Abstract

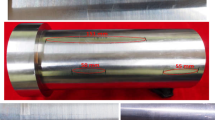

In view of its excellent wear and corrosion resistance, AISI 440C steel is the material of choice for the fabrication of ball screws used in actuator systems of satellite launch vehicles. During the routine acceptance test of a ball screw, longitudinal cracks were observed at the shaft location of the ball screw. The optical microstructure of the ball screw material (AISI 440C) revealed the presence of aligned carbides (carbide banding). Fractographic observations revealed the cracking to be along the carbide bands. Based on detailed optical and scanning electron microscopic observations, the cracking of the ball screws was attributed to the carbide bands.

Similar content being viewed by others

References

H.K.D.H. Bhadesia, Steels for bearings. Prog. Mater Sci. 57, 268–435 (2012)

J.R. Yang, T.H. Yu, C.H. Wang, Martensitic transformations in AISI 440C stainless steel. Mater. Sci. Eng., A 438–440, 276–280 (2006)

K. Clemons, C. Lorraine, G. Salgado, A. Taylor, J. Ogren, P. Umin, O.S. Es-said, Effects of heat treatments in steels for bearing applications. J. Mater. Eng. Perform. 16(5), 592–597 (2007)

R.J. Parker, E.N. Bamberger, Effect of carbide distribution on rolling-element fatigue life of AMS 5749. NASA Tech. Paper 2189, 1–11 (1983)

S.C. Krishna, K.T. Tharian, K.V.A. Chakravarthi, A.K. Jha, B. Pant, Heat treatment and thermo-mechanical treatment to modify carbide banding in AISI 440C steel: a case study. Metallogr. Microstruct. Anal. 5(2), 108–115 (2016)

D.W. Hetzner, W. Van Geertruyden, Crystallography and metallography of carbides in high alloy steels. Mater. Charact. 59, 825–841 (2008)

H.A.J. Chin, K.K. Starr, J.W. Samuelson, D.A. Haluch, H.R. Nesor, Influence of metallurgical factors on the performance of AISI 440C bearings. in AIAA, 26th joint propulsion conference, pp. 1–6 (1990)

Acknowledgments

The authors wish to place on record their deep sense of gratitude to the Group Director, Materials and Metallurgy Group, and the Deputy Director, Materials and Mechanical Entity, for their encouragement and support during the course of this work. They wish to thank the Director, VSSC, for his kind permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manwatkar, S.K., Bahrudheen, A., Tiwari, S.B. et al. Failure Analysis of AISI 440C Steel Ball Screws Used in the Actuator System of a Satellite Launch Vehicle. J Fail. Anal. and Preven. 17, 505–512 (2017). https://doi.org/10.1007/s11668-017-0268-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0268-5