Abstract

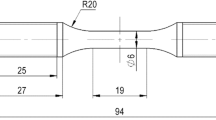

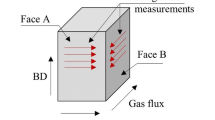

17-4 PH stainless steels are extensively used in aerospace applications due to their high strength, corrosion resistance, and precipitation hardening ability. Extensive machining is required while manufacturing complex aerospace components. In the current failure, through-thickness long cracks were observed on a component during the second stage of machining. Machining was carried out on a solution-treated rod. Residual stress analysis revealed that unmachined bare rod and semi-machined uncracked hardware had compressive residual stresses, whereas tensile residual stresses were present on the cracked hardware. Transgranular cleavage features were present on the cracked surface, whereas tensile-tested specimens fabricated near and slightly away from the cracked region revealed dimple features. The microstructure consists of lath martensite and a small amount of delta ferrite with different sizes. X-ray diffraction analysis on the cracked and uncracked regions of the cracked hardware also confirmed the phases and types of residual stresses. Microhardness was found to be lower near the cracked region than away from crack region. The failure is attributed to tensile residual stresses aided through improper machining.

Similar content being viewed by others

References

Technical data blue sheet of Allegheny technologies. http:// www.alleghenyludlum.com

ATI technical data sheet, Stainless steel AL 17-4TM precipitation hardening alloy. http://www.specialtysteelsupply.com/brochure/17-4-technical-data.pdf. Accessed 1 Apr 2015

U.K. Viswanathan, S. Banerjee, R. Krishnan, Effects of aging on the microstructure of 17–4 PH stainless steel. Mater. Sci. Eng. A. 104, 181–189 (1988)

J. Tian, W. Wang, W. Yan, Z. Jiang, Y. Shan, K. Yang, Cracking due to Cu and Ni segregation in a 17–4 PH stainless steel piston rod. Eng. Fail. Anal. 65, 57–64 (2016)

A.E. Hicho, J.H. Smith, Metallurgical evaluation of 17-4 PH stainless steel castings, National Institute of Standards and Technology, Report No. NISTIR 894075, May, 1989

A. Samuel, K. Narayan Prabhu, Residual stress and distortion during quench hardening of steels: a review. JMEPEG. 31, 5161–5188 (2022)

K.S. Raja, K.P. Rao, On the hardness criterion for stress corrosion cracking resistance of 17–4 PH stainless steel. J. Mater. Sci. Lett. 12, 963 (1993)

A.R. Etemadi, A.E. PeimanBehjati, S.D. Motiei, S. Misaeedi, Failure analysis of holding yokes made of investment cast 17–4 PH stainless steel. Eng. Fail. Anal. 18, 1242–1246 (2011)

C. FahirArisoy, M. GokahanBasman, KelamiSesen, Failure of a 17–4 PH stainless steel sailboat propeller shaft. Eng. Fail. Anal. 10, 711–717 (2003)

D. Tanner, Residual stress determination using hardness testing, Thesis, August, 2018

C. Ruud, Measurement of Residual Stress, in Handbook of Residual Stress and Deformation of Steel. ed. by G. Totten, M. Howes, T. Inoue (ASM International, Almere, 2002), p.99–115

Acknowledgment

Authors wish to place on record their deep sense of gratitude to Group Director, Materials and Metallurgy Group and Deputy Director, Materials and Mechanical Entity for their encouragement and support during the course of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yerrinaidu, L., Ranjith, R., Prakash, F.G. et al. Analysis of Cracks in Solution-Treated AISI 17-4PH Stainless Steel Observed During Machining of Aerospace Component. J Fail. Anal. and Preven. 23, 2003–2013 (2023). https://doi.org/10.1007/s11668-023-01740-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01740-6