}\) and Eq 23 becomes

Eq 24 together with the calculation of the driving force by means of Eq 20 thus gives the possibility to calculate growth under the PARA or NPLE conditions.

3.4 Criteria for PARA or NPLE

In order to check if the formation or shrinkage of \(\beta\) can occur under PARA or NPLE conditions a criteria must be established. In fact Eq 24 can always be used with the driving force calculated according to PARA or NPLE. In general we expect the rates calculated by Eqs 17 and 24 to differ by many orders of magnitude. A negative driving force would predict shrinkage under the PARA or NPLE conditions and a positive would predict growth. An interesting observation is that there is a range of situations where a particle would shrink under the PARA or NPLE conditions and grow (slowly) under the ortho-equilibrium (OE), i.e. full partitioning local equilibrium.

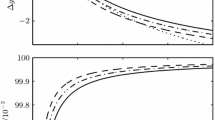

Growth rate as a function of particles size for the precipitation of M\(_{\text {23}}\)C\(_{\text {6}}\) from ferrite at 1053 K in steel A: Fe-2Cr-0.2C (mass%) and steel B: Fe-2Cr-0.05C (mass%). Steel A shows a transition to rapid growth above a critical size and Steel B shows no such a transition. Redrawn from results of Ref. [2]

What does this mean in reality? A naive interpretation may be that the particle quickly dissolves and then re-precipitate under the OE conditions (a slow process). We can conclude this is actually wrong after examining the example given in the section below.

4 Application Examples and Discussion

As mentioned in Sect. 1, Chen et al.[2] presented a method for multicomponent precipitate growth based on the search of the operating interfacial tielines and the set of flux-balance equations taking the effect of interfacial energy into account. In order to be able to deal with a large number of particles of different sizes, they proposed an approximate analytic treatment for the diffusion analysis. However, this method still requires extensive computational efforts to find a solution to the operating tieline and flux balance simultaneously for each particle size and an average matrix concentration. The whole process involves intensive numerical iterations and is time consuming and prone to convergence problems. They investigated two steels with the method and found that for one of them, precipitation changes gradually and spontaneously from the slow OE mode to fast NPLE mode upon increasing the particle size; for the other, precipitation keep the OE conditions. An illustration from their article is reproduced in Fig. 2. We certainly would like to be able to obtain this result with the modified simple model presented in the section above. Indeed, we can achieve this by calculating the growth rates under both the slow OE mode, i.e. Eq 17 and the two fast modes, NPLE and PARA. When all rates are positive we choose the mode with the largest velocity which will be for PARA or NPLE. If the fast modes are negative and the slow mode positive we choose the slow mode. When all rates are negative we choose the slow dissolution under OE.

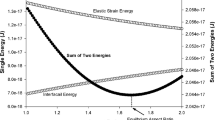

As an example steel A in Fig. 2 has been considered and the results using the modified simple model are shown in Fig. 3. It should be mentioned that the thermodynamic and kinetic databases (TCFE4 and MOB2) and interfacial energy and molar volume data (0.4 J/m\(^2\) and 6 \(\times\) 10\(^{-6}\) m\(^3\)/mol) employed in the present work are the same as those adopted in Ref. [2]. Another point to make is that the NPLE and PARA conditions yield the same results in this case because the concentration of C in M\(_{\text {23}}\)C\(_{\text {6}}\) is stoichiometric so that their driving forces and critical sizes have no difference. For a clear and direct comparison, the results in Fig. 2 and that from DICTRA are also included in Fig. 3. If we always choose the mode with the highest growth rate the net results are then very similar to the results obtained with the more elaborate models except for a gradual transition zone, which can be treated in an ad-hoc empirical way in future. The results for steel B in Fig. 2 are shown in Fig. 4 and as can be seen only the slow mode has a positive growth rate, which is quite close to the results from Ref. [2]. The noticeable yet acceptable difference between the results is caused by the fact that in this case the actual operating interfacial tielines moves away more and more from the tielines passing through the average matrix concentration as the particle size increases.

It is thus obvious that the modification of the simplified model to handle rapid PARA or NPLE reactions described in Sect. 3 works quite satisfactorily. Comparing with more elaborate operating-tieline-search methods, the modified simple model is much easier to implement and it runs without glitch and much faster. The gains of the simplicity and speed are achieved at the sacrifice of accuracy, which we believe is acceptable in most situations considering various assumptions, approximations, data uncertainties involved.

Average radius of cementite precipitates in martensite steel Fe-16.08Co-4.97Ni-0.71Cr-2.82Mo-0.247C (mass%) during tempering at 783 K. Red line: PARA, blue line: OE, and red circles: Equivalent radius based on the measurements of Ghosh et al.[7] (Color figure online)

5 Pragmatic Solution and a Suggested Algorithm

A pragmatic solution could be to classify certain phases as PARA/NPLE equilibrium phases and always treat these using PARA/NPLE conditions, i.e. use Eq 24 for them. The other phases are treated with Eq 17.

-

Distinguish between PARA/NPLE equilibrium phases and other phases

-

Calculate the critical sizes for different phases for a given composition of the matrix

-

Calculate the growth or shrinkage rate for each particle size class from the critical size for each phase

-

Let the particles grow or shrink and calculate the total change in matrix composition.

-

Repeat from second step

6 Model Implementation in TC-PRISMA

The algorithm suggested above has been implemented in TC-PRISMA,[2,8,9] a precipitation simulation module available in the Thermo-Calc software and database package[4] since Version 2019b. Here we show the simulation results for the cementite precipitation during tempering of an ultra-high-strength steel experimentally investigated by Ghosh et al.[7] The spherical approximation has been used. The predicted mean radius under PARA conditions is in agreement with the equivalent radius converted from the experimental results on disk/plate like precipitates (Fig. 5). As can be easily seen, the OE results deviate from reality by several orders of magnitude. For both the PARA and OE simulations, the latest thermodynamic and kinetic databases TCFE12 and MOBFE7 were used. The volume and interfacial energy data were all from the thermodynamic database calculation and estimation respectively in TC-PRISMA. A mobility enhancement activation energy value, 3458 J/mol, has been added according to Hillert’s formula,[10] \(\Delta E=14000w_C\) (mass% of C), to slow down slightly the diffusion of C in martensite in recognizing many experimental observations.

7 Conclusion

The so-called simplified model for growth has been modified to consider general off-diagonal coefficients in the \(\mathbf{L}\) matrix and the diffusion of fast moving elements by means of paraequilibrium (PARA) and non-partioning local equilibrium (NPLE). The modification works quite well and the result agree satisfactorily with the calculations based on finding the operating tie-line.

Change history

02 August 2022

A Correction to this paper has been published: https://doi.org/10.1007/s11669-022-00980-7

References

A. Borgenstam, A. Engström, L. Höglund, J. Ågren, Dictra, a Tool for Simulation of Diffusional Transformations in Alloys. J. Ph. Equilib. 21, 269-280 (2000)

Q. Chen, J. Jeppsson, J. Ågren, Analytical Treatment of Diffusion During Precipitate Growth in Multicomponent Systems. Acta Material. 56, 1890–1896 (2008)

J. Agren, M. Clavaguera-Mora, J. Golaewski, G. Inden, H. Kumar, S. Christoph, Application of Computational Thermodynamics to Phase Transformation Nucleation and Coarsening. CALPHAD 24, 41-54 (2000)

J.-O. Andersson, T. Helander, L. Höglund, P.-F. Shi, B. Sundman, Thermo-Calc and Dictra, Computational Tools for Materials Science. Calphad 26, 273-312 (2002)

J.-O. Andersson, J. Ågren, Models for Numerical Treatment of Multicomponent Diffusion in Simple Phases. J. Appl. Phys. 27, 1350-1355 (1992)

J.-E. Morral, G.-R. Purdy, Particle Coarsening in Binary and Multicomponent Alloys. Scripta Metal and Mater 30, 905-908 (1994)

G. Ghosh, C.-E. Campbell, G.-B. Olson, An Analytical Electron Microscopy Study of Paraequilibrium Cementite Precipitation in Ultra-high-strength Steel. Metall. Mater. Trans. A 30A, 501-512 (1999)

Q. Chen, K. Wu, G. Sterner, P. Mason, Modeling Precipitation Kinetics During Heat Treatment with Calphad-based Tools. J. Mater. Eng. Perf. 23, 4193-4196 (2014)

K. Wu, Q. Chen, P. Mason, Simulation of Precipitation Kinetics with Non-spherical Particles. J. Ph. Eq. Diff. 39, 571-583 (2018)

M. Hillert, The Kinetics of the First Stage of Tempering. Acta Metall. 7, 653-658 (1959)

Acknowledgments

The work has been performed within the FraMat project supported by VINNOVA, the Swedish Governmental Agency for Innovation Systems and Swedish industry. We thank our colleague Dr. Kaisheng Wu for helpful discussions and software implementation.

Funding

Open access funding provided by Royal Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of former JPED Editor-in-Chief John Morral. The special issue was organized by Prof. Yongho Sohn, University of Central Florida; Prof. Ji-Cheng Zhao, University of Maryland; Dr. Carelyn Campbell, National Institute of Standards and Technology; and Dr. Ursula Kattner, National Institute of Standards and Technology.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ågren, J., Chen, Q. Simplified Growth Model for Multicomponent Systems - Inclusion of PARA and NPLE Conditions. J. Phase Equilib. Diffus. 43, 738–744 (2022). https://doi.org/10.1007/s11669-022-00969-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-022-00969-2