Abstract

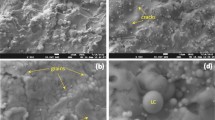

The elemental interdiffusion between the bond-coat in the thermal barrier coatings (TBCs) system and the superalloy substrate has emerged as a critical factor affecting the service life of the TBCs-coated turbine blades in aero-engines. To address this issue, a NiCrAlY bond-coat with low Al content and high Y content was designed and sprayed on the superalloy using high velocity oxygen fuel method. The performance of the as-deposited coating was assessed through isothermal oxidation test at 1000 °C for durations ranging from 10 to 1000 h. The results revealed the precipitation of c-Y2O3 particles at the grain boundaries of the as-deposited coating. These particles appeared to impede the diffusion of coating elements, resulting in improved oxidation resistance. The oxidation mechanism of the as-deposited coating on the flat region was divided into two stages: the preferential oxidation of Al and the formation of spinel; the inward growth of alumina along with outward growth of spinel. In the concave area, the oxidation mechanism was characterized by a rapid thickening of the spinel phase and NiO, attributed to the thinner coating and special Ni diffusion method. Semi-molten particles formed an overlaying structure after oxidation as the elements diffused in surrounding areas, with only the Ni element remaining inside it. The designed low Al content NiCrAlY coating exhibits excellent oxidation resistance at 1000 °C.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study. The processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

N.P. Padture, M. Gell, and E.H. Jordan, Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284.

H. Dong, G.J. Yang, C.X. Li, X.T. Luo, and C.J. Li, Effect of TGO Thickness on Thermal Cyclic Lifetime and Failure Mode of Plasma-Sprayed TBC s, J. Am. Ceram. Soc., 2014, 97(4), p 1226-1232.

A.G. Evans, D.R. Mumm, J.W. Hutchinson, G.H. Meier, and F.S. Pettit, Mechanisms Controlling the Durability of Thermal Barrier Coatings, Prog. Mater. Sci., 2001, 46(5), p 505-553.

A. Scrivani, U. Bardi, L. Carrafiello, A. Lavacchi, F. Niccolai, and G. Rizzi, A Comparative Study of High Velocity Oxygen Fuel, Vacuum Plasma Spray, and Axial Plasma Spray for the Deposition of CoNiCrAlY Bond Coat Alloy, J. Therm. Spray Technol., 2003, 12(4), p 504-507.

W. Brandl, D. Toma, J. Krüger, H.J. Grabke, and G. Matthäus, The Oxidation Behaviour of HVOF Thermal-Sprayed MCrAlY Coatings, Surf. Coat. Technol., 1997, 94–95, p 21-26.

W. Brandl, D. Toma, and H.J. Grabke, The Characteristics of Alumina Scales Formed on HVOF-Sprayed MCrAlY Coatings, Surf. Coat. Technol., 1998, 108–109, p 10-15.

A. Sato, Y. Aoki, M. Arai, and H. Harada, Effect of Aluminide Coating on Creep Properties of Ni-Base Single Crystal Superalloys, J. Jpn. Inst. Met., 2007, 71(3), p 320-325.

S. Tian, M. Wang, T. Li, B. Qian, and J. Xie, Influence of TCP Phase and Its Morphology on Creep Properties of Single Crystal Nickel-Based Superalloys, Mater. Sci. Eng. A, 2010, 527(21–22), p 5444-5451.

K. Rahmani and S. Nategh, Influence of Aluminide Diffusion Coating on Low Cycle Fatigue Properties of René 80, Mater. Sci. Eng. A, 2008, 486(1–2), p 686-695.

H.U. Hong, J.G. Yoon, B.G. Choi, I.S. Kim, and C.Y. Jo, On the Mechanism of Secondary Reaction Zone Formation in a Coated Nickel-Based Single-Crystal Superalloy Containing Ruthenium, Scr. Mater., 2013, 69(1), p 33-36.

M. Elsaß, M. Frommherz, A. Scholz, and M. Oechsner, Interdiffusion in MCrAlY Coated Nickel-Base Superalloys, Surf. Coat. Technol., 2016, 307, p 565-573.

T. Liang, H. Guo, H. Peng, and S. Gong, Precipitation Phases in the Nickel-Based Superalloy DZ 125 with YSZ/CoCrAlY Thermal Barrier Coating, J. Alloys Compd., 2011, 509(34), p 8542-8548.

C. Liu, Y. Chen, L. Qiu, H. Liu, M. Bai, and P. Xiao, The Al-Enriched γ’-Ni3Al-Base Bond Coat for Thermal Barrier Coating Applications, Corros. Sci., 2020, 167, p 108523.

H. Yao, L. Yang, Z. Bao, S. Zhu, and F. Wang, Low Inter-Diffusivity γ’-Base Bondcoats for Single Crystal Superalloy René N5. I: Primary Study of Microstructures and Oxidation Behaviors at 1100 °C, Corros. Sci., 2019, 147, p 299-312.

D. Naumenko, B.A. Pint, and W. Quadakkers, Current Thoughts on Reactive Element Effects in Alumina-Forming Systems: In Memory of John Stringer, Oxid. Met., 2016, 86, p 1-43.

L. Yang, M. Chen, J. Wang, Z. Bao, S. Zhu, and F. Wang, Diffusion of Ta and its Influence on Oxidation Behavior of Nanocrystalline Coatings with Different Ta, Y and Al Contents, Corros. Sci., 2017, 126, p 344-355.

H. Yao, L. Yang, Z. Bao, S. Zhu, and F. Wang, Low Inter-Diffusivity γ’-Base Bondcoats for Single Crystal Superalloy René N5. II: Cyclic Oxidation Behavior at 1100 °C, Corros. Sci., 2019, 159, p 108127.

A. Gil, V. Shemet, R. Vassen, M. Subanovic, J. Toscano, D. Naumenko, L. Singheiser, and W. Quadakkers, Effect of Surface Condition on the Oxidation Behaviour of MCrAlY Coatings, Surf. Coat. Technol., 2006, 201(7), p 3824-3828.

D. Sun, C. Liang, J. Shang, J. Yin, Y. Song, W. Li, T. Liang, and X. Zhang, Effect of Y2O3 Contents on Oxidation Resistance at 1150°C and Mechanical Properties at Room Temperature of ODS Ni-20Cr-5Al Alloy, Appl. Surf. Sci., 2016, 385, p 587-596.

P. Richer, M. Yandouzi, L. Beauvais, and B. Jodoin, Oxidation Behaviour of CoNiCrAlY Bond Coats Produced by Plasma HVOF and Cold Gas Dynamic Spraying, Surf. Coat. Technol., 2010, 204(24), p 3962-3974.

A. Feizabadi, M.S. Doolabi, S. Sadrnezhaad, and M. Rezaei, Cyclic Oxidation Characteristics of HVOF Thermal-Sprayed NiCoCrAlY and CoNiCrAlY Coatings at 1000° C, J. Alloys Compd., 2018, 746, p 509-519.

A.C. Karaoglanli, Y. Ozgurluk, and K.M. Doleker, Comparison of Microstructure and Oxidation Behavior of CoNiCrAlY Coatings Produced by APS, SSAPS, D-gun, HVOF and CGDS Techniques, Vacuum, 2020, 180, p 109609.

G. Meng, H. Liu, M. Liu, T. Xu, G. Yang, C. Li, and C. Li, Large-Grain α-Al2O3 Enabling Ultra-High Oxidation-Resistant MCrAlY Bond Coats by Surface Pre-Agglomeration Treatment, Corros. Sci., 2020, 163, p 108275.

G. Meng, B. Zhang, H. Liu, G. Yang, T. Xu, C. Li, and C. Li, Highly Oxidation Resistant and Cost Effective MCrAlY Bond Coats Prepared by Controlled Atmosphere Heat Treatment, Surf. Coat. Technol., 2018, 347, p 54-65.

D. Seo, K. Ogawa, T. Shoji, and S. Murata, High-Temperature Oxidation Behavior and Surface Roughness Evolution of VPS NiCrAlY Coating, J. Therm. Spray Technol., 2008, 17, p 136-143.

Y. Li, C. Li, Q. Zhang, L. Xing, and G. Yang, Effect of Chemical Compositions and Surface Morphologies of MCrAlY Coating on its Isothermal Oxidation Behavior, J. Therm. Spray Technol., 2011, 20, p 121-131.

Z. Zhao, J. Wang, M. Chen, J. Zhang, F. Wang, and D.J. Young, Comparative Study on the Initial Oxidation Behavior of Conventional and Nanocrystalline MCrAlY Coatings-Effect of Microstructure Evolution and Dynamic Mechanisms, Acta Mater., 2022, 239, p 118264.

S. Kung, Gibbs Energy of Formation of Nickel Chromite, Metall. Trans. B, 1991, 22(5), p 673-675.

I. Barin, G. Platzki, Thermochemical Data of Pure Substances. (Wiley Online Library, 1989)

B.A. Pint, Experimental Observations in Support of the Dynamic-Segregation Theory to Explain the Reactive-Element Effect, Oxid. Met., 1996, 45(1), p 1-37.

A. Gil, D. Naumenko, R. Vassen, J. Toscano, M. Subanovic, L. Singheiser, and W.J. Quadakkers, Y-Rich Oxide Distribution in Plasma sprayed MCrAlY-Coatings Studied by SEM with a Cathodoluminescence Detector and RAMAN Spectroscopy, Surf. Coat. Technol., 2009, 204(4), p 531-538.

J. Toscano, R. Vaβen, A. Gil, M. Subanovic, D. Naumenko, L. Singheiser, and W.J. Quadakkers, Parameters Affecting TGO Growth and Adherence on MCrAlY-Bond Coats for TBC’s, Surf. Coat. Technol., 2006, 201(7), p 3906-3910.

J. Toscano, Influence of Composition and Processing on the Oxidation Behviour of MCrAlY Coatings for TBC Applications: Werkstoffstruktur und Eigenschaften; (2008)

I. Usov, P. Arendt, L. Stan, R. Depaula, H. Wang, S. Foltyn, and P. Dowden, Characteristics of Alumina Diffusion Barrier Films on Hastelloy, J. Mater. Res., 2004, 19(4), p 1175-1180.

P. Fielitz, K. Kelm, R. Bertram, A.H. Chokshi, and G. Borchardt, Aluminium-26 Grain Boundary Diffusion in Pure and Y-Doped Polycrystalline α-Alumina, Acta Mater., 2017, 127, p 302-311.

A.D. Pelton, H. Schmalzried, and J. Sticher, Computer-Assisted Analysis and Calculation of Phase Diagrams of the Fe-Cr-O Fe-Ni-O and Cr-Ni-O Systems, J. Phys. Chem. Solids, 1979, 40(12), p 1103-1122.

Acknowledgments

Financial support provided by Guangdong Basic and Applied Basic Research Foundation (No. 2022A1515110198), National Natural Science Foundation of China (No. 11890684 and No. U2341257), National Science and Technology Major Project (J2022-V-0003-0029), Innovation Capability Support Program of Shaanxi (Program No. 2022TD-28).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, Y., Liu, J., Luo, J. et al. Investigation on the Oxidation Behavior of the NiCrAlY Bond-Coat with Low Al Content Sprayed by High Velocity Oxygen Fuel Method. J Therm Spray Tech (2024). https://doi.org/10.1007/s11666-024-01767-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11666-024-01767-7