Abstract

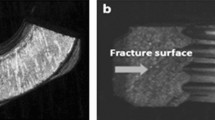

Integrated Nano-Satellite Launcher System (INLS-2U) is a non-pyrotechnic satellite dispenser that provides safe and reliable separation of nanosatellites into orbits. After the acceptance testing of this satellite separation system, all fasteners were verified for 80% torque retention. During this verification, one of the 70 Nos. of hexagonal socket head cap fasteners (M4 × 0.7 × 10L) has failed. These fasteners are used for the assembly of side plates to the bottom and top plates of the non-pyrotechnic dispenser. The material for construction of the bottom/top/side plate is AA2014 in T651 condition, and the fasteners are made of 35NCD16 steel material with cadmium plating. Detailed metallurgical analysis was carried out to find the reason for the fastener failure. Based on the detailed fractographic and metallographic analysis, it is concluded that the root cause of fastener failure is attributed to ‘hydrogen embrittlement.’

Similar content being viewed by others

References

V. González, P. Muro, Failure Analysis Study on a Fractured Bolt. Eng. Fail. Anal. (2019). https://doi.org/10.1016/j.engfailanal.2019.104355

G.N. Melhem, Aerospace fasteners: use in structural applications, in Encyclopedia of Aluminum and Its Alloys. (CRC Press, Boca Raton, 2019), p. 30–35. https://doi.org/10.1201/9781351045636-140000240

K.F. Best, High Strength Materials for Aircraft Landing Gear. Aircr. Eng. Aerosp. Technol. 58, 14–24 (1986). https://doi.org/10.1108/eb036313

S. Brahimi, Hydrogen Embrittlement in Coated Steel Fasteners–A Review of the Literature. (IBECA Technologies Corp., Montreal, 2006)

C. Trevisiol, A. Jourani, S. Bouvier, Effect of Hardness, Microstructure, Normal Load and Abrasive Size on Friction and on Wear Behaviour of 35NCD16 Steel. Wear. 388–389, 101–111 (2017). https://doi.org/10.1016/j.wear.2017.05.008

A.K. Shukla, V.M.J. Sharma, S.V.S.N. Murty, P.R. Narayanan, S.C. Sharma, Integrity of Structural and Thermo-Structural Materials for Indian Space Programme. Procedia Eng. 86, 8–17 (2014). https://doi.org/10.1016/j.proeng.2014.11.005

A.K. Jha, P.R. Narayanan, K. Sreekumar, M.C. Mittal, K.N. Ninan, Hydrogen Embrittlement of 3.5Ni–1.5Cr–0.5Mo Steel Fastener. Eng. Fail. Anal. 15(5), 431–439 (2008). https://doi.org/10.1016/j.engfailanal.2007.05.008

E. Villalba, A. Atrens, Hydrogen Embrittlement and Rock Bolt Stress Corrosion Cracking. Eng. Fail. Anal. 16, 164–175 (2009). https://doi.org/10.1016/j.engfailanal.2008.01.004

H.K. Birnbaum, P. Sofronis, Hydrogen-Enhanced Localized Plasticity-a Mechanism for Hydrogen-Related Fracture. Mater. Sci. Eng. A. 176, 191–202 (1994). https://doi.org/10.1016/0921-5093(94)90975-X

A.K. Jha, S.M. Sushant, K. Sreekumar, Hydrogen-Induced Intergranular Stress Corrosion Cracking (HI-IGSCC) of 0.35C–3.5Ni–1.5Cr–0.5Mo Steel Fastener. Eng. Fail. Anal. 17, 777–786 (2010). https://doi.org/10.1016/j.engfailanal.2009.10.007

S.P. Lynch, Comments on “A Unified Model of Environment-Assisted Cracking.” Scr. Mater. 61, 331–334 (2009). https://doi.org/10.1016/J.Scriptamat.2009.02.031

ASTM Standard, B 766 – 86, Standard Specification for Electrodeposited Coatings of Cadmium. (ASTM International, West Conshohocken, PA, Reapproved 2003)

K.G. Reddy, A.K. Jha, V. Diwakar, Failure of cadmium plated maraging steel tension bolt. Eng. Fail. Anal. 8, 263–269 (2001). https://doi.org/10.1016/S1350-6307(00)00011-X

Metals Handbook Vol 10: Failure Analysis and Prevention: Boyer, H.E. Handbook Vol-10-Prevention/dp/B000EME3B6

Acknowledgment

Authors wish to place on record their deep sense of gratitude to Group Director, MMG and Deputy Director, VSSC (MME) for their support, encouragement, and guidance during the analysis. We also acknowledge our gratitude to Director, VSSC for permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jalaja, K., Dhanya, M.S., Manwatkar, S.K. et al. Metallurgical Analysis of M4 Fastener Used in Integrated Nano-satellite Launcher System (INLS-2U) Failed During Torque Retention Check. J Fail. Anal. and Preven. 23, 1092–1100 (2023). https://doi.org/10.1007/s11668-023-01649-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01649-0