Abstract

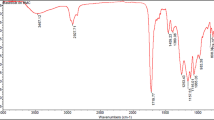

Automotive headlamps, constructed using different components are likely affected by haziness, dirtiness, fogginess, cloudiness, or white patches caused by oxidation, chemical attack, water vapors, flying debris, and dirt. In the present work, we have identified the root causes of outer lens yellowness issue in a headlamp and provided possible remedies. For this attempt, two headlamps were analyzed for the yellowness root cause analysis and their failure prevention. Several parts of the headlamp assembly, such as outer lens, dust caps and housing assembly, were characterized for the thermal, structural, and morphological analysis. Yellowness is mostly caused by the liberation of lower temperature volatile organic compounds due to thermal decomposition and oxidation of lower molecular weight additives present in the polymers. Thermal properties of clear transparent headlamp parts (OK) and yellow colored headlamp parts (NOT-OK) were analyzed using differential scanning calorimetry, thermogravimetric analysis. The chemical structure similarity of the NOT-OK and OK headlamps parts was characterized by the fourier transform infrared spectroscopy analysis. The liberation of lower temperature volatile organic components and their deposition onto the inside layer of the outer lens resulted in the yellowness issue in the headlamp. The headlamp component that contributed to the liberation of lower temperature volatile organic components was identified and remedies have been implemented for the failure prevention in future headlamp parts.

Similar content being viewed by others

References

J.A. Sanguesa, V. Torres-Sanz, P. Garrido, F.J. Martinez, J.M. Marquez-Barja, A review on electric vehicles: technologies and challenges. Smart Cities. 4(1), 372–404 (2021)

Y. Miao, P. Hynan, A. Von Jouanne, A. Yokochi, Current li-ion battery technologies in electric vehicles and opportunities for advancements. Energies. 12(6), 1074 (2019)

S.A.Q. Mohammed, J.W. Jung, A comprehensive state-of-the-art review of wired/wireless charging technologies for battery electric vehicles: classification/common topologies/future research issues. IEEE Access. 9, 19572–19585 (2021)

D.W. Eby, L.J. Molnar, L. Zhang, R.MSt. Louis, N. Zanier, L.P. Kostyniuk, S. Stanciu, Use, perceptions, and benefits of automotive technologies among aging drivers. Inj. Epidemiol. 3(1), 28 (2016)

C.D. May, R.J. Watling, The development of analytical and interpretational protocols to facilitate the provenance establishment of polycarbonate headlamp lens material. J. Forensic Sci. 56, s47–s57 (2011)

B.T. Anthony, Lexan polycarbonate for automotive forward lighting. Mater. Des. 6, 293–302 (1985)

C. Seubert, K. Nietering, M. Nichols, R. Wykoff, S. Bollin, An overview of the scratch resistance of automotive coatings: exterior clearcoats and polycarbonate hardcoats. Coatings. 2(4), 221–234 (2012)

K.L. Camera, B. Wenning, A. Lal, C.K. Ober, Transient materials from thermally-sensitive polycarbonates and polycarbonate. Polymer (Guildf). 101, 59–66 (2016)

U. Ali, K.J.B.A. Karim, N.A. Buang, A review of the properties and applications of poly (Methyl Methacrylate) (PMMA). Polym. Rev. 55(4), 678–705 (2015)

A.M. Omer, Energy use and environmental impacts: a general review. J. Renew. Sustain. Energy. 1, 053101 (2009)

M.E. Nichols, C.A. Peters, The effect of weathering on the fracture energy of hardcoats over polycarbonate. Polym. Degrad. Stab. 75(3), 439–446 (2002)

C. Yan, J. Zhang, J. Han, X. Wang, Z. Guan, L. Zhang, C. Liu, C. Shen, Improvement of environmental stress cracking resistance of polycarbonate by silicone coating. Polym. Test. 60, 6–11 (2017)

M.M. Ferreira, V. de Freitas Cunha Lins, Failure in automotive headlight lenses. Eng. Fail. Anal. 104, 844–855 (2019)

D. Kyriacos, Polycarbonates, in Brydson’s Plastics Materials. (Elsevier, 2017), p. 457–485

M.D. Pustode, C.S. Singh, R. Verma, T. Kochi, H. Barge, S. Gouda, A. Dutta, Root cause analysis and mitigation of white patch formation in automotive headlmap. J. Fail. Anal. Prev. 21(2), 387–397 (2021)

T. Schmauder, K.D. Nauenburg, K. Kruse, G. Ickes, Hard coatings by plasma CVD on polycarbonate for automotive and optical applications. Thin Solid Films. 502(1), 270–274 (2006)

M. Barletta, M. Puopolo, G. Rubino, V. Tagliaferri, S. Vesco, Hard transparent coatings on thermoplastic polycarboate. Prog. Org. Coatings. 90, 178–186 (2016)

P. Sarkar, A.K. Bhowmick, Sustainable rubbers and rubber additives. J. Appl. Polym. Sci. 135(24), 1–33 (2018)

M.J. Samide, G.D. Smith, J. Chromatogr, Analysis and quantitation of volatile organic compounds emitted from plastics used in museum construction by evolved gas analysis-gas chromatography-mass spectrometry. J. Chromatogr. 1426, 201–208 (2015)

V. Ambrogi, C. Carfagna, P. Cerruti, V. Marturano, Additives in polymers. Modifications of polymer properties (Elsevier, 2017), p. 87–108

H. Yahyaei, M. Mohseni, S. Bastani, Using Taguchi experimental design to reveal the impact of parameters affecting the abrasion resistance of sol–gel based UV curable nanocomposite films on polycarbonate. J. Sol-Gel Sci. Technol. 59, 95–105 (2011)

Acknowledgments

The authors would like to thank Minda-Rinder plant for cooperation throughout the characterization and analysis process. The authors also thankful to the CREAT management team of UNO Minda Limited for the motivation.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chandkoti, I., Naikwadi, A.T., Mali, M. et al. Failure Analysis of Yellowness Issue in Automotive Headlamp and its Remedies. J Fail. Anal. and Preven. 22, 1590–1603 (2022). https://doi.org/10.1007/s11668-022-01451-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01451-4