Abstract

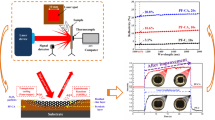

This study is about material and processes technologies for the realization of diffuse reflective screens supporting high temperatures. The use of high-energy lasers leads to material issues for high temperature diffuse reflective screen applications. Solutions exist for temperatures below 350 °C. In this context, other technological solutions need to be investigated to produce high temperature resistant screens. Diffuse reflectivity is studied for different alumina coatings obtained by thermal spraying. Plasma and flame processes and different powders (size, microstructure) are selected. The aim is to create various coating microstructures (pore size, porous architecture, nano area) and analyze the influence on diffuse reflectivity. Depending on thermal spray processes (APS, flame), spraying parameters and powder-based material (fine powder, nano-agglomerated, flexicord), diffuse reflective values range from 74 to 92%. Best results are obtained by combining the plasma spray process and a nano-agglomerated powder. However, a dense coating (porosity lower than 2%) or a too porous one (especially with connected pore columns) are less efficient. To obtain a high diffuse reflectivity, important parameters are a porosity of 7–9%, the presence of a nanostructured microstructure, a mean gray level with isotropic or laser lighting as high as possible to preserve powder white color.

Similar content being viewed by others

References

C. Chevalier, N.A. Fleurot and J.M. Di Nicola, LIL and LMJ laser facility status, in Proceeding SPIE 5580, 26th International Congress on High-Speed Photography and Photonics (2005). https://doi.org/10.1117/12.569638

N. Fleurot, C. Chevalier and J.L. Bourgade, The Laser Mégajoule (LMJ) Project Dedicated to Inertial Confinement Melting: Development and Construction Status, Fusion Eng. Des., 2005, 74(1–4), p 147-154. https://doi.org/10.1016/j.fusengdes.2005.06.251

D.H. Sliney and W.A. Palmisano, The Evaluation of Laser Hazards, Am. Ind. Hyg. Assoc. J., 2007, 29(5), p 425-431. https://doi.org/10.1080/00028896809343029

A.W. Springsteen, Laser cavity material, Patent US4912720A (1988). https://patents.google.com/patent/US4912720A/en

A. Krajewski and P. Mazzinghi, Study of the Reflectivity of ceramic Materials for Laser-cavity Mirrors, J. Mater. Sci., 1994, 29, p 232-238. https://doi.org/10.1007/BF00356598

V. Debout, A. Vardelle, P. Abélard, P. Fauchais, E. Meillot, E. Bruneton, S. Schelz and N. Branland, Optical Properties of Yttria-Stabilized Zirconia Plasma-Sprayed Coatings, Thermal Spray 2006: Science, Innovation and Application, on CD-ROM, B. Marple, M. Hyland, Y.-C. Lau, R. Lima, and J. Voyer, Ed., May 15-18, 2006 (Seattle, WA), ASM International, 2006, 1480 p. https://doi.org/10.31399/asm.cp.itsc2006p0525

A. Ferriere, L. Lestrade and J.F. Robert, Optical Properties of Plasma-Sprayed ZrO2-Y2O3 at High Temperature for Solar Applications, J. Sol. Energy Eng., 2000, 122(1), p 9-13. https://doi.org/10.1115/1.556275

M. Kambara, A. Shinozawa, K. Aoshika, K. Eguchi and T. Yoshida, Development of Porous YSZ Coatings with Modified Thermal and Optical Properties by Plasma Spray Physical Vapor Deposition, J. Solid Mech. Mater. Eng., 2010, 4(2), p 94-106. https://doi.org/10.1299/jmmp.4.94

L. Wang, J.I. Eldridge and S.M. Guo, Thermal Radiation Properties of Plasma-Sprayed Gd2Zr2O7 Thermal Barrier Coatings, Scr. Mater., 2013, 69(9), p 674-677. https://doi.org/10.1016/j.scriptamat.2013.07.026

M. Tului, F. Arezzo and L. Pawlowski, Optical Properties of Plasma Sprayed ZnO+Al2O3 Coatings, Surf. Coat. Technol., 2004, 179(1), p 47-55. https://doi.org/10.1016/S0257-8972(03)00800-4

X. Liu, X. Lu, Y. Song, S. Xia, R. Ren, Y. Wang, D. Zhao and M. Wang, Plasma-Sprayed Graphene Nanosheets/ZnO/Al2O3 Coatings with Highly Efficient Microwave Absorption Properties, J. Therm. Spray Technol., 2021, 30, p 1524-1534. https://doi.org/10.1007/s11666-021-01223-w

Z. Yang, F. Luo, J. Xu, W. Zhou and D. Zhu, Dielectric and Microwave Absorption Properties of LaSrMnO3/Al2O3 Ceramic Coatings Fabricated by Atmospheric Plasma Spraying, J. Alloys Compd., 2016, 662, p 607-611. https://doi.org/10.1016/j.jallcom.2015.12.113

J. Zhu, L. Gao, Z. Ma, Y. Liu and F. Wang, Optical Property of La1−xSrxTiO3+δ Coatings Deposited by Plasma Spraying Technique, Appl. Surf. Sci., 2015, 356, p 935-940. https://doi.org/10.1016/j.apsusc.2015.08.183

J. Zhu, Z. Ma, L. Gao, Y. Liu and F. Wang, Influence of Microstructure on the Optical Property of Plasma-Sprayed Al, Cu, and Ag Coatings, Mater. Des., 2016, 111, p 192-197. https://doi.org/10.1016/j.matdes.2016.08.090

P. Fauchais, A. Vardelle and B. Dussoubs, Quo Vadis Thermal Spraying?, J. Therm. Spray Technol., 2001, 10, p 44-66. https://doi.org/10.1361/105996301770349510

R. McPherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramic Coatings, Surf. Coat. Technol., 1989, 39-40(1), p 173-181. https://doi.org/10.1016/0257-8972(89)90052-2

J.G. Odhiambo, W.G. Li, Y.T. Zhao and C.L. Li, Porosity and Its Significance in Plasma-Sprayed Coatings, Coatings, 2019, 9(7), p 460-479. https://doi.org/10.3390/coatings9070460

W. Tillmann, O. Khalil and I. Baumann, Influence of Spray Gun Parameters on Inflight Particle’s Characteristics, the Splat-Type Distribution, and Microstructure of Plasma-Sprayed YSZ Coatings, Surf. Coat. Technol., 2021, 406, p 126705. https://doi.org/10.1016/j.surfcoat.2020.126705

C.J. Li, J. Zou, H.B. Huo, J.T. Yao and G.J. Yang, Microstructure and Properties of Porous Abradable Alumina Coatings Flame-Sprayed with Semi-molten Particles, J. Therm. Spray Technol., 2016, 25, p 264-272. https://doi.org/10.1007/s11666-015-0287-2

K.A. Habib, J.J. Saura, C. Ferrer, M.S. Damra, E. Giménez and L. Cabedo, Comparison of Flame Sprayed Al2O3/TiO2 Coatings: Their Microstructure, Mechanical Properties and Tribology Behavior, Surf. Coat. Technol., 2006, 201(3-4), p 1436-1443. https://doi.org/10.1016/j.surfcoat.2006.02.011

F. Vargas, H. Ageorges, P. Fournier, P. Fauchais and M.E. López, Mechanical and Tribological Performance of Al2O3-TiO2 Coatings Elaborated by Flame and Plasma Spraying, Surf. Coat. Technol., 2010, 205(4), p 1132-1136. https://doi.org/10.1016/j.surfcoat.2010.07.061

J. Marthe, E. Meillot, G. Jeandel, F. Enguehard and J. Ilavsky, Enhancement of Scattering and Reflectance Properties of Plasma-Sprayed Alumina Coatings by Controlling the Porosity, Surf. Coat. Technol., 2013, 220, p 80-84. https://doi.org/10.1016/j.surfcoat.2012.05.048

A. Stuke, R. Carius, J.-L. Marqués, G. Mauer, M. Schulte, D. Sebold, R. Vaßen and D. Stöver, Optimizing of the Reflectivity of Air Plasma Sprayed Ceramic Thermal Barrier Coatings, Adv. Ceram. Coat. Interfaces II Ceram. Eng. Sci. Proc., 2009, 28(3), p 99-113. https://doi.org/10.1002/9780470339510.ch11

A. Stuke, H. Kassner, J.L. Marqués, R. Vassen, D. Stöver and R. Carius, Suspension and Air Plasma-Sprayed Ceramic Thermal Barrier Coatings with High Infrared Reflectance, Int. J. Appl. Ceram. Technol., 2012, 9(3), p 561-574. https://doi.org/10.1111/j.1744-7402.2011.02689.x

R. Vassen, H. Kassner, A. Stuke, D.E. Mack, M.O.D. Jarligo, and D. Stöver, Functionally Graded Thermal Barrier Coatings with Improved Reflectivity and High-Temperature Capability, Materials Science Forum, 631-632 (Trans Tech Publications, Ltd., 2009), p. 73-78. https://doi.org/10.4028/www.scientific.net/MSF.631-632.73

L. Del Campo, D. De Sousa Meneses, K. Wittmann-Ténèze, A. Bacciochini, A. Denoirjean and P. Echegut, Effect of Porosity on the Infrared Radiative Properties of Plasma-Sprayed Yttria-Stabilized Zirconia Ceramic Thermal Barrier Coatings, J. Phys. Chem. C, 2014, 118(25), p 13590-13597. https://doi.org/10.1021/jp5014362

F. Blanchard, B. Baloukas, M. Azzi, F. Ben Ettouil, J.E. Klemberg-Sapieha, C. Moreau and L. Martinu, A Comparative Study of the Optical and Microstructural Properties of Suspension and Atmospheric Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2022, 449, p 128949. https://doi.org/10.1016/j.surfcoat.2022.128949

K.S. Caruso, D.G. Drewry, D.E. King and J.S. Jones, Heat Treatment of Plasma-Sprayed Alumina: Evolution of Microstructure and Optical Properties, Adv. Ceram. Coat. Interfaces II Ceram. Eng. Sci. Proc., 2009, 28(3), p 175-192. https://doi.org/10.1002/9780470339510.ch18

G. He, W. Guo, D. He, J. Zhang, Z. Xing, Z. Lv, L. Jia and Y. Huang, Study of the Mechanical Properties and Thermal Control Performance of Plasma-Sprayed Alumina Coating on Aluminum Alloy Surface, Appl. Sci., 2023, 13(2), p 956. https://doi.org/10.3390/app13020956

D. Toru, A. Quet, D. De SousaMeneses, L. del Campo and P. Echegut, Influence of Microstructure and Composition on Optical Properties of Plasma Sprayed Al/Al2O3 Cermets, J. Phys. Chem. C, 2015, 119(10), p 5426-5433. https://doi.org/10.1021/jp5113137

P. Ctibor, L. Kraus, J. Tuominen, P. Vuoristo and P. Chraska, Improvement of Mechanical Properties of Alumina and Zirconia Plasma Sprayed Coatings Induced by Laser Post-Treatment, Ceram. Silik., 2007, 51(4), p 181-189.

J.T. Yao, J.Q. Ren, H.B. Huo, G.J. Yang, C.X. Li and C.J. Li, Deposition Behavior of Semi-Molten Spray Particles During Flame Spraying of Porous Metal Alloy, J. Therm. Spray Technol., 2014, 23, p 991-999. https://doi.org/10.1007/s11666-014-0119-9

P.P. Psyllaki, M. Jeandin and D.I. Pantelis, Microstructure and Wear Mechanisms of Thermal-Sprayed Alumina Coatings, Mater. Lett., 2001, 47(12), p 77-82. https://doi.org/10.1016/S0167-577X(00)00215-9

F.L. Toma, S. Scheitz, L.M. Berger, V. Sauchuk, M. Kusnezoff and S. Thiele, Comparative Study of the Electrical Properties and Characteristics of Thermally Sprayed Alumina and Spinel Coatings, J. Therm. Spray Technol., 2010, 20, p 195-204. https://doi.org/10.1007/s11666-010-9580-2

P. Junge, M. Greinacher, D. Kober, P. Stargardt and C. Rupprecht, Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina, Ceram. Coat., 2022, 12, p 847. https://doi.org/10.3390/coatings12121847

M.M. Bajgiran, M.R. Rad, A. McDonald and C. Moreau, Microstructure, Phase and Dielectric Strength of Thermally Sprayed Alumina Layers in Coating-Based Heating Systems, Int. J. Appl. Ceram. Technol., 2021, 18, p 1641-1656. https://doi.org/10.1111/ijac.13731

R.S. Lima and B.R. Marple, Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review, J. Therm. Spray Technol., 2007, 16, p 40-63. https://doi.org/10.1007/s11666-006-9010-7

P.P. Bandyopadhyay, D. Chicot, B. Venkateshwarlu, V. Racherla, X. Decoopman and J. Lesage, Mechanical Properties of Conventional and Nanostructured Plasma Sprayed Alumina Coatings, Mech. Des., 2012, 53, p 61-71. https://doi.org/10.1016/j.mechmat.2012.05.006

V.P. Singh, A. Sil and R. Jayaganthan, A Study on Sliding and Erosive Wear Behaviour of Atmospheric Plasma Sprayed Conventional and Nanostructured Alumina Coatings, Mater. Des., 2011, 32(2), p 584-591. https://doi.org/10.1016/j.matdes.2010.08.019

D. Zois, A. Lekatou, M. Vardavoulias, I. Panagiotopoulos and A. Vazdirvanidis, A Comparative Microstructural Investigation of Nanostructured and Conventional Al2O3 Coatings Deposited by Plasma Spraying, J. Therm. Spray Technol., 2008, 17, p 887-894. https://doi.org/10.1007/s11666-008-9268-z

R. Westergard, L.C. Erickson, N. Axén, H.M. Hawthorne and S. Hogmark, The Erosion and Abrasion Characteristics of Alumina Coatings Plasma Sprayed Under Different Spraying Conditions, Tribol. Int., 1998, 31(5), p 271-279. https://doi.org/10.1016/S0301-679X(98)00033-4

O. Sarikaya, Effect of Some Parameters on Microstructure and Hardness of Alumina Coatings Prepared by the Air Plasma Spraying Process, Surf. Coat. Technol., 2005, 190(2-3), p 388-393. https://doi.org/10.1016/j.surfcoat.2004.02.007

H. Aghajani, Z. Valefi and P. Zamani, Phase Composition, Microstructure, Mechanical Properties, and Wear Performance of Nanostructured Al2O3 and Al2O3-Y2O3 Coatings Deposited by Plasma Spraying, Appl. Surf. Sci., 2022, 585, p 152754. https://doi.org/10.1016/j.apsusc.2022.152754

P. Fauchais, J.V.R. Heberlein and M.I. Boulos, Thermal Spray Fundamentals, Springer, New York, 2021, p 6. https://doi.org/10.1007/978-0-387-68991-3

O. Rojas, R. Muñoz, J.D. Holguín, M.E. López, H. Ageorges and F. Vargas, Porosity Formation Phenomena in Glass Particles Atomised by Oxyacetylene Flame-Spraying: Effect of Feedstock Powders and Atomisation Conditions, Ceram. Int., 2023, 49(9), p 14512-14524. https://doi.org/10.1016/j.ceramint.2023.01.041

M.P. Planche, S. Costil, C. Verdy and C. Coddet, Different Spray Processes for Different Al2O3 Coating Properties, Appl. Phys. A, 2010, 99, p 665-671. https://doi.org/10.1007/s00339-010-5586-3

M. Hauer, M. Meyer, D. Billieres, C. Bricquet, F. Gerstgrasser, J. Kiilakoski, J. Lejay and K.M. Henkel, Use of Different Process Gases for Manufacturing Isolating Alumina Coatings by Flame Spraying with Cords, J. Therm. Spray Technol., 2021, 20, p 222-235. https://doi.org/10.1007/s11666-021-01160-8

R. McPherson, Formation of Metastable Phases in Flame- and Plasma-Prepared Alumina, J. Mater. Sci., 1973, 8, p 851-858. https://doi.org/10.1007/BF02397914

J.M. Guillemany, J. Nutting and M.J. Dougan, A Transmission Electron Microscopy Study of the Microstructures Present in Alumina Coatings Produced by Plasma Spraying, J. Therm. Spray Technol., 1997, 6, p 425-429. https://doi.org/10.1007/s11666-997-0025-5

C.C. Stahr, S. Saaro, L.M. Berger, J. Dubský, K. Neufuss and M. Herrmann, Dependence of the Stabilization of α-Alumina on the Spray Process, J. Therm. Spray Technol., 2007, 16, p 822-830. https://doi.org/10.1007/s11666-007-9107-7

G. Darut, H. Ageorges, A. Denoirjean, G. Montavon and P. Fauchais, Effect of the Structural Scale of Plasma-Sprayed Alumina Coatings on Their Friction Coefficients, J. Therm. Spray Technol., 2008, 17, p 788-795. https://doi.org/10.1007/s11666-008-9255-4

D. Godlinski, M. Kuntz and G. Grathwohl, Transparent Alumina with Submicrometer Grains by Float Packing and Sintering, J. Am. Ceram. Soc., 2002, 85(10), p 2449-2456. https://doi.org/10.1111/j.1151-2916.2002.tb00479.x

R. Apetz and M.P.B. van Bruggen, Transparent Alumina: A Light-Scattering Model, J. Am. Ceram. Soc., 2003, 86(3), p 480-486. https://doi.org/10.1111/j.1151-2916.2003.tb03325.x

B.N. Kim, K. Hiraga, K. Morita, H. Yoshida, T. Miyazaki and Y. Kagawa, Microstructure and Optical Properties of Transparent Alumina, Acta Mater., 2009, 57(5), p 1319-1326. https://doi.org/10.1016/j.actamat.2008.11.010

A. Krell, P. Blank, H. Ma, T. Hutzler, M.P.B. van Bruggen and R. Apetz, Transparent Sintered Corundum with High Hardness and Strength, J. Am. Ceram. Soc., 2004, 86(1), p 12-18. https://doi.org/10.1111/j.1151-2916.2003.tb03270.x

X. Mao, S. Wang, S. Shimai and J. Guo, Transparent Polycrystalline Alumina Ceramics with Orientated Optical Axes, J. Am. Ceram. Soc., 2008, 91(10), p 3431-3433. https://doi.org/10.1111/j.1551-2916.2008.02611.x

J. Marthe, Élaboration par spraying plasma d’un revêtement bicouche d’alumine réfléchissant et diffusant. Contribution à la compréhension des phénomènes interaction rayonnement/matière, Thesis, Université de Loraine, (2013), in French https://hal.univ-lorraine.fr/tel-01750539

X.T. Luo, S.-P. Li, G.C. Li, Y.C. Xie, H. Zhang, R.Z. Huang and C.J. Li, Cold Spray (CS) Deposition of a Durable Silver Coating with High Infrared Reflectivity for Radiation Energy Saving in the Polysilicon CVD Reactor, Surf. Coat. Technol., 2021, 409, p 126841. https://doi.org/10.1016/j.surfcoat.2021.126841

L. Gao, Z. Ma, F. Wang, and W. Li, Reflectivity and laser irradiation of plasma sprayed Al coating, in Proceedings Volume 9543, Third International Symposium on Laser Interaction with Matter; 95430N, 2015. https://doi.org/10.1117/12.2181605

G.M. Ingo, Origin of Darkening in 8 wt.% YttriaZirconia Plasma-Sprayed Thermal Barrier Coatings, J. Am. Ceram. Soc., 1991, 74(2), p 381-386. https://doi.org/10.1111/j.1151-2916.1991.tb06891.x

A. Hospach, G. Mauer, R. Vaßen and D. Stöver, Characteristics of Ceramic Coatings Made by Thin Film Low Pressure Plasma Spraying (LPPS-TF), J. Therm. Spray Technol., 2012, 21, p 435-440. https://doi.org/10.1007/s11666-012-9748-z

T.B. Zhuravleva and A.A. Kokhanovsky, Influence of Surface Roughness on the Reflective Properties of Snow, J. Quant. Spectrosc. Radiat. Transf., 2011, 112(8), p 1353-1368. https://doi.org/10.1016/j.jqsrt.2011.01.004

A.K.R. Choudhury, Principles of Colour and Appearance Measurement, Woodhead Publishing Limited, 2014. https://doi.org/10.1533/9780857099242.53

M. Yang, W. Xu, J. Li, Z. Zhou and Y. Lu, A Modified Version of BRDF Model Based on Kubelka–Munk Theory for Coating Materials, Optik, 2019, 193, p 162982. https://doi.org/10.1016/j.ijleo.2019.162982

A. Ikesue and Y.L. Aung, Anisotropic Alumina Ceramics with Isotropic Optical Properties, J. Adv. Ceram., 2023, 12(1), p 72-81. https://doi.org/10.26599/JAC.2023.9220667

Acknowledgments

ICB is supported by the EUR-EIPHI Graduate School (Grant No. 17-EURE-0002). This study was also supported by MBDA France.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Darut, G., Verdy, C., Pommies, M. et al. Development of Thermal Spray Alumina Coating for High Diffuse Reflectivity Application in Lambertian Screen. J Therm Spray Tech 32, 2778–2801 (2023). https://doi.org/10.1007/s11666-023-01660-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01660-9