Abstract

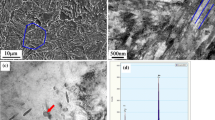

The influence of temperature, CO2 and H2S partial pressure on the corrosion behavior of J55, N80, and L80 carbon steels was investigated using immersion tests, scanning electron microscopy, x-ray diffraction, and E–pH diagrams. The corrosion rates of J55, N80, and L80 were 0.05–0.65 mm/a under working conditions of 20–40 °C, 0.21–0.63MPa CO2 partial pressure, and 0.5–5kPa H2S partial pressure. The corrosion rate increased with increases in temperature and in CO2 partial pressure. The corrosion rate at 40 °C decreased as PCO2/PH2S increased. The corrosion data at 20 °C were scattered, but the corrosion rate approximately followed an upward trend as the ratio of CO2 to H2S partial pressure (PCO2/PH2S) increased. The primary corrosion product was mackinawite, and the corrosion scale was loose, flocculent, or cracked; thus, the protection offered by the corrosion scale was poor.

Similar content being viewed by others

References

C. Qiang. Gas storage: the "granary" of the natural gas industry [N]. China Petrochemical News, 2021-04-26 (005)

Z. Bo, Wu. Lv Bolin, C.L. Yuhang, Z. Shuaiqi, Overview and trend of development of salt cavern gas storage at home and abroad. China Well Mineral Salt. 52(01), 21–24 (2021)

Li. Zhi, Z. Kuiwen, Z. Lichun, G. Fenglin, Improving the peak shaving capacity of gas storage in Lamadian oilfield. Oil Gas Field Surf. Eng. 04, 12–13 (2001)

F. Liang. Research on storage and production technology of underground gas storage. Daqing Petroleum Institute, (2003)

L. Lifeng, Z. Xinwei, L. Jinheng, Z. Hua, Y. Haijun, Li. Xiang, Failure analysis and preventive measures of salt cavern underground gas storage. Oil Gas Stor. and Transp. 29(6), 407–410 (2010)

W. Zhaohui, C. Jun, Analysis on the corrosion law of oil casing in Dazhangtuo gas storage well. Pet. Drilling Prod. Technol. 42(06), 791–796 (2020)

H. Haijun, Wellbore safety assessment of l well in L gas storage. Pet. Tubular Goods Instrum. 5(2), 43–46 (2019)

NACE International. Preparation, installation, analysis and interpretation of corrosion coupons in oilfield operations: SP0775-2013[S]. Houston: NACE International, (2013)

Z. Yongzhang, Z. Jianmin, Z. Jian, The influence of oil well produced fluid composition and temperature on the corrosion behavior of Q235 steel. Mater. Mech. Eng. 32(12), 25–28 (2008)

Z. Shidong, Y. Zhifu, B. Zhenquan, W. Jianfeng, Z. Shugen, T. Wei, The effect of temperature on the corrosion behavior of P110 steel. J. Chinese Soc. Corros. Prot. 29(06), 493–498 (2009)

Z. Shidong, Li. Jinling, Y. Zhigang, Z. Shijun, Li. Hui, W. Ke, Ma. Haixia, The influence of temperature on the CO2 corrosion behavior of J55 tubing. Mater. Mech. Eng. 38(08), 6–10 (2014)

Li Huixin. Corrosion product evolution of low alloy steel under high H2S environment and its effect on corrosion behavior [D]. University of Science and Technology Beijing, p 15 (2019)

Xu. Haisheng, Li. Qianding, X. Ganglin et al., Corrosion research of N80 tubing steel in CO2/H2S water medium. Mater. Prot. 07, 59–62 (2009)

W. Ma, Q. Hang, W. Huang, Y. Dou, Z. Wang, Study on failure behavior of gas well tubing under CO2 corrosion after erosion. J. Fail. Anal. Prev. 20, 950–957 (2020)

Ning J, Zheng Y, Brown B, et al. Construction and verification of Pourbaix diagrams for hydrogen sulfide corrosion of mild steel[C]. NACE International, Huston, 2015, paper No.5507. (2015)

Y. Xiaoqi. Research on CO2 corrosion mechanism and product film characteristics of 13Cr martensitic stainless steel [D]. University of Science and Technology Beijing, pp 41–48. (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, W. Corrosion Behavior of Gas Storage Well Pipe Strings in Corrosive H2S–CO2 Environment. J Fail. Anal. and Preven. 22, 368–376 (2022). https://doi.org/10.1007/s11668-021-01311-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-021-01311-7