Abstract

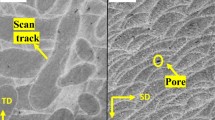

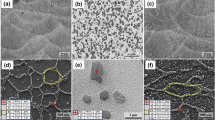

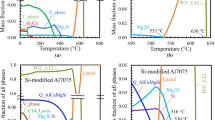

This study investigated the microstructures and tensile properties of as-build and heat-treated (including T6, T2, and T6-T2 treatments) AlSi10Mg samples fabricated by laser powder bed fusion (LPBF). The microstructure analysis revealed that the trend of eutectic Al-Si phase distribution along grain boundaries for heat-treated samples was significantly weakened, and the eutectic Al-Si phase was transformed into Si particles which were uniformly distributed in α-Al matrix. For the T6-T2-treated specimens, the Si content in particles was the highest. Meanwhile, the T6 treatment increased the proportion of equiaxed grains on vertical section most significantly. However, in the wake of heat treatments, the average grain size on horizontal section had little change while the average grain size on vertical section was increased. The properties analysis demonstrated that the T6-T2-treated specimens obtained the best elongation and worst strength. Besides, the T6 treatment eliminated the anisotropy of the LPBFed specimens basically and synergistically obtained the best combination of strength and plasticity. The T6 treatment weakened the direction difference to the greatest extent, whereas the T2 treatment minimized the stress concentration. According to the comparative finding, the Si content in particles played an important part in properties. Besides, the relationship among inverse pole figure (IPF) maps, pole figure (PF) maps, the mass fraction and distribution of Si in Al matrix and Si particle, the grain size, kernel average misorientation (KAM), and mechanical properties under different heat treatments was established, which provided a new idea for the selection of heat treatments on LPBFed parts.

Similar content being viewed by others

Data availability

Not applicable

Code availability

Not applicable

References

Laguna O, Lietor P, Iglesias Godino F, Corpas-Iglesias F (2021) A review on additive manufacturing and materials for catalytic applications: milestones, key concepts, advances and perspectives. Mater Design 208:109927. https://doi.org/10.1016/j.matdes.2021.109927

Blakey-Milner B, Gradl P, Snedden G, Brooks M, Pitot J, Lopez E, Leary M, Berto F, Plessis A (2021) Metal additive manufacturing in aerospace: a review. Mater Design 209:110008. https://doi.org/10.1016/j.matdes.2021.110008

Zhang J, Song B, Wei Q, Bourell D, Shi Y (2019) A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends. J Mater Sci Technol 35:270–284. https://doi.org/10.1016/j.jmst.2018.09.004

Singh R, Gupta A, Tripathi O, Srivastava S, Singh B, Awasthi A, Rajput S, Sonia P, Singhal P, Saxena K (2020) Powder bed fusion process in additive manufacturing: an overview. Mater Today: Proceedings 26:3058–3070. https://doi.org/10.1016/j.matpr.2020.02.635

Wang L, Jiang X, Zhu Y, Zhu X, Sun J, Yan B (2018) An approach to predict the residual stress and distortion during the selective laser melting of AlSi10Mg parts. Int J Adv Manuf Tech 97:3535–3546. https://doi.org/10.1007/s00170-018-2207-3

Calignano F, Cattano G, Manfredi D (2018) Manufacturing of thin wall structures in AlSi10Mg alloy by laser powder bed fusion through process parameters. J Mate Process Tech 255:773–783. https://doi.org/10.1016/j.jmatprotec.2018.01.029

Yang T, Liu T, Liao W (2019) The influence of process parameters on vertical surface roughness of the AlSi10Mg parts fabricated by selective laser melting. J Mater Process Tech 266:26–36. https://doi.org/10.1016/j.jmatprotec.2018.10.015

Shen X, Cheng Z, Wang C, Wu H, Yang Q, Wang G, Huang S (2021) Effect of heat treatments on the microstructure and mechanical properties of Al-Mg-Sc-Zr alloy fabricated by selective laser melting. Opt Laser Technol 143:107312. https://doi.org/10.1016/j.optlastec.2021.107312

Wang Y, Lin X, Kang N, Wang Z, Liu Y, Huang W (2022) Influence of post-heat treatment on the microstructure and mechanical properties of Al-Cu-Mg-Zr alloy manufactured by selective laser melting. J Mater Sci Technol 111(3):5–48. https://doi.org/10.1016/j.jmst.2021.09.036

Babu A, Huang A, Birbilis N (2021) On the heat treatment and mechanical properties of a high solute Al-Zn-Mg alloy processed through laser powder bed fusion process. Mat Sci Eng A 807:140857. https://doi.org/10.1016/j.msea.2021.140857

Xiao Y, Yang Q, Bian Z, Chen H, Wu Y, Lian Q, Chen Z, Wang W (2021) Microstructure, heat treatment and mechanical properties of TiB2/Al-7Si-Cu-Mg alloy fabricated by selective laser melting. Mat Sci Eng A 809:140951. https://doi.org/10.1016/j.msea.2021.140951

Prashanth K, Scudino S, Klauss H, Surreddi K, Löber L, Wang Z, Chaubey A, Kühn U, Eckert J (2014) Microstructure and mechanical properties of Al-12Si produced by selective laser melting: effect of heat treatment. Mat Sci Eng A 590:153–160. https://doi.org/10.1016/j.msea.2013.10.023

Li X, Wang X, Saunders M, Suvorova A, Zhang L, Liu Y, Fang M, Huang Z, Sercombe T (2015) A selective laser melting and solution heat treatment refined Al–12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater 95:74–82. https://doi.org/10.1016/j.actamat.2015.05.017

Wang P, Li H, Prashanth K, Eckert J, Scudino S (2017) Selective laser melting of Al-Zn-Mg-Cu: heat treatment, microstructure and mechanical properties. J Alloy Compd 707:287–290. https://doi.org/10.1016/j.jallcom.2016.11.210

Kang N, Coddet P, Ammar M-R, Liao H, Coddet C (2017) Characterization of the microstructure of a selective laser melting processed Al-50Si alloy: effect of heat treatments. Mater Charact 130:243–249. https://doi.org/10.1016/j.matchar.2017.06.026

Wang P, Gammer C, Brenne F, Niendorf T, Eckert J, Scudino S (2018) A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: microstructure, heat treatment and mechanical properties. Compos Part B 147:162–168. https://doi.org/10.1016/j.compositesb.2018.04.026

Zhang M, Zhou X, Wang D, Zhu W, Li J, Zhao Y (2019) AlCoCuFeNi high-entropy alloy with tailored microstructure and outstanding compressive properties fabricated via selective laser melting with heat treatment. Mat Sci Eng A 743:773–784. https://doi.org/10.1016/j.msea.2018.11.118

Zhang H, Gu D, Dai D, Ma C, Li Y, Cao M, Li S (2020) Influence of heat treatment on corrosion behavior of rare earth element Sc modified Al-Mg alloy processed by selective laser melting. Appl Surf Sci 509:145330. https://doi.org/10.1016/j.apsusc.2020.145330

Wang C, Zhu J, Wang G, Qin Y, Sun M, Yang J, Shen X, Huang S (2022) Effect of building orientation and heat treatment on the anisotropic tensile properties of AlSi10Mg fabricated by selective laser melting. J Alloy Compd 895:162665. https://doi.org/10.1016/j.jallcom.2021.162665

Wei P, Chen Z, Zhang S, Fang X, Lu B, Zhang L, Wei Z (2021) Microstructure, Effect of T6 heat treatment on the surface tribological and corrosion properties of AlSi10Mg samples produced by selective laser melting. Mater Charact 171:110769. https://doi.org/10.1016/j.matchar.2020.110769

Li W, Li S, Liu J, Zhang A, Zhou Y, Wei Q, Yan C, Shi Y (2016) Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: microstructure evolution, mechanical properties and fracture mechanism. Mat Sci Eng A 663:116–125. https://doi.org/10.1016/j.msea.2016.03.088

Takata N, Kodaira H, Sekizawa K, Suzuki A, Kobashi M (2017) Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mat Sci Eng A 704:218–228. https://doi.org/10.1016/j.msea.2017.08.029

Subramaniyan A, Reddy A, Mathias S, Shrivastava A, Raghupatruni P (2021) Influence of post-processing techniques on the microstructure, properties and surface integrity of Al-Si-Mg alloy processed by laser powder bed fusion technique. Surf Coat Tech 425:127679. https://doi.org/10.1016/j.surfcoat.2021.127679

Butler C, Babu S, Lundy R, Meehan R, Punch J, Jeffers N (2021) Effects of processing parameters and heat treatment on thermal conductivity of additively manufactured AlSi10Mg by selective laser melting. Mater Charact 173:110945. https://doi.org/10.1016/j.matchar.2021.110945

Guo Y, Su H, Zhou H, Shen Z, Liu Y, Zhang J, Liu L, Fu H (2022) Unique strength-ductility balance of AlCoCrFeNi2.1 eutectic high entropy alloy with ultra-fine duplex microstructure prepared by selective laser melting. J Mater Sci Technol 111:298–306. https://doi.org/10.1016/j.jmst.2021.10.013

Wang L, Zhang Y, Hua X, Shen C, Li F, Huang Y, Ding Y, Zhang P, Lu Q, Zhang T, Shang J (2021) Twin-wire plasma arc additive manufacturing of the Ti–45Al titanium aluminide: processing, microstructures and mechanical properties. Intermetallics 136:107277. https://doi.org/10.1016/j.intermet.2021.107277

Sridharan N, Gussev M, Seibert R, Parish C, Norfolk M, Terrani K, Babu S (2016) Rationalization of anisotropic mechanical properties of Al-6061 fabricated using ultrasonic additive manufacturing. Acta Mater 117:228–237. https://doi.org/10.1016/j.actamat.2016.06.048

Rao J, Zhang Y, Fang X, Chen Y, Wu X, Davies C (2017) The origins for tensile properties of selective laser melted aluminium alloy A357. Addit Manuf 17:113–122. https://doi.org/10.1016/j.addma.2017.08.007

Han Q, Jiao Y (2019) Effect of heat treatment and laser surface remelting on AlSi10Mg alloy fabricated by selective laser melting. Int J Adv Manuf Tech 102:3315–3324. https://doi.org/10.1007/s00170-018-03272-y

Funding

This work was supported by the financial support of the National Key Research and Development Program of China grants (2022YFB4602300), the National Natural Science Foundation of China (nos. 51901135, 52071205), and Equipment Pre-research Shared Technology Project of China (50922060201).

Author information

Authors and Affiliations

Contributions

XZ: supervising, editing, experiments. DD: supervising. AD: writing. QS: experiments. JS: experiments. LG: editing. BS: supervising, editing. ZC: experiments.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable

Consent to participate

The authors declare that they consent to participate in this paper.

Consent for publication

The authors declare that they consent to publish this paper.

Conflict of interest

The authors declare no competing interests.

Disclaimer

The State Key Labs of Advanced High-temperature Materials and Precision Forming and Metal Matrix Composites do not mind being the author’s unit. They also do not affect your decision to publish and share the results in your journal.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, X., Du, D., Dong, A. et al. Effect of heat treatments on microstructure and mechanical properties of AlSi10Mg alloys fabricated by laser powder bed fusion. Int J Adv Manuf Technol 127, 4211–4223 (2023). https://doi.org/10.1007/s00170-023-11812-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11812-4