Abstract

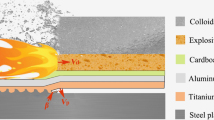

The aim of this study was to develop an efficient method for producing refractory metal coatings. To that end, tantalum coatings were deposited on Ti6Al4V substrates using a self-designed wire electrical explosion spraying technique. A uniform, dense coating was obtained for an energy density of 88.4 J/mm3 and a spraying distance of 5mm. The surface roughness of the tantalum coatings increased with the spraying distance as the latter affected the size distribution, velocity, and temperature of the explosive products, and so the flattening degree of splats. In addition, the microstructure of coating was also affected by the spraying distance. The adhesive strength of the tantalum coatings was 76 N at an energy density of 88.4 J/mm3 and spraying distance of 5 mm. The α-Ta phase and a metallurgy layer near the interface ensured that the adhesive strength of the tantalum coatings deposited by wire electrical explosion spraying was higher than those generated using other techniques.

Similar content being viewed by others

References

A. Maho, S. Linden, C. Arnould, S. Detriche, J. Delhalle, and Z. Mekhalif, Tantalum Oxide/Carbon Nanotubes Composite Coatings on Titanium and Their Functionalization with Organophosphonic Molecular Films: A High Quality Scaffold for Hydroxyapatite Growth, J. Colloid Interface Sci., 2012, 371, p 150-158.

J.F. Blanco, F.M. Sanchez-Guijo, S. Carrancio, S. Muntion, J. Garcia-Brinon, and M.C. del Canizo, Titanium and Tantalum as Mesenchymal Stem Cell Scaffolds for Spinal Fusion: An In Vitro Comparative Study, Eur. Spine J., 2011, 20, p 353-360.

X. Li, L. Wang, X. Yu, Y. Feng, C. Wang, K. Yang, and D. Su, Tantalum Coating on Porous Ti6Al4V Scaffold Using Chemical Vapor Deposition and Preliminary Biological Evaluation, Mater. Sci. Eng. C, 2013, 33, p 2987-2994.

L. Wu, Y. Dong, L. Yao, C. Liu, A.M. Al-Bishari, K.H.R. Yie, H. Zhang, J. Liu, and G. Wu, Nanoporous Tantalum Coated Zirconia Implant Improves Osseointegration, Ceram. Int., 2020, 46, p 17437-17448.

F. Wang, C. Li, S. Zhang, and H. Liu, Tantalum Coated on Titanium Dioxide Nanotubes by Plasma Spraying Enhances Cytocompatibility for Dental Implants, Surf. Coat. Technol., 2020, 382, p 125161.

T.-Y. Kuo, W.-H. Chin, C.-S. Chien, and Y.-H. Hsieh, Mechanical and Biological Properties of Graded Porous Tantalum Coatings Deposited on Titanium Alloy Implants by Vacuum Plasma Spraying, Surf. Coat. Technol., 2019, 372, p 399-409.

E. Vetrivendan, J. Jayaraj, S. Ningshen, C. Mallika, and U. Kamachi Mudali, Argon shrouded plasma spraying of tantalum over titanium for corrosion protection in fluorinated nitric acid media, J. Therm. Spray Technol., 2018, 27, p 512-523.

Q. Qin, F. Yang, T. Shi, Z. Guo, H. Sun, P. Li, X. Lu, C. Chen, J. Hao, and P. Cao, Spheroidization of tantalum powder by radio frequency inductively coupled plasma processing, Adv. Powder Technol., 2019, 30, p 1709-1714.

S. Dittrick, V.K. Balla, S. Bose, and A. Bandyopadhyay, Wear Performance of Laser Processed Tantalum Coatings, Mater. Sci. Eng. C, 2011, 31, p 1832-1835.

Q. Li, Q.-Z. Song, J.-Z. Wang, and Y.-X. Duo, Effect of Charging Energy on Droplet Diameters and Properties of High-Carbon Steel Coatings Sprayed By Wire Explosion Spraying, Surf. Coat. Technol., 2011, 206, p 202-207.

S.-X. Hou, Z.-D. Liu, and D.-Y. Liu, The Study of NiAl–TiB2 Coatings Prepared by Electro-Thermal Explosion Ultrahigh Speed Spraying Technology, Surf. Coat. Technol., 2011, 205, p 4562-4568.

A.I. Ryakhovskiy, V.I. Antonov, and N.V. Kalinin, The EOS Choice Effect on the Simulated Results Obtained for an Underwater Electrical Explosion of Conductors, St. Petersburg Polytech. Univ. J. Phys. Math., 2017, 3, p 192-198.

D. Romanov, S. Moskovskii, S. Konovalov, K. Sosnin, V. Gromov, and Y. Ivanov, Improvement of Copper Alloy Properties in Electro-Explosive Spraying of ZnO-Ag Coatings Resistant to Electrical Erosion, J. Mater. Res. Technol., 2019, 8, p 5515-5523.

X.-B. Zou, Z.-G. Mao, X.-X. Wang, and W.-H. Jiang, Nanopowder Production by Gas-Embedded Electrical Explosion of Wire, Chin. Phys. B, 2013, 22, p 045206.

S.L. Lee, D. Windover, M. Audino, D.W. Maston, and E.D. McClanahan, High-Rate Sputter Deposited Tantalum Coating on Steel for Wear and Erosion Mitigation, Surf. Coat. Technol., 2002, 149, p 62-69.

Y. Wan, W. Tang, J. Li, and D. Xiong, Comparison of Method and Performance in Tantalum Coating Prepared by Molten Salt Electroplating and Glow Infiltration, Surf. Coat. Technol., 2019, 375, p 315-322.

F. Han, L. Zhu, Z.-H. Liu, and L. Gong, The Study of Refractory Ta10W and Non-Refractory Ni60A Coatings Deposited by Wire Electrical Explosion Spraying, Surf. Coat. Technol., 2019, 374, p 44-51.

W. Li, C. Cao, and S. Yin, Solid-State Cold Spraying of Ti and Its Alloys: A Literature Review, Prog. Mater. Sci., 2020, 110, p 100633.

H. Assadi, H. Kreye, F. Gärtner, and T. Klassen, Cold Spraying – A Materials Perspective, Acta Mater., 2016, 116, p 382-407.

G. Hou, X. Zhao, Y. An, H. Zhou, and J. Chen, Effect of Spraying Parameter and Injector Angle on the Properties of In-Flight Particles and Alumina Coatings on Al Alloy with PA-HT, Ceram. Int., 2018, 44, p 3173-3182.

S. Goutier, M. Vardelle, and P. Fauchais, Comparison Between Metallic and Ceramic Splats: Influence of Viscosity and Kinetic Energy on the Particle Flattening, Surf. Coat. Technol., 2013, 235, p 657-668.

R. Smeets, B. Stadlinger, F. Schwarz, B. Beck-Broichsitter, O. Jung, C. Precht, F. Kloss, A. Grobe, M. Heiland, and T. Ebker, Impact of Dental Implant Surface Modifications on Osseointegration, Biomed Res. Int., 2016, 2016, p 6285620.

P.M. Brett, J. Harle, V. Salih, R. Mihoc, I. Olsen, F.H. Jones, and M. Tonetti, Roughness Response Genes in Osteoblasts, Bone, 2004, 35, p 124-133.

A.A. Tiamiyu, and C.A. Schuh, Particle Flattening During Cold Spray: Mechanistic Regimes Revealed by Single Particle Impact Tests, Surf. Coat. Technol., 2020, 403, 126386.

A.C. Hee, S.S. Jamali, A. Bendavid, P.J. Martin, and Y. Zhao, Corrosion Behavior and Adhesion Properties of Sputtered Tantalum Coating on Ti6Al4V Substrate, Surf. Coat. Technol., 2016, 307, p 666-675.

D. Bernoulli, A. Rico, A. Wyss, K. Thorwarth, J.P. Best, R. Hauert, and R. Spolenak, Improved Contact Damage Resistance of Hydrogenated Diamond-Like Carbon (DLC) with a Ductile α-Ta Interlayer, Diam. Relat. Mater., 2015, 58, p 78-83.

D.B. Wei, X.H. Chen, P.Z. Zhang, F. Ding, F.K. Li, and Z.J. Yao, Plasma Surface Tantalum Alloying on Titanium and Its Corrosion Behavior in Sulfuric Acid and Hydrochlotic Acid, Appl. Surf. Sci., 2018, 441, p 448-457.

Acknowledgments

The authors are grateful for the financial support from the National Natural Science Foundation of China (Grant No. 51765038) and the Open Fund for State Key Laboratory of Special Rare Metal Materials (Grant No. SKL2021K001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, H., Wang, X., He, C. et al. Tantalum Coatings Deposited on Ti6Al4V Alloy by Self-Designed Wire Electrical Explosion Spraying. J Therm Spray Tech 31, 636–643 (2022). https://doi.org/10.1007/s11666-022-01333-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01333-z