Abstract

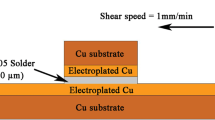

The early corrosion detection of a semiconductor package is the desired goal for industrial semiconductor manufacturing owing to its capability to predict corrosion activity before the product leaves the assembly line. However, the standard procedure for early correction detection always faces great challenges and is yet to be available. Usually, the detected corrosion activities show some degree of failure. Leadframe discoloration provides insights into early corrosion detection in a semiconductor package. This study adopted an unbiased highly accelerated stress test (uHAST) to induce discoloration by promoting the suitable equilibrium moisture content (EMC). The wedge bond of Cu wire onto the Ag-plated Cu leadframe was used. To obtain the actual EMC, dew-point analysis was performed by dry- and wet-bulb data collection. The semiconductor package was subjected to several sets of uHAST condition comprising different combinations of temperature and relative humidity (RH) for 168 h. Mechanical decapsulation was used to expose the wedge bond of Cu wire onto the Ag-plated Cu leadframe followed by qualitative and X-ray photoelectron spectroscopy (XPS) analysis. We found that a higher percentage of EMC facilitated the discoloration of Cu-wedge bond. XPS analysis further confirmed that the discoloration was associated with early corrosion activities. Therefore, uHAST may be used as an early corrosion detection procedure by considering the combination effect of RH and temperature through EMC analysis.

Similar content being viewed by others

References

N. Ross, M. Asokan, G.I.A. Kumar, J. Caperton, J. Alptekin, A.S. Salunke, O.M. Chyan, Mechanistic study of copper wire-bonding failures on packaging devices in acidic chloride environments. Microelectron. Reliab. 113, 113917 (2020)

K. Shinohara, T. Kobayashi and A. Miyota, Effect of Bonding Position between Cu Wire and Al pad in THB Reliability Test, in 2023 International Conference on Electronics Packaging (ICEP, 2023), pp. 83-84.

V. Mathew, E. Wikramanayake, and S. F. Chopin, Corrosion of copper wire bonded packages by chlorine containing foreign particles, in 2020 IEEE 70th Electron. Components Technol. Conf. (IEEE, 2020), pp. 504–511.

Z. Bachok, A.A. Saad, F.C. Ani, A. Jalar, M.A. Abas, Structural assessment of lead free solder joint of miniaturized electronics assembly. Int. J. Integr. Eng. 10, 26 (2018)

N. Jiang, L. Zhang, Z.-Q. Liu, L. Sun, W.-M. Long, P. He, M.-Y. Xiong, M. Zhao, Reliability issues of lead-free solder joints in electronic devices. Sci. Technol. Adv. Mater. 20, 876 (2019)

M.A. Bakar, A. Atiqah, A. Jalar, Review on corrosion in electronic packaging trends of collaborative between academia-industry. Sustainability. 14, 15730 (2022)

K. A. Hamid, A. H. Badarisman, A. Jalar, and M. A. Bakar, Investigation of integrated factors in the occurrence of copper wire bonding corrosion of semiconductor packages in J. Phys. Conf. Ser. (IOP Publishing, 2022), p. 12016.

R. Klengel, S. Klengel, J. Schischka, N. Araki, M. Eto, T. Haibara, and T. Yamada, Corrosion effects and reliability improvement of silver wire bonded contacts in automotive application in 2021 23rd Eur. Microelectron. Packag. Conf. Exhib. (IEEE, 2021), pp. 1–7.

S. Supramaniam, M.A. Bakar, A. Jalar, Early corrosion detection of Cu-Ag wedge bonding in semiconductor package. J Fail Anal Prev. 22(6), 2317–2325 (2022)

A.A. Omar, A. Jalar, K.A. Hamid, Evolution of discrete semiconductor copper wedge bond in biased temperature humidity chamber. J. Teknol. 84(6–2), 129–135 (2022)

A.A. Omar, A. Jalar, M.A. Bakar, K.A. Hamid, Sulfur ingression on encapsulated leadframe of discrete semiconductor package. IEEE Trans. Compon. Packag. Manuf. Technol. 12(3), 544–550 (2022)

W. Qin, Corrosion Mechanisms of Copper and Gold Ball Bonds in Semiconductor Packages: A Unification of Structure-Based Inference and Electrochemical Investigation in Adv. Driv. Assist. Syst. Auton. Veh. From Fundam. to Appl. (Springer, 2022), pp. 581–629.

J. Wang, Y. Niu, S. Shao, H. Wang, J. Xu, V. Pham, S. Park, A comprehensive solution for modeling moisture induced delamination in electronic packaging during solder reflow Microelectron. Reliab. 112, 113791 (2020)

A. J. Garete, Z. Li, A. Taduran, and M. N. A. P. Balasundaram, Enabling MSL1 Zero Delamination through Advanced Packaging Solutions for Robust Automotive Power Package, in 2020 15th Int. Microsystems, Packag. Assem. Circuits Technol. Conf. (IEEE, 2020), pp. 99–102.

İ Baylakoğlu, A. Fortier, S. Kyeong, R. Ambat, H. Conseil-Gudla, M.H. Azarian, M.G. Pecht, The detrimental effects of water on electronic devices. E-Prime-Advances Electr. Eng. Electron. Energy. 1, 100016 (2021)

A. J. Garete, Z. Li, and A. Taduran, Epoxy molding compound development for improved MSL1 delamination resistance in plastic encapsulated clip bond power package in 2020 IEEE 22nd Electron. Packag. Technol. Conf. (IEEE, 2020), pp. 90–94.

R.J. Rathish, S.S. Prabha, R. Dorothy, S. Jancyrani, S. Rajendran, G. Singh, S.S. Kumaran, Corrosion issues in electronic equipments-an overview. Int. J. Corros. Scale Inhib. 8, 799 (2019)

Z. Meng and Y. Zhou, Corrosion induced reliability degradation due to pad design variation, in 2019 20th Int. Conf. Electron. Packag. Technol. (IEEE, 2019), pp. 1–4.

A. Herrmann, M. van Soestbergen, S.J.F. Erich, L.G.J. van der Ven, H.P. Huinink, W.D. van Driel, A. Mavinkurve, F. De Buyl, O.C.G. Adan, Elucidating the large variation in ion diffusivity of microelectronic packaging materials. Microelectron. Reliab. 136, 114656 (2022)

J. Lefebvre, F. Galli, C.L. Bianchi, G.S. Patience, D.C. Boffito, Experimental methods in chemical engineering: X-ray photoelectron spectroscopy-XPS. Canadian J Chem Eng. 97(10), 2588–2593 (2019)

F.A. Stevie, C.L. Donley, Introduction to x-ray photoelectron spectroscopy. J Vacuum Sci Technol A. 38, 63204 (2020)

A. H. Badarisman, H. Ideris, and K. A. Hamid, Post Plate Bake as the Electronic Package Corrosion Firewall, in 2022 IEEE 39th Int. Electron. Manuf. Technol. Conf. (IEEE, 2022), pp. 1–4.

G.I. Ashok Kumar, A. Lambert, J. Caperton, M. Asokan, W. Yi, O. Chyan, Comparative study of chloride and fluoride induced aluminum pad corrosion in wire-bonded device packaging assembly. Corros Mater Degrad. 2(3), 447–460 (2021)

Acknowledgment

We express our deep appreciation to the Reliability Laboratory Team and Material Analysis Team of Nexperia Malaysia Sdn Bhd who have supported us in our analyses for this project. We also gratefully acknowledge the financial support and research facilities provided by the Ministry of Education, Malaysia, under Fundamental Research Grant Scheme (FRGS/1/2020/TK0/UKM/01/3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Supramaniam, S., Bakar, M.A., Atiqah, A. et al. Moisture Content and Early Corrosion Detection of Cu Wire Bonding in a Semiconductor Package. J Fail. Anal. and Preven. 23, 2362–2369 (2023). https://doi.org/10.1007/s11668-023-01751-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01751-3