Abstract

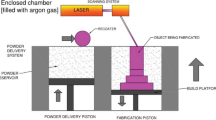

In situ TiC-NiCr cermet was manufactured through the selective laser melting (SLM) of an elemental powder mixture prepared using high energy milling for 15 hours. Effects of the applied laser energy densities (138.7, 218.9, 346.7, 378.2 and 416 J.mm-3) on the microstructure, densification, hardness and wear properties of the samples were investigated. Microstructural evaluation of the SLM processed samples using scanning electron microscopy showed that energy densities of lower than 346.7 J.mm-3 result in a relatively non-uniform distribution of TiC and more defects in the cermets. It was also found that by increasing the energy density to 416 J.mm-3; densification is affected due to increased defects. Vickers microhardness test was used for hardness measurement, which showed the highest average hardness value of 1369.5 HV1 at a laser energy density of 378.2 J.mm-3. However, hardness decreased at energy densities of higher than 378.2 J.mm-3. Pin-on-disk dry sliding wear tests were conducted at room (for SLM processed samples) and elevated temperatures (for the specimen manufactured at 378.2 J.mm-3 energy density). The results showed that increasing the input energy density causes a slight improvement in wear resistance at room temperature. At elevated temperatures, the wear rate showed fluctuations, and the lowest wear rate and friction coefficient were achieved at 600 °C.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings are available and will be provided on demand.

References

Z. Guo, J. Xiong, M. Yang and C. Jiang, WC-TiC-Ni Cemented Carbide with Enhanced Properties, J. Alloys Compd., 2008, 465, p 157–162. https://doi.org/10.1016/j.jallcom.2007.10.132

M. Gaier, T.Z. Todorova, Z. Russell, Z.N. Farhat, J.W. Zwanziger and K.P. Plucknett, The Influence of Intermetallic Ordering on Wear and Indentation Properties of TiC-Ni 3 Al Cermets, Wear, 2019, 426–427, p 390–400. https://doi.org/10.1016/j.wear.2018.12.034

H. Reshetnyak and J. Kuybarsepp, Mechanical Properties of Hard Metals and Their Erosive Wear Resistance, Wear, 1994, 177, p 185–193. https://doi.org/10.1016/0043-1648(94)90244-5

I. Hussainova, Effect of Microstructure on the Erosive Wear of Titanium Carbide-Based Cermets, Wear, 2003, 255, p 121–128. https://doi.org/10.1016/S0043-1648(03)00198-4

F. Akhtar and S.J. Guo, Microstructure, Mechanical and Fretting Wear Properties of TiC-Stainless Steel Composites, Mater. Charact., 2008, 59, p 84–90. https://doi.org/10.1016/j.matchar.2006.10.021

S. Singh, D. Gupta and S. Kaushal, Dry Sliding Wear Performance of Ni–Sic Composites Developed Through an In Situ Microwave Casting Process, J. Tribol., 2020 https://doi.org/10.1115/1.4047032

S. Singh, D. Gupta and V. Jain, Novel Microwave Composite Casting Process: Theory, Feasibility And Characterization, Mater. Des., 2016, 111, p 51–59. https://doi.org/10.1016/j.matdes.2016.08.071

S. Singh, D. Gupta and V. Jain, Microwave Melting and Processing of Metal–Ceramic Composite Castings, Proc. Inst Mech. Eng. Part B J. Eng. Manuf., 2018, 232, p 1235–1243. https://doi.org/10.1177/0954405416666900

A. Aramian, N. Razavi, Z. Sadeghian and F. Berto, A Review of Additive Manufacturing of Cermets, Addit. Manuf., 2020, 33, 101130. https://doi.org/10.1016/j.addma.2020.101130

T. Lin, Y. Guo, Z. Wang, H. Shao, H. Lu, F. Li and X. He, Effects of Chromium and Carbon Content on Microstructure and Properties of TiC-Steel Composites, Int. J. Refract. Met. Hard Mater., 2018, 72, p 228–235. https://doi.org/10.1016/j.ijrmhm.2017.12.037

Y.X. Li, J.D. Hu, Y.H. Liu, Y. Yang and Z.X. Guo, Effect of C/Ti Ratio on the Laser Ignited Self-Propagating High-Temperature Synthesis Reaction of Al-Ti-C System for Fabricating TiC/Al Composites, Mater. Lett., 2007, 61, p 4366–4369. https://doi.org/10.1016/j.matlet.2007.02.004

B. AlMangour, D. Grzesiak and J.M. Yang, In situ Formation of TiC-Particle-Reinforced Stainless Steel Matrix Nanocomposites During Ball Milling: Feedstock Powder Preparation for Selective Laser Melting at Various Energy Densities, Powder Technol., 2018, 326, p 467–478. https://doi.org/10.1016/j.powtec.2017.11.064

A. Fukuda, M. Takemoto, T. Saito, S. Fujibayashi, M. Neo, D.K. Pattanayak, T. Matsushita, K. Sasaki, N. Nishida, T. Kokubo and T. Nakamura, Osteoinduction of porous Ti implants with a channel structure fabricated by selective laser melting, Acta Biomater., 2011, 7, p 2327–2336. https://doi.org/10.1016/j.actbio.2011.01.037

X. Zhang, Z. Guo, C. Chen and W. Yang, Additive Manufacturing of WC-20Co Components by 3D Gel-Printing, Int. J. Refract. Met. Hard Mater., 2018, 70, p 215–223. https://doi.org/10.1016/j.ijrmhm.2017.10.005

D. Gu and W. Meiners, Microstructure Characteristics and Formation Mechanisms of in Situ WC Cemented Carbide Based Hardmetals Prepared by Selective Laser Melting, Mater. Sci. Eng. A., 2010, 527, p 7585–7592. https://doi.org/10.1016/j.msea.2010.08.075

A. Davydova, A. Domashenkov, A. Sova, I. Movtchan, P. Bertrand, B. Desplanques, N. Peillon, S. Saunier, C. Desrayaud, S. Bucher and C. Iacob, Selective Laser Melting Of Boron Carbide Particles Coated by a Cobalt-Based Metal Layer, J. Mater. Process. Technol., 2016, 229, p 361–366. https://doi.org/10.1016/j.jmatprotec.2015.09.033

D. Gu, W. Meiners, Y.C. Hagedorn, K. Wissenbach and R. Poprawe, Bulk-form TiCx/Ti Nanocomposites with Controlled Nanostructure Prepared by a New Method: Selective Laser Melting, J. Phys. D. Appl. Phys., 2010 https://doi.org/10.1088/0022-3727/43/29/295402

S. Uchida, T. Kimura, T. Nakamoto, T. Ozaki, T. Miki, M. Takemura, Y. Oka and R. Tsubota, Microstructures and Electrical and Mechanical Properties of Cu-Cr Alloys Fabricated by Selective Laser Melting, Mater. Des., 2019, 175, 107815. https://doi.org/10.1016/j.matdes.2019.107815

T.N. Le and Y.L. Lo, Effects of Sulfur Concentration and Marangoni Convection on Melt-Pool Formation in Transition Mode Of Selective Laser Melting Process, Mater. Des., 2019, 179, 107866. https://doi.org/10.1016/j.matdes.2019.107866

N. Yang, Y. Tian and D. Zhang, Novel Real Function Based Method to Construct Heterogeneous Porous Scaffolds and Additive Manufacturing for use in Medical Engineering, Med. Eng. Phys., 2015, 37, p 1037–1046. https://doi.org/10.1016/j.medengphy.2015.08.006

M. Taheri Andani, C. Haberland, J.M. Walker, M. Karamooz, A. Sadi Turabi, S. Saedi, R. Rahmanian, H. Karaca, D. Dean, M. Kadkhodaei and M. Elahinia, Achieving Biocompatible Stiffness in NiTi Through Additive Manufacturing, J. Intell. Mater. Syst. Struct., 2016, 27, p 2661–2671. https://doi.org/10.1177/1045389X16641199

J.J.S. Dilip, S. Zhang, C. Teng, K. Zeng, C. Robinson, D. Pal and B. Stucker, Influence of Processing Parameters on the Evolution of Melt Pool, Porosity, and Microstructures in Ti-6Al-4V Alloy Parts Fabricated by Selective Laser Melting, Prog. Addit. Manuf., 2017, 2, p 157–167. https://doi.org/10.1007/s40964-017-0030-2

M.A. Matin, L. Lu and M. Gupta, Investigation of the Reactions Between Boron and Titanium Compounds with Magnesium, Scr. Mater., 2001, 45, p 479–486. https://doi.org/10.1016/S1359-6462(01)01059-4

H.Y. Wang, Q.C. Jiang, X.L. Li and J.G. Wang, In Situ Synthesis of TiC/Mg Composites in Molten Magnesium, Scr. Mater., 2003, 48, p 1349–1354. https://doi.org/10.1016/S1359-6462(03)00014-9

S.C. Tjong, Novel Nanoparticle-Reinforced Metal Matrix Composites with Enhanced Mechanical Properties, Adv. Eng. Mater., 2007, 9, p 639–652. https://doi.org/10.1002/adem.200700106

M. Krasnowski and T. Kulik, Nanocrystalline FeAl-TiN Composites Obtained by Hot-Pressing Consolidation of Reactively Milled Powders, Scr. Mater., 2007, 57, p 553–556. https://doi.org/10.1016/j.scriptamat.2007.04.031

C. Han, C. Den, D. Zhao and K. Hu, Milling Performance of TiC-Ni Cermet Tools Toughened by TiN Nanoparticles, Int. J. Refract. Met. Hard Mater., 2012 https://doi.org/10.1016/j.ijrmhm.2011.06.005

G. Bolelli, A. Colella, L. Lusvarghi, S. Morelli, P. Puddu, E. Righetti, P. Sassatelli and V. Testa, TiC–NiCr Thermal Spray Coatings as An Alternative to WC-CoCr and Cr3C2–NiCr, Wear, 2020, 450, p 203273.

T.L. Stewart and K.P. Plucknett, The Sliding Wear of TiC and Ti(C, N) Cermets Prepared with a Stoichiometric Ni3Al Binder, Wear, 2014, 318, p 153–167. https://doi.org/10.1016/j.wear.2014.06.025

S. Buchholz, Z.N. Farhat, G.J. Kipouros and K.P. Plucknett, The Reciprocating Wear Behaviour of TiC-Ni3Al Cermets, Int. J. Refract. Met. Hard Mater., 2012, 33, p 44–52. https://doi.org/10.1016/j.ijrmhm.2012.02.008

J. Meng, J. Lu, J. Wang and S. Yang, Tribological Behavior of TiCN-Based Cermets at Elevated Temperatures, Mater. Sci. Eng., A, 2006, 418, p 68–76.

I. Hussainova, J. Pirso, M. Antonov and K. Juhani, High Temperature Erosion of Ti(Mo)C–Ni Cermets, Wear, 2009, 267, p 1894–1899.

M. Antonov, I. Hussainova, R. Veinthal and J. Pirso, Effect of Temperature and Load on Three-Body Abrasion of Cermets and Steel, Tribol. Int., 2012, 46, p 261–268.

M. Antonov, I. Hussainova, J. Kubarsepp and R. Traksmaa, Oxidation-Abrasion of TiC-Based Cermets in SiC Medium, Wear, 2011, 273, p 23–31.

M. Antonov, I. Hussainova, J. Pirso and O. Volobujeva, Assessment of Mechanically Mixed Layer Developing During High Temperature Erosion of Cermets, Wear, 2007, 263, p 878–886.

F.H. Stott, The Role of Oxidation in the Wear of Alloys, Tribol. Int., 1998, 31, p 61–71.

J. Jiang, F.H. Stott and M.M. Stack, The Role of Triboparticulates in Dry Sliding Wear, Tribol. Int., 1998, 31, p 245–256.

D. Gu, Y.C. Hagedorn, W. Meiners, K. Wissenbach and R. Poprawe, Nanocrystalline TiC Reinforced Ti Matrix Bulk-Form Nanocomposites by Selective Laser Melting (SLM): Densification, Growth Mechanism and Wear Behavior, Compos. Sci. Technol., 2011, 71, p 1612–1620. https://doi.org/10.1016/j.compscitech.2011.07.010

R. Bidulský, J. Bidulská, F. Arenas and M.A. Grande, Wear Characteristics of Sintered Cermets, High Temp. Mater. Process., 2012, 31, p 13–17. https://doi.org/10.1515/htmp.2011.123

S.S. Babu, S.M. Kelly, M. Murugananth and R.P. Martukanitz, Reactive Gas Shielding During Laser Surface Alloying for Production of Hard Coatings, Surf. Coatings Technol., 2006, 200, p 2663–2671. https://doi.org/10.1016/j.surfcoat.2005.02.160

A. Aramian, Z. Sadeghian, N. Razavi, K.G. Prashanth and F. Berto, Effect of selective laser melting process parameters on microstructural and mechanical properties of TiC-NiCr Cermet, Ceram. Int. 46(18) A, p 28749–28757. https://doi.org/10.1016/j.ceramint.2020.08.037

A. Aramian, Z. Sadeghian, K.G. Prashanth and F. Berto, In Situ Fabrication of TiC-NiCr Cermets by Selective Laser Melting, Int. J. Refract. Met. Hard Mater., 2020, 87, 105171. https://doi.org/10.1016/j.ijrmhm.2019.105171

H. Wang, X. Yan, H. Zhang, M. Gee, C. Zhao, X. Liu and X. Song, Oxidation-Dominated Wear Behaviors of Carbide-Based Cermets: A Comparison Between WC-WB-Co and Cr3C2-NiCr Coatings, Ceram. Int., 2019, 45, p 21293–21307. https://doi.org/10.1016/j.ceramint.2019.07.113

D. Dai and D. Gu, Tailoring Surface Quality Through Mass and Momentum Transfer Modeling Using a Volume of Fluid Method in Selective Laser Melting of TiC/AlSi10Mg Powder, Int. J. Mach. Tools Manuf., 2015, 88, p 95–107. https://doi.org/10.1016/j.ijmachtools.2014.09.010

C.C. Jiang, T. Goto and T. Hirai, Microhardness of Nonstoichiometric TiCx, Plates Prepared by Chemical Vapour Deposition, J Less-Common Metals, 1990, 163(2), p 339–346. https://doi.org/10.1016/0022-5088(90)90600-0

V.N. Lipatnikov, A.A. Rempel and A.I. Gusev, Atomic Ordering and Hardness of Nonstoichiometric Titanium Carbide, Int. J. Refract Metal Hard Mater., 1997, 15(1–3), p 61–64. https://doi.org/10.1016/S0263-4368(96)00020-0

Y. Liu, B.H. Yu, D.H. Guan, Z.B. Wang and J. Bi, Microstructure and Properties of TiC/NiCr cermets Produced by Partial Liquid-Phase Sintering, J. Mater. Sci. Lett., 2001, 20, p 619–620. https://doi.org/10.1023/A:1010965216385

K. Bonny, P. De Baets, J. Vleugels, S. Huang, O. Van der Biest and B. Lauwers, Impact of Cr3C2/VC Addition on the Dry Sliding Friction and Wear Response of WC-Co Cemented Carbides, Wear, 2009, 267, p 1642–1652. https://doi.org/10.1016/j.wear.2009.06.013

M.Z. Huq and J.P. Celis, Reproducibility of Friction and Wear Results in Ball-On-Disc Unidirectional Sliding Tests of TiN-Alumina Pairings, Wear, 1997 https://doi.org/10.1016/S0043-1648(97)00167-1

N.P. Suh, The Delamination Theory of Wear, Wear, 1973 https://doi.org/10.1016/0043-1648(73)90125-7

J. Pirso, M. Viljus, K. Juhani and M. Kuningas, Three-Body Abrasive Wear of TiC-NiMo Cermets, Tribol. Int., 2010, 43, p 340–346. https://doi.org/10.1016/j.triboint.2009.06.014

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi, A. Milanti, K. Niemi and P. Vuoristo, Micromechanical Properties and Sliding Wear Behaviour of HVOF-Sprayed Fe-based alloy Coatings, Wear, 2012, 276–277, p 29–47. https://doi.org/10.1016/j.wear.2011.12.001

B.V. Padmini, M. Mathapati, H.B. Niranjan, P. Sampathkumaran, S. Seetharamu, M.R. Ramesh and N. Mohan, High Temperature Tribological Studies of Cold Sprayed Nickel Based Alloy on Low Carbon Steels, Mater. Today Proc., 2019 https://doi.org/10.1016/j.matpr.2019.09.025

G. Bolelli, L.M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, C. Lyphout, N. Markocsan, P. Nylén, P. Sassatelli, R. Trache and P. Vuoristo, Sliding and Abrasive Wear Behaviour of HVOF- and HVAF-Sprayed Cr3C2–NiCr Hardmetal Coatings, Wear, 2016, 358–359, p 32–50.

B. Basu, M. Kalin, Tribology of Ceramics and Composites: A Materials Science Perspective, John Wiley & Sons, Oct. 2011, 1st ed. ISBN: 978-0-470-52263-9.

M. Roy, A. Pauschitz, J. Wernisch and F. Franek, The Influence of Temperature on the Wear of Cr3C2-25(Ni20Cr) Coating - Comparison Between Nanocrystalline Grains and Conventional Grains, Wear, 2004, 257, p 799–811. https://doi.org/10.1016/j.wear.2004.05.001

B.V. Manoj Kumar, B. Basu, J. Vizintin and M. Kalina, Tribochemistry in Sliding Wear of TiCN–Ni-Based Cermets, J. Mater. Res., 2008, 23(5), p 1214–1227. https://doi.org/10.1557/JMR.2008.0165

Acknowledgment

The present research was supported by Shahid Chamran University of Ahvaz under grant number GN26247.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aramian, A., Sadeghian, Z., Razavi, N. et al. Room and High-Temperature Sliding Wear Behavior of In Situ TiC-Based Cermet Fabricated through Selective Laser Melting. J. of Materi Eng and Perform 30, 6777–6787 (2021). https://doi.org/10.1007/s11665-021-05995-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05995-8