Abstract

This paper offers a concise critical review of finite element studies of the jetting phenomenon in cold spray (CS). CS is a deposition technique wherein solid particles impact a substrate at high velocities, inducing severe plastic deformation and material deposition. These high-velocity particle impacts lead to the ejection of material in a jet-like shape at the periphery of the particle/substrate interface, a phenomenon known as "jetting". Jetting has been the subject of numerous studies over recent decades and remains a point of debate. Two main mechanisms, Adiabatic Shear Instability (ASI) and Hydrodynamic Pressure-Release (HPR), have been proposed to explain the jetting phenomenon. These mechanisms are mainly elucidated through finite element method (FEM) simulations, a numerical technique rooted in continuum mechanics. However, it is important to emphasize that FEM is limited by the equations established for analysis, and as such, its predictive capabilities are confined to those principles clearly defined within these equations. The choice of employed equations and approaches significantly influence the outcomes and predictions in FEM. While recognizing FEM's capabilities, this study reviews the ASI and HPR mechanisms within the context of CS. Additionally, this paper reviews FEM's algorithms and the core principles that govern FEM in calculating plastic deformation, which can lead to the formation of jetting.

Similar content being viewed by others

References

H. Assadi, H. Kreye, F. Gärtner, and T. Klassen, Cold Spraying—A Materials Perspective, Acta Mater., 2016, 116, p 382-407. https://doi.org/10.1016/J.ACTAMAT.2016.06.034

K. Kim, M. Watanabe, and S. Kuroda, Jetting-Out Phenomenon Associated with Bonding of Warm-Sprayed Titanium Particles onto Steel Substrate, J. Therm. Spray Technol., 2009, 18, p 490. https://doi.org/10.1007/s11666-009-9379-1

A.A. Tiamiyu, Y. Sun, K.A. Nelson, and C.A. Schuh, Site-Specific Study of Jetting, Bonding, and Local Deformation During High-Velocity Metallic Microparticle Impact, Acta Mater., 2021, 202, p 159-169. https://doi.org/10.1016/j.actamat.2020.10.057

M. Razavipour, S. Rahmati, A. Zúñiga, D. Criado, and B. Jodoin, Bonding Mechanisms in Cold Spray: Influence of Surface Oxidation During Powder Storage, J. Therm. Spray Technol., 2020 https://doi.org/10.1007/s11666-020-01123-5

R. Nikbakht, M. Saadati, T.-S. Kim, M. Jahazi, H.S. Kim, and B. Jodoin, Cold Spray Deposition Characteristic and Bonding of CrMnCoFeNi High Entropy Alloy, Surf. Coat. Technol., 2021, 425, p 127748. https://doi.org/10.1016/j.surfcoat.2021.127748

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394. https://doi.org/10.1016/S1359-6454(03)00274-X

M. Hassani-Gangaraj, D. Veysset, V.K. Champagne, K.A. Nelson, and C.A. Schuh, Adiabatic Shear Instability is Not Necessary for Adhesion in Cold Spray, Acta Mater., 2018, 158, p 430-439. https://doi.org/10.1016/J.ACTAMAT.2018.07.065

H. Assadi, F. Gärtner, T. Klassen, and H. Kreye, Comment on ‘Adiabatic Shear Instability is Not Necessary for Adhesion in Cold Spray,’ Scr. Mater., 2019, 162, p 512-514. https://doi.org/10.1016/j.scriptamat.2018.10.036

M. Hassani-Gangaraj, D. Veysset, V.K. Champagne, K.A. Nelson, and C.A. Schuh, Response to Comment on “Adiabatic Shear Instability is Not Necessary for Adhesion in Cold Spray,” Scr. Mater., 2019, 162, p 515-519. https://doi.org/10.1016/j.scriptamat.2018.12.015

S. Rahmati and A. Ghaei, The Use of Particle/Substrate Material Models in Simulation of Cold-Gas Dynamic-Spray Process, J. Therm. Spray Technol., 2014, 23, p 530-540. https://doi.org/10.1007/s11666-013-0051-4

W.H. Johnson and G.R. Cook, A constitutive model and data for metals subjected to large strains, high strain rates and high. Proceedings of the 7th International Symposium on Ballistics, The Hague, Netherlands (1983), p. 541-547

C.Y. Gao and L.C. Zhang, A Constitutive Model for Dynamic Plasticity of FCC Metals, Mater. Sci. Eng. A, 2010, 527, p 3138-3143. https://doi.org/10.1016/j.msea.2010.01.083

P. Landau, S. Osovski, A. Venkert, V. Gärtnerová, and D. Rittel, The Genesis of Adiabatic Shear Bands, Sci. Rep., 2016, 6, p 37226. https://doi.org/10.1038/srep37226

V. Abaqus, 6.14 Online Documentation Help Theory Manual: Dassault Systms, Simulia Inc., Johnston, 2016.

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25, p 681-688. https://doi.org/10.1016/j.matdes.2004.03.008

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56, p 4858-4868. https://doi.org/10.1016/J.ACTAMAT.2008.06.003

C.J. Akisin, C.J. Bennett, F. Venturi, H. Assadi, and T. Hussain, Numerical and Experimental Analysis of the Deformation Behavior of CoCrFeNiMn High Entropy Alloy Particles onto Various Substrates During Cold Spraying, J. Therm. Spray Technol., 2022, 31, p 1085-1111. https://doi.org/10.1007/s11666-022-01377-1

Q. Chen, W. Xie, V.K. Champagne, A. Nardi, J.-H. Lee, and S. Müftü, On Adiabatic Shear Instability in Impacts of Micron-Scale Al-6061 Particles with Sapphire and Al-6061 Substrates, Int. J. Plast., 2023, 166, p 103630. https://doi.org/10.1016/j.ijplas.2023.103630

L. Palodhi and H. Singh, On the Dependence of Critical Velocity on the Material Properties During Cold Spray Process, J. Therm. Spray Technol., 2020, 29, p 1863-1875. https://doi.org/10.1007/s11666-020-01105-7

F. Meng, S. Yue, and J. Song, Quantitative Prediction of Critical Velocity and Deposition Efficiency in Cold-Spray: A Finite-Element Study, Scr. Mater., 2015, 107, p 83-87. https://doi.org/10.1016/j.scriptamat.2015.05.026

F. Meng, H. Aydin, S. Yue, and J. Song, The Effects of Contact Conditions on the Onset of Shear Instability in Cold-Spray, J. Therm. Spray Technol., 2015, 24, p 711-719. https://doi.org/10.1007/s11666-015-0229-z

C.-J. Li, W.-Y. Li, and H. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 15, p 212-222. https://doi.org/10.1361/105996306X108093

W.-Y. Li and W. Gao, Some Aspects on 3D Numerical Modeling of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, Appl. Surf. Sci., 2009, 255, p 7878-7892. https://doi.org/10.1016/J.APSUSC.2009.04.135

W.-Y. Li, H. Liao, C.-J. Li, G. Li, C. Coddet, and X. Wang, On High Velocity Impact of Micro-Sized Metallic Particles in Cold Spraying, Appl. Surf. Sci., 2006, 253, p 2852. https://doi.org/10.1016/j.apsusc.2006.05.126

M.A. Adaan-Nyiak and A.A. Tiamiyu, Recent Advances on Bonding Mechanism in Cold Spray Process: A Review of Single-Particle Impact Methods, J. Mater. Res., 2023, 38, p 69-95. https://doi.org/10.1557/s43578-022-00764-2

W.-Y. Li, S. Yin, and X.-F. Wang, Numerical Investigations of the Effect of Oblique Impact on Particle Deformation in Cold Spraying by the SPH Method, Appl. Surf. Sci., 2010, 256, p 3725-3734. https://doi.org/10.1016/j.apsusc.2010.01.014

M. Yu, W.-Y. Li, F.F. Wang, and H.L. Liao, Finite Element Simulation of Impacting Behavior of Particles in Cold Spraying by Eulerian Approach, J. Therm. Spray Technol., 2012, 21, p 745-752. https://doi.org/10.1007/s11666-011-9717-y

B. Yildirim, S. Muftu, and A. Gouldstone, Modeling of high velocity impact of spherical particles, Wear, 2011, 270, p 703-713. https://doi.org/10.1016/j.wear.2011.02.003

S. Lepi, Practical Guide to Finite Elements: A Solid Mechanics Approach, Taylor & Francis, Oxford, 1998.

R. Hedayati and M. Sadighi, Bird Strike: An Experimental Theoretical and Numerical Investigation, Elsevier, Amsterdam, 2015.

K.H. Huebner, D.L. Dewhirst, D.E. Smith, and T.G. Byrom, The Finite Element Method for Engineers, Wiley, New York, 2001.

P. Wriggers, Nonlinear Finite Element Methods, Springer, Berlin Heidelberg, 2008.

L.M. Pereira, A. Zúñiga, B. Jodoin, R.G.A. Veiga, and S. Rahmati, Unraveling Jetting Mechanisms in High-Velocity Impact of Copper Particles Using Molecular Dynamics Simulations, Addit. Manuf., 2023, 75, p 103755. https://doi.org/10.1016/j.addma.2023.103755

F. Dunne and N. Petrinic, Introduction to Computational Plasticity, OUP Oxford, Oxford, 2005.

E.A. de Souza Neto, D. Peric, and D.R.J. Owen, Computational Methods for Plasticity: Theory and Applications, Wiley, New York, 2011.

A. Khoei, Computational Plasticity in Powder Forming Processes, Elsevier, Amsterdam, 2010.

Q.H. Shah and H. Abid, LS-DYNA for Beginners: An Insight Into Ls-Prepost and Ls-Dyna, LAP Lambert Academic Publishing, Saarbrucken, 2012.

L.M. Kachanov, Fundamentals of the Theory of Plasticity, Dover Publications, Mineola, 2013.

M. Okereke and S. Keates, Finite Element Applications: A Practical Guide to the FEM Process, Springer, Cham, 2018.

C.Y. Gao, FE Realization of a Thermo-Visco-Plastic Constitutive Model Using VUMAT in ABAQUS/Explicit Program. Computational Mechanics: Proceedings of International Symposium on Computational Mechanics (Springer, Berlin, Heidelberg, 2009), p. 301

L. Ming and O. Pantalé, An Efficient and Robust VUMAT Implementation of Elastoplastic Constitutive Laws in Abaqus/Explicit Finite Element Code, Mech. Ind., 2018, 19, p 308. https://doi.org/10.1051/meca/2018021

G.N. Devi, S. Kumar, T.B. Mangalarapu, G. Vinay, N.M. Chavan, and A.V. Gopal, Assessing Critical Process Condition for Bonding in Cold Spraying, Surf. Coat. Technol., 2023, 470, p 129839. https://doi.org/10.1016/j.surfcoat.2023.129839

Z. Dai, F. Xu, J. Wang, and L. Wang, Investigation of Dynamic Contact Between Cold Spray Particles and Substrate Based on 2D SPH Method, Int. J. Solids Struct., 2023, 284, p 112520. https://doi.org/10.1016/j.ijsolstr.2023.112520

S. Rahmati, A. Zúñiga, B. Jodoin, and R.G.A. Veiga, Deformation of Copper Particles Upon Impact: A Molecular Dynamics Study of Cold Spray, Comput. Mater. Sci., 2020, 171, p 109219. https://doi.org/10.1016/j.commatsci.2019.109219

N. Deng, D. Qu, K. Zhang, G. Liu, S. Li, and Z. Zhou, Simulation and Experimental Study on Cold Sprayed WCu Composite with High Retainability of W Using Core-Shell Powder, Surf. Coat. Technol., 2023, 466, p 129639. https://doi.org/10.1016/j.surfcoat.2023.129639

P. Khamsepour, C. Moreau, and A. Dolatabadi, Effect of Particle and Substrate Pre-heating on the Oxide Layer and Material Jet Formation in Solid-State Spray Deposition: A Numerical Study, J. Therm. Spray Technol., 2023, 32, p 1153-1166. https://doi.org/10.1007/s11666-022-01509-7

S. Rahmati and B. Jodoin, Physically Based Finite Element Modeling Method to Predict Metallic Bonding in Cold Spray, J. Therm. Spray Technol., 2020, 29, p 611-629. https://doi.org/10.1007/s11666-020-01000-1

S. Rahmati, R.G.A. Veiga, A. Zúñiga, and B. Jodoin, A Numerical Approach to Study the Oxide Layer Effect on Adhesion in Cold Spray, J. Therm. Spray Technol., 2021 https://doi.org/10.1007/s11666-021-01245-4

W.Y. Li, C. Zhang, C.-J. Li, and H. Liao, Modeling Aspects of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, ASM Int., 2009, 18, p 921-933.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Cuboid Model

Appendix A: Cuboid Model

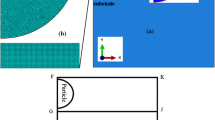

In the ABAQUS/Explicit software (Ref 14), a two-dimensional Lagrangian model employing four-node plane strain elements was employed to simulate the impact of a 50 µm copper cuboid onto a rigid wall (utilizing analytical rigid (Ref 14)). A mesh size of 1 µm was opted for to ensure accurate representation of the extensive deformation induced during high-velocity impacts. It's worth noting that various element sizes were evaluated, and 1 μm was selected for its promising results in this study. A schematic representation of the simulation setup is shown in Fig. 16. The impact velocity was set at 500 m/s, and the initial temperature was maintained at room temperature (300 K). Outputs were saved for each increment to capture the progressive behavior. For contact formulation, surface-to-surface contact was employed. The underside of the cuboid that collided with the substrate was defined as the slave surface (second surface), while the rigid wall surface was selected as the master surface (first surface) (Ref 14). The contact property was configured with a normal behavior (hard contact) using the default settings (Ref 14). Additionally, the material behavior was assumed to be linear elastic in this simulation The material properties utilized for this simulation are outlined in Table 1.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahmati, S., Mostaghimi, J., Coyle, T. et al. Jetting Phenomenon in Cold Spray: A Critical Review on Finite Element Simulations. J Therm Spray Tech (2024). https://doi.org/10.1007/s11666-024-01766-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11666-024-01766-8