Abstract

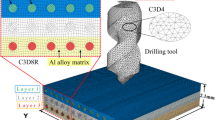

Cracking from tooth root bending fatigue is the main form of tooth failure. The current research on root crack and fracture is based on analytical and finite element models, while experimental studies are scarcely and not sufficiently deep. Therefore, this paper carries out a detailed study of tooth root crack initiation, propagation, and fracture surface based on gear bending fatigue tests. The double tooth loading test fixture of gear bending fatigue test is designed, and the bending stress of tooth root is derived based on the double tooth loading point. Gear specimens are divided into three parts and are tested in groups at four stress levels. The crack initiation location, propagation path and fracture surface of the test gear are studied to obtain the surface characteristics of the fatigue zone and static fracture zone. The tooth root crack initiation location of the test gear is compared with the traditional 30° tangent method, and the actual crack location is found to be slightly less than 10% smaller than the 30° tangent. This provides an experimental basis for the study of crack-based mesh stiffness and dynamic characteristics.

Similar content being viewed by others

References

W. Li, S. Deng, B. Liu, Experimental study on the influence of different carburized layer depth on gear contact fatigue strength. Eng. Fail. Anal. 107, 104225 (2020)

W. Guo-jun, J. Mei-hua, Z. Shi-shun, X. An-tao, Using Multiaxial fatigue method to Predict Gear Bending Fatigue Life. in Advanced design and manufacture II, 2010, ed. by D. Su, Q.B. Zhang, S.F. Zhu eds.

X.X. Bian, G. Zhou, T.J.Z. Liwei, Investigation of bending fatigue strength limit of alloy steel gear teeth. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 226, 615 (2012)

C. Gorla, F. Rosa, E. Conrado, H. Albertini, Bending and contact fatigue strength of innovative steels for large gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 228, 2469 (2014)

I.J. Hong, A. Kahraman, N. Anderson, A rotating gear test methodology for evaluation of high-cycle tooth bending fatigue lives under fully reversed and fully released loading conditions. Int. J. Fatigue. 133, 105432 (2020)

I.J. Hong, A. Kahraman, N. Anderson, An experimental evaluation of high-cycle gear tooth bending fatigue lives under fully reversed and fully released loading conditions with application to planetary gear sets. J. Mech. Des. 143, 023402 (2021)

T. Xin, Z. Rupeng, L. Meijun, X. Xingbo, T. Peng, Analyse bending fatigue strength test of cylindrical gear of third-generation aviation gear steel. J. Aerosp. Power. 36, 1756 (2021)

L. Bonaiti, A.B.M. Bayoumi, F. Concli, F. Rosa, C. Gorla, Gear root bending strength: a comparison between single tooth bending fatigue tests and meshing gears. J. Mech. Des. 143, 103402 (2021)

H. He, Y. Zhou, H. Liu, C. Zhu, B. Xiao, T. Zhang, Study on gear bending fatigue considering gradient characteristics: numerical analysis and experiments. Eng. Fract. Mech. 277, 108983 (2023)

C.J. Li, H. Lee, Gear fatigue crack prognosis using embedded model, gear dynamic model and fracture mechanics. Mech. Syst. Signal Process. 19, 836 (2005)

A.K. Eriki, R. Ravichandra, M.E. Mustaffa, Spur gear crack propagation path analysis using finite element method. in International multiconference of engineers and computer scientist, Imecs 2012, Vol II, 2012, ed. by S.I. Ao, O. Castillo, C. Douglas, D.D. Feng, J.A. Lee, eds.

J. Ma, R. Shao, F. Dong, Three-dimensional extended analysis and life prediction of gear crack. in Frontiers of manufacturing and design science II, 2012, ed. by D. Sun, W.P. Sung, R. Chen, eds.

N.K. Raghuwanshi, A. Parey, Experimental measurement of gear mesh stiffness of cracked spur gear by strain gauge technique. Measurement. 86, 266 (2016)

S. Zouari, M. Maatar, T. Fakhfakh, M. Haddar, Three-dimensional analyses by finite element method of a spur gear: effect of cracks in the teeth foot on the mesh stiffness. J. Fail. Anal. Prev. 7, 475 (2007)

S. Zouari, M. Maatar, T. Fakhfakh, M. Haddar, Following spur gear crack propagation in the tooth foot by finite element method. J. Fail. Anal. Prev. 10, 531 (2010)

J.G. Verma, S. Kumar, P.K. Kankar, Crack growth modeling in spur gear tooth and its effect on mesh stiffness using extended finite element method. Eng. Fail. Anal. 94, 109 (2018)

S. Wang, R. Zhu, An improved mesh stiffness calculation model for cracked helical gear pair with spatial crack propagation path. Mech. Syst. Signal Process. 172, 108989 (2022)

R. Shao, X. Huang, Y. Li, Influence of crack on structure vibration of gear tooth. J. Fail. Anal. Prev. 9, 563 (2009)

H. Ma, X. Pang, J. Zeng, Q. Wang, B. Wen, Effects of gear crack propagation paths on vibration responses of the perforated gear system. Mech. Syst. Signal Process. 62–63, 113 (2015)

B. Zhao, The application of wavelet finite element method on multiple cracks identification of gear pump gear. Eng. Comput. 31, 281 (2015)

P. Kumar, H. Hirani, A. Agrawal, Fatigue failure prediction in spur gear pair using AGMA approach. Mater. Today Proc. 4(2), 2470–2477 (2017)

K. Vuckovic, I. Cular, R. Masovic, I. Galic, D. Zezelj, Numerical model for bending fatigue life estimation of carburized spur gears with consideration of the adjacent tooth effect. Int. J. Fatigue. 153, 106515 (2021)

Acknowledgments

The authors would like to acknowledge the financial support from the NSFC, the research is funded by National Natural Science Foundation of China (Contract No. 51775036) and these supports are gracefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Wei Li and other co-authors declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Li, Z. & Zhang, S. Analysis of Tooth Root Crack Initiation, Propagation and Fracture Surface Based on Gear Bending Fatigue Test. J Fail. Anal. and Preven. 23, 1288–1297 (2023). https://doi.org/10.1007/s11668-023-01685-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01685-w