Abstract

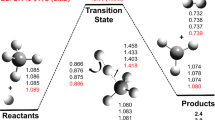

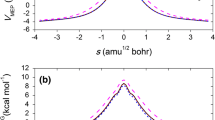

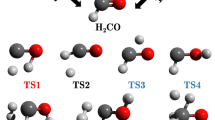

This article will provide an introduction to the importance of integrated computational analysis to better understand high temperature hydrogen attack (HTHA) and a review of the diverse experimental research that has been presented over the years. To form methane inside of a void, a minimum distance between iron (Fe), carbon (C), and hydrogen (H) must exist.

Similar content being viewed by others

References

M.B. Djukic, G.M. Bakic, V. Sijacki Zeravcic, A. Sedmak, B. Rajicic, The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: localized plasticity and decohesion. Eng. Fract. Mech. 216, 1–33 (2019). https://doi.org/10.1016/j.engfracmech.2019.106528

M.B. Djukic, V. Sijacki Zeravcic, G.M. Bakic, A. Sedmak, B. Rajicic, Hydrogen damage of steels: a case study and hydrogen embrittlement model. Eng. Fail. Anal. 58, 485–498 (2015). https://doi.org/10.1016/j.engfailanal.2015.05.017

M.B. Djukic, G.M. Bakic, V.S. Zeravcic, B. Rajicic, A. Sedmak, R. Mitrovic, Z. Miskovic, Towards a unified and practical industrial model for prediction of hydrogen embrittlement and damage in steels. Procedia Struct. Integr. 2, 604–611 (2016). https://doi.org/10.1016/j.prostr.2016.06.078

R.P. Gangloff, Critical Issues in Hydrogen Assisted Cracking of Structural Alloys (Elsevier, Amsterdam, 2006), p. 1–24. https://doi.org/10.1016/B978-008044635-6.50015-7

S.M. Schlögl, J. Svoboda, E. Van Der Giessen, Evolution of the methane pressure in a standard 2.25Cr-1Mo steel during hydrogen attack. Acta Mater. 49, 2227–2238 (2001). https://doi.org/10.1016/S1359-6454(01)00132-X

B.J. Lee, J.W. Jang, A modified embedded-atom method interatomic potential for the Fe-H system. Acta Mater. 55, 6779–6788 (2007). https://doi.org/10.1016/j.actamat.2007.08.041

B.J. Lee, A modified embedded-atom method interatomic potential for the Fe–C system. Acta Mater. 54, 701–711 (2006). https://doi.org/10.1016/j.actamat.2005.09.034

M.B. Djukic, G.M. Bakic, V.S. Zeravcic, A. Sedmak, B. Rajicic, Hydrogen embrittlement of industrial components: prediction, prevention, and models. Corrosion. 72, 943–961 (2016). https://doi.org/10.5006/1958

API-571, Damage mechanisms affecting fixed equipment in the refining industry, Am. Pet. Inst. (2003) 1–270. http://scholar.google.com/scholar?hl=en&btnG=Search&q=intitle:Damage+Mechanisms+Affecting+Fixed+Equipment+in+the+Refining+Industry#0

R.K. Dayal, N. Parvathavarthini, Hydrogen embrittlement in power plant steels. Sadhana Acad. Proc Eng. Sci. 28, 431–451 (2003). https://doi.org/10.1007/BF02706442

M. Sabine, V. Der Giessen, Micromechanics of High Temperature Hydrogen Attack (Univ. Groningen, Groningen, 1999), p. 1–11

Z. Tarzimoghadam, D. Ponge, J. Kloewer, D. Raabe, Hydrogen-assisted failure in nickel base alloy UNS N07718 zahra. In: NACE—CORROSION 2016 Conference and Expo (2016). p. 1–10.

M. Dadfarnia, M.L. Martin, D.E. Moore, S.E. Orwig, P. Sofronis, A model for high temperature hydrogen attack in carbon steels under constrained void growth. Int. J. Fract. 219, 1–17 (2019). https://doi.org/10.1007/s10704-019-00376-8

API RP 941 7TH ED, Steels for hydrogen service at elevated temperatures and pressures in petroleum refineries and petrochemical plants. API Publ. 1997, 1–14 (2008)

S. Wang, M.L. Martin, P. Sofronis, S. Ohnuki, N. Hashimoto, I.M. Robertson, Hydrogen-induced intergranular failure of iron. Acta Mater. 69, 275–282 (2014). https://doi.org/10.1016/j.actamat.2014.01.060

M.L. Martin, B.P. Somerday, R.O. Ritchie, P. Sofronis, I.M. Robertson, Hydrogen-induced intergranular failure in nickel revisited. Acta Mater. 60, 2739–2745 (2012). https://doi.org/10.1016/j.actamat.2012.01.040

S. Wang, M.L. Martin, I.M. Robertson, P. Sofronis, Effect of hydrogen environment on the separation of Fe grain boundaries. Acta Mater. 107, 279–288 (2016). https://doi.org/10.1016/j.actamat.2016.01.067

S. Pillot, P. Bourges, C. Chauvy, L. Coudreuse, P. Toussaint, K. Orie, Effect of ageing and hydrogen on fracture mechanics and CVN properties of 2.25Cr-1Mo steel grades—application to Mpt issues. In: NACE—CORROSION 2009 Conference and Expo (2009), p. 1–19

A. Kaufman, B. Feldman, R. Balali, Hydrogen damage and prevention in the oil refinery. In: NACE—CORROSION 2011 Conference and Expo (2011), p. 1–15

J.C. Staats, G.M. Buchheim, A new practical method for prioritizing equipment in HTHA service for inspection and replacement and the challenges in obtaining process conditions to be used in the HTHA assessment. In: NACE—CORROSION 2016 Conference and Expo (2016), p. 1–13

C. Krauß, G. Andersohn, M. Oeschsner, Influence of different zinc-containing topcoat systems on the susceptibility against hydrogen re-embrittlement of high strength steel. In: NACE—CORROSION 2014 Conference and Expo (2014), p. 1–9

P.L. Andresen, T.M. Angeliu, Evaluation of the role of hydrogen in SCC in hot water. NACE Int. Corros. 1997, 1–12 (1997)

R. Johnsen, O.E. Kongstein, B. Nyhus, Susceptibility of hydrogen induced stress cracking of duplex stainless steel at elevated temperature. In: NACE—CORROSION 2011 Conference and Expo (2011), p. 1–15

A.S. Melfi, Influence of hydrogen concentration and distribution on fracture in nickel. Mech. Eng. Undergrad. Honor. Theses. 55, 1–47 (2016)

Z.E. des akademischen Grades, Micro Scale Modeling Grain Boundary Damage Under Creep Conditions (Otto-von-Guericke-University, Magdeburg, 2014), p. 1–113

A.A. Benzerga, J.B. Leblond, Ductile Fracture by Void Growth to Coalescence. (Elsevier Inc., Amsterdam, 2010) https://doi.org/10.1016/S0065-2156(10)44003-X

B. Revil-Baudard, O. Cazacu, S. Thuillier, E. Maire, Effect of stress triaxiality on porosity evolution in notched bars: quantitative agreement between a recent dilatational model and X-ray tomography data. Mech. Res. Commun. 50, 77–82 (2013). https://doi.org/10.1016/j.mechrescom.2013.04.005

M.J. Nemcko, H. Qiao, P. Wu, D.S. Wilkinson, Effects of void fraction on void growth and linkage in commercially pure magnesium. Acta Mater. 113, 68–80 (2016). https://doi.org/10.1016/j.actamat.2016.04.008

V. Tvergaard, Mechanical models of the effect of grain boundary sliding on creep and creep rupture. Rev. Phys. Appl. 23, 595–604 (1988). https://doi.org/10.1051/rphysap:01988002304059500

A. Hosokawa, D.S. Wilkinson, J. Kang, E. Maire, Onset of void coalescence in uniaxial tension studied by continuous X-ray tomography. Acta Mater. 61, 1021–1036 (2013). https://doi.org/10.1016/j.actamat.2012.08.002

E.V.D.R. Giessen, M.W.D. Van Der Burg, A. Needleman, V. Tvergaard, Void growth due to creep and grain boundary diffusion at high triaxialities. J Mech. Phys. Solids. 43, 123–165 (1995)

D. Eliezer, High-temperature hydrogen attack of carbon steel. J. Mater. Sci. 16, 2962–2966 (1981). https://doi.org/10.1007/BF00540300

S. Pillot, P. Bourges, I. Creusot, G. Masson, L. Coudreuse, I. Loire, P. Toussaint, R. De Chatelet, Effect of hydrogen on mechanical behavior for 2¼ Cr 1Mo steel grades (standard and vanadium added). In: NACE—CORROSION 2008 Conference and Expo (2008), p. 1–19

S. Pillot, S. Corre, L. Coudreuse, C. Chauvy, P. Toussaint, Development and production of creep and hydrogen resistant grade 91 (9 Cr1 Mov) heavy plates for new generating high efficiency refining reactors. In: NACE—CORROSION 2013 Conference and Expo 91 (2013), p. 1–15

E. van der Giessen, V. Tvergaard, Interaction of Cavitating Grain Boundary Facets in Creeping Polycrystals, vol 17 (Elsevier, Amsterdam, 1994), p. 47–69. https://doi.org/10.1016/0167-6636(94)90013-2

T. Laha, R. Balasubramaniam, M.N. Mungole, A. Tewari, R.G. Baligidad, Microstructural evolution in iron aluminide Fe–28Al–2C after high-temperature hydrogen treatment. Metall. Mater. Trans. A. 35A, 1789–1790 (2004). https://doi.org/10.1007/s11661-004-0087-7

M.C. White, Stress-accelerated high temperature hydrogen attack in a catalytic reformer combined feed-effluent exchanger. In: Materials and Corrosion Engineering and Technology - Projects Engineering Services Shell Global Solutions International (n.d.), p. 1–10

L.C. Chen, P. Shewmon, Stress-assisted hydrogen attack cracking in 2.25Cr-1Mo steels at elevated temperatures. Metall. Mater. Trans. A. 26A, 2317–2318 (1995). https://doi.org/10.1007/BF02671246

E.E. Fletcher, A.R. Elsea, The Effects of High Pressure, High-Temperature Hydrogen on Steel (DMIC, 1964), p. 1–70

S.M. Schlogl, E. Van Der Giessen, Y. Van Leeuwen, On methane generation and decarburization in low-alloy Cr–Mo steels during hydrogen attack. Metall. Mater. Trans. A Phys. Metall Mater. Sci. 31A, 125–137 (2000). https://doi.org/10.1007/s11661-000-0059-5

S.M. Schlögl, E. Van Der Giessen, Computational model for carbon diffusion and methane formation in a ferritic steel during hydrogen attack. Scr. Mater. 46, 431–436 (2002). https://doi.org/10.1016/S1359-6462(02)00008-8

M.L. Martin, M. Dadfarnia, S. Orwig, D. Moore, P. Sofronis, A microstructure-based mechanism of cracking in high temperature hydrogen attack. Acta Mater. 140, 300–304 (2017). https://doi.org/10.1016/j.actamat.2017.08.051

S. Decker, T. Hynes, G. Buchheim, Safe operation of a high temperature hydrogen attack affected DHT reactor. In: NACE—CORROSION 2009 Conference and Expo (2009), p. 1–14

S.N. Karlsdottir, G. Ltd, T. Jonsson, Hydrogen damage of carbon steel fragments from the IDDP-1 geothermal well. In: NACE—CORROSION 2018 Conference and Expo (2018), p. 1–11

M.W.D. Van Der Burg, E. Van Der Giessen, R.C. Brouwer, Investigation of hydrogen attack in 2.25Cr–1Mo steels with a high-triaxiality void growth model. Acta Mater. 44, 505–518 (1996). https://doi.org/10.1016/1359-6454(95)00203-0

S. Tang, T.F. Guo, L. Cheng, Modeling hydrogen attack effect on creep fracture toughness. Int. J. Solids Struct. 48, 2909–2919 (2011). https://doi.org/10.1016/j.ijsolstr.2011.06.007

API RP 941 8TH Edition, Steels for hydrogen service at elevated temperatures and pressures in petroleum refineries and petrochemical plants. API Publ. 941, 1–56 (2016)

N.N. Kolgatin, Z.A. Glikman, V.P. Teodorovich, V.I. Deryabina, Failure of steels in hydrogen at high temperature and pressures. All-Unin Res. Inst. Petrochem. Process. 1, 17–18 (1959)

Bakerrisk, Avoiding high temperature hydrogen attack, Bak. Risk. 1–2 (2015)

M. Ransick, P. Shewmon, Effect of cold work on hydrogen attack. Metall. Trans. A. 12A, 17–18 (1981). https://doi.org/10.1080/0075417X.2011.614738

G. Sundararajan, P.G. Shewmon, The kinetics of hydrogen attack of steels. Metall. Mater. Trans. A. 12A, 1761–1762 (1981). https://doi.org/10.1179/cmq.1967.6.1.9

T.A. Parthasarathy, P.G. Shewmon, Effects of tempering on the carbon activity and hydrogen attack kinetics of 2.25Cr–1 Mo steel. Metall. Trans. A. 15A, 2021–2022 (1984). https://doi.org/10.1007/bf02670341

G. Sundararajan, P.G. Shewmon, The hydrogen attack of HSLA steels. Metall. Trans. A. 11, 509–516 (1980). https://doi.org/10.1007/BF02654574

M.M. Al-aradah, M. Al-Otaibi, M.E. Moh’d, Evaluation of HTHA effect on carbon steel & carbon 0 .5 Mo exchanger using various NDE techniques for reformer waste heat boiler gas exchanger in hydrogen unit, Mina Abdulla Refinery, Kuwait National Petroleum Company (2009), p. 1–33

M. Al Arada, M. Al Otaibi, Evaluation of high temperature hydrogen attack effect on carbon steel-0.5 Mo heat exchanger. In: NACE—CORROSION 2014 Conference and Expo (2014), p. 1–11

U.S.C.S. and H.I. Board, Investigation report—catastrophic rupture of heat exchanger (seven fatalities). U.S. Chem. Saf. Hazard Investig. Board (2010), p. 1–160. https://doi.org/10.5271/sjweh.3533

I.D. Skrypnyk, Analytic evaluation of hydrogen-assisted void growth at high temperatures. Mater. Sci. 33, 478–490 (1997)

K.H. Subramanian, J.I. Mickalonis, G.L. Edgemon, Characteristic electrochemical noise during electrochemical determination of hydrogen permeation. In: NACE—CORROSION 2006 Conference and Expo (2006), p. 1–10

D.J. Benac, P. McAndrew, Reducing the risk of high temperature hydrogen attack (HTHA) failures. J. Fail. Anal. Prev. 12, 624–627 (2012). https://doi.org/10.1007/s11668-012-9605-x

P.G. Shewmon, Hydrogen attack of carbon steel. Metall. Trans. A. 7A, 279–280 (1976). https://doi.org/10.1007/BF02644468

S. Wang, A. Nagao, P. Sofronis, I.M. Robertson, Hydrogen-modified dislocation structures in a cyclically deformed ferritic-pearlitic low carbon steel. Acta Mater. 144, 164–176 (2018). https://doi.org/10.1016/j.actamat.2017.10.034

L. S, Hydrogen embrittlement (HE) phenomena and mechanisms. In: Stress Corrosion Cracking Theory Practice (Woodhead Publishing Series in Metals and Surface Engineering, 2011), p. 90–130. https://doi.org/10.1533/9780857093769.1.90

N. Trimborn, Detecting and quantifying high temperature hydrogen attack (HTHA). In: 19th World Conference Non-Destructive Testing 2016 (2016), p. 1–4

B. Chambers, M. Gonzalez, Y. Chen, W. Marc, Sulfide stress cracking of super 13Cr martensitic stainless steel—localized corrosion and hydrogen embrittlement influences. In: NACE—CORROSION 2018 Conference and Expo (2018), p. 1–15

T. Tran, B. Brown, S. Nesic, Corrosion of mild steel in an aqueous CO2 environment—basic electrochemical mechanisms revisited. In: NACE—CORROSION 2015 Conference and Expo (2015), p. 1–11

P. Shewmon, Y.H. Xue, Effect of high-pressure hydrogen on crack growth in carbon steel. Metall. Trans. A. 22A, 2703–2704 (1991). https://doi.org/10.1007/BF02851364

M.W.D. Van Der Burg, E. Van Der Giessen, A Continuum damage relation for hydrogen attack cavitation. Acta Mater. 45, 3047–3057 (1997). https://doi.org/10.1016/S1359-6454(96)00382-5

A.A. Saguees, B.O. Hall, H. Wiedersich, Mechanisms of hydrogen attack. Scr. Met. 12, 319–326 (1978). https://doi.org/10.1016/0036-9748(78)90121-7

A. Needleman, J.R. Rice, Plastic creep flow effects in the diffusive cavitation of grain boundaries. Acta Metall. 28, 1315–1332 (1980). https://doi.org/10.1016/0001-6160(80)90001-2

H.M. Shih, R.R. Johnson, A model calculation of the Nelson curves for hydrogen attack. Acta Metall. 30, 537–545 (1982). https://doi.org/10.1016/0001-6160(82)90234-6

P. Shewmon, Synergism between creep ductility and grain boundary bubbles. Acta Mater. 35, 1317–1324 (1987)

A.A. Astaf’ev, Dissolution and redistribution of hydrogen in steel. Plenum Publ. Corp. 37, 192–193 (1995)

M. Castillo, C.E. Rogers, J.H. Payer, M. Quintana, Hydrogen permeation and hydrogen concentration measurements to model diffusible hydrogen in weld metal. Corrosion. 2000, 1–14 (2000)

T. Boellinghaus, E. Viyanit, H. Hoffmeister, Numerical modelling of hydrogen assisted cracking. In: NACE International (2001), p. 1–17

D. Ilin, Simulation of hydrogen diffusion in fcc polycrystals. Effect of deformation and grain boundaries. PhD Thesis, University Bordeaux (2014), p. 1–203

S.N. Karlsdottir, I.O. Thorbjornsson, R. University, Hydrogen embrittlement and corrosion in high temperature geothermal well. In: NACE—CORROSION 2012 Conference and Expo (2012), p. 1–18

A. Turnbull, A review of the possible effects of hydrogen on lifetime of carbon steel nuclear waste canister. Nagra. (2009), p. 1–68

T.G. Martin, K. Wilken, Hydrogen induced cracking failure of SA 516 grade 70 steel in near neutral to high PH solution: part 1 field investigation. In: NACE—CORROSION 2003 Conference and Expo (2003) 1–19.

R.J. Conder, P. Felton, R. Burke, P. Dent, Hydrogen embrittlement testing of high strength low carbon martensitic steels. In: NACE—CORROSION 2010 Conference and Expo (2010), p. 1–14

M. Sagara, Y. Tomio, Y. Otome, N. Sawawatari, T. Omura, H. Amaya, Evaluation of susceptibility to hydrogen embrittlement of high strength corrosion resistant alloys. In: NACE—CORROSION 2016 Conference and Expo (2016), p. 1–15

W. Huang, W. Sun, A. Samson, D. Muise, Investigation of hydrogen embrittlement susceptibility of precipitation hardened nickel alloys under cathodic protection condition. In: NACE—CORROSION 2013 Conference and Expo (2014), p. 1–15

G. Schmitt, T. Gommlich, K. Schoettler, Atomic hydrogen from electroplating of high strength steels—how much is trapped in the coating? Guenter. In: NACE—CORROSION 2016 Conference and Expo (2016), p. 1–10

B. Worthingham, L. Yang, F. King, J. Xie, Hydrogen effects on high strength pipeline steels. In: NACE—CORROSION 2009 Conference and Expo (2009), p. 1–15

K. Takai, Y. Homma, J. Seki, Hydrogen trapping sites in high-strength steels at delayed fracture. In: NACE—CORROSION 1996 Conference and Expo (1996), p. 1–13

S. Ronneteg, A. Juhlin, U. Kivisakk, Hydrogen embrittlement of duplex stainless steels testing of different product forms at low temperature. In: NACE—CORROSION 2007 Conference and Expo (2007), p. 1–9

Y.I. Archakov, I. Grebeshkova, V. Dubovskii, Hydrogen Resistance of Steels 20, 12 MKh, and 30KhMA at Elevated Temperature (Plenum Publ. Co., 1969), p. 18–19

M.R. Louthan, Effect of Hydrogen on Metals, E. I. Du Pont Nemours Co Savannah River Lab. Aiken, S.C. (1974), p. 1–25

Y. Zhao, M.Y. Seok, I.C. Choi, Y.H. Lee, S.J. Park, U. Ramamurty, J.Y. Suh, J. Il Jang, The role of hydrogen in hardening/softening steel: Influence of the charging process, Scr. Mater. 107 (2015) 46–49. https://doi.org/10.1016/j.scriptamat.2015.05.017.

P. Timmins, Solutions to hydrogen attack in steels. Am. Soc. Met. Intl. 8,1–198 (1997)

T.A. Parthasarathy, H.F. Lopez, P.G. Shewmon, Hydrogen Attack kinetics of 2.25 Cr-1 Mo steel weld metals. Metall. Trans. A. 16A, 1143–1144 (1985). https://doi.org/10.1007/BF02811683

D. Moorhead, H. Nelson, Fractography of the High Temperature Hydrogen Attack of a Medium Carbon Steel (NASA) (National Aeronautics and Space Administration, 1975), p. 1–17

P. Elliot, Materials performance in high-temperature environments—making the choice. In: NACE—CORROSION 2000 Conference and Expo (2000), p. 1–22

J.L. Carpenter, W.F. Stuhrke, Hydrogen embrittlment of structural alloys—a technology survey. Natl. Aeronaut. Sp. Adm. 168, 1–123 (1976)

P. Aaltonen, T. Saario, P. Karjalainen-Roikonen, J. Piippo, S. Tahtinen, Vacancy-creep model for EAC of metallic materials in high temperature water. In: NACE—CORROSION 1996 Conference and Expo (1996), p. 1–12

H.R. Copson, The influence of corrosion on the cracking of pressure vessels. Int. Nickel Company, Inc. A-151 (1953), p. 1–19

F. El Shawesh, Effect of strain rate and temperature on the susceptibility of 304 austenitic stainless steel to hydrogen embrittlement. In: NACE—CORROSION 1998 Conference and Expo (1998), p. 1–12

F. Silva, J. Santos, R. Gouveia, Dissolution of grain boundary carbides by the effect of solution annealing heat treatment and aging treatment on heat-resistant cast steel HK30. Metals (Basel). 7, 1–12 (2017). https://doi.org/10.3390/met7070251

A. Roy, High Temperature Hydrgoen Attack (HTHA), Swiss, Re (2015), p. 1–32

RDK Audit, Refineria di Korsou technical audit report, RDK Audit (2017), p. 1–82

E.I.C.E. Eady, Welding and cuttting. Aerlikon Metco. 16, 275–336 (2017)

P.G. Shewmon, Hydrogen attack of pressure vessel steel. Ohio State Univ. Dep. Metall. Eng. (1980), p. 1–8

X. Roumeau, High-temperature cracking of 800 HT pigtails in a hydrogen unit. In: NACE—CORROSION 2010 Conference and Expo (2010) 1–11.

C. Thomas, Risk analysis for high temperature hydrogen attack. Quest Integr. Gr. Ltd. (1914). https://doi.org/10.1049/jiee-1.1914.0084

U.S.C.S. and H.I. Board, CSB Safety Alert: Preventing high temperature hydrogen attack (HTHA) CSB safety guidance to prevent HTHA. U.S. Chemical Safety Hazard Investigation Board (2016), p. 1–2

MTI, MTI project refining methods for predicting HTHA. Materials Technology Institute Publications (2016), p. 1–16

C.R. Industry, California emphasis program California refining industry Naphtha Hydrotreater Units. State California Department Industry Relations (2010), p. 1–15

J. Rothwell, Maintaining the integrity of process plant susceptible to high temperature hydrogen attack. Part 2: factors affecting carbon steels RR1134, TWl Ltd. (2018), p. 1–58

B. Saba, Evaluation of Mechanical Fitness for Service of High Temperature Hydrogen Attacked Steels (Louisiana State University and Agricultural and Mechanical College, 2003), p. 1–174

M.A. Wahab, B.M. Saba, A. Raman, Fracture mechanics evaluation of a 0.5Mo carbon steel subjected to high temperature hydrogen attack. J. Mater. Process. Technol. 153–154, 938–944 (2004). https://doi.org/10.1016/j.jmatprotec.2004.04.149

T. Silfies, J.D. Dobis, M. Nugent, Looking behind the curtain of API RP 941 high temperature hydrogen attack (HTHA) data. In: NACE—CORROSION 2016 Conference and Expo (2016), p. 1–12

G.M. McKimpson, Initial Hydrogen Attack Kinetics in a Carbon Steel (Ohio State University University Microfilms International, 1977), p. 1–162

J. Brear, J. Church, Technical basis for API Publication RP941 (Nelson Curves). Res. Gate (1996), p. 1–12

H. Damage, G.H. Joint, I. Project, P. You, C.A.N. Trust, Preventing HTHA failures with the buckeye model. Equity Engineering (2013), p. 1–2

M. Nugent, T. Silfies, J.D. Dobis, A review of high temperature hydrogen attack (HTHA) modeling, prediction, and non-intrusive inspection in refinery applications. In: NACE—CORROSION 2017 Conference and Expo (2017), p. 1–13

A. G142-98, Standard test method for determination of susceptibility of metals to embrittlement in hydrogen containing environments at high pressure, high temperature, or both. ASTM Int. (2016). https://doi.org/10.1520/G0142-98R16.2.

API 579-1, Fitness-for-service. API Publ. (2016), p. 1–1320

API 580, API RP 580: Risk-based inspection, API (2009), p. 1–96

API-581, API RP 581: Risk-based inspection technology, API Recomm. Pract. 581 (2008), p. 1–654. http://www.irantpm.ir/wp-content/uploads/2011/08/API-581-2008.pdf

C. Allevato, Utilizing acoustic emission testing to detect high-temperature hydrogen attack (HTHA) in Cr–Mo reformer reactors and piping during thermal gradients. Procedia Eng. 10, 3552–3560 (2011). https://doi.org/10.1016/j.proeng.2011.04.585

C. Nageswaran, Maintaining the integrity of process plant susceptible to high temperature hydrogen attack. Part 1: analysis of non-destructive testing techniques. Crown 1, 1–58 (2018)

A. Yamani, A cost effective development of an ultrasonic A-scans database for high-temperature hydrogen attack. Elsevier Ltd. 41, 163–168 (2008). https://doi.org/10.1016/j.ndteint.2007.10.007

B.A. Kolachev, Hydrogen in metals and alloys. Met. Sci. Heat Treat. 41, 93–100 (1999)

B.A. Kolachev, Hydrogen embrittlement of metals. Itogi Nauk. Tekh. Met. Term. Obrab. 23, 3–46 (1989)

C. Georghe, Metallurgia. 8, 34–39 (1964)

C. Borchers, T. Michler, A. Pundt, Effect of hydrogen on the mechanical properties of stainless steels. Adv. Eng. Mater. 10, 11–23 (2008). https://doi.org/10.1002/adem.200700252

M. Nugent, T. Silfies, P. Kowalski, N. Sutton, Recent applications of evaluations of equipment in HTHA service. In: NACE—CORROSION 2018 Conference and Expo (2018), p. 1–23

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bodden Connor, M.T., Barrett, C.D. Introduction of Molecular Dynamics for HTHA and a Review Article of HTHA. J Fail. Anal. and Preven. 22, 1326–1345 (2022). https://doi.org/10.1007/s11668-022-01419-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01419-4