Abstract

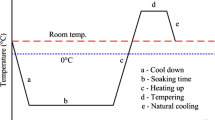

In this study, a novel attempt was made to deposit 86WC-10Co-4Cr cermet layer on 1.2709 tool steel substrate prepared by selective laser melting (SLM) process using detonation spraying method. The laser power of 350 W, scan speed of 25 mm/s, hatch spacing of 0.15 mm, and layer thickness of 50 µm were used to fabricate samples at 45° build orientation. The calculated volumetric energy density for fabricating the samples was 1867 J/mm3. The SLM printed samples were annealed and air cooled at 500 °C in a box furnace with a dwell time of 6 h. The average particle size of the powder measured before and after the ball milling process was 237.49 and 43.06 μm, respectively. A coating thickness of 100 μm was targeted using the detonation spraying process. An average spray loss of 13% was observed during cermet coating. The results were compared between the as-built specimen, the heat treated specimen and the 86WC-10Co-4Cr coated specimen. The average Vickers microhardness of the coated sample was found to be 81.04 and 48.96% superior to the as-built and heat treated samples. The average contact angles measured from the as-built, heat treated and coated samples were 82.5°, 64° and 93.9°, respectively, indicating the superior hydrophobic surface in the coated sample. The coated sample offered reduced abrasive wear, improved corrosion inhibition, and better 2D and 3D surface roughness properties than the as-built and heat treated samples, which promises its further use in cermet-based rapid tooling applications.

Similar content being viewed by others

Abbreviations

- SLM:

-

Selective laser melting

- WC:

-

Tungsten carbide

- Co:

-

Cobalt

- Cr:

-

Chromium

- VED:

-

Volumetric energy density

- HVOF:

-

High velocity oxygen fuel

- CAD:

-

Computer aided design

- STL:

-

Standard triangulation language

- SEM:

-

Scanning electron microscope

- XRD:

-

X-ray diffraction

- WCA:

-

Water contact angle

- FWHM:

-

Full width-half maximum

- EDS:

-

Energy-dispersive x-ray spectroscopy

- ASTM:

-

American Society for Testing and Materials

- ISO:

-

International Organization for Standardization

- Rp:

-

Maximum peak height of the roughness profile.

- Rv:

-

Maximum valley depth of the roughness profile.

- Rz:

-

Maximum height of roughness profile.

- Rc:

-

Mean height of the roughness profile elements.

- Rt:

-

Total height of roughness profile.

- Ra:

-

Arithmetic mean deviation of the roughness profile.

- Rq:

-

Root-mean-square (RMS) deviation of the roughness profile.

- Rsk:

-

Skewness of the roughness profile.

- Sq:

-

Root mean square height

- Ssk:

-

Skewness

- Sku:

-

Kurtosis

- Sp:

-

Maximum peak height

- Sv:

-

Maximum pit height

- Sz:

-

Maximum height

- Sa:

-

Arithmetic mean height

References

L. Kučerová, K. Burdová, Š Jeníček, and I. Chena, Effect of Solution Annealing and Precipitation Hardening at 250 °C-550 °C on Microstructure and Mechanical Properties of Additively Manufactured 1.2709 Maraging Steel, Mat. Sci. Eng. A, 2021, 814, p 141195.

K.A. Mumtaz, P. Erasenthiran, and N. Hopkinson, High Density Selective Laser Melting of Waspaloy®, J. Mater. Process. Technol., 2008, 195(1-3), p 77-87.

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, and S.L. Sing, Review of Selective Laser Melting: Materials and Applications, Appl. Phys. Rev., 2015, 2(4).

R. Casati, J. Lemke, C. Masneri, and M.V. Politecnico, Influence of Heat Treatment Condition on Properties of 1. 2709 Maraging Steel Fabricated by Selective Laser Melting, n.d., p 2709.

J. Piekło and A. Garbacz-Klempka, Use of Maraging Steel 1.2709 for Implementing Parts of Pressure Mold Devices with Conformal Cooling System, Materials, 2020, 13(23), p 1-22.

R. Wrobel and B. Mecrow, Review of AM for Electrical Machines, 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), IEEE, n.d., 1, p 15-22.

G. Yang, Y. Xie, S. Zhao, L. Qin, X. Wang, and B. Wu, Quality Control: Internal Defects Formation Mechanism of Selective Laser Melting Based on Laser-Powder-Melt Pool Interaction: A Review, Chin. J. Mech. Eng. Addit. Manuf. Front., 2022, 1(3), p 100037. https://doi.org/10.1016/j.cjmeam.2022.100037

M. Zhao, C. Duan, and X. Luo, Metallurgical Defect Behavior, Microstructure Evolution, and Underlying Thermal Mechanisms of Metallic Parts Fabricated by Selective Laser Melting Additive Manufacturing, J. Laser Appl. Laser Inst. Am., 2020, 32(2), p 022012.

M. Mashlan, F. Linderhof, M. Davidova, H. Kubickova, and E. Zemtsova, Changes of Phase Composition of Maraging Steel 1.2709 during Selective Laser Melting, Hyperfine Interact., 2019, 241(1), p 1-8.

S. Cooke, K. Ahmadi, S. Willerth, and R. Herring, Metal Additive Manufacturing: Technology, Metallurgy and Modelling, J. Manuf. Process., 2020, 57, p 978-1003. https://doi.org/10.1016/j.jmapro.2020.07.025

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, and S.S. Babu, The Metallurgy and Processing Science of Metal Additive Manufacturing, Int. Mater. Rev., 2016, 61(5), p 315-360.

B. Zhang, Y. Li, and Q. Bai, Defect Formation Mechanisms in Selective Laser Melting: A Review, Chin J Mech Eng, 2017, 30(3), p 515-527. (English Edition)

J. Li, J. Hu, L. Cao, S. Wang, H. Liu, and Q. Zhou, Multi-Objective Process Parameters Optimization of SLM Using the Ensemble of Metamodels, J. Manuf. Process., 2021, 68(PA), p 198-209. https://doi.org/10.1016/j.jmapro.2021.05.038

H. Ali, L. Ma, H. Ghadbeigi, and K. Mumtaz, In-Situ Residual Stress Reduction, Martensitic Decomposition and Mechanical Properties Enhancement through High Temperature Powder Bed Pre-Heating of Selective Laser Melted Ti6Al4V, Mater. Sci. Eng. A, 2017, 695, p 211-220.

D. Buchbinder, W. Meiners, N. Pirch, K. Wissenbach, and J. Schrage, Investigation on Reducing Distortion by Preheating during Manufacture of Aluminum Components Using Selective Laser Melting, J. Laser Appl., 2014, 26(1), p 012004.

C. Turk, H. Zunko, C. Aumayr, H. Leitner, and M. Kapp, Advances in Maraging Steels for Additive Manufacturing, BHM Berg- Huettenmaenn. Monatsh., 2019, 164(3), p 112-116.

Y. Kok, X.P. Tan, P. Wang, M.L.S. Nai, N.H. Loh, E. Liu, and S.B. Tor, Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review, Mater. Des., 2018, 139, p 565-586. https://doi.org/10.1016/j.matdes.2017.11.021

H. Huang, T. Zhang, C. Chen, S.R.E. Hosseini, J. Zhang, and K. Zhou, Anisotropy in the Tensile Properties of a Selective Laser Melted Ti-5Al-5Mo-5V-1Cr-1Fe Alloy during Aging Treatment, Materials, 2022, 15(16), p 5493.

P. Kumaravelu, S. Arulvel, and J. Kandasamy, Surface Coatings and Surface Modification Techniques for Additive Manufacturing BT—Innovations in Additive Manufacturing, M.A. Khan and J.T.W. Jappes, Eds., Springer International Publishing, Cham, 2022, p 221-238. https://doi.org/10.1007/978-3-030-89401-6_10

G.S. Sharma, M. Sugavaneswaran, U. Vijayalakshmi, and R. Prakash, Influence of γ-Alumina Coating on Surface Properties of Direct Metal Laser Sintered 316L Stainless Steel, Ceram. Int., 2019, 45(10), p 13456-13463. https://doi.org/10.1016/j.ceramint.2019.04.046

A. Madhan Kumar and N. Rajendran, Influence of Zirconia Nanoparticles on the Surface and Electrochemical Behaviour of Polypyrrole Nanocomposite Coated 316L SS in Simulated Body Fluid, Surf. Coat. Technol., 2012, 213, p 155-166. https://doi.org/10.1016/j.surfcoat.2012.10.039

H. Frank, M. Ambos, S. Lutze, and M. Scholz, Improvement of the Properties of Additively Manufactured Steel Parts by Combination of Heat Treatment and Hard Coatings, IOP Conf. Ser. Mater. Sci. Eng., 2021, 1147(1), p 012001.

J. Kübarsepp and K. Juhani, Cermets with Fe-Alloy Binder: A Review, Int. J. Refract. Met. Hard Mater., 2020, 92, p 105290. https://doi.org/10.1016/j.ijrmhm.2020.105290

K. Torkashvand, S. Joshi, and M. Gupta, Advances in Thermally Sprayed WC-Based Wear-Resistant Coatings: Co-Free Binders, Process Routes and Tribological Behavior, J. Therm. Spray Technol., 2022, 31(3), p 342-377. https://doi.org/10.1007/s11666-022-01358-4

G. Bolelli, L.M. Berger, T. Börner, H. Koivuluoto, L. Lusvarghi, C. Lyphout, N. Markocsan, V. Matikainen, P. Nylén, P. Sassatelli, R. Trache, and P. Vuoristo, Tribology of HVOF- and HVAF-Sprayed WC-10Co4Cr Hardmetal Coatings: A Comparative Assessment, Surf. Coat. Technol., 2015, 265, p 125-144. https://doi.org/10.1016/j.surfcoat.2015.01.048

R. Ahmed, O. Ali, C.C. Berndt, and A. Fardan, Sliding Wear of Conventional and Suspension Sprayed Nanocomposite WC-Co Coatings: An Invited Review, J. Therm. Spray Technol., 2021, 30(4), p 800-861. https://doi.org/10.1007/s11666-021-01185-z

B. Zhang, L. Zhu, H. Liao, and C. Coddet, Improvement of Surface Properties of SLM Parts by Atmospheric Plasma Spraying Coating, Appl. Surf. Sci., 2012, 263, p 777-782.

M. Frankiewicz, E. Chlebus, and K. Kobiela, APS Sprayed Coatings onto the Selective Laser Melted Substrates, Przegląd Spawalnictwa Weld. Technol. Rev., 2012, 84(9), p 27-30.

W. Tillmann, L. Hagen, C. Schaak, J. Liß, M. Schaper, K.P. Hoyer, M.E. Aydinöz, and K.U. Garthe, Adhesion of HVOF-Sprayed WC-Co Coatings on 316L Substrates Processed by SLM, J. Therm. Spray Technol., 2020, 29(6), p 1396-1409.

P. Suresh Babu, P. Chanikya Rao, A. Jyothirmayi, P. Sudharshan Phani, L. Rama Krishna, and D. Srinivasa Rao, Evaluation of Microstructure, Property and Performance of Detonation Sprayed WC-(W, Cr)2C-Ni Coatings, Surf. Coat. Technol., 2018, 335, p 345-354. https://doi.org/10.1016/j.surfcoat.2017.12.055

K. Monkova, I. Zetkova, L. Kučerová, M. Zetek, P. Monka, and M. Daňa, Study of 3D Printing Direction and Effects of Heat Treatment on Mechanical Properties of MS1 Maraging Steel, Arch. Appl. Mech., 2019, 89(5), p 791-804.

U. Scipioni Bertoli, A.J. Wolfer, M.J. Matthews, J.P.R. Delplanque, and J.M. Schoenung, On the Limitations of Volumetric Energy Density as a Design Parameter for Selective Laser Melting, Mater. Des., 2017, 113, p 331-340. https://doi.org/10.1016/j.matdes.2016.10.037

P. Ferro, R. Meneghello, G. Savio, and F. Berto, A Modified Volumetric Energy Density-Based Approach for Porosity Assessment in Additive Manufacturing Process Design, Int. J. Adv. Manuf. Technol., 2020, 110(7-8), p 1911-1921.

L. Kučerová, K. Burdová, Š Jeníček, and J. Volkmannová, Microstructure and Mechanical Properties of 3D Printed Tool Steel after Various Precipitation Hardening Treatments, Manufacturing Technology, 2022, 22(2), p 185-191.

S.B. Pitchuka, B. Basu, and G. Sundararajan, A Comparison of Mechanical and Tribological Behavior of Nanostructured and Conventional Wc-12co Detonation-Sprayed Coatings, J. Therm. Spray Technol., 2013, 22(4), p 478-490.

H. Saini, D. Kumar, and V.N. Shukla, Hot Corrosion Behaviour of Nanostructured Cermet Based Coatings Deposited by Different Thermal Spray Techniques: A Review, Mater. Today Proc., 2017, 4(2), p 541-545. https://doi.org/10.1016/j.matpr.2017.01.055

S. Rao and M. Palle, Effect of D-Gun Sprayed Ceramic Coatings on Aluminum Material to Review Hardness and Corrosion Properties Effect of D-Gun Sprayed Ceramic Coatings on Aluminum Material to Review Hardness and Corrosion Properties. Int. J. Curr. Eng. Technol. 2017, p 0-4.

Author information

Authors and Affiliations

Contributions

N.S: Conceptualization, Methodology, Investigation, Writing–Original Draft, Writing—Revised Draft. G.A: Resources, Validation, Formal analysis, Supervision, Project administration.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sathishkumar, N., Arumaikkannu, G. Detonation Spraying of a Cermet Coating to Improve the Surface Properties of Tool Steel Parts Produced by the Selective Laser Melting Process. J Therm Spray Tech 32, 2439–2459 (2023). https://doi.org/10.1007/s11666-023-01651-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01651-w