Abstract

Hydrocarbon bulk oil storage tanks are critical assets in an oil terminal and pumping station. These tanks are used for receiving, storage and pumping operations around the year. American Petroleum Institute (API) provides legislation (API-653) for their maintenance. In this study, a system of bulk storage tanks is considered along with associated instrumentation for a terminal station of one of the leading oil companies based in Karachi, Pakistan. An approach of reliability-centered maintenance (RCM) for the system and associated instrumentation is applied. A failure mode and effects analysis (FMEA) is also performed using failure data. The risk priority number (RPN) for each failure has been calculated for the existing maintenance plan and the additional recommended controls. Existing maintenance strategies are analyzed. The shortcomings are identified, and an RCM framework is proposed. The reliability of the system with and without RCM is considered. The results revealed that if the RCM approach is utilized, its reliability as of today would have been the same as it was exhibited nine years ago, that is, 99.72% which is a 0.52% increase from the case if RCM is not implemented. Furthermore, RPN decreases up to nearly 67% after implementing the proposed controls, for the storage tank foundation. This implies that the risk of damage to the tank foundation can be decreased by a staggering 67%.

Similar content being viewed by others

Abbreviations

- API:

-

American Petroleum Institute

- ATGS:

-

Auto-Tank gauging system

- D :

-

Detection

- FMEA:

-

Failure mode and effects analysis

- FMECA:

-

Failure mode, effects and criticality analysis

- FTA:

-

Fault tree analysis

- HMI:

-

Human–machine interface

- MOV:

-

Motor-operated valve

- O :

-

Occurrence

- RBI:

-

Risk-based inspection

- RCM:

-

Reliability-centered maintenance

- RPN:

-

Risk priority number

- S :

-

Severity

- SAP:

-

Systems, applications and products in data processing

- SCADA:

-

Supervisory control and data acquisition system

References

American-Petroleum-Institute, API 653: Tank Inspection, Repair, Alteration, and Reconstruction, 5th edn. (American-Petroleum-Institute, Washington, 2014), p.1–173

I. Animah, M. Shafiee, Application of risk analysis in the liquefied natural gas (LNG) sector: an overview. J. Loss Prev. Process Ind. (2020). https://doi.org/10.1016/j.jlp.2019.103980

M. Baghbani, S. Iranzadeh, M.B. Khajeh, Investigating the relationship between RPN parameters in fuzzy PFMEA and OEE in a sugar factory. J. Loss Prev. Process Ind. 60, 221–232 (2019). https://doi.org/10.1016/j.jlp.2019.05.003

H.S. Bakouch, M.A. Jazi, S. Nadarajah, A. Dolati, R. Roozegar, A Lifetime model with increasing failure rate. Appl. Math. Model. 38, 5392–5406 (2014). https://doi.org/10.1016/j.apm.2014.04.028

J. Balaraju, M.G. Raj, C.S. Murthy, Fuzzy-FMEA risk evaluation approach for LHD machine – a case study. J. Sustain. Min. 18, 257–268 (2019). https://doi.org/10.1016/j.jsm.2019.08.002

M. Bertolini, M. Bevilacqua, F.E. Ciarapica, G. Giacchettab, Development of risk-based inspection and maintenance procedures for an oil refinery. J. Loss Prev. Process Ind. 22, 244–253 (2009). https://doi.org/10.1016/j.jlp.2009.01.003

E. Calixto, Reliability and maintenance. in: Calixto, E. ed. Gas and Oil Reliability Engineering. 2 ed. Gulf Professional Publishing, Boston (2016). https://doi.org/10.1016/B978-0-12-805427-7.00003-8.

V.G. Cancho, F.L. Neto, G.D.C. Barriga, The Poisson-exponential lifetime distribution. Comput. Stat. Data Anal. 55, 677–686 (2011). https://doi.org/10.1016/j.csda.2010.05.033

J. Carretero, J.M. Pérez, García-Carballeira, F., Calderón, A., Fernández, J. D. García, J. D., Lozano, A., Cardona, L., Cotaina, N., Prete, P., Applying RCM in large scale systems: a case study with railway networks. Reliab. Eng. Syst. Saf. 82, 257–273 (2003). https://doi.org/10.1016/S0951-8320(03)00167-4

A.D. Carter, Mechanical Reliability. (MacMillan Education LTD, London, 1986)

J.I. Chang, C.C. Lin, A study of storage tank accidents. J. Loss Prev. Process Ind. 19, 51–59 (2006). https://doi.org/10.1016/j.jlp.2005.05.015

P. Chemweno, L. Pintelon, A.V. Horenbeek, P. Muchiri, Development of a risk assessment selection methodology for asset maintenance decision-making: an analytic network process (ANP) approach. Int. J. Prod. Econ. 170, 663–676 (2015). https://doi.org/10.1016/j.ijpe.2015.03.017

Z. Chen, X. Wu, J. Qin, Risk assessment of an oxygen-enhanced combustor using a structural model based on the FMEA and fuzzy fault tree. J. Loss Prev. Process Ind. 32, 349–357 (2014). https://doi.org/10.1016/j.jlp.2014.10.004

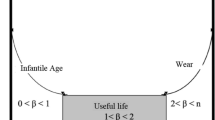

T. L. Cheng, A critical discussion on bathtub curve, in 42nd Annual Conference of the Republic of China and the 12th National Quality Management Seminar (2006) http://www.bm.nsysu.edu.tw/tutorial/iylu/conferance%20paper/B035.pdf. http://www.bm.nsysu.edu.tw/tutorial/iylu/conferance%20paper/B035.pdf.

Crawley, F., Failure modes and effects analysis (FMEA) and failure modes, effects and criticality analysis (FMECA), in A Guide to Hazard Identification Methods 2ed.: Elsevier, Amsterdam (2020) https://doi.org/10.1016/B978-0-12-819543-7.00012-4.

C. Crippa, L. Fiorentini, V. Rossini, R. Stefanelli, S. Tafaro, M. Marchi, Fire risk management system for safe operation of large atmospheric storage tanks. J. Loss Prev. Process Ind. 22, 574–581 (2009). https://doi.org/10.1016/j.jlp.2009.05.003

F. Crotogino, Traditional bulk energy storage: coal and underground natural gas and oil storage, in T. M. Letcher ed. Storing Energy. 2 ed.: Elsevier, Amsterdam (2022) https://doi.org/10.1016/B978-0-12-824510-1.00021-0.

V.S. Deshpande, J.P. Modak, Application of RCM to a medium-scale industry. Reliab. Eng. Syst. Saf. 77, 31–43 (2002). https://doi.org/10.1016/S0951-8320(02)00011-X

J. Dias, E. Nunes, S. Sousa, Productivity improvement of transmission electron microscopes—a case study. Procedia Manuf. 51, 1559–1566 (2020). https://doi.org/10.1016/j.promfg.2020.10.217

Ding, R., Liu, Z., Xu, J., Meng, F., Sui, Y., Men, X., 2021. A Novel Approach for Reliability Assessment of Residual Heat Removal System for HPR1000 based on Failure Mode and Effect Analysis, Fault Tree Analysis, and Fuzzy Bayesian Network Methods. Reliability Engineering and System Safety 216. https://doi.org/10.1016/j.ress.2021.107911.

R. F. Drenick, The failure law of complex equipment. J. Soc. Ind. Appl. Math. 8, 680–690 (1960). http://www.jstor.org/stable/2099056.

C.E. Ebeling, An Introduction to Reliability and Maintainability Engineering. (McGraw-Hill Inc, New York, 1997)

T. Elusakin, M. Shafiee, Reliability analysis of subsea blowout preventers with condition-based maintenance using stochastic petri nets. J. Loss Prev. Process Ind. (2020). https://doi.org/10.1016/j.jlp.2019.104026

M.H. Enjavimadar, M. Rastegar, Optimal reliability-centred maintenance strategy based on the failure modes and effect analysis in power distribution systems. Electric Power Syst. Res. (2022). https://doi.org/10.1016/j.epsr.2021.107647

S. Eriksen, I.B. Utne, M. Lützen, An RCM approach for assessing reliability challenges and maintenance needs of unmanned cargo ships. Reliab. Eng. Syst. Saf. 210, 107550 (2021). https://doi.org/10.1016/j.ress.2021.107550

L. Fan, H. Su, W. Wang, E. Zio, L. Zhang, Z. Yang, S. Peng, W. Yu, L. Zuo, J. Zhang, A systematic method for the optimization of gas supply reliability in natural gas pipeline network based on bayesian networks and deep reinforcement learning. Reliab. Eng. Syst. Saf. 225, 108613 (2022). https://doi.org/10.1016/j.ress.2022.108613

M.A. Filz, J.E.B. Langner, C. Herrmann, S. Thiede, Data-driven failure mode and effect analysis (FMEA) to enhance maintenance planning. Comput. Ind. (2021). https://doi.org/10.1016/j.compind.2021.103451

P.A.A. Garcia, R. Schirru, P.F.F. Melo, A fuzzy data envelopment analysis approach for FMEA. Prog. Nucl. Energy. 46, 359–373 (2005). https://doi.org/10.1016/j.pnucene.2005.03.016

J.J. George, V.R. Renjith, P. George, A.S. George, Application of fuzzy failure mode effect and criticality analysis on unloading facility of LNG terminal. J. Loss Prev. Process Ind. 61, 104–113 (2019). https://doi.org/10.1016/j.jlp.2019.06.009

S.S. Grossel, Book review: guidelines for mechanical integrity systems, the center for chemical process safety. J. Loss Prev. Process Ind. 20, 108–110 (2007). https://doi.org/10.1016/j.jlp.2006.10.001

L. Guo, J. Gao, J. Yang, J. Kang, Criticality evaluation of petrochemical equipment based on fuzzy comprehensive evaluation and a BP neural network. J. Loss Prev. Process Ind. 22, 469–476 (2009). https://doi.org/10.1016/j.jlp.2009.03.003

X. Guo, J. Ji, F. Khan, L. Ding, Y. Yang, Fuzzy bayesian network based on an improved similarity aggregation method for risk assessment of storage tank accident. Process Saf. Environ. Prot. 149, 817–830 (2021). https://doi.org/10.1016/j.psep.2021.03.017

R.D. Gupta, D. Kundu, Generalized exponential distribution: existing results and some recent developments. Journal of Statistical Planning and Inference. 137, 3537–3547 (2007). https://doi.org/10.1016/j.jspi.2007.03.030

H. Hammoum, K. Bouzelha, H.A. Aider, N.E. Hannachi, Tanks criticality assessment by the dependability method: a case study. Eng. Fail. Anal. 41, 10–22 (2014). https://doi.org/10.1016/j.engfailanal.2013.07.016

B.M. Hsu, M.H. Shu, B.S. Chen, Evaluating lifetime performance for the Pareto model with censored and imprecise information. J. Stat. Comput. Simul. 81, 1817–1833 (2011). https://doi.org/10.1080/00949655.2010.506439

J.M. Juran, Juran’s Quality Control Handbook. (McGraw-Hill Inc, London, 1988)

J. Kang, W. Liang, L. Zhang, Z. Lu, D. Liu, W. Yin, G. Zhang, A new risk evaluation method for oil storage tank zones based on the theory of two types of hazards. J. Loss Prev. Process Ind. 29, 267–276 (2014). https://doi.org/10.1016/j.jlp.2014.03.007

F. Keynia, M. Mirhosseini, A. Heydari, A. Fekih, A budget allocation and programming-based RCM approach to improve the reliability of power distribution networks. Energy Rep. 8, 5591–5602 (2022). https://doi.org/10.1016/j.egyr.2022.04.029

J.S. Kim, D.H. An, S.Y. Lee, A failure analysis of fillet joint cracking in an oil storage tank. J. Loss Prev. Process Ind. 22, 845–849 (2009). https://doi.org/10.1016/j.jlp.2009.08.014

L.N. Komariah, S. Arita, B.E. Prianda, T.K. Dewi, Technical assessment of biodiesel storage tank: a corrosion case study. J. King Saud Univ. Eng. Sci. (2021). https://doi.org/10.1016/j.jksues.2021.03.016

J.F. Lawless, Statistical Models and Methods for Lifetime Data. (Wiley InterScience, Washington, 2003) https://doi.org/10.1002/9781118033005

A.J. Lemonte, A new exponential-type distribution with constant, decreasing, increasing, upside-down bathtub and bathtub-shaped failure rate function. Comput. Stat. Data Anal. 62, 149–170 (2013). https://doi.org/10.1016/j.csda.2013.01.011

D. Li, J. Gao, Study and application of reliability-centered maintenance considering radical maintenance. J. Loss Prev. Process Ind. 23, 622–629 (2010). https://doi.org/10.1016/j.jlp.2010.06.008

H. Li, M. Yazdi, Developing failure modes and effect analysis on offshore wind turbines using two-stage optimization probabilistic linguistic preference relations, in Advanced Decision-Making Methods and Applications in System Safety and Reliability Problems: Approaches, Case Studies, Multi-criteria Decision-Making, Multi-objective Decision-Making, Fuzzy Risk-Based Models. Springer International Publishing, Cham (2022) https://doi.org/10.1007/978-3-031-07430-1_4

W. Limin, Fault tree analysis for oil tank fire and explosion, in IEEE International Conference on Emergency Management and Management Sciences (ICEMMS), Langfang, Hebei Province, China (2010) https://doi.org/10.1109/ICEMMS.2010.5563394

C. Matthews, Tank repairs and alterations, A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus, Woodhead Publishing, 2011. https://doi.org/10.1533/9780857095275.157

J. Menčík, Reliability of systems, in J. Mencik ed. Concise Reliability for Engineers. IntechOpen, Rijeka, Croatia (2016) https://doi.org/10.5772/62358

M.F. Milazzo, G. Ancione, P. Bragatto, E. Proverbio, A probabilistic approach for the estimation of the residual useful lifetime of atmospheric storage tanks in oil industry. J. Loss Prev. Process Ind. (2022). https://doi.org/10.1016/j.jlp.2022.104781

N. Z. Milovanović, R. L. Papić, Z. S. Milovanović, V. Z. Janičić-Milovanović, S. R. Dumonjić-Milovanović, D. J. Branković, Qualitative analysis in the reliability assessment of the steam turbine plant, in Kumar, A. A. R., M. ed. The Handbook of Reliability, Maintenance, and System Safety through Mathematical Modeling. Academic Press (2021) https://doi.org/10.1016/B978-0-12-819582-6.00008-3

J. Moubray, Reliability Centered Maintenance. (Industrial Press Inc, New York, 1997) https://doi.org/10.1002/qre.4680080114

S. Ni, Y. Tang, G. Wang, L. Yang, B. Lei, Z. Zhang, Risk identification and quantitative assessment method of offshore platform equipment. Energy Rep. 8, 7219–7229 (2022). https://doi.org/10.1016/j.egyr.2022.05.159

M. Ohring, L. Kasprzak, The mathematics of failure and reliability, in M. Ohring, L. Kasprzak, eds. Reliability and failure of electronic materials and devices. 2 ed. Boston, 2015 Academic Press. https://doi.org/10.1016/B978-0-12-088574-9.00004-5

A. Ozdemir, E. D. Kuldasli, RCM Application for Turkish National power transmission system, 11th International Conference on Probabilistic Methods Applied to Power Systems (PMAPS), 2010 Istanbul, Turkey. IEEE. https://doi.org/10.1109/PMAPS.2010.5528989

D. Panchal, D. Kumar, Integrated framework for behaviour analysis in a process plant. J. Loss Prev. Process Ind. 40, 147–161 (2016). https://doi.org/10.1016/j.jlp.2015.12.021

H. Pasman, W. Rogers, How trustworthy are risk assessment results, and what can be done about the uncertainties they are plagued with? J. Loss Prev. Process Ind. 55, 162–177 (2018). https://doi.org/10.1016/j.jlp.2018.06.004

J.F.W. Peeters, R.J.I. Basten, T. Tinga, Improving failure analysis efficiency by combining FTA and FMEA in a recursive manner. Reliab. Eng. Syst. Saf. 172, 36–44 (2018). https://doi.org/10.1016/j.ress.2017.11.024

L. Pelissero, Mechanical Integrity of Atmospheric Tanks 2nd International Conference on System Reliability and Safety, 2017 Italy. https://doi.org/10.1109/ICSRS.2017.8272841

P. Pougnet, F. Bayle, H. Maanane, P. R. Dahoo, Reliability prediction of embedded electronic systems: the FIDES guide, in E. H. Abdelkhalak, P. Pougnet, ed. Embedded Mechatronic Systems. 2 edn.: Elsevier, Amsterdam. https://doi.org/10.1016/B978-1-78548-189-5.50008-2.

Y. Redutskiy, C.M. Camitz-Leidland, A. Vysochyna, K.T. Anderson, M. Balycheva, Safety systems for the oil and gas industrial facilities: design, maintenance policy choice, and crew scheduling. Reliab. Eng. Syst. Saf. (2021). https://doi.org/10.1016/j.ress.2021.107545

V.R. Renjith, M.J. Kalathil, P.H. Kumar, D. Madhavan, Fuzzy FMECA (failure mode effect and criticality analysis) of LNG storage facility. J. Loss Prev. Process Ind. 56, 537–547 (2018). https://doi.org/10.1016/j.jlp.2018.01.002

C. Riverol, V. Pilipovik, A reliability prediction methodology based on improved radial basis function neural network (RBFNN): a condensate light crude oil stabilization facility as case study. Saf. Reliab. 40, 157–164 (2021). https://doi.org/10.1080/09617353.2021.1989227

M. Shafiee, T. Elusakin, E. Enjema, Subsea blowout preventer (BOP): design, reliability, testing, deployment, and operation and maintenance challenges. J. Loss Prev. Process Ind. (2020). https://doi.org/10.1016/j.jlp.2020.104170

M.M. Shahri, A.E. Jahromi, M. Houshmand, Failure mode and effect analysis using an integrated approach of clustering and MCDM under pythagorean fuzzy environment. J. Loss Prev. Process Ind. (2021). https://doi.org/10.1016/j.jlp.2021.104591

J. Shuai, K. Han, X. Xu, Risk-based inspection for large-scale crude oil tanks. J. Loss Prev. Process Ind. 25, 166–175 (2012). https://doi.org/10.1016/j.jlp.2011.08.004

Y. Tang, Q. Liu, J. Jing, Y. Yang, Z. Zou, A framework for identification of maintenance significant items in reliability-centered maintenance. Energy. 118, 1295–1303 (2017). https://doi.org/10.1016/j.energy.2016.11.011

M. Villarini, V. Cesarotti, L. Alfonsi, V. Introna, Optimization of photovoltaic maintenance plan by means of a FMEA approach based on real data. Energy Convers. Manage. 152, 1–12 (2017). https://doi.org/10.1016/j.enconman.2017.08.090

C.R. Vishnu, V. Regikumar, Reliability Based Maintenance Strategy Selection in Process Plants: A Case Study. Procedia Technology 25, 1080–1087 (2016). https://doi.org/10.1016/j.protcy.2016.08.211.

Y. Wang, G. Cheng, H. Hu, W. Wu, development of a risk-based maintenance strategy using FMEA for a continuous catalytic reforming plant. J. Loss Prev. Process Ind. 25, 958–965 (2012). https://doi.org/10.1016/j.jlp.2012.05.009

N. Williard, S. Mathew, Book review: effective FMEAs. Microelectron. Reliab. (2012). https://doi.org/10.1016/j.microrel.2012.05.004

C.W. Wu, M.H. Shu, Y.N. Chang, Variable-sampling plans based on lifetime-performance index under exponential distribution with censoring and its extensions. Appl. Math. Model. 55, 81–93 (2018). https://doi.org/10.1016/j.apm.2017.10.027

Z. Wu, L. Hou, S. Wu, X. Wu, F. Liu, The time-to-failure assessment of large crude oil storage tank exposed to pool fire. Fire Saf. J. 117, 1–13 (2020). https://doi.org/10.1016/j.firesaf.2020.103192

M. Xie, Y. Tang, T.N. Goh, A modified weibull extension with bathtub-shaped failure rate function. Reliab. Eng. Syst. Saf. 76, 279–285 (2002). https://doi.org/10.1016/S0951-8320(02)00022-4

M. Yazdi, S. Daneshvar, H. Setareh, An extension to fuzzy developed failure mode and effects analysis (FDFMEA) application for aircraft landing system. Saf. Sci. 98, 113–123 (2017). https://doi.org/10.1016/j.ssci.2017.06.009

A. Yu, H. Liu, L. Zhang, Y. Chen, A new data envelopment analysis-based model for failure mode and effect analysis with heterogeneous information. Comput. Ind. Eng. (2021). https://doi.org/10.1016/j.cie.2021.107350

Y. Zennir, A. B. Ahmed, E. A. Mechhoud, Safety study of the industrial systems with fmea(c): application to the TK102 Storage Tank, in European Control Conference, 2014 Strasbourg, France. IEEE, pp. 2804–2809. https://doi.org/10.1109/ECC.2014.6862345

Y. Zhang, X. Liu, J. Lai, Y. Wei, J. Luo, Corrosion fatigue life prediction of crude oil storage tank via improved equivalent initial flaw size. Theor. Appl. Fract. Mech. (2021). https://doi.org/10.1016/j.tafmec.2021.103023

F. Zheng, M. Zhang, J. Song, F.Z. Chen, Analysis on risk of multi—factor disaster and disaster control in oil and gas storage tank. Procedia Eng. 211, 1058–1064 (2018). https://doi.org/10.1016/j.proeng.2017.12.110

R. Zinke, J. Melnychuk, F. Köhler, U. Krause, Quantitative risk assessment of emissions from external floating roof tanks during normal operation and in case of damages using bayesian networks. Reliab. Eng. Syst. Saf. (2020). https://doi.org/10.1016/j.ress.2020.106826

E. Zio, M. Fan, Z. Zeng, R. Kang, Application of reliability technologies in civil aviation: lessons learnt and perspectives. Chin. J. Aeronaut. 32, 143–158 (2019). https://doi.org/10.1016/j.cja.2018.05.014

S. Zou, Y. Kuang, D. Tang, Z. Guo, S. Xu, Risk Analysis of High Level Radioactive Waste Storage Tank based on HAZOP. Ann. Nucl. Energy. 119, 106–116 (2018). https://doi.org/10.1016/j.anucene.2018.04.021

Acknowledgment

The authors sincerely thank Dr. Muhammad A. Sheikh retired as a Reader from The University of Manchester, UK, for his critical discussion on modeling results and reading during manuscript preparation.

Author information

Authors and Affiliations

Contributions

FA was involved in research methodology, writing—reviewing and editing, industrial data support, reliability analysis and supervision. SZ was responsible for reviewing the literature, writing the original draft, and reviewing and editing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Akbar, F., Zaki, S. Fixed-Roof Hydrocarbon Oil Storage Tank: An Approach to Reliability Engineering Tools. J Fail. Anal. and Preven. 23, 2044–2064 (2023). https://doi.org/10.1007/s11668-023-01733-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01733-5