Abstract

Mechanical properties of AlSi12 alloy, which was manufactured by laser powder bed fusion (LPBF) technique, were investigated. Some basic properties of fabricated objects such as density and tensile strength were clarified. The suitable laser irradiation condition of fabricated objects that had own high relative density was showed. The microstructure of fabricated objects with as-manufactured condition was also evaluated. The fabricated objects exhibited the similar ultimate tensile strength and the Young’s modulus according to the building directions, although other mechanical properties slightly differed. Mechanical properties of fabricated objects made by reused powders also exhibited the similar values of those manufactured by unused powders. In contrast, the mechanical properties excluding the Young’s modulus of the fabricated objects, which were annealed, differed due to annealing treatment. Furthermore, the mechanical properties excluding the Young’s modulus of the fabricated objects for the designed shapes manufactured to the tensile test specimen were smaller than those of the fabricated objects machined from LPBFed rectangular block. Therefore, the attention is necessary for the mechanical design of fabricated object through LPBF technique and that with annealing treatment, because of the difference in the mechanical properties between the object built as the designed shape and the object made from LPBFed bulk product.

Similar content being viewed by others

References

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, S.L. Sing, Review of selective laser melting: materials and applications. Appl. Phys. Rev. 2, 041101 (2015)

A. Bandyopadhyay, B. Heer, Additive manufacturing of multi-material structures. Mater. Sci. Eng. R 129, 1–16 (2018)

H. Kyogoku, T.-T. Ikeshoji, A review of metal additive manufacturing technologies: mechanism of defects formation and simulation of melting and solidification phenomena in laser powder bed fusion. Mech. Eng. Rev. 7(1), 19–00182 (2020)

M. Adachi, S. Koiwai, Present state of metal additive manufacturing promoting revolution of manufacturing and issues for practical application. J. Jpn. Foundry Eng. Soc. 91(9), 603–611 (2019). (in Japanese)

H. Bikas, P. Stavropoulos, G. Chryssolouris, Additive manufacturing methods and modelling approaches: a critical review. Int. J. Adv. Manuf. Technol. 83, 389–405 (2016)

A. Lindberg, J. Alfthan, H. Pettersson, G. Flodberg, L. Yang, Mechanical performance of polymer powder bed fused objects—FEM simulation and verification. Addit. Manuf. 24, 577–586 (2018)

B. Brenken, E. Barocio, A. Favaloro, V. Kunc, R.B. Pipes, Development and validation of extrusion deposition additive manufacturing process simulations. Addit. Manuf. 25, 218–226 (2019)

J. Ning, E. Mirkoohi, Y. Dong, D.E. Sievers, H. Garmestani, S.Y. Liang, Analytical modeling of 3D temperature distribution in selective laser melting of Ti–6Al–4V considering part boundary condition. J. Manuf. Process. 44, 319–326 (2019)

E.O. Olakanmi, R.F. Cochrane, K.W. Dalgarno, Densification mechanism and microstructural evolution in selective laser sintering of Al–12Si powders. J. Mater. Process. Technol. 211, 113–121 (2011)

R. Chou, A. Ghosh, S.C. Chou, M. Paliwal, M. Brochu, Microstructure and mechanical properties of Al10SiMg fabricated by pulsed laser powder bed fusion. Mater. Sci. Eng. A 689, 53–62 (2017)

M. Javidani, J. Arreguin-Zavala, J. Danovitch, Y. Tian, M. Brochu, Additive manufacturing of AlSi10Mg alloy using direct energy deposition: microstructure and hardness characterization. J. Therm. Spray Technol. 26, 587–597 (2017)

N. Takata, H. Kodaira, K. Sekizawa, A. Suzuki, M. Kobashi, Microstructure and mechanical properties of Al–10Si–0.4Mg alloy fabricated by selective laser melting. J. Jpn. Inst. Light Met. 67(11), 528–588 (2017). (in Japanese)

J.N.D. Ngnekou, Y. Nadot, G. Henaff, J. Nicolai, W.H. Kan, J.M. Cairney, L. Ridosz, Fatigue properties of AlSi10Mg produced by additive layer manufacturing. Int. J. Fatigue 119, 160–172 (2019)

M. Lorusso, A. Aversa, D. Manfredi, F. Calignano, E.P. Ambrosio, D. Ugues, M. Pavese, Tribological behavior of aluminum alloy AlSi10Mg–TiB2 composites produced by direct metal laser sintering (DMLS). J. Mater. Eng. Perform. 25, 3152–3160 (2016)

T. Kimura, T. Nakamoto, Thermal and mechanical properties of commercial-purity aluminum fabricated using selective laser melting. J. Jpn. Inst. Light Met. 66(4), 167–173 (2016). (in Japanese)

Y. Zhang, L. Wu, X. Gox, X. Kane, Y. Deng, Y.G. Jung, J.H. Lee, J. Zhang, Additive manufacturing of metallic materials: a review. J. Mater. Eng. Perform. 27, 1–13 (2018)

S. Vock, B. Kloden, A. Kirchner, T. Weisgarber, B. Kieback, Powders for powder bed fusion: a review. Prog. Addit. Manuf. 4, 383–397 (2019)

V. Gunenthiram, P. Peyre, M. Schneider, M. Dal, F. Coste, I. Koutiri, R. Fabbro, Experimental analysis of spatter generation and melt-pool behavior during the powder bed laser beam melting process. J. Mater. Process. Technol. 251, 376–386 (2018)

J. Metelkova, Y. Kinds, K. Kempen, C.D. Formanoir, A. Witvrouw, B.V. Hooreweder, On the influence of laser defocusing in selective laser melting of 316L. Addit. Manuf. 23, 161–169 (2018)

P. Vora, K. Mumtaz, I. Todd, N. Hopkinson, AlSi12 in situ alloy formation and residual stress reduction using anchorless selective laser melting. Addit. Manuf. 7, 12–19 (2015)

J. Ning, D.E. Sievers, H. Garmestani, S.Y. Liang, Analytical modeling of in-process temperature in powder bed additive manufacturing considering laser power absorption, latent heat, scanning strategy, and powder packing. Materials 12, 808 (2019)

K.G. Prashanth, S. Scudino, H.J. Klauss, K.B. Surreddi, L. Lober, Z. Wang, A.K. Chaubey, U. Kuhn, J. Eckert, Microstructure and mechanical properties of Al–12Si produced by selective laser melting: effect of heat treatment. Mater. Sci. Eng. A 590, 153–160 (2014)

J. Fiocchi, A. Tuissi, P. Bassani, C.A. Biffi, Low temperature annealing dedicated to AlSi10Mg selective laser melting products. J. Alloys Compd. 695, 3402–3409 (2017)

A. Tridello, J. Fiocchi, C.A. Biffi, G. Chiandussi, M. Rossetto, A. Tuissi, D.S. Paolino, VHCF response of Gaussian SLM AlSi10Mg specimens: effect of a stress relief heat treatment. Int. J. Fatigue 124, 435–443 (2019)

L.F. Wang, J. Sun, X.L. Yu, Y. Shi, X.G. Zhu, L.Y. Cheng, H.H. Liang, B. Yan, L.J. Guo, Enhancement in mechanical properties of selectively laser-melted AlSi10Mg aluminum alloys by T6-like heat treatment. Mater. Sci. Eng. A 734, 299–310 (2018)

T. Morinaga, S. Zaima, Y. Aono, T. Shimizu, On the strength of the aluminium castings specified in Japanese Industrial Standard (JIS) (Part 1): on the mechanical properties of miniature lader parabolic reflector made from Al–7% Si alloy. J. Jpn. Foundarymen’s Soc. 14(3), 172–181 (1964). (in Japanese)

K. Kimura, M. Muraki, T. Hayakawa, Study on T5 treatment for improving dimensional stabilities of aluminum alloy castings—studies on heat treatments of aluminum alloy castings (1st report). J. Jpn. Inst. Light Met. 21(5), 324–336 (1971). (in Japanese)

M. Avalle, G. Belingardi, M.P. Cavatorta, R. Doglione, Casting defects and fatigue strength of a die cast aluminium alloy: a comparison between standard specimens and production components. Int. J. Fatigue 24, 1–9 (2002)

Japan Light Metal Association, Aluminium Handbook, 7th edn. (Japan Light Metal Association, Tokyo, 2007), pp. 11–223, 320. (in Japanese)

X.P. Li, K.M. O’Donnell, T.B. Sercombe, Selective laser melting of Al–12Si alloy: enhanced densification via powder drying. Addit. Manuf. 10, 10–14 (2016)

P. Wang, J. Li, Y. Guo, J. Wang, Z. Yang, M. Liang, The formation mechanism of the composited ceramic coating with thermal protection feature on an Al–12Si piston alloy via a modified PEO process. J. Alloys Compd. 682, 357–365 (2016)

A.S. Fefelov, A.G. Merkushev, O.A. Chikova, Microstructure and mechanical properties of Al–12Si produced by selective laser melting. Earth Environ. Sci. 87, 092011 (2017)

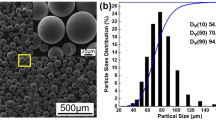

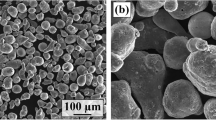

R. Baitimerov, P. Lykov, D. Zherebtsov, L. Radionova, A. Shultc, K.G. Prashanth, Influence of powder characteristics on processability of AlSi12 alloy fabricated by selective laser melting. Materials 11, 742 (2018)

S. Catchpole-Smith, N. Aboulkhair, L. Parry, C. Tuck, I.A. Ashcroft, A. Clare, Fractal scan strategies for selective laser melting of ‘unweldable’ nickel superalloys. Addit. Manuf. 15, 113–122 (2017)

H.P. Tang, G.Y. Yang, W.P. Jia, W.W. He, S.L. Lu, M. Qian, Additive manufacturing of a high niobium-containing titanium aluminide alloy by selective electron beam melting. Mater. Sci. Eng. 636, 103–107 (2015)

T. Kimura, T. Nakamoto, T. Ozaki, K. Sugita, M. Mizuno, H. Araki, Microstructural formation and characterization mechanisms of selective laser melted Al–Si–Mg alloys with increasing magnesium content. Mater. Sci. Eng. A 754, 786–798 (2019)

Japanese Industrial Standards Committee, JIS Z 2241 Metallic Materials—Tensile Testing—Method of Test at Room Temperature (Japanese Industrial Standards Committee, Tokyo, 2011). (in Japanese)

E. Brandl, U. Heckenberger, V. Holzinger, D. Buchbinder, Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 34, 159–169 (2012)

N.T. Aboulkhair, N.M. Everitt, I. Ashcroft, C. Tuck, Reducing porosity in AlSi10Mg pars produced by selective laser malting. Addit. Manuf. 1(4), 77–86 (2014)

N. Read, W. Wang, K. Essa, M.M. Attallah, Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development. Mater. Des. 65, 427–434 (2015)

H. Rao, S. Giet, K. Yang, X. Wu, C.H.J. Davies, The influence of processing parameters on aluminium alloy A357 manufactured by Selective Laser Melting. Mater. Des. 109, 334–346 (2016)

C. Zhang, H. Zhu, Z. Hu, L. Zhang, X. Zeng, A comparative study on single-laser and multi-laser selective laser melting AlSi10Mg: defects, microstructure and mechanical properties. Mater. Sci. Eng. A 746, 416–423 (2019)

M. Mohammadi, H. Asgari, Achieving low surface roughness AlSi10Mg 200C parts using direct metal laser sintering. Addit. Manuf. 20, 23–32 (2018)

M. Fousova, D. Dvorsky, M. Vronka, D. Vojtech, P. Lejcek, The use of selective laser melting to increase the performance of AlSi9Cu3Fe alloy. Materials 11, 1918 (2018)

Q. Han, Y. Jiao, Effect of heat treatment and laser surface remelting on AlSi10Mg alloy fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 102, 3315–3324 (2019)

M. Awd, S. Siddique, J. Johannsen, C. Emmelmann, F. Walther, Very high-cycle fatigue properties and microstructural damage mechanisms of selective laser melted AlSi10Mg alloy. Int. J. Fatigue 124, 55–69 (2019)

S.R. Ch, A. Raja, P. Nadig, R. Jayaganthan, N.J. Vasa, Influence of working environment and built orientation on the tensile properties of selective laser melted AlSi10Mg alloy. Mater. Sci. Eng. A 750, 141–151 (2019)

T. Kimura, T. Nakamoto, Microstructures and mechanical properties of Al–10%Si–0.4%Mg fabricated by selective laser melting. J. Jpn. Soc. Powder Powder Metall. 61(11), 531–537 (2014). (in Japanese)

P. Fathi, M. Mohammadi, X. Duan, A.M. Nasiri, A comparative study on corrosion and microstructure of direct metal laser sintered AlSi10Mg_200C and die cast A360.1 aluminum. J. Mater. Process. Technol. 259, 1–14 (2018)

P. Wang, C. Gammer, F. Brenne, T. Niendorf, J. Eckert, S. Scudino, A heat treatable TiB2/Al–3.5Cu–1.5Mg–1Si composite fabricated by selective laser melting: microstructure, heat treatment and mechanical properties. Compos. B 147, 162–168 (2018)

P.D. Nezhadfar, R. Shrestha, N. Phan, N. Shamsaei, Fatigue behavior of additively manufactured 17-4 PH stainless steel: synergistic effects of surface roughness and heat treatment. Int. J. Fatigue 124, 188–204 (2019)

R. Li, H. Chen, H. Zhu, M. Wang, C. Chen, T. Yuan, Effect of aging treatment on the microstructure and mechanical properties of Al–3.02Mg–0.2Sc–0.1Zr alloy printed by selective laser melting. Mater. Des. 168, 107668 (2019)

E. Beevers, A.D. Brandão, J. Gumpinger, M. Gschweitl, C. Seyfert, P. Hofbauer, T. Rohr, T. Ghidini, Fatigue properties and material characteristics of additively manufactured AlSi10Mg—effect of the contour parameter on the microstructure, density, residual stress, roughness and mechanical properties. Int. J. Fatigue 117, 148–162 (2018)

L. Newton, N. Senin, C. Gomez, R. Danzl, F. Helmli, L. Blunt, R. Leach, A real topography measurement of metal additive surfaces using focus variation microscopy. Addit. Manuf. 25, 365–389 (2019)

Acknowledgments

The authors thank the staff members of the Machine and Workshop Engineering at the Graduate School of Engineering, University of Hyogo. The authors also thank the involved staff members of the Hyogo Prefectural Institute of Technology in this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kimura, M., Hirayama, A., Yoshioka, J. et al. Mechanical Properties of AlSi12 Alloy Manufactured by Laser Powder Bed Fusion Technique. J Fail. Anal. and Preven. 20, 1884–1895 (2020). https://doi.org/10.1007/s11668-020-00998-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00998-4