Abstract

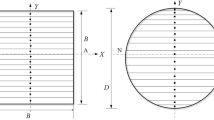

The purpose of this research is to acquire an optimum design of FGMs for cylindrical and spherical vessels such that the whole material contributes to the load bearing. To do so, a reasonable yield strength profile for FGM is proposed and used in the material tailoring equation. In conjunction with equilibrium and compatibility equations as well as considering stress boundary conditions, a nonlinear ODE in terms of inclusion volume fraction is constituted and solved via applying initial conditions. For verification, a FE simulation made by ABAQUS software is performed that shows good agreement between the simulation and analysis results.

Similar content being viewed by others

Abbreviations

- \( a,b \) :

-

Internal and external radii, respectively

- \( P_{a} ,P_{b} \) :

-

Internal and external pressures, respectively

- \( T_{a} ,T_{b} \) :

-

Internal and external temperatures, respectively

- \( E \) :

-

Elastic modulus

- \( V \) :

-

Poisson’s ratio

- \( k \) :

-

Thermal conductivity

- \( \alpha \) :

-

Coefficient of expansion

- \( S_{\text{y}} \) :

-

Yield stress

- A :

-

Coefficient of yield strength function

- A ′ :

-

Fraction coefficient of yield strength function

- \( B \) :

-

Exponent of yield strength function

- \( \zeta \) :

-

Volume fraction of inclusion phase

- \( \zeta_{0} \) :

-

Volume fraction of inclusion phase at the inner radius

- \( \sigma_{\text{r}} ,\sigma_{\theta } \) :

-

Radial and circumferential stresses, respectively

- \( \varepsilon_{\text{r}} ,\varepsilon_{\theta } \) :

-

Radial and circumferential strains, respectively

References

A.T. Function, Z. Yang, L. Zhang et al., Theoretical design of sedimentation applied to the fabrication of functionally graded materials. Metall. Mater. Trans. B [Internet]. 34, 605–609 (2003). https://doi.org/10.1007/s11663-003-0030-0

T. Mahmoudi, A. Parvizi, E. Poursaeidi et al., Thermo-mechanical analysis of functionally graded wheel-mounted brake disk. J. Mech. Sci. Technol. 29, 4197–4204 (2015)

M. Koizumi, Recent progress of functionally gradient materials in Japan. Ceram. Eng. Sci. Proc. 13, 333–347 (1992)

S. Alikarami, A. Parvizi, Elasto-plastic analysis and finite element simulation of thick-walled functionally graded cylinder subjected to combined pressure and thermal loading. Sci. Eng. Compos. Mater. 24, 609–620 (2017)

M.A. Benatta, A. Kaci, A. Tounsi et al., Nonlinear bending analysis of functionally graded plates under pressure loads using a four variable refined plate theory. Int. J. Comput. Methods 11, 1350062 (2004). https://doi.org/10.1142/S021987621350062X

T.H. Daouadji, A.H. Henni, A. Tounsi et al., A new hyperbolic shear deformation theory for bending analysis of functionally graded plates. Appl. Math. Model. 2012, 2489–2508 (2012)

M. Niino, K. Kisara, M. Mori, Feasibility study of FGM technology in space solar power systems (SSPS). Mater. Sci. Forum [Internet] 492, 163–170 (2005)

H. Shah, A. Rahman, D. Choudhury et al., In vivo and in vitro outcomes of alumina, zirconia and their composited ceramic-on-ceramic hip joints. J. Ceram. Soc. Jpn. 1214, 382–387 (2013)

A. Bandyopadhyay, B.V. Krishna, W. Xue et al., Application of laser engineered net shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants. J. Mater. Sci. Mater. Med. 20, 29 (2009)

S. Hosseini-Hashemi, I. Nahas, M. Fakher et al., Surface effects on free vibration of piezoelectric functionally graded nanobeams using nonlocal elasticity. Acta Mech. 225, 1555–1564 (2014)

O. Carvalho, M. Buciumeanu, S. Madeira et al., Optimization of AlSi-CNTs functionally graded material composites for engine piston rings. Mater. Des. 80, 163–173 (2015)

A.W. Leissa, M. Vagins, The design of orthotropic materials for stress optimization. Int. J. Solids Struct. 14, 517–526 (1978)

M. Sadeghian, H.E. Toussi, Solutions to the problem of thermo-mechanical yielding in functionally graded material cylindrical vessels. J. Reinf. Plast. Compos. 32, 1624–1633 (2013)

M. Sun, M.W. Hyer, Use of material tailoring to improve buckling capacity of elliptical composite cylinders. AIAA J. 46, 770–782 (2008)

J.R. Cho, J.H. Choi, A yield-criteria tailoring of the volume fraction in metal-ceramic functionally graded material. Eur. J. Mech. A/Solids. 23, 271–281 (2004)

B.M. Love, R.C. Batra, Determination of effective thermomechanical parameters of a mixture of two elastothermoviscoplastic constituents. Int. J. Plast 22, 1026–1061 (2006)

F.N. Dehnavi, A. Parvizi, Investigation of thermo-elasto-plastic behavior of thick-walled spherical vessels with inner functionally graded coatings. Meccanica [Internet]. 52, 2421–2438 (2017)

D. Leutz, T. Wallmersperger, Thermo-mechanical behavior of functionally graded materials: modeling, simulation and error estimation. Mech. Adv. Mater. Struct. 18, 32–52 (2011)

Z. Mazarei, M.Z. Nejad, A. Hadi, Thermo-elasto-plastic analysis of thick-walled spherical pressure vessels made of functionally graded materials. Int. J. Appl. Mech. 8, 1–25 (2016)

M.R. Eslami, M.H. Babaei, R. Poultangari, Thermal and mechanical stresses in a functionally graded thick sphere. Int. J. Press. Vessel. Pip. [Internet] 82, 522–527 (2005)

Y. Tanigawa, M. Matsumoto, T. Akai, Optimization problem of material composition for nonhomogeneous plate to minimize thermal stresses when subjected to unsteady heat supply. Trans. Jpn Soc. Mech. Eng. Ser. A. 62, 115–122 (1996)

K.S.S. Ravichandran, Thermal residual stresses in a functionally graded material system. Mater. Sci. Eng. A 201, 269–276 (1995)

B. Agarwal, P.C. Upadhyay, L. Banta et al., Transient temperature distribution in composites with layers of Functionally Graded Materials (FGMs). J. Reinf. Plast. Compos. 25, 513–542 (2006)

A. Parvizi, R. Naghdabadi, J. Arghavani, Analysis of Al A359/SiCp functionally graded cylinder subjected to internal pressure and temperature gradient with elastic-plastic deformation. J. Therm. Stress. [Internet] 34, 1054–1070 (2011). https://doi.org/10.1080/01495739.2011.605934

A. Parvizi, S. Alikarami, M. Asgari, Exact solution for thermoelastoplastic behavior of thick-walled functionally graded sphere under combined pressure and temperature gradient loading. J Therm Stress 39, 1152–1170 (2016). https://doi.org/10.1080/01495739.2016.1188614

F. Nosouhi Dehnavi, A. Parvizi, K. Abrinia, Novel material tailoring method for internally pressurized FG spherical and cylindrical vessels. Acta Mech. Sin. Xuebao. 34, 936–948 (2018)

G.J. Nie, R.C. Batra, Material tailoring and analysis of functionally graded isotropic and incompressible linear elastic hollow cylinders. Compos. Struct. 92, 265–274 (2010)

H.M. Xu, X.F. Yao, X.Q. Feng et al., Anti-plane Yoffe moving crack problem in isotropic functionally graded materials. J. Reinf. Plast. Compos. 26, 127–137 (2007)

A. Alibeigloo, Thermo elasticity solution of functionally graded, solid, circular, and annular plates integrated with piezoelectric layers using the differential quadrature method. Mech. Adv. Mater. Struct. 25, 766–784 (2018)

Z. Yang, M. Liu, C. Deng et al., Thermal stress analysis of W/Cu functionally graded materials by using finite element method. J. Phys: Conf. Ser. 419, 012051 (2013)

C.F. Deng, Y.X. Ma, P. Zhang et al., Thermal expansion behaviors of aluminum composite reinforced with carbon nanotubes. Mater. Lett. 62, 2301–2303 (2008)

J.M. Molina, J. Narciso, L. Weber et al., Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution. Mater. Sci. Eng. A 480, 483–488 (2008)

Z. Li, R.C. Bradt, Thermal expansion of the cubic (3C) polytype of SiC. J. Mater. Sci. 21, 4366–4368 (1986)

G.A. Slack, Thermal conductivity of pure and impure silicon, silicon carbide, and diamond. J. Appl. Phys. 35, 3460–3466 (1964)

T. Mori, K. Tanaka, Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 21, 571–574 (1973)

Z.-Q. Cheng, R.C. Batra, Three-dimensional thermoelastic deformations of a functionally graded elliptic plate. Compos. Part B Eng. 31, 97–106 (2000)

J.N. Reddy, Z.Q. Cheng, Three-dimensional thermomechanical deformations of functionally graded rectangular plates. Eur. J. Mech. A/Solids. 20, 841–855 (2001)

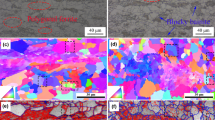

R. Rodríguez-Castro, R.C. Wetherhold, M.H. Kelestemur, Microstructure and mechanical behavior of functionally graded Al A359/SiCp composite. Mater. Sci. Eng. A 323, 445–456 (2002)

D. Dumont, A. Deschamps, Y. Brechet, A model for predicting fracture mode and toughness in 7000 series aluminium alloys. Acta Mater. 52, 2529–2540 (2004)

R.G. Munro, Material properties of a sintered α-SiC. J. Phys. Chem. Ref. Data 26, 1195–1203 (1997)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hashemi, M.S., Akbari, A. & Parvizi, A. New Physically Consistent Yield Model to Optimize Material Design for Functionally Graded Vessels. J Fail. Anal. and Preven. 20, 470–482 (2020). https://doi.org/10.1007/s11668-020-00844-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00844-7